seat adjustment FORD SIERRA 1983 1.G Engine Electrical Systems Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1983, Model line: SIERRA, Model: FORD SIERRA 1983 1.GPages: 24, PDF Size: 0.93 MB

Page 13 of 24

10The distributor cap (except on 1.6 and 1.8

litre CVH (R6A type) engines) and the HT

leads should be cleaned and checked at the

specified intervals. To test the HT leads,

remove them together with the distributor

cap, then connect an ohmmeter to the end of

each lead and its appropriate terminal within

the cap in turn (see illustration). If the

resistance of any lead is greater than the

maximum given in the Specifications, check

that the lead connection in the cap is good

before renewing the lead.

Refitting

11Before fitting the spark plugs, check that

the threaded connector sleeves are tight and

that the plug exterior surfaces are clean. As

the plugs incorporate taper seats also make

sure that the threads and seats are clean.

12On DOHC models before refitting thespark plugs, coat their threads with suitable

antiseize compound, taking care not to

contaminate the electrodes.

13Screw in the spark plugs by hand, then

tighten them to the specified torque. Do not

exceed the torque figure.

14Push the HT leads firmly onto the spark

plugs, and where applicable refit the air

cleaner and/or inlet hose.Testing

All models except 1.6 and 1.8 litre

CVH (R6A type)

1The coil is located on the left-hand side of

the engine compartment and is retained by a

metal strap (see illustration). It is of high

output type and the HT tower should be kept

clean at all times to prevent possible arcing.

Bosch and Femsa coils are fitted with

protective plastic covers and Polmot coils are

fitted with an internal fusible link.

2To ensure that the correct HT polarity at the

spark plugs, the LT coil leads must always be

connected correctly. The black lead must

always be connected to the terminal marked +

115, and the green lead to the terminal

marked /1. Incorrect connections can cause

poor starting, misfiring, and short spark plug

life.

3To test the coil first disconnect the LT and

HT leads. Connect an ohmmeter betweenboth LT terminals and check that the primary

winding resistance is as given in the

Specifications. Connect the ohmmeter

between the HT terminal and either LT

terminal and check that the secondary

winding resistance is as given in the

Specifications. If either winding resistance is

not as specified, the coil should be renewed.

Reconnect the LT and HT leads on

completion.

1.6 and 1.8 litre (R6A type) CVH

models

4The coil fitted to these models is located

towards the front right-hand side of the

cylinder block (see illustration).

5Testing of the coil should be entrusted to a

Ford dealer or a suitable specialist.

Removal

All models except 1.6 and 1.8 litre

CVH (R6A type)

6Disconnect the battery negative lead,

7Disconnect the LT and HT leads from the

coil (see illustration).

8Remove the securing screw(s) and detach

the coil and strap assembly from the body

panel. Note that on models with the ESC

system, the coil strap is secured by the top

ESC module securing screw. On certain

models with the ESC II or EEC IV systems, an

“octane adjustment” service lead may be

connected to one of the coil securing screws.

On 2.0 litre DOHC fuel-injected models, the

coil/ignition module heat shield must be

removed for access to the coil securing bolts.

The heat shield is secured by two screws.

Note that on certain models, an earthing lead

12Coil - testing, removal and

refitting

Engine electrical systems 5•13

5

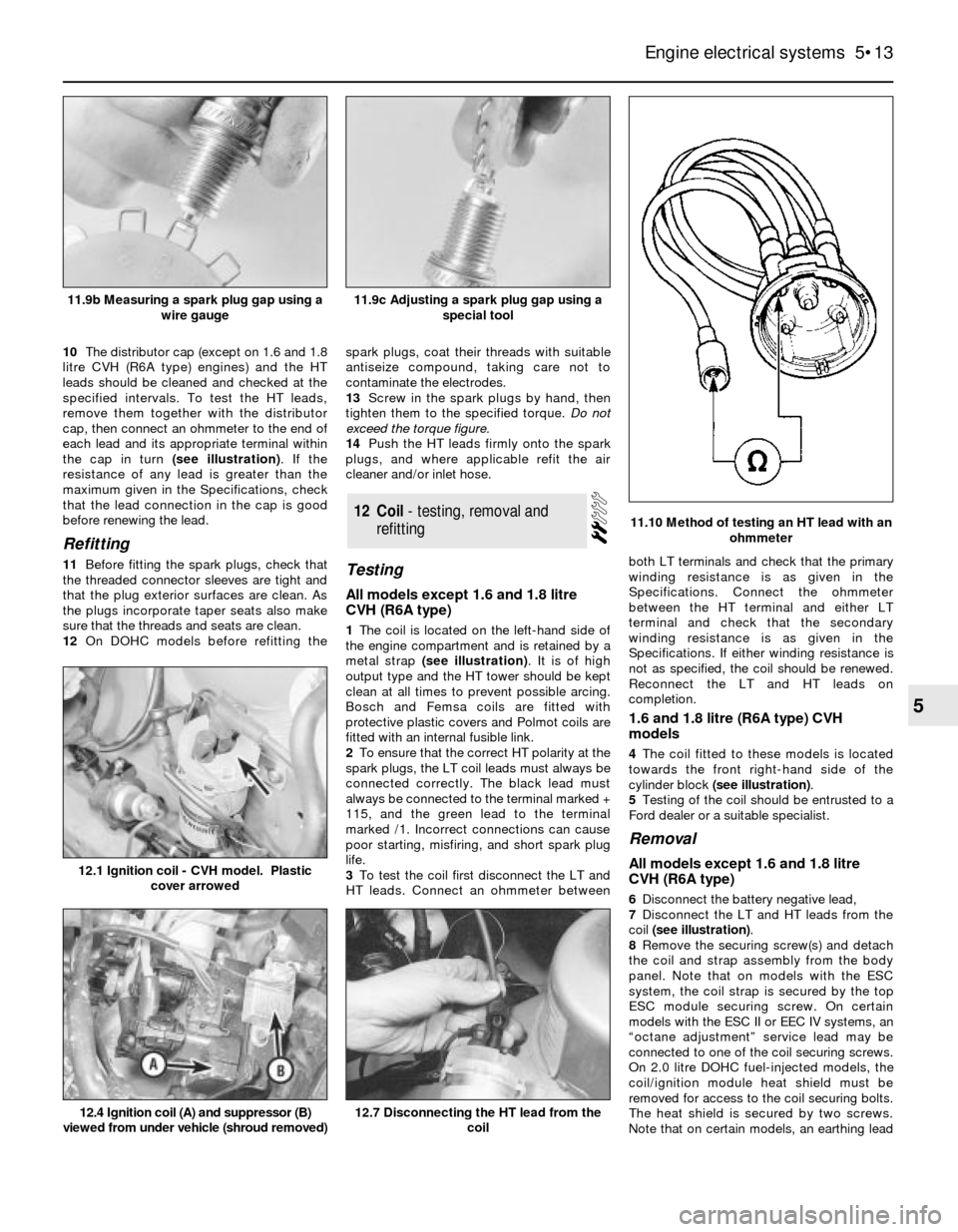

11.10 Method of testing an HT lead with an

ohmmeter

12.4 Ignition coil (A) and suppressor (B)

viewed from under vehicle (shroud removed)12.7 Disconnecting the HT lead from the

coil

12.1 Ignition coil - CVH model. Plastic

cover arrowed

11.9c Adjusting a spark plug gap using a

special tool11.9b Measuring a spark plug gap using a

wire gauge

Page 18 of 24

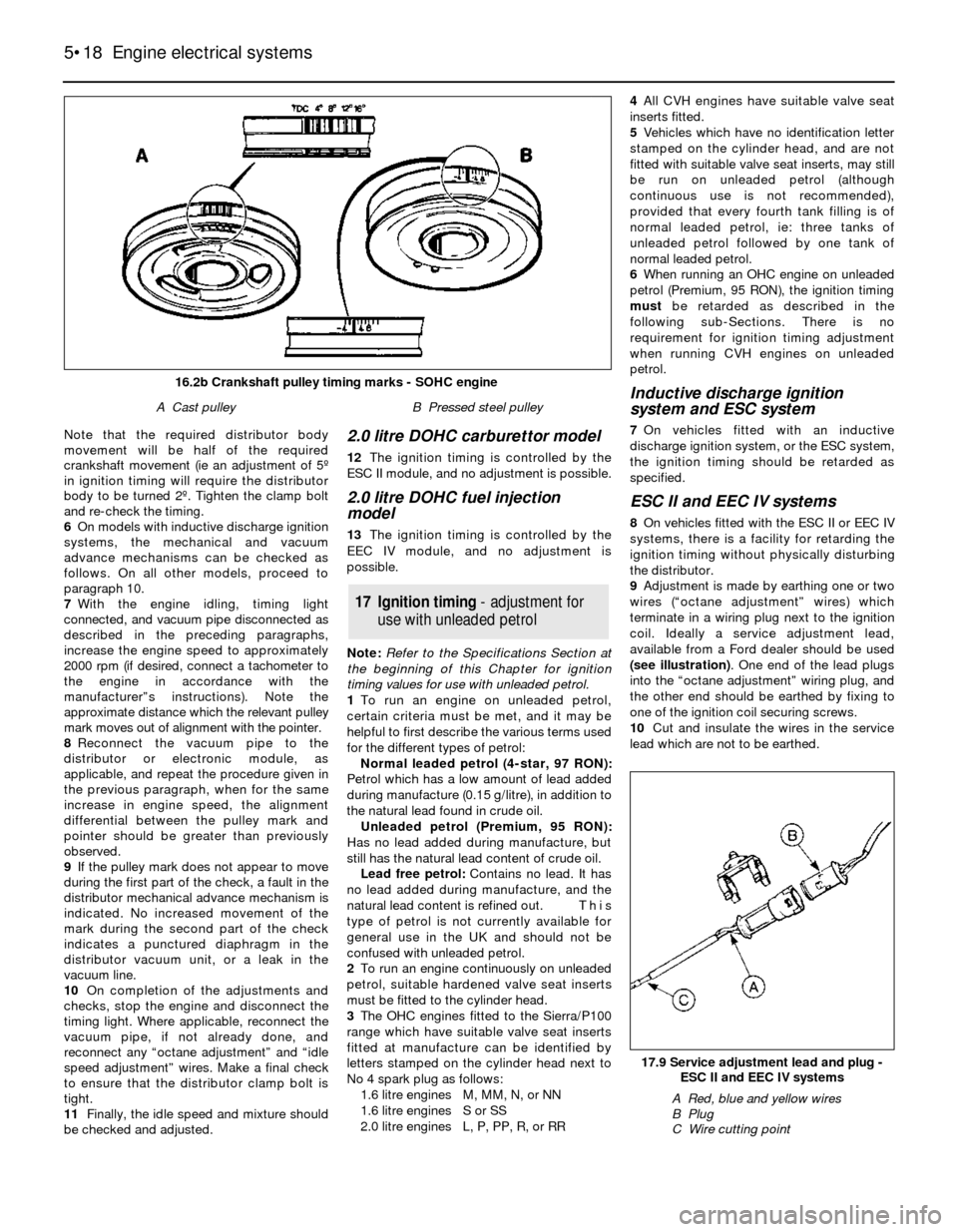

Note that the required distributor body

movement will be half of the required

crankshaft movement (ie an adjustment of 5º

in ignition timing will require the distributor

body to be turned 2º. Tighten the clamp bolt

and re-check the timing.

6On models with inductive discharge ignition

systems, the mechanical and vacuum

advance mechanisms can be checked as

follows. On all other models, proceed to

paragraph 10.

7With the engine idling, timing light

connected, and vacuum pipe disconnected as

described in the preceding paragraphs,

increase the engine speed to approximately

2000 rpm (if desired, connect a tachometer to

the engine in accordance with the

manufacturer”s instructions). Note the

approximate distance which the relevant pulley

mark moves out of alignment with the pointer.

8Reconnect the vacuum pipe to the

distributor or electronic module, as

applicable, and repeat the procedure given in

the previous paragraph, when for the same

increase in engine speed, the alignment

differential between the pulley mark and

pointer should be greater than previously

observed.

9If the pulley mark does not appear to move

during the first part of the check, a fault in the

distributor mechanical advance mechanism is

indicated. No increased movement of the

mark during the second part of the check

indicates a punctured diaphragm in the

distributor vacuum unit, or a leak in the

vacuum line.

10On completion of the adjustments and

checks, stop the engine and disconnect the

timing light. Where applicable, reconnect the

vacuum pipe, if not already done, and

reconnect any “octane adjustment” and “idle

speed adjustment” wires. Make a final check

to ensure that the distributor clamp bolt is

tight.

11Finally, the idle speed and mixture should

be checked and adjusted.2.0 litre DOHC carburettor model

12The ignition timing is controlled by the

ESC II module, and no adjustment is possible.

2.0 litre DOHC fuel injection

model

13The ignition timing is controlled by the

EEC IV module, and no adjustment is

possible.

Note: Refer to the Specifications Section at

the beginning of this Chapter for ignition

timing values for use with unleaded petrol.

1To run an engine on unleaded petrol,

certain criteria must be met, and it may be

helpful to first describe the various terms used

for the different types of petrol:

Normal leaded petrol (4-star, 97 RON):

Petrol which has a low amount of lead added

during manufacture (0.15 g/litre), in addition to

the natural lead found in crude oil.

Unleaded petrol (Premium, 95 RON):

Has no lead added during manufacture, but

still has the natural lead content of crude oil.

Lead free petrol: Contains no lead. It has

no lead added during manufacture, and the

natural lead content is refined out. This

type of petrol is not currently available for

general use in the UK and should not be

confused with unleaded petrol.

2To run an engine continuously on unleaded

petrol, suitable hardened valve seat inserts

must be fitted to the cylinder head.

3The OHC engines fitted to the Sierra/P100

range which have suitable valve seat inserts

fitted at manufacture can be identified by

letters stamped on the cylinder head next to

No 4 spark plug as follows:

1.6 litre enginesM, MM, N, or NN

1.6 litre enginesS or SS

2.0 litre enginesL, P, PP, R, or RR4All CVH engines have suitable valve seat

inserts fitted.

5Vehicles which have no identification letter

stamped on the cylinder head, and are not

fitted with suitable valve seat inserts, may still

be run on unleaded petrol (although

continuous use is not recommended),

provided that every fourth tank filling is of

normal leaded petrol, ie: three tanks of

unleaded petrol followed by one tank of

normal leaded petrol.

6When running an OHC engine on unleaded

petrol (Premium, 95 RON), the ignition timing

must be retarded as described in the

following sub-Sections. There is no

requirement for ignition timing adjustment

when running CVH engines on unleaded

petrol.

Inductive discharge ignition

system and ESC system

7On vehicles fitted with an inductive

discharge ignition system, or the ESC system,

the ignition timing should be retarded as

specified.

ESC II and EEC IV systems

8On vehicles fitted with the ESC II or EEC IV

systems, there is a facility for retarding the

ignition timing without physically disturbing

the distributor.

9Adjustment is made by earthing one or two

wires (“octane adjustment” wires) which

terminate in a wiring plug next to the ignition

coil. Ideally a service adjustment lead,

available from a Ford dealer should be used

(see illustration). One end of the lead plugs

into the “octane adjustment” wiring plug, and

the other end should be earthed by fixing to

one of the ignition coil securing screws.

10Cut and insulate the wires in the service

lead which are not to be earthed.

17Ignition timing -adjustmentfor

usewithunleadedpetrol

5•18Engine electrical systems

17.9 Service adjustment lead and plug -

ESC II and EEC IV systems

A Red, blue and yellow wires

B Plug

C Wire cutting point

16.2b Crankshaft pulley timing marks - SOHC engine

A Cast pulleyB Pressed steel pulley