ESP FORD SIERRA 1983 1.G DOHC Engine Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1983, Model line: SIERRA, Model: FORD SIERRA 1983 1.GPages: 18, PDF Size: 0.9 MB

Page 9 of 18

6Loosen the alternator lower mounting

through-bolt, then remove the alternator

upper mounting bolt, and swing the alternator

away from the engine.

7Unscrew the central securing bolt, and

withdraw the drivebelt tensioner assembly.

8Unscrew the eleven securing bolts, and

remove the lower timing chain cover. Recover

the rubber gasket.

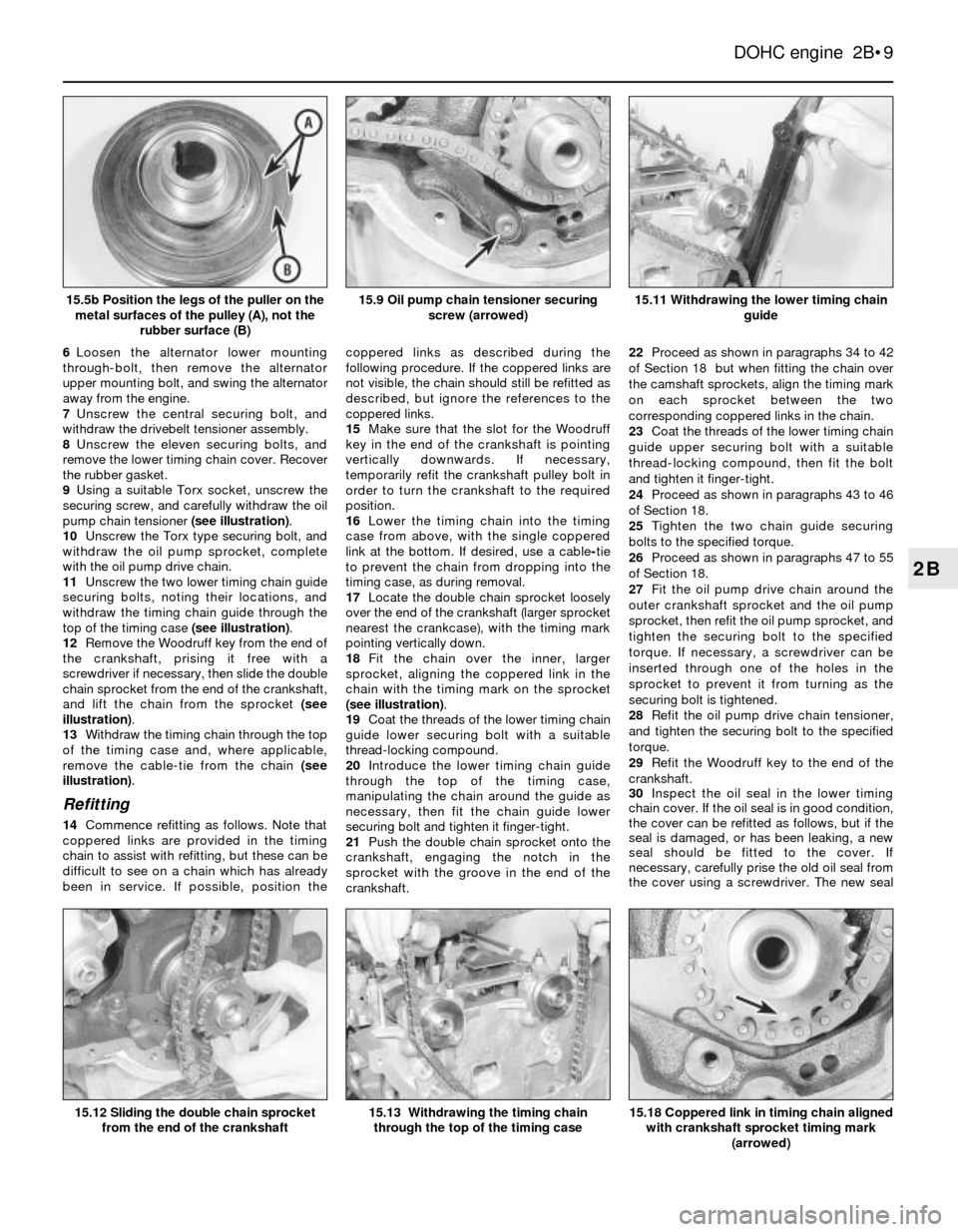

9Using a suitable Torx socket, unscrew the

securing screw, and carefully withdraw the oil

pump chain tensioner (see illustration).

10Unscrew the Torx type securing bolt, and

withdraw the oil pump sprocket, complete

with the oil pump drive chain.

11Unscrew the two lower timing chain guide

securing bolts, noting their locations, and

withdraw the timing chain guide through the

top of the timing case (see illustration).

12Remove the Woodruff key from the end of

the crankshaft, prising it free with a

screwdriver if necessary, then slide the double

chain sprocket from the end of the crankshaft,

and lift the chain from the sprocket (see

illustration).

13Withdraw the timing chain through the top

of the timing case and, where applicable,

remove the cable-tie from the chain (see

illustration).

Refitting

14Commence refitting as follows. Note that

coppered links are provided in the timing

chain to assist with refitting, but these can be

difficult to see on a chain which has already

been in service. If possible, position thecoppered links as described during the

following procedure. If the coppered links are

not visible, the chain should still be refitted as

described, but ignore the references to the

coppered links.

15Make sure that the slot for the Woodruff

key in the end of the crankshaft is pointing

vertically downwards. If necessary,

temporarily refit the crankshaft pulley bolt in

order to turn the crankshaft to the required

position.

16Lower the timing chain into the timing

case from above, with the single coppered

link at the bottom. If desired, use a cable-tie

to prevent the chain from dropping into the

timing case, as during removal.

17Locate the double chain sprocket loosely

over the end of the crankshaft (larger sprocket

nearest the crankcase), with the timing mark

pointing vertically down.

18Fit the chain over the inner, larger

sprocket, aligning the coppered link in the

chain with the timing mark on the sprocket

(see illustration).

19Coat the threads of the lower timing chain

guide lower securing bolt with a suitable

thread-locking compound.

20Introduce the lower timing chain guide

through the top of the timing case,

manipulating the chain around the guide as

necessary, then fit the chain guide lower

securing bolt and tighten it finger-tight.

21Push the double chain sprocket onto the

crankshaft, engaging the notch in the

sprocket with the groove in the end of the

crankshaft.22Proceed as shown in paragraphs 34 to 42

of Section 18 but when fitting the chain over

the camshaft sprockets, align the timing mark

on each sprocket between the two

corresponding coppered links in the chain.

23Coat the threads of the lower timing chain

guide upper securing bolt with a suitable

thread-locking compound, then fit the bolt

and tighten it finger-tight.

24Proceed as shown in paragraphs 43 to 46

of Section 18.

25Tighten the two chain guide securing

bolts to the specified torque.

26Proceed as shown in paragraphs 47 to 55

of Section 18.

27Fit the oil pump drive chain around the

outer crankshaft sprocket and the oil pump

sprocket, then refit the oil pump sprocket, and

tighten the securing bolt to the specified

torque. If necessary, a screwdriver can be

inserted through one of the holes in the

sprocket to prevent it from turning as the

securing bolt is tightened.

28Refit the oil pump drive chain tensioner,

and tighten the securing bolt to the specified

torque.

29Refit the Woodruff key to the end of the

crankshaft.

30Inspect the oil seal in the lower timing

chain cover. If the oil seal is in good condition,

the cover can be refitted as follows, but if the

seal is damaged, or has been leaking, a new

seal should be fitted to the cover. If

necessary, carefully prise the old oil seal from

the cover using a screwdriver. The new seal

DOHC engine 2B•9

2B

15.11 Withdrawing the lower timing chain

guide

15.18 Coppered link in timing chain aligned

with crankshaft sprocket timing mark

(arrowed)15.13 Withdrawing the timing chain

through the top of the timing case

15.9 Oil pump chain tensioner securing

screw (arrowed)15.5b Position the legs of the puller on the

metal surfaces of the pulley (A), not the

rubber surface (B)

15.12 Sliding the double chain sprocket

from the end of the crankshaft

Page 10 of 18

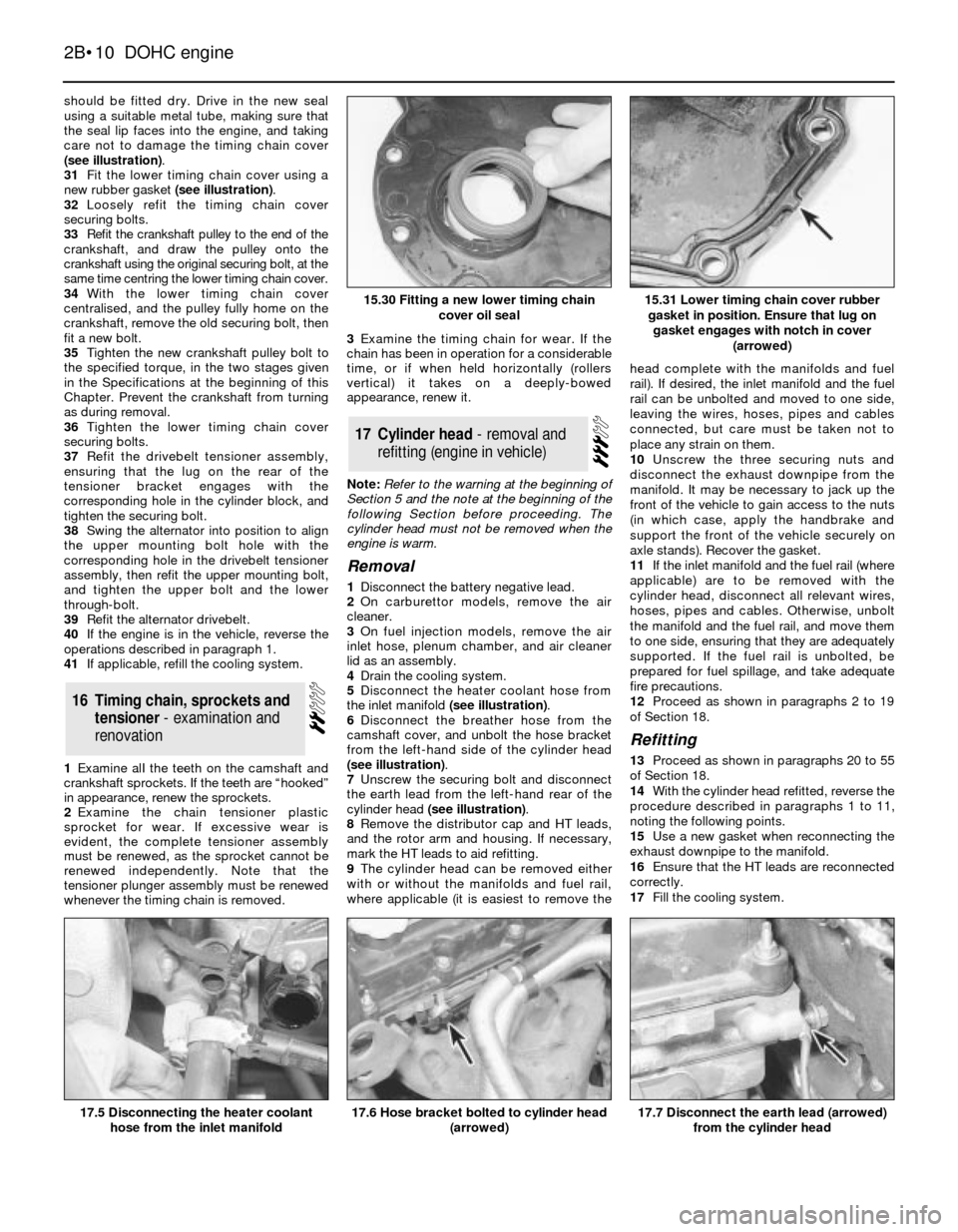

should be fitted dry. Drive in the new seal

using a suitable metal tube, making sure that

the seal lip faces into the engine, and taking

care not to damage the timing chain cover

(see illustration).

31Fit the lower timing chain cover using a

new rubber gasket (see illustration).

32Loosely refit the timing chain cover

securing bolts.

33Refit the crankshaft pulley to the end of the

crankshaft, and draw the pulley onto the

crankshaft using the original securing bolt, at the

same time centring the lower timing chain cover.

34With the lower timing chain cover

centralised, and the pulley fully home on the

crankshaft, remove the old securing bolt, then

fit a new bolt.

35Tighten the new crankshaft pulley bolt to

the specified torque, in the two stages given

in the Specifications at the beginning of this

Chapter. Prevent the crankshaft from turning

as during removal.

36Tighten the lower timing chain cover

securing bolts.

37Refit the drivebelt tensioner assembly,

ensuring that the lug on the rear of the

tensioner bracket engages with the

corresponding hole in the cylinder block, and

tighten the securing bolt.

38Swing the alternator into position to align

the upper mounting bolt hole with the

corresponding hole in the drivebelt tensioner

assembly, then refit the upper mounting bolt,

and tighten the upper bolt and the lower

through-bolt.

39Refit the alternator drivebelt.

40If the engine is in the vehicle, reverse the

operations described in paragraph 1.

41If applicable, refill the cooling system.

1Examine alI the teeth on the camshaft and

crankshaft sprockets. If the teeth are “hooked”

in appearance, renew the sprockets.

2Examine the chain tensioner plastic

sprocket for wear. If excessive wear is

evident, the complete tensioner assembly

must be renewed, as the sprocket cannot be

renewed independently. Note that the

tensioner plunger assembly must be renewed

whenever the timing chain is removed.3Examine the timing chain for wear. If the

chain has been in operation for a considerable

time, or if when held horizontally (rollers

vertical) it takes on a deeply-bowed

appearance, renew it.

Note: Refer to the warning at the beginning of

Section 5 and the note at the beginning of the

following Section before proceeding. The

cylinder head must not be removed when the

engine is warm.

Removal

1Disconnect the battery negative lead.

2On carburettor models, remove the air

cleaner.

3On fuel injection models, remove the air

inlet hose, plenum chamber, and air cleaner

lid as an assembly.

4Drain the cooling system.

5Disconnect the heater coolant hose from

the inlet manifold (see illustration).

6Disconnect the breather hose from the

camshaft cover, and unbolt the hose bracket

from the left-hand side of the cylinder head

(see illustration).

7Unscrew the securing bolt and disconnect

the earth lead from the left-hand rear of the

cylinder head (see illustration).

8Remove the distributor cap and HT leads,

and the rotor arm and housing. If necessary,

mark the HT leads to aid refitting.

9The cylinder head can be removed either

with or without the manifolds and fuel rail,

where applicable (it is easiest to remove thehead complete with the manifolds and fuel

rail). If desired, the inlet manifold and the fuel

rail can be unbolted and moved to one side,

leaving the wires, hoses, pipes and cables

connected, but care must be taken not to

place any strain on them.

10Unscrew the three securing nuts and

disconnect the exhaust downpipe from the

manifold. It may be necessary to jack up the

front of the vehicle to gain access to the nuts

(in which case, apply the handbrake and

support the front of the vehicle securely on

axle stands). Recover the gasket.

11If the inlet manifold and the fuel rail (where

applicable) are to be removed with the

cylinder head, disconnect all relevant wires,

hoses, pipes and cables. Otherwise, unbolt

the manifold and the fuel rail, and move them

to one side, ensuring that they are adequately

supported. If the fuel rail is unbolted, be

prepared for fuel spillage, and take adequate

fire precautions.

12Proceed as shown in paragraphs 2 to 19

of Section 18.

Refitting

13Proceed as shown in paragraphs 20 to 55

of Section 18.

14With the cylinder head refitted, reverse the

procedure described in paragraphs 1 to 11,

noting the following points.

15Use a new gasket when reconnecting the

exhaust downpipe to the manifold.

16Ensure that the HT leads are reconnected

correctly.

17Fill the cooling system.

17Cylinder head - removal and

refitting (engine in vehicle)

16Timing chain, sprockets and

tensioner - examination and

renovation

2B•10DOHC engine

15.30 Fitting a new lower timing chain

cover oil seal

17.5 Disconnecting the heater coolant

hose from the inlet manifold17.7 Disconnect the earth lead (arrowed)

from the cylinder head17.6 Hose bracket bolted to cylinder head

(arrowed)

15.31 Lower timing chain cover rubber

gasket in position. Ensure that lug on

gasket engages with notch in cover

(arrowed)

Page 11 of 18

Note: New cylinder head bolts, a new cylinder

head gasket, a new timing chain tensioner

plunger assembly, a new upper timing chain

cover gasket, and a new camshaft cover

gasket and reinforcing sleeve sealing rings,

must be used on refitting.

Removal

1With the manifolds removed, proceed as

follows.

2Unscrew the eleven bolts and four nuts,

and remove the camshaft cover. Recover the

gasket.

3Unscrew the four securing bolts and three

studs, and remove the upper timing chain

cover. Note the locations of the studs to aid

refitting.

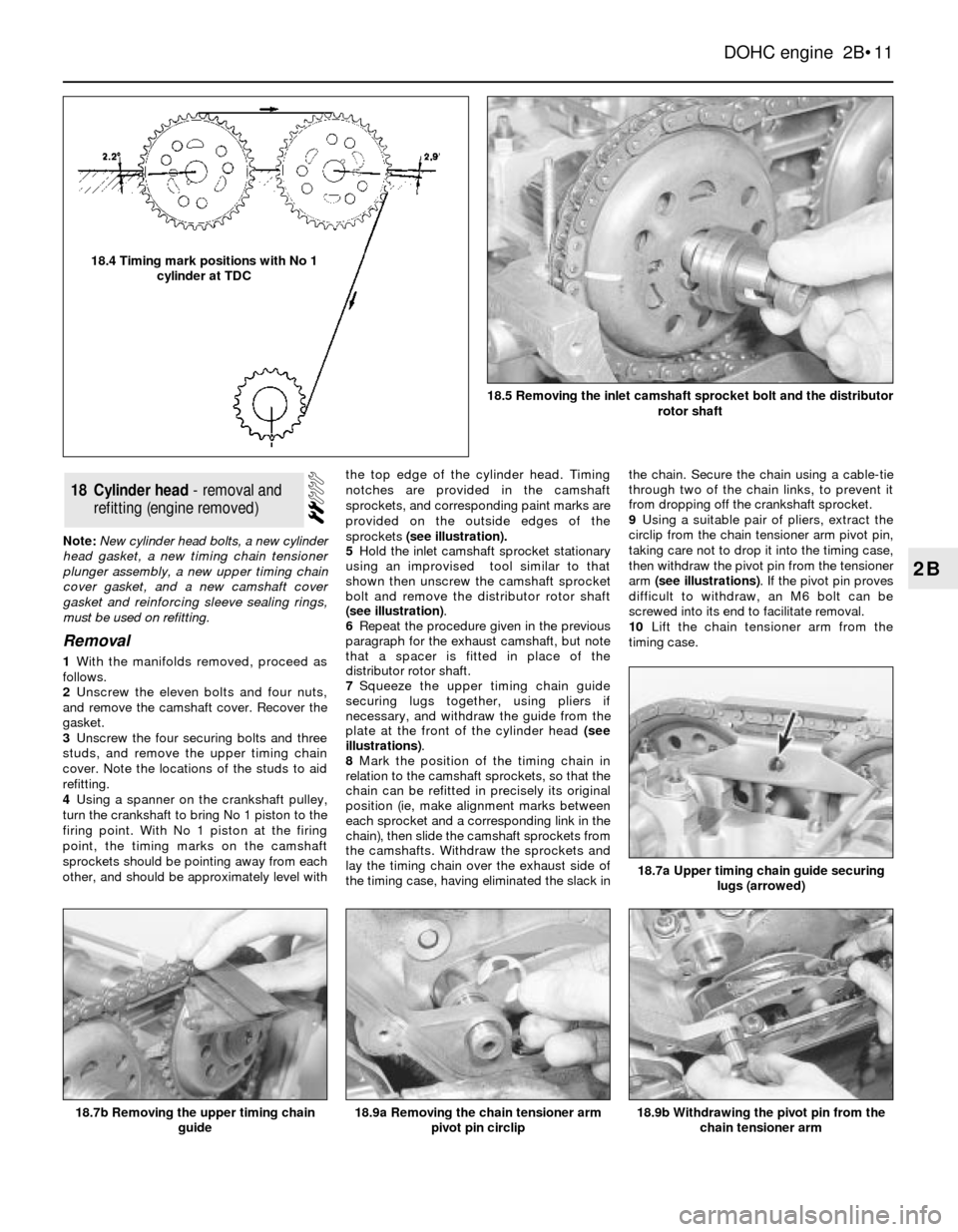

4Using a spanner on the crankshaft pulley,

turn the crankshaft to bring No 1 piston to the

firing point. With No 1 piston at the firing

point, the timing marks on the camshaft

sprockets should be pointing away from each

other, and should be approximately level withthe top edge of the cylinder head. Timing

notches are provided in the camshaft

sprockets, and corresponding paint marks are

provided on the outside edges of the

sprockets (see illustration).

5Hold the inlet camshaft sprocket stationary

using an improvised tool similar to that

shownthen unscrew the camshaft sprocket

bolt and remove the distributor rotor shaft

(see illustration).

6Repeat the procedure given in the previous

paragraph for the exhaust camshaft, but note

that a spacer is fitted in place of the

distributor rotor shaft.

7Squeeze the upper timing chain guide

securing lugs together, using pliers if

necessary, and withdraw the guide from the

plate at the front of the cylinder head (see

illustrations).

8Mark the position of the timing chain in

relation to the camshaft sprockets, so that the

chain can be refitted in precisely its original

position (ie, make alignment marks between

each sprocket and a corresponding link in the

chain), then slide the camshaft sprockets from

the camshafts. Withdraw the sprockets and

lay the timing chain over the exhaust side of

the timing case, having eliminated the slack inthe chain. Secure the chain using a cable-tie

through two of the chain links, to prevent it

from dropping off the crankshaft sprocket.

9Using a suitable pair of pliers, extract the

circlip from the chain tensioner arm pivot pin,

taking care not to drop it into the timing case,

then withdraw the pivot pin from the tensioner

arm (see illustrations). If the pivot pin proves

difficult to withdraw, an M6 bolt can be

screwed into its end to facilitate removal.

10Lift the chain tensioner arm from the

timing case.

18Cylinder head - removal and

refitting (engine removed)

DOHC engine 2B•11

2B

18.7a Upper timing chain guide securing

lugs (arrowed)

18.9b Withdrawing the pivot pin from the

chain tensioner arm18.9a Removing the chain tensioner arm

pivot pin circlip18.7b Removing the upper timing chain

guide

18.5 Removing the inlet camshaft sprocket bolt and the distributor

rotor shaft

18.4 Timing mark positions with No 1

cylinder at TDC