compression ratio FORD SIERRA 1987 2.G DOHC Engine Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1987, Model line: SIERRA, Model: FORD SIERRA 1987 2.GPages: 18, PDF Size: 0.9 MB

Page 1 of 18

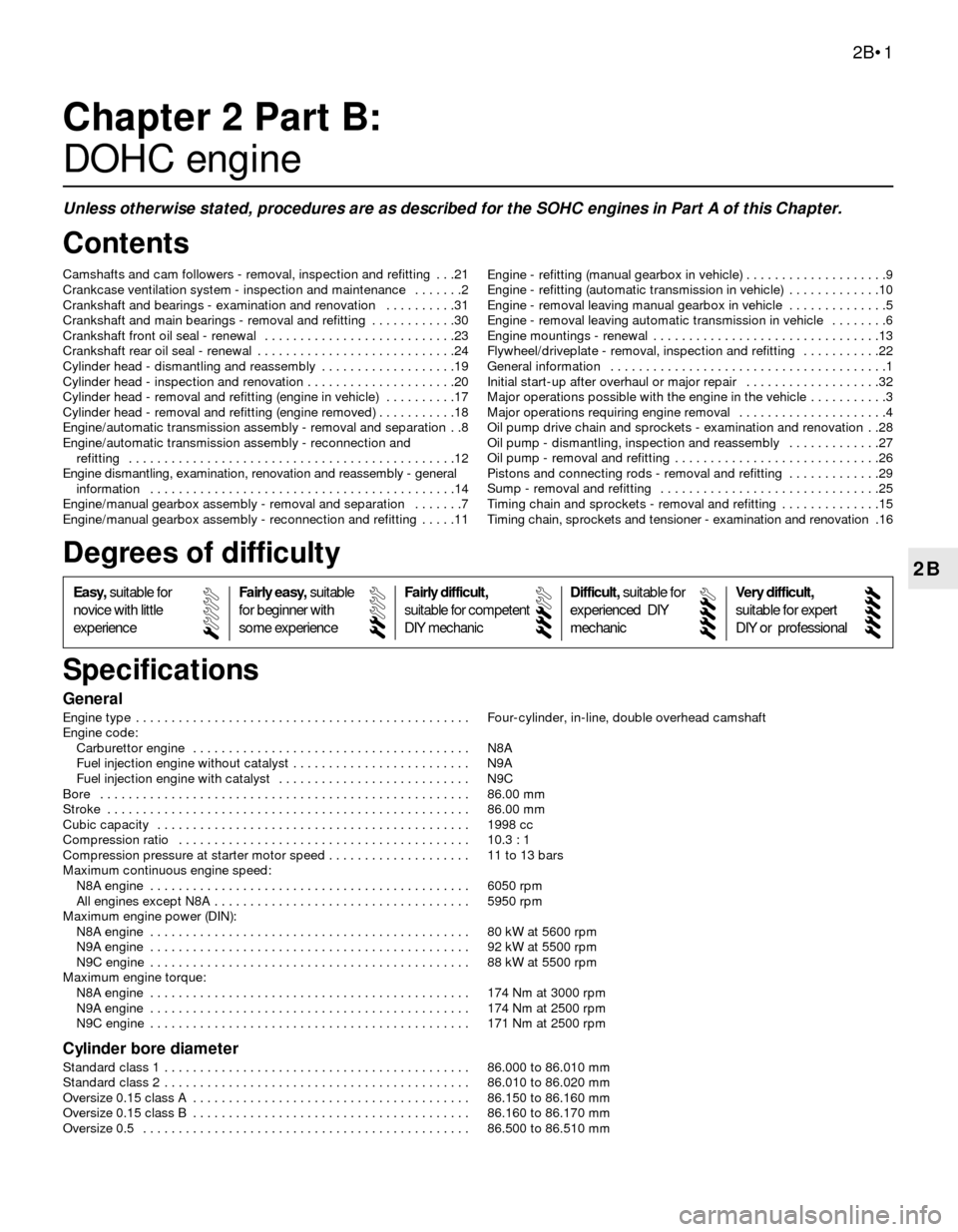

General

Engine type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Four-cylinder, in-line, double overhead camshaft

Engine code:

Carburettor engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . N8A

Fuel injection engine without catalyst . . . . . . . . . . . . . . . . . . . . . . . . . N9A

Fuel injection engine with catalyst . . . . . . . . . . . . . . . . . . . . . . . . . . . N9C

Bore . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86.00 mm

Stroke . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86.00 mm

Cubic capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1998 cc

Compression ratio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10.3 : 1

Compression pressure at starter motor speed . . . . . . . . . . . . . . . . . . . . 11 to 13 bars

Maximum continuous engine speed:

N8A engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6050 rpm

All engines except N8A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5950 rpm

Maximum engine power (DIN):

N8A engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80 kW at 5600 rpm

N9A engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92 kW at 5500 rpm

N9C engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88 kW at 5500 rpm

Maximum engine torque:

N8A engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174 Nm at 3000 rpm

N9A engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174 Nm at 2500 rpm

N9C engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171 Nm at 2500 rpm

Cylinder bore diameter

Standard class 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86.000 to 86.010 mm

Standard class 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86.010 to 86.020 mm

Oversize 0.15 class A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86.150 to 86.160 mm

Oversize 0.15 class B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86.160 to 86.170 mm

Oversize 0.5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86.500 to 86.510 mm

Chapter 2 Part B:

DOHC engine

Camshafts and cam followers - removal, inspection and refitting . . .21

Crankcase ventilation system - inspection and maintenance . . . . . . .2

Crankshaft and bearings - examination and renovation . . . . . . . . . .31

Crankshaft and main bearings - removal and refitting . . . . . . . . . . . .30

Crankshaft front oil seal - renewal . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Crankshaft rear oil seal - renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Cylinder head - dismantling and reassembly . . . . . . . . . . . . . . . . . . .19

Cylinder head - inspection and renovation . . . . . . . . . . . . . . . . . . . . .20

Cylinder head - removal and refitting (engine in vehicle) . . . . . . . . . .17

Cylinder head - removal and refitting (engine removed) . . . . . . . . . . .18

Engine/automatic transmission assembly - removal and separation . .8

Engine/automatic transmission assembly - reconnection and

refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Engine dismantling, examination, renovation and reassembly - general

information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Engine/manual gearbox assembly - removal and separation . . . . . . .7

Engine/manual gearbox assembly - reconnection and refitting . . . . .11Engine - refitting (manual gearbox in vehicle) . . . . . . . . . . . . . . . . . . . .9

Engine - refitting (automatic transmission in vehicle) . . . . . . . . . . . . .10

Engine - removal leaving manual gearbox in vehicle . . . . . . . . . . . . . .5

Engine - removal leaving automatic transmission in vehicle . . . . . . . .6

Engine mountings - renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Flywheel/driveplate - removal, inspection and refitting . . . . . . . . . . .22

General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Initial start-up after overhaul or major repair . . . . . . . . . . . . . . . . . . .32

Major operations possible with the engine in the vehicle . . . . . . . . . . .3

Major operations requiring engine removal . . . . . . . . . . . . . . . . . . . . .4

Oil pump drive chain and sprockets - examination and renovation . .28

Oil pump - dismantling, inspection and reassembly . . . . . . . . . . . . .27

Oil pump - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Pistons and connecting rods - removal and refitting . . . . . . . . . . . . .29

Sump - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Timing chain and sprockets - removal and refitting . . . . . . . . . . . . . .15

Timing chain, sprockets and tensioner - examination and renovation .16

2B•1

Specifications Contents

2B

Unless otherwise stated, procedures are as described for the SOHC engines in Part A of this Chapter.

Easy,suitable for

novice with little

experienceFairly easy,suitable

for beginner with

some experienceFairly difficult,

suitable for competent

DIY mechanic

Difficult,suitable for

experienced DIY

mechanicVery difficult,

suitable for expert

DIY or professional

Degrees of difficulty