alternator FORD SIERRA 1990 2.G Routine Manintenance And Servicing Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1990, Model line: SIERRA, Model: FORD SIERRA 1990 2.GPages: 22, PDF Size: 1.26 MB

Page 2 of 22

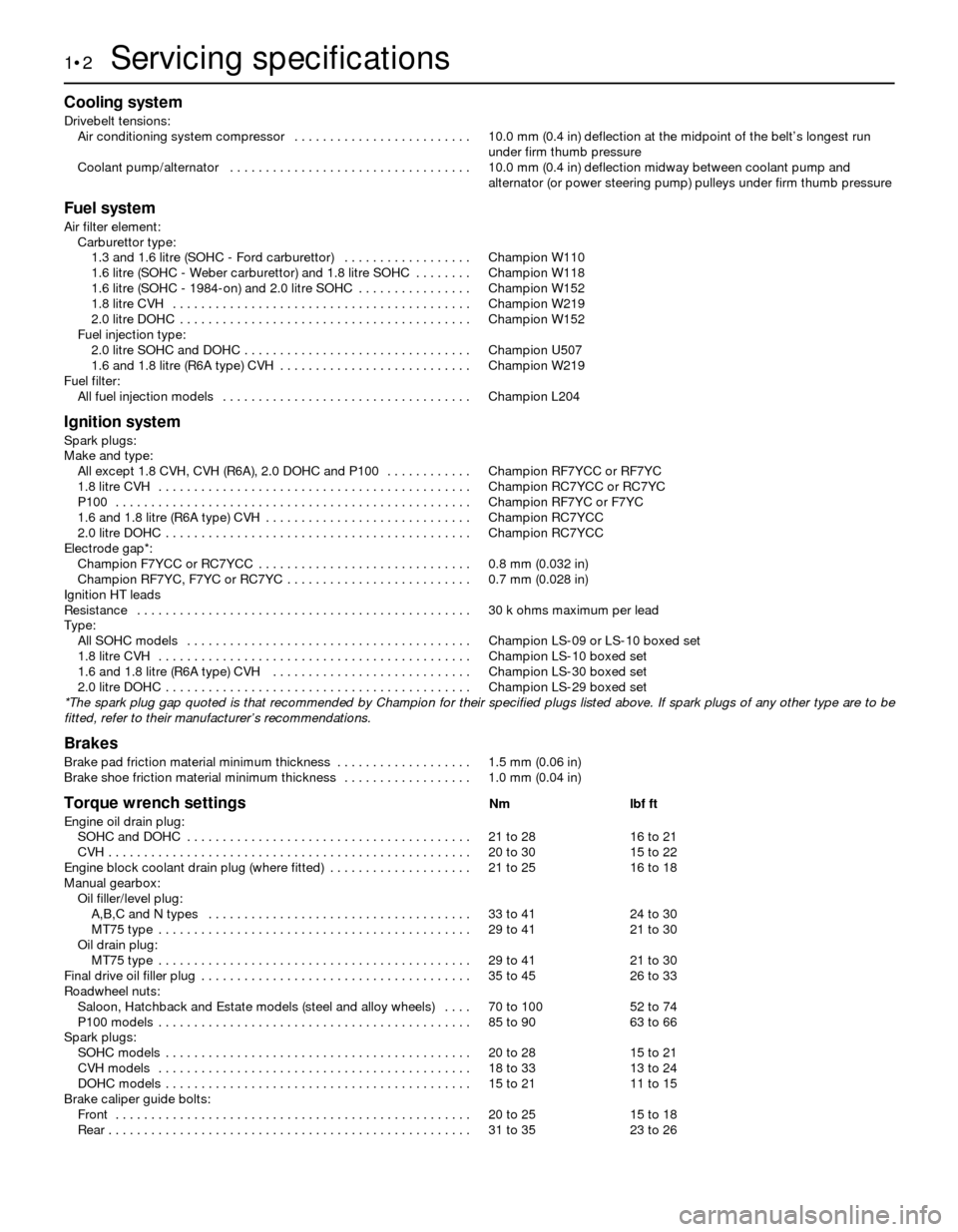

Cooling system

Drivebelt tensions:

Air conditioning system compressor . . . . . . . . . . . . . . . . . . . . . . . . .10.0 mm (0.4 in) deflection at the midpoint of the belt’s longest run

under firm thumb pressure

Coolant pump/alternator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10.0 mm (0.4 in) deflection midway between coolant pump and

alternator (or power steering pump) pulleys under firm thumb pressure

Fuel system

Air filter element:

Carburettor type:

1.3 and 1.6 litre (SOHC - Ford carburettor) . . . . . . . . . . . . . . . . . .Champion W110

1.6 litre (SOHC - Weber carburettor) and 1.8 litre SOHC . . . . . . . .Champion W118

1.6 litre (SOHC - 1984-on) and 2.0 litre SOHC . . . . . . . . . . . . . . . .Champion W152

1.8 litre CVH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Champion W219

2.0 litre DOHC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Champion W152

Fuel injection type:

2.0 litre SOHC and DOHC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Champion U507

1.6 and 1.8 litre (R6A type) CVH . . . . . . . . . . . . . . . . . . . . . . . . . . .Champion W219

Fuel filter:

All fuel injection models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Champion L204

Ignition system

Spark plugs:

Make and type:

All except 1.8 CVH, CVH (R6A), 2.0 DOHC and P100 . . . . . . . . . . . .Champion RF7YCC or RF7YC

1.8 litre CVH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Champion RC7YCC or RC7YC

P100 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Champion RF7YC or F7YC

1.6 and 1.8 litre (R6A type) CVH . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Champion RC7YCC

2.0 litre DOHC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Champion RC7YCC

Electrode gap*:

Champion F7YCC or RC7YCC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.8 mm (0.032 in)

Champion RF7YC, F7YC or RC7YC . . . . . . . . . . . . . . . . . . . . . . . . . .0.7 mm (0.028 in)

Ignition HT leads

Resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30 k ohms maximum per lead

Type:

All SOHC models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Champion LS-09 or LS-10 boxed set

1.8 litre CVH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Champion LS-10 boxed set

1.6 and 1.8 litre (R6A type) CVH . . . . . . . . . . . . . . . . . . . . . . . . . . . .Champion LS-30 boxed set

2.0 litre DOHC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Champion LS-29 boxed set

*The spark plug gap quoted is that recommended by Champion for their specified plugs listed above. If spark plugs of any other type are to be

fitted, refer to their manufacturer’s recommendations.

Brakes

Brake pad friction material minimum thickness . . . . . . . . . . . . . . . . . . .1.5 mm (0.06 in)

Brake shoe friction material minimum thickness . . . . . . . . . . . . . . . . . .1.0 mm (0.04 in)

Torque wrench settingsNmlbf ft

Engine oil drain plug:

SOHC and DOHC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21 to 2816 to 21

CVH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20 to 3015 to 22

Engine block coolant drain plug (where fitted) . . . . . . . . . . . . . . . . . . . .21 to 25 16 to 18

Manual gearbox:

Oil filler/level plug:

A,B,C and N types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33 to 4124 to 30

MT75 type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29 to 4121 to 30

Oil drain plug:

MT75 type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29 to 4121 to 30

Final drive oil filler plug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35 to 4526 to 33

Roadwheel nuts:

Saloon, Hatchback and Estate models (steel and alloy wheels) . . . .70 to 10052 to 74

P100 models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85 to 9063 to 66

Spark plugs:

SOHC models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20 to 2815 to 21

CVH models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18 to 3313 to 24

DOHC models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15 to 2111 to 15

Brake caliper guide bolts:

Front . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20 to 2515 to 18

Rear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31 to 3523 to 26

1•2Servicing specifications

Page 5 of 22

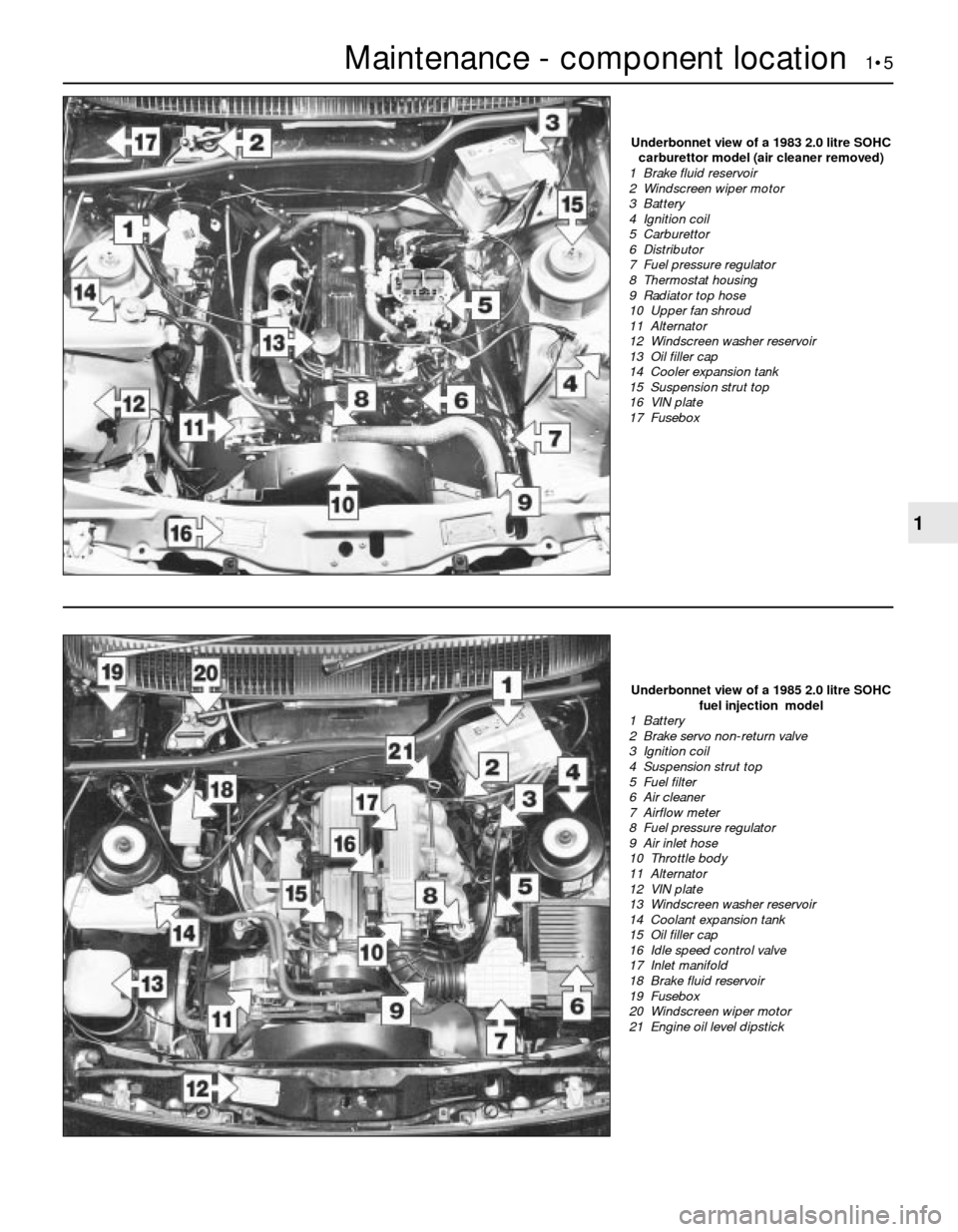

Maintenance - component location 1•5

1

Underbonnet view of a 1985 2.0 litre SOHC

fuel injection model

1 Battery

2 Brake servo non-return valve

3 Ignition coil

4 Suspension strut top

5 Fuel filter

6 Air cleaner

7 Airflow meter

8 Fuel pressure regulator

9 Air inlet hose

10 Throttle body

11 Alternator

12 VIN plate

13 Windscreen washer reservoir

14 Coolant expansion tank

15 Oil filler cap

16 Idle speed control valve

17 Inlet manifold

18 Brake fluid reservoir

19 Fusebox

20 Windscreen wiper motor

21 Engine oil level dipstick

Underbonnet view of a 1983 2.0 litre SOHC

carburettor model (air cleaner removed)

1 Brake fluid reservoir

2 Windscreen wiper motor

3 Battery

4 Ignition coil

5 Carburettor

6 Distributor

7 Fuel pressure regulator

8 Thermostat housing

9 Radiator top hose

10 Upper fan shroud

11 Alternator

12 Windscreen washer reservoir

13 Oil filler cap

14 Cooler expansion tank

15 Suspension strut top

16 VIN plate

17 Fusebox

Page 6 of 22

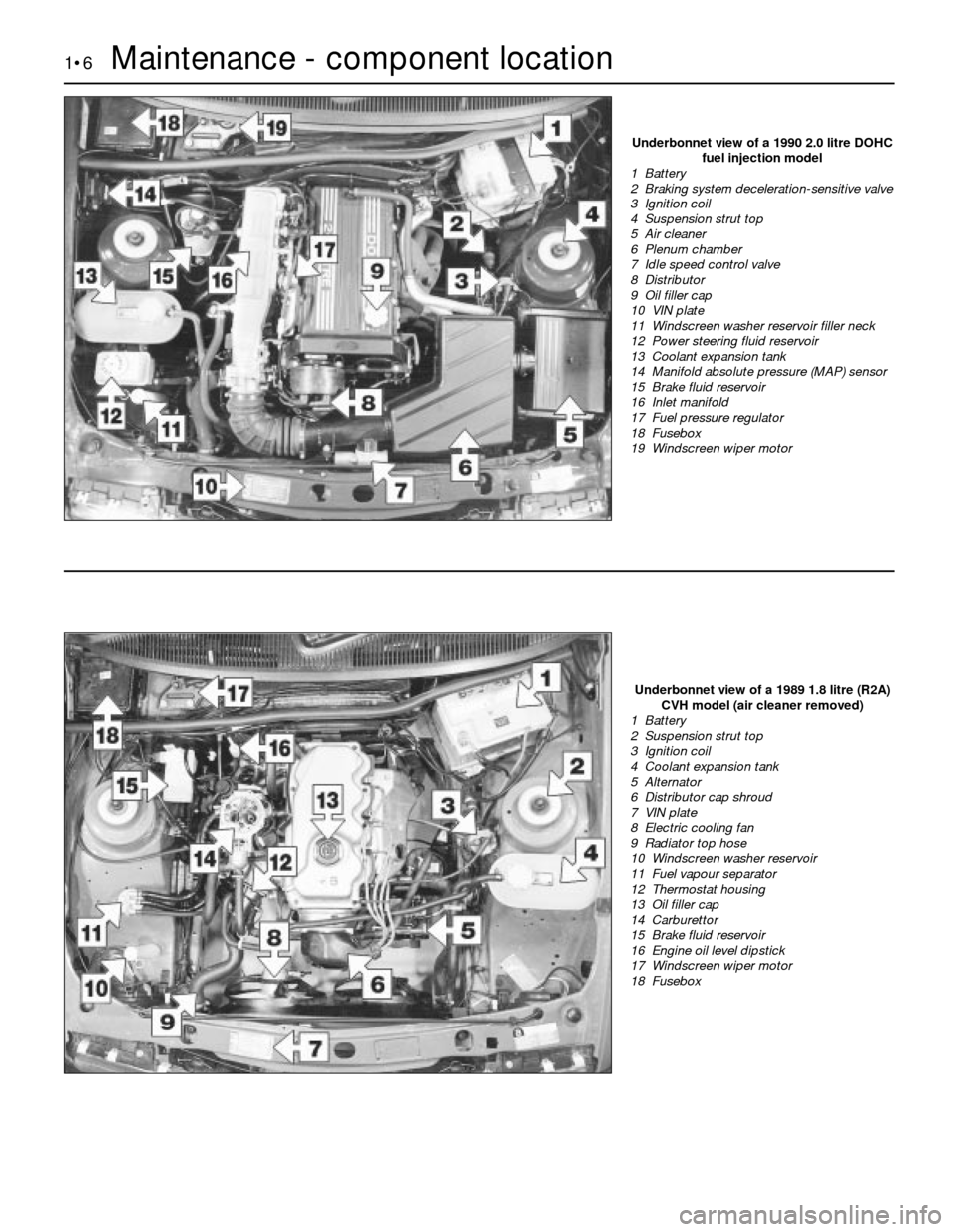

1•6Maintenance - component location

Underbonnet view of a 1990 2.0 litre DOHC

fuel injection model

1 Battery

2 Braking system deceleration-sensitive valve

3 Ignition coil

4 Suspension strut top

5 Air cleaner

6 Plenum chamber

7 Idle speed control valve

8 Distributor

9 Oil filler cap

10 VIN plate

11 Windscreen washer reservoir filler neck

12 Power steering fluid reservoir

13 Coolant expansion tank

14 Manifold absolute pressure (MAP) sensor

15 Brake fluid reservoir

16 Inlet manifold

17 Fuel pressure regulator

18 Fusebox

19 Windscreen wiper motor

Underbonnet view of a 1989 1.8 litre (R2A)

CVH model (air cleaner removed)

1 Battery

2 Suspension strut top

3 Ignition coil

4 Coolant expansion tank

5 Alternator

6 Distributor cap shroud

7 VIN plate

8 Electric cooling fan

9 Radiator top hose

10 Windscreen washer reservoir

11 Fuel vapour separator

12 Thermostat housing

13 Oil filler cap

14 Carburettor

15 Brake fluid reservoir

16 Engine oil level dipstick

17 Windscreen wiper motor

18 Fusebox

Page 7 of 22

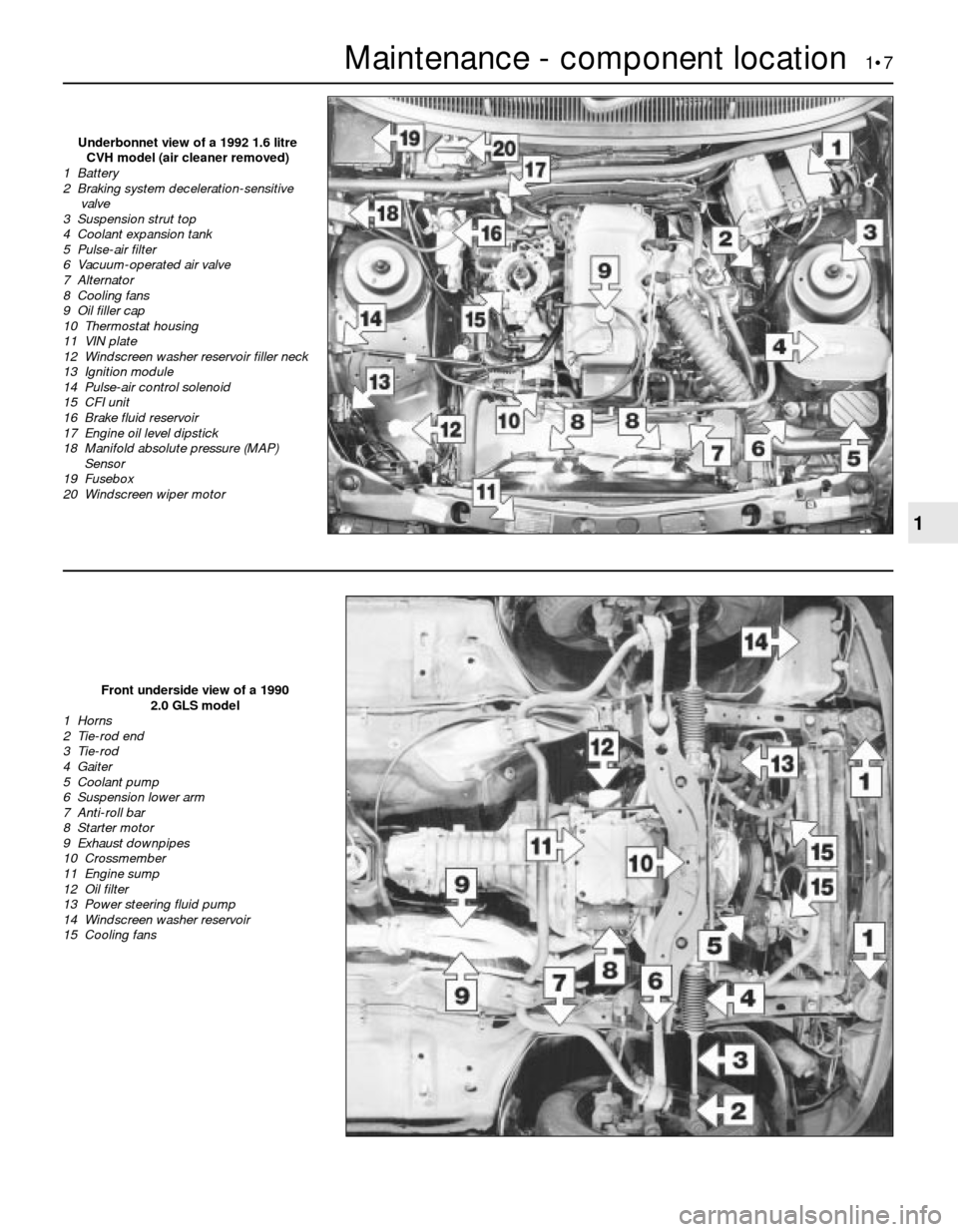

Maintenance - component location 1•7

1

Front underside view of a 1990

2.0 GLS model

1 Horns

2 Tie-rod end

3 Tie-rod

4 Gaiter

5 Coolant pump

6 Suspension lower arm

7 Anti-roll bar

8 Starter motor

9 Exhaust downpipes

10 Crossmember

11 Engine sump

12 Oil filter

13 Power steering fluid pump

14 Windscreen washer reservoir

15 Cooling fans

Underbonnet view of a 1992 1.6 litre

CVH model (air cleaner removed)

1 Battery

2 Braking system deceleration-sensitive

valve

3 Suspension strut top

4 Coolant expansion tank

5 Pulse-air filter

6 Vacuum-operated air valve

7 Alternator

8 Cooling fans

9 Oil filler cap

10 Thermostat housing

11 VIN plate

12 Windscreen washer reservoir filler neck

13 Ignition module

14 Pulse-air control solenoid

15 CFI unit

16 Brake fluid reservoir

17 Engine oil level dipstick

18 Manifold absolute pressure (MAP)

Sensor

19 Fusebox

20 Windscreen wiper motor

Page 14 of 22

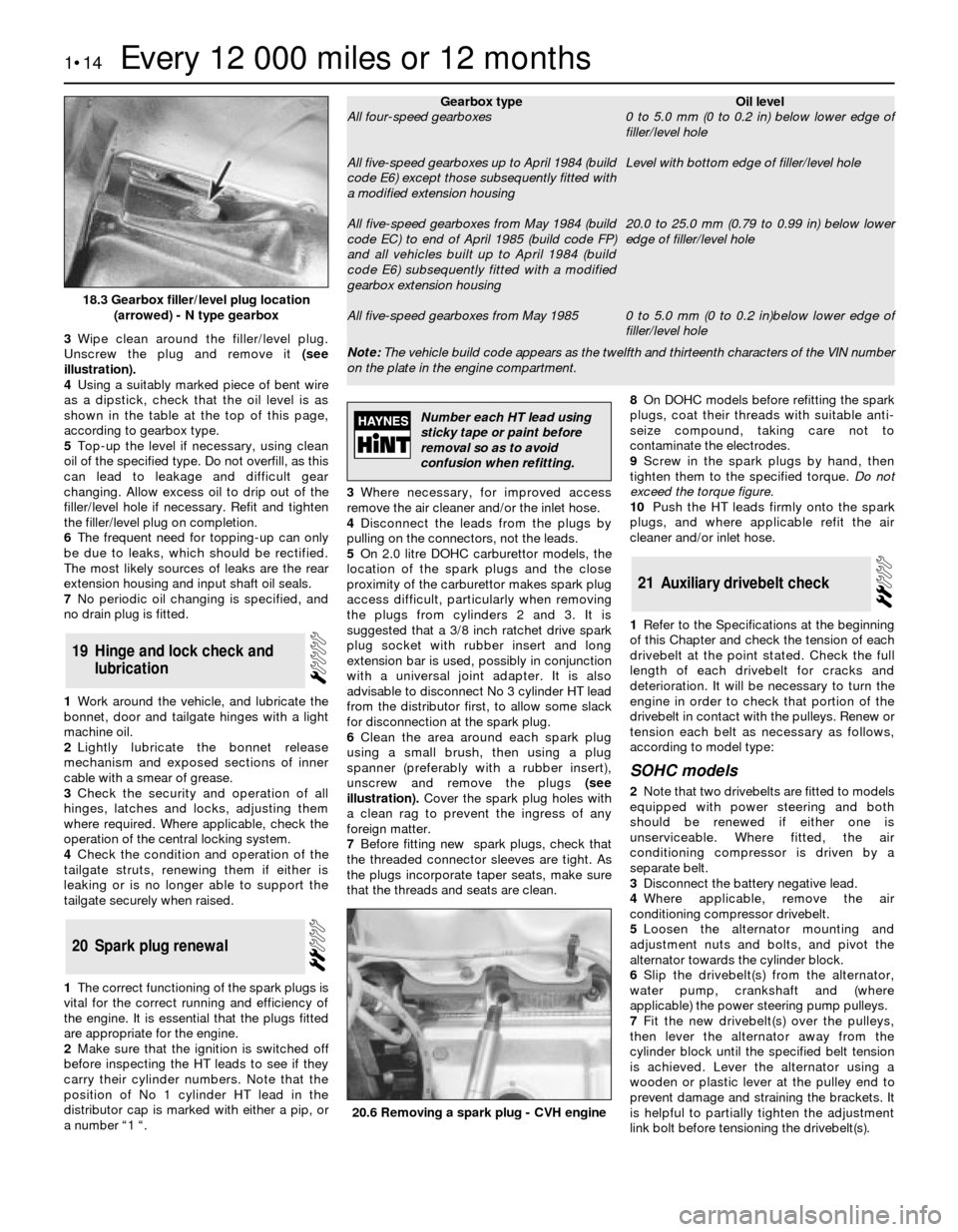

3Wipe clean around the filler/level plug.

Unscrew the plug and remove it(see

illustration).

4Using a suitably marked piece of bent wire

as a dipstick, check that the oil level is as

shown in the table at the top of this page,

according to gearbox type.

5Top-up the level if necessary, using clean

oil of the specified type. Do not overfill, as this

can lead to leakage and difficult gear

changing. Allow excess oil to drip out of the

filler/level hole if necessary. Refit and tighten

the filler/level plug on completion.

6The frequent need for topping-up can only

be due to leaks, which should be rectified.

The most likely sources of leaks are the rear

extension housing and input shaft oil seals.

7No periodic oil changing is specified, and

no drain plug is fitted.

1Work around the vehicle, and lubricate the

bonnet, door and tailgate hinges with a light

machine oil.

2Lightly lubricate the bonnet release

mechanism and exposed sections of inner

cable with a smear of grease.

3Check the security and operation of all

hinges, latches and locks, adjusting them

where required. Where applicable, check the

operation of the central locking system.

4Check the condition and operation of the

tailgate struts, renewing them if either is

leaking or is no longer able to support the

tailgate securely when raised.

1The correct functioning of the spark plugs is

vital for the correct running and efficiency of

the engine. It is essential that the plugs fitted

are appropriate for the engine.

2Make sure that the ignition is switched off

before inspecting the HT leads to see if they

carry their cylinder numbers. Note that the

position of No 1 cylinder HT lead in the

distributor cap is marked with either a pip, or

a number “1 “.3Where necessary, for improved access

remove the air cleaner and/or the inlet hose.

4Disconnect the leads from the plugs by

pulling on the connectors, not the leads.

5On 2.0 litre DOHC carburettor models, the

location of the spark plugs and the close

proximity of the carburettor makes spark plug

access difficult, particularly when removing

the plugs from cylinders 2 and 3. It is

suggested that a 3/8 inch ratchet drive spark

plug socket with rubber insert and long

extension bar is used, possibly in conjunction

with a universal joint adapter. It is also

advisable to disconnect No 3 cylinder HT lead

from the distributor first, to allow some slack

for disconnection at the spark plug.

6Clean the area around each spark plug

using a small brush, then using a plug

spanner (preferably with a rubber insert),

unscrew and remove the plugs(see

illustration).Cover the spark plug holes with

a clean rag to prevent the ingress of any

foreign matter.

7Before fitting new spark plugs, check that

the threaded connector sleeves are tight. As

the plugs incorporate taper seats, make sure

that the threads and seats are clean.8On DOHC models before refitting the spark

plugs, coat their threads with suitable anti-

seize compound, taking care not to

contaminate the electrodes.

9Screw in the spark plugs by hand, then

tighten them to the specified torque. Do not

exceed the torque figure.

10Push the HT leads firmly onto the spark

plugs, and where applicable refit the air

cleaner and/or inlet hose.

1Refer to the Specifications at the beginning

of this Chapter and check the tension of each

drivebelt at the point stated. Check the full

length of each drivebelt for cracks and

deterioration. It will be necessary to turn the

engine in order to check that portion of the

drivebelt in contact with the pulleys. Renew or

tension each belt as necessary as follows,

according to model type:

SOHC models

2Note that two drivebelts are fitted to models

equipped with power steering and both

should be renewed if either one is

unserviceable. Where fitted, the air

conditioning compressor is driven by a

separate belt.

3Disconnect the battery negative lead.

4Where applicable, remove the air

conditioning compressor drivebelt.

5Loosen the alternator mounting and

adjustment nuts and bolts, and pivot the

alternator towards the cylinder block.

6Slip the drivebelt(s) from the alternator,

water pump, crankshaft and (where

applicable) the power steering pump pulleys.

7Fit the new drivebelt(s) over the pulleys,

then lever the alternator away from the

cylinder block until the specified belt tension

is achieved. Lever the alternator using a

wooden or plastic lever at the pulley end to

prevent damage and straining the brackets. It

is helpful to partially tighten the adjustment

link bolt before tensioning the drivebelt(s).

21Auxiliary drivebelt check

20Spark plug renewal

19Hinge and lock check and

lubrication

1•14Every 12 000 miles or 12 months

18.3 Gearbox filler/level plug location

(arrowed) - N type gearbox

20.6 Removing a spark plug - CVH engine

Note: The vehicle build code appears as the twelfth and thirteenth characters of the VIN number

on the plate in the engine compartment.

Gearbox type

All four-speed gearboxes

All five-speed gearboxes up to April 1984 (build

code E6) except those subsequently fitted with

a modified extension housing

All five-speed gearboxes from May 1984 (build

code EC) to end of April 1985 (build code FP)

and all vehicles built up to April 1984 (build

code E6) subsequently fitted with a modified

gearbox extension housing

All five-speed gearboxes from May 1985Oil level

0 to 5.0 mm (0 to 0.2 in) below lower edge of

filler/level hole

Level with bottom edge of filler/level hole

20.0 to 25.0 mm (0.79 to 0.99 in) below lower

edge of filler/level hole

0 to 5.0 mm (0 to 0.2 in)below lower edge of

filler/level hole

Number each HT lead using

sticky tape or paint before

removal so as to avoid

confusion when refitting.

Page 15 of 22

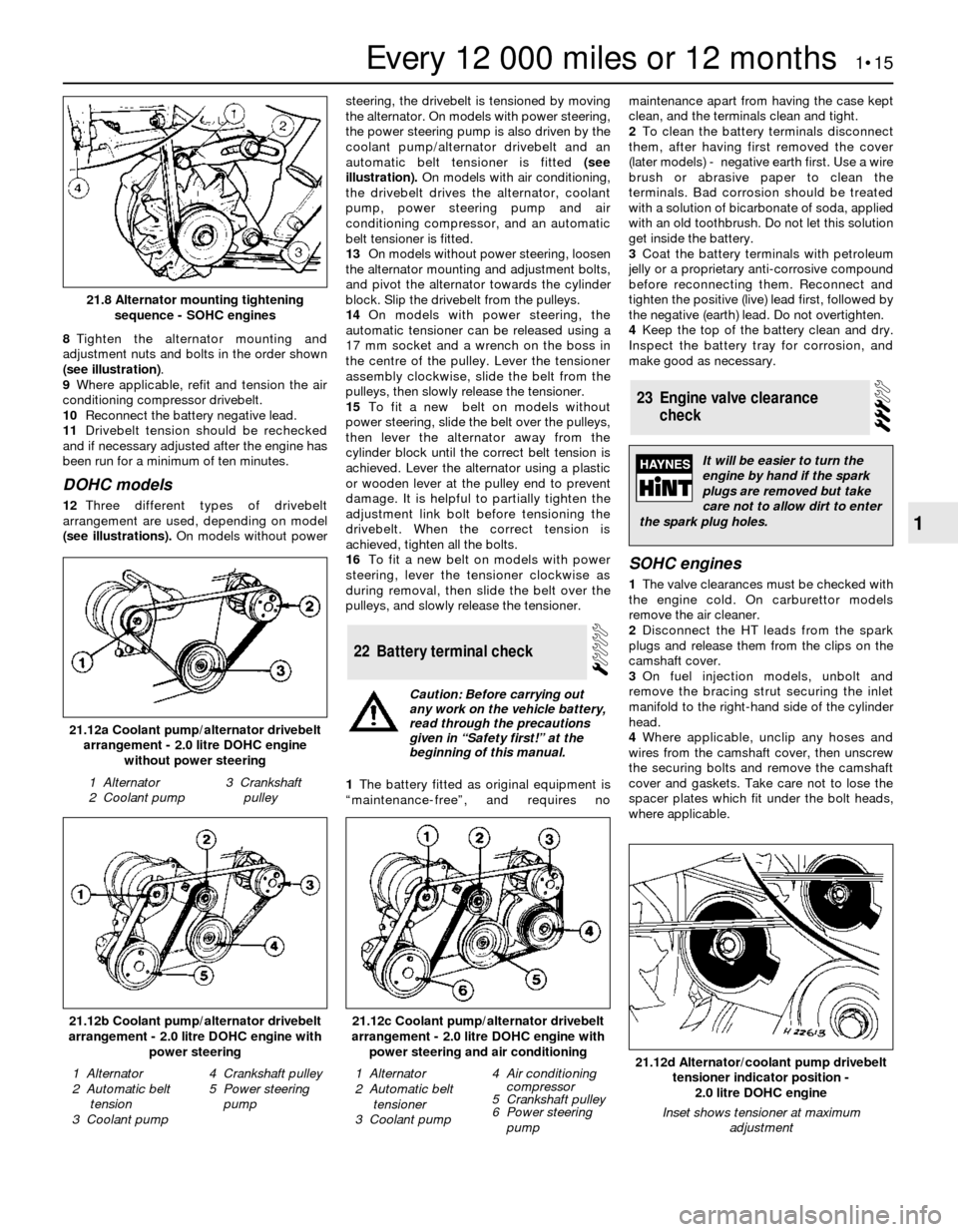

8Tighten the alternator mounting and

adjustment nuts and bolts in the order shown

(see illustration).

9Where applicable, refit and tension the air

conditioning compressor drivebelt.

10Reconnect the battery negative lead.

11Drivebelt tension should be rechecked

and if necessary adjusted after the engine has

been run for a minimum of ten minutes.

DOHC models

12Three different types of drivebelt

arrangement are used, depending on model

(see illustrations).On models without powersteering, the drivebelt is tensioned by moving

the alternator. On models with power steering,

the power steering pump is also driven by the

coolant pump/alternator drivebelt and an

automatic belt tensioner is fitted (see

illustration).On models with air conditioning,

the drivebelt drives the alternator, coolant

pump, power steering pump and air

conditioning compressor, and an automatic

belt tensioner is fitted.

13On models without power steering, loosen

the alternator mounting and adjustment bolts,

and pivot the alternator towards the cylinder

block. Slip the drivebelt from the pulleys.

14On models with power steering, the

automatic tensioner can be released using a

17 mm socket and a wrench on the boss in

the centre of the pulley. Lever the tensioner

assembly clockwise, slide the belt from the

pulleys, then slowly release the tensioner.

15To fit a new belt on models without

power steering, slide the belt over the pulleys,

then lever the alternator away from the

cylinder block until the correct belt tension is

achieved. Lever the alternator using a plastic

or wooden lever at the pulley end to prevent

damage. It is helpful to partially tighten the

adjustment link bolt before tensioning the

drivebelt. When the correct tension is

achieved, tighten all the bolts.

16To fit a new belt on models with power

steering, lever the tensioner clockwise as

during removal, then slide the belt over the

pulleys, and slowly release the tensioner.

1The battery fitted as original equipment is

“maintenance-free”, and requires nomaintenance apart from having the case kept

clean, and the terminals clean and tight.

2To clean the battery terminals disconnect

them, after having first removed the cover

(later models) - negative earth first. Use a wire

brush or abrasive paper to clean the

terminals. Bad corrosion should be treated

with a solution of bicarbonate of soda, applied

with an old toothbrush. Do not let this solution

get inside the battery.

3Coat the battery terminals with petroleum

jelly or a proprietary anti-corrosive compound

before reconnecting them. Reconnect and

tighten the positive (live) lead first, followed by

the negative (earth) lead. Do not overtighten.

4Keep the top of the battery clean and dry.

Inspect the battery tray for corrosion, and

make good as necessary.

SOHC engines

1The valve clearances must be checked with

the engine cold. On carburettor models

remove the air cleaner.

2Disconnect the HT leads from the spark

plugs and release them from the clips on the

camshaft cover.

3On fuel injection models, unbolt and

remove the bracing strut securing the inlet

manifold to the right-hand side of the cylinder

head.

4Where applicable, unclip any hoses and

wires from the camshaft cover, then unscrew

the securing bolts and remove the camshaft

cover and gaskets. Take care not to lose the

spacer plates which fit under the bolt heads,

where applicable.

23Engine valve clearance

check

22Battery terminal check

Every 12 000 miles or 12 months 1•15

1

21.12b Coolant pump/alternator drivebelt

arrangement - 2.0 litre DOHC engine with

power steering

1 Alternator

2 Automatic belt

tension

3 Coolant pump4 Crankshaft pulley

5 Power steering

pump21.12d Alternator/coolant pump drivebelt

tensioner indicator position -

2.0 litre DOHC engine

Inset shows tensioner at maximum

adjustment

1 Alternator

2 Automatic belt

tensioner

3 Coolant pump4 Air conditioning

compressor

5 Crankshaft pulley

6 Power steering

pump

21.12c Coolant pump/alternator drivebelt

arrangement - 2.0 litre DOHC engine with

power steering and air conditioning

21.12a Coolant pump/alternator drivebelt

arrangement - 2.0 litre DOHC engine

without power steering

1 Alternator

2 Coolant pump3 Crankshaft

pulley

21.8 Alternator mounting tightening

sequence - SOHC engines

Caution: Before carrying out

any work on the vehicle battery,

read through the precautions

given in “Safety first!” at the

beginning of this manual.

It will be easier to turn the

engine by hand if the spark

plugs are removed but take

care not to allow dirt to enter

the spark plug holes.