seat adjustment FORD SIERRA 1987 2.G SOHC Engines Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1987, Model line: SIERRA, Model: FORD SIERRA 1987 2.GPages: 24, PDF Size: 1.03 MB

Page 16 of 24

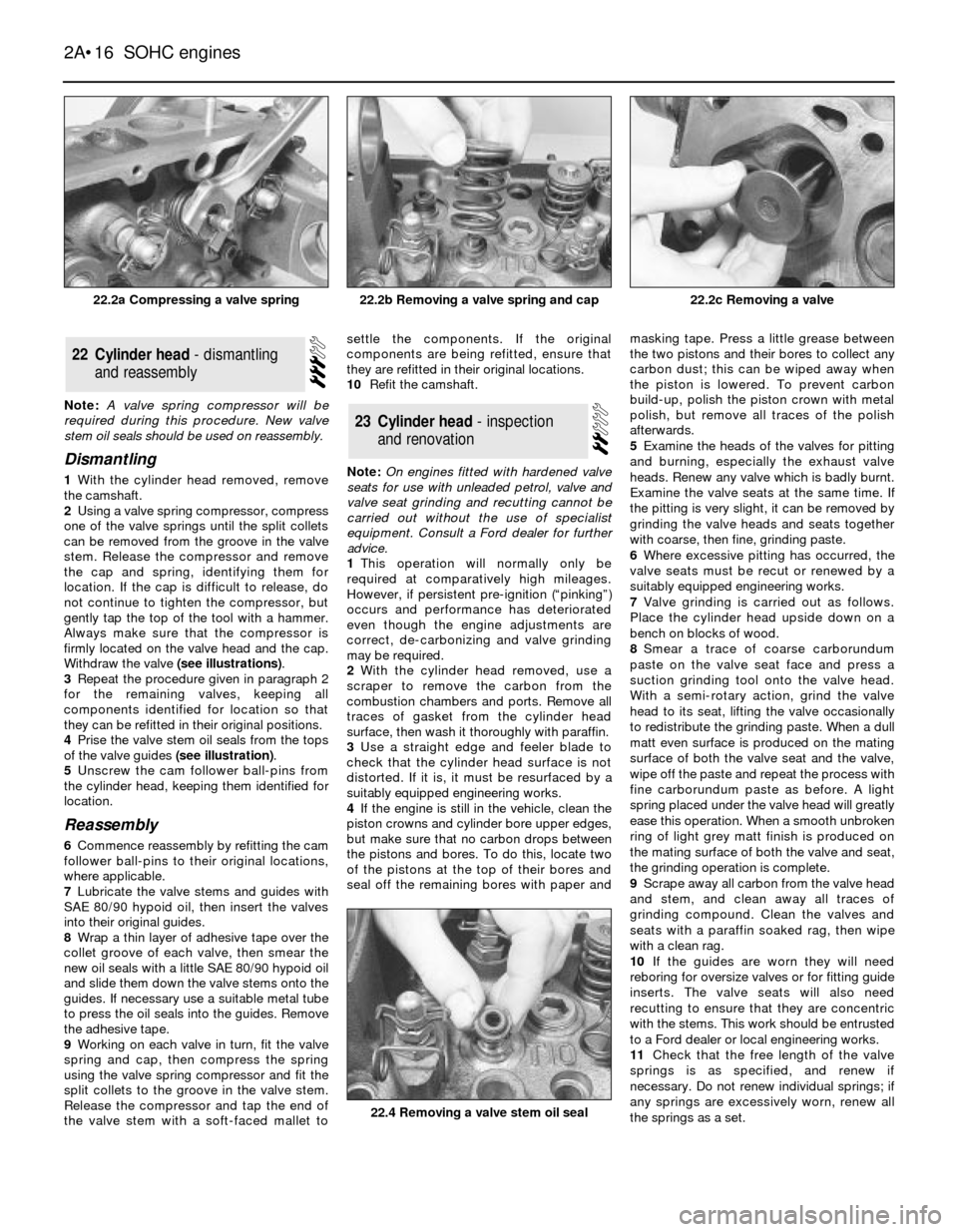

Note: A valve spring compressor will be

required during this procedure. New valve

stem oil seals should be used on reassembly.

Dismantling

1With the cylinder head removed, remove

the camshaft.

2Using a valve spring compressor, compress

one of the valve springs until the split collets

can be removed from the groove in the valve

stem. Release the compressor and remove

the cap and spring, identifying them for

location. If the cap is difficult to release, do

not continue to tighten the compressor, but

gently tap the top of the tool with a hammer.

Always make sure that the compressor is

firmly located on the valve head and the cap.

Withdraw the valve (see illustrations).

3Repeat the procedure given in paragraph 2

for the remaining valves, keeping all

components identified for location so that

they can be refitted in their original positions.

4Prise the valve stem oil seals from the tops

of the valve guides (see illustration).

5Unscrew the cam follower ball-pins from

the cylinder head, keeping them identified for

location.

Reassembly

6Commence reassembly by refitting the cam

follower ball-pins to their original locations,

where applicable.

7Lubricate the valve stems and guides with

SAE 80/90 hypoid oil, then insert the valves

into their original guides.

8Wrap a thin layer of adhesive tape over the

collet groove of each valve, then smear the

new oil seals with a little SAE 80/90 hypoid oil

and slide them down the valve stems onto the

guides. If necessary use a suitable metal tube

to press the oil seals into the guides. Remove

the adhesive tape.

9Working on each valve in turn, fit the valve

spring and cap, then compress the spring

using the valve spring compressor and fit the

split collets to the groove in the valve stem.

Release the compressor and tap the end of

the valve stem with a soft-faced mallet tosettle the components. If the original

components are being refitted, ensure that

they are refitted in their original locations.

10Refit the camshaft.

Note: On engines fitted with hardened valve

seats for use with unleaded petrol, valve and

valve seat grinding and recutting cannot be

carried out without the use of specialist

equipment. Consult a Ford dealer for further

advice.

1This operation will normally only be

required at comparatively high mileages.

However, if persistent pre-ignition (ÒpinkingÓ)

occurs and performance has deteriorated

even though the engine adjustments are

correct, de-carbonizing and valve grinding

may be required.

2With the cylinder head removed, use a

scraper to remove the carbon from the

combustion chambers and ports. Remove all

traces of gasket from the cylinder head

surface, then wash it thoroughly with paraffin.

3Use a straight edge and feeler blade to

check that the cylinder head surface is not

distorted. If it is, it must be resurfaced by a

suitably equipped engineering works.

4If the engine is still in the vehicle, clean the

piston crowns and cylinder bore upper edges,

but make sure that no carbon drops between

the pistons and bores. To do this, locate two

of the pistons at the top of their bores and

seal off the remaining bores with paper andmasking tape. Press a little grease between

the two pistons and their bores to collect any

carbon dust; this can be wiped away when

the piston is lowered. To prevent carbon

build-up, polish the piston crown with metal

polish, but remove all traces of the polish

afterwards.

5Examine the heads of the valves for pitting

and burning, especially the exhaust valve

heads. Renew any valve which is badly burnt.

Examine the valve seats at the same time. If

the pitting is very slight, it can be removed by

grinding the valve heads and seats together

with coarse, then fine, grinding paste.

6Where excessive pitting has occurred, the

valve seats must be recut or renewed by a

suitably equipped engineering works.

7Valve grinding is carried out as follows.

Place the cylinder head upside down on a

bench on blocks of wood.

8Smear a trace of coarse carborundum

paste on the valve seat face and press a

suction grinding tool onto the valve head.

With a semi-rotary action, grind the valve

head to its seat, lifting the valve occasionally

to redistribute the grinding paste. When a dull

matt even surface is produced on the mating

surface of both the valve seat and the valve,

wipe off the paste and repeat the process with

fine carborundum paste as before. A light

spring placed under the valve head will greatly

ease this operation. When a smooth unbroken

ring of light grey matt finish is produced on

the mating surface of both the valve and seat,

the grinding operation is complete.

9Scrape away all carbon from the valve head

and stem, and clean away all traces of

grinding compound. Clean the valves and

seats with a paraffin soaked rag, then wipe

with a clean rag.

10If the guides are worn they will need

reboring for oversize valves or for fitting guide

inserts. The valve seats will also need

recutting to ensure that they are concentric

with the stems. This work should be entrusted

to a Ford dealer or local engineering works.

11Check that the free length of the valve

springs is as specified, and renew if

necessary. Do not renew individual springs; if

any springs are excessively worn, renew all

the springs as a set.

23Cylinder head - inspection

and renovation

22Cylinder head - dismantling

and reassembly

2A¥16SOHC engines

22.2a Compressing a valve spring22.2c Removing a valve

22.4 Removing a valve stem oil seal

22.2b Removing a valve spring and cap