power steering FORD SIERRA 1992 2.G Cooling And Air Conditioning Systems Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1992, Model line: SIERRA, Model: FORD SIERRA 1992 2.GPages: 12, PDF Size: 0.62 MB

Page 1 of 12

System type

SOHC models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Pressurised, with belt-driven coolant pump, crossflow radiator,

thermo-viscous fan, thermostat, and expansion tank

CVH and DOHC models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Pressurised, with belt-driven coolant pump, crossflow radiator,

electric fan, thermostat, and expansion tank

Thermostat

Nominal temperature rating (fully open):

SOHC models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88ºC (190º F)

CVH models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100ºC (212ºF)

DOHC models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102ºC (216ºF)

Opening temperature:

SOHC models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85 to 89ºC (185 to 192ºF)

CVH models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88ºC (190ºF)

CVH (R6A type) models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85 to 89ºC (185 to 192ºF)

DOHC models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85 to 89ºC (185 to 192ºF)

Expansion tank cap opening pressure

SOHC models:

Up to 1987 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.85 to 1.1 bar (12 to 16 lbf/in2)

From 1987 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.0 to 1.25 bar (15 to 18 lbf/in2)

CVH models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.0 to 1.25 bar (15 to 18 lbf/in2)

DOHC models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.0 to 1.4 bar (15 to 20 lbf/in2)

Coolant mixture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . See Chapter 1 Specifications

System capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . See Chapter 1 Specifications

Drivebelt tensions

Air conditioning system compressor . . . . . . . . . . . . . . . . . . . . . . . . . . . 10.0 mm (0.4 in) deflection at the midpoint of the belt’s longest run

under firm thumb pressure

Coolant pump/alternator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10.0 mm (0.4 in) deflection midway between coolant pump and

alternator (or power steering pump) pulleys under firm thumb pressure

Chapter 3

Cooling, heating and air conditioning systems

Air conditioning system - component renewal . . . . . . . . . . . . . . . . . .21

Coolant pump - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . .9

Coolant pump/alternator drivebelt(s) - checking, renewal and

tensioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Coolant pump/alternator drivebelt tensioner (DOHC models with

power steering) - removal and refitting . . . . . . . . . . . . . . . . . . . . . .11

Cooling fan switch - removal and refitting . . . . . . . . . . . . . . . . . . . . .14

Cooling system - draining . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Cooling system - filling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Cooling system - flushing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Electric cooling fan - removal and refitting . . . . . . . . . . . . . . . . . . . . .13

Expansion tank and coolant level sensor - removal and refitting . . . .15General information and precautions . . . . . . . . . . . . . . . . . . . . . . . . . .1

Heater controls - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . .17

Heater motor - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . .20

Heater unit - overhaul . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Heater unit - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Radiator - inspection and cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Radiator - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Temperature gauge sender - removal and refitting . . . . . . . . . . . . . .16

Thermostat - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Thermostat - testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Thermo-viscous cooling fan (SOHC models) - removal and refitting .12

3•1

Specifications Contents3

Easy,suitable for

novice with little

experienceFairly easy,suitable

for beginner with

some experienceFairly difficult,

suitable for competent

DIY mechanic

Difficult,suitable for

experienced DIY

mechanicVery difficult,

suitable for expert

DIY or professional

Degrees of difficulty

Page 7 of 12

36Tighten the coolant pump securing bolts,

and where applicable the pump pulley

securing bolts, to the specified torque.

37On completion, refill the cooling system.

Refer to Chapter 1, Section 21.

Removal

1Remove the alternator drivebelt.

2Loosen the alternator lower mounting

through-bolt, then remove the alternator

upper mounting bolt and swing the alternator

away from the engine.

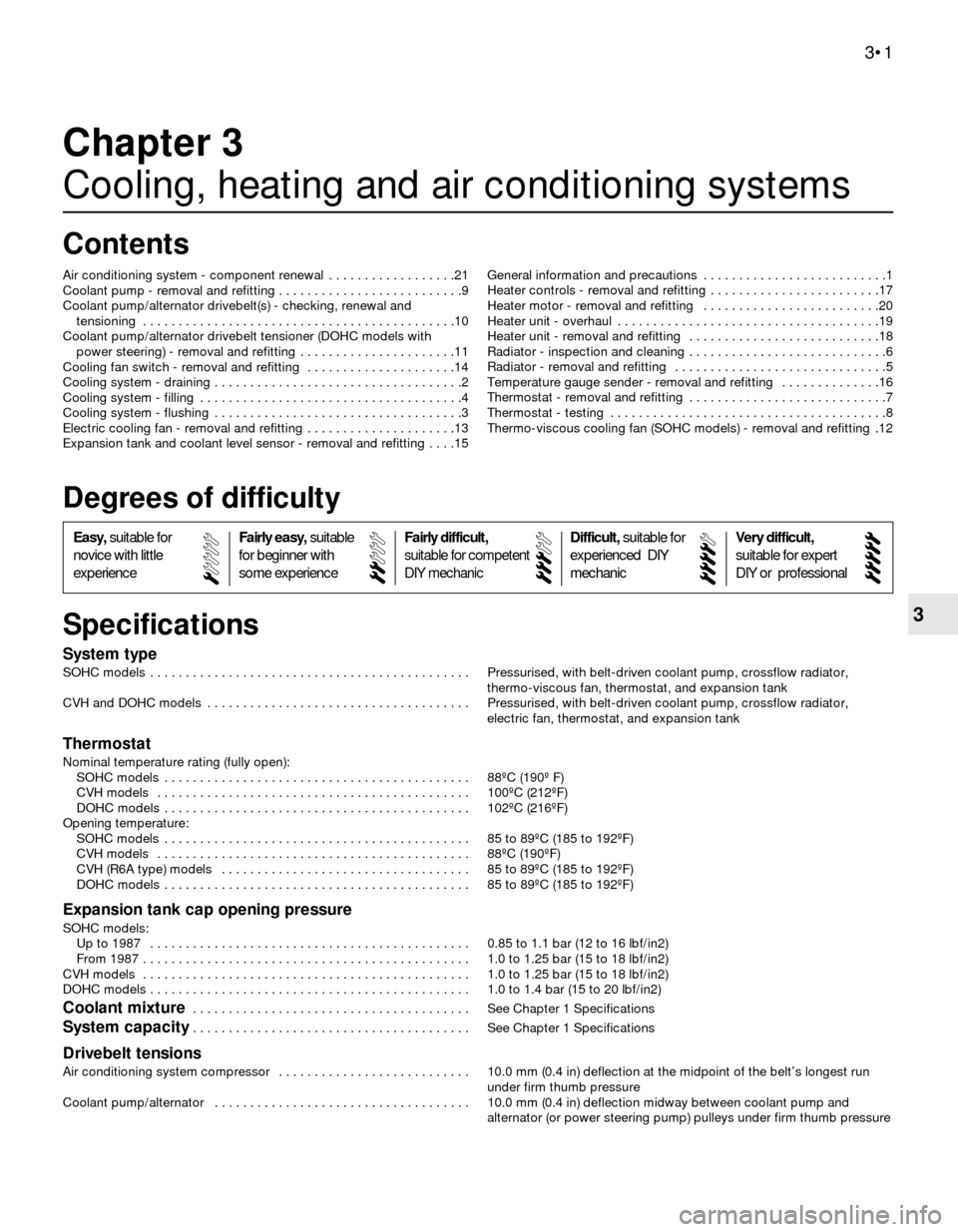

3Unscrew the central securing bolt, and

withdraw the drivebelt tensioner assembly

(see illustration).

Refitting

4Commence refitting by positioning the

tensioner on the cylinder block, ensuring that

the lug on the rear of the tensioner bracket

engages with the corresponding hole in the

cylinder block. Tighten the securing bolt.

5Swing the alternator into position, to align

the upper mounting bolt hole with the

corresponding hole in the drivebelt tensionerassembly. Refit the upper mounting bolt, and

tighten the upper bolt and lower through-bolt.

6Fit the drivebelt by reversing the removal

procedure, and release the tensioner to

tension the drivebelt.

7Observe the tensioner indicator, which

should be central in its slot (see illustration).

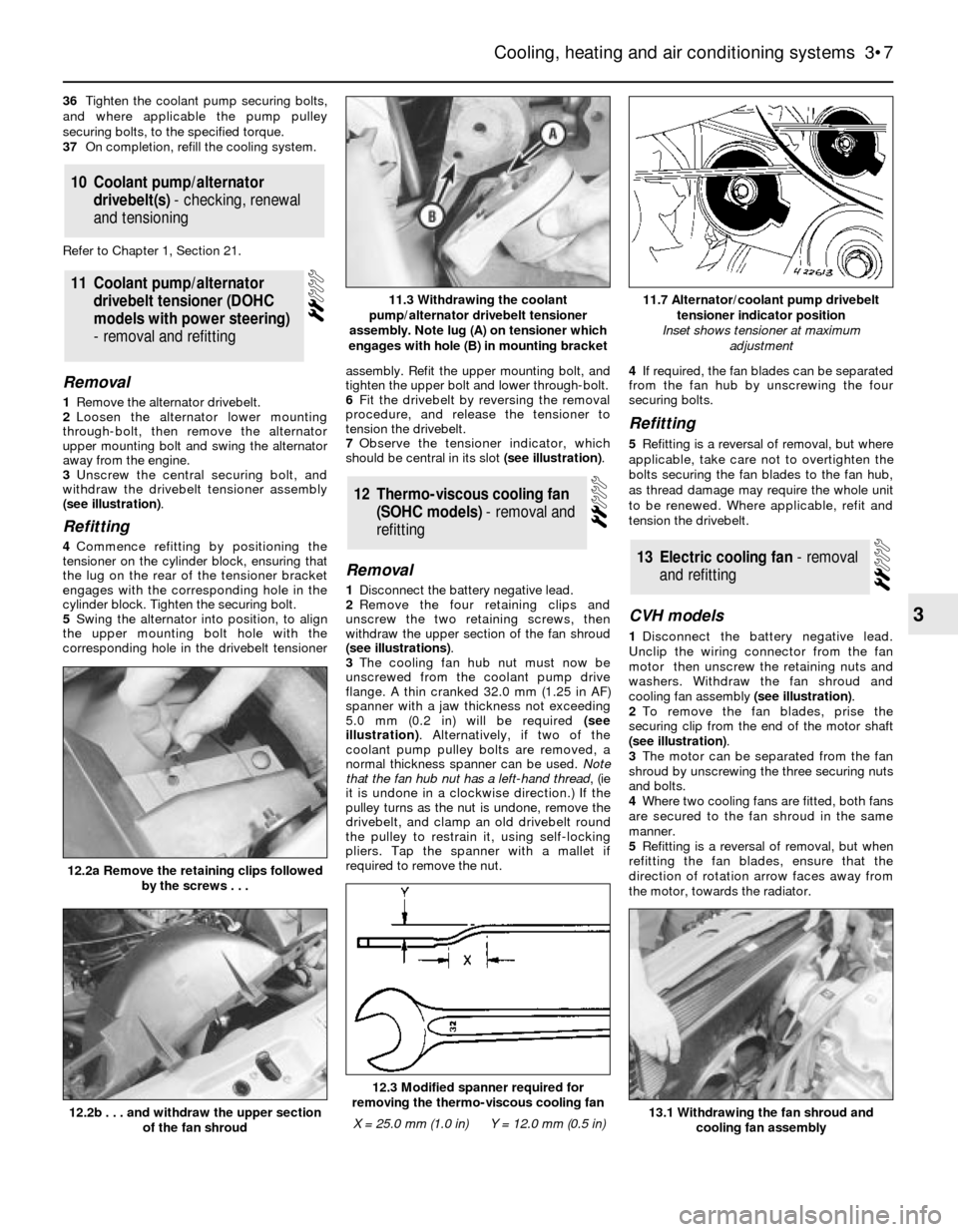

Removal

1Disconnect the battery negative lead.

2Remove the four retaining clips and

unscrew the two retaining screws, then

withdraw the upper section of the fan shroud

(see illustrations).

3The cooling fan hub nut must now be

unscrewed from the coolant pump drive

flange. A thin cranked 32.0 mm (1.25 in AF)

spanner with a jaw thickness not exceeding

5.0 mm (0.2 in) will be required (see

illustration). Alternatively, if two of the

coolant pump pulley bolts are removed, a

normal thickness spanner can be used.Note

that the fan hub nut has a left-hand thread, (ie

it is undone in a clockwise direction.) If the

pulley turns as the nut is undone, remove the

drivebelt, and clamp an old drivebelt round

the pulley to restrain it, using self-locking

pliers. Tap the spanner with a mallet if

required to remove the nut.4If required, the fan blades can be separated

from the fan hub by unscrewing the four

securing bolts.

Refitting

5Refitting is a reversal of removal, but where

applicable, take care not to overtighten the

bolts securing the fan blades to the fan hub,

as thread damage may require the whole unit

to be renewed. Where applicable, refit and

tension the drivebelt.

CVH models

1Disconnect the battery negative lead.

Unclip the wiring connector from the fan

motor then unscrew the retaining nuts and

washers. Withdraw the fan shroud and

cooling fan assembly (see illustration).

2To remove the fan blades, prise the

securing clip from the end of the motor shaft

(see illustration).

3The motor can be separated from the fan

shroud by unscrewing the three securing nuts

and bolts.

4Where two cooling fans are fitted, both fans

are secured to the fan shroud in the same

manner.

5Refitting is a reversal of removal, but when

refitting the fan blades, ensure that the

direction of rotation arrow faces away from

the motor, towards the radiator.

13Electric cooling fan -removal

andrefitting

12Thermo-viscous cooling fan

(SOHC models) - removal and

refitting

11Coolant pump/alternator

drivebelt tensioner (DOHC

models with power steering)

- removal and refitting

10Coolant pump/alternator

drivebelt(s) - checking, renewal

and tensioning

Cooling, heating and air conditioning systems 3•7

3

12.2a Remove the retaining clips followed

by the screws . . .

13.1 Withdrawing the fan shroud and

cooling fan assembly

12.3 Modified spanner required for

removing the thermo-viscous cooling fan

X = 25.0 mm (1.0 in)Y = 12.0 mm (0.5 in)12.2b . . . and withdraw the upper section

of the fan shroud

11.7 Alternator/coolant pump drivebelt

tensioner indicator position

Inset shows tensioner at maximum

adjustment11.3 Withdrawing the coolant

pump/alternator drivebelt tensioner

assembly. Note lug (A) on tensioner which

engages with hole (B) in mounting bracket