AUX FORD SIERRA 1992 2.G SOHC Engines User Guide

[x] Cancel search | Manufacturer: FORD, Model Year: 1992, Model line: SIERRA, Model: FORD SIERRA 1992 2.GPages: 24, PDF Size: 1.03 MB

Page 19 of 24

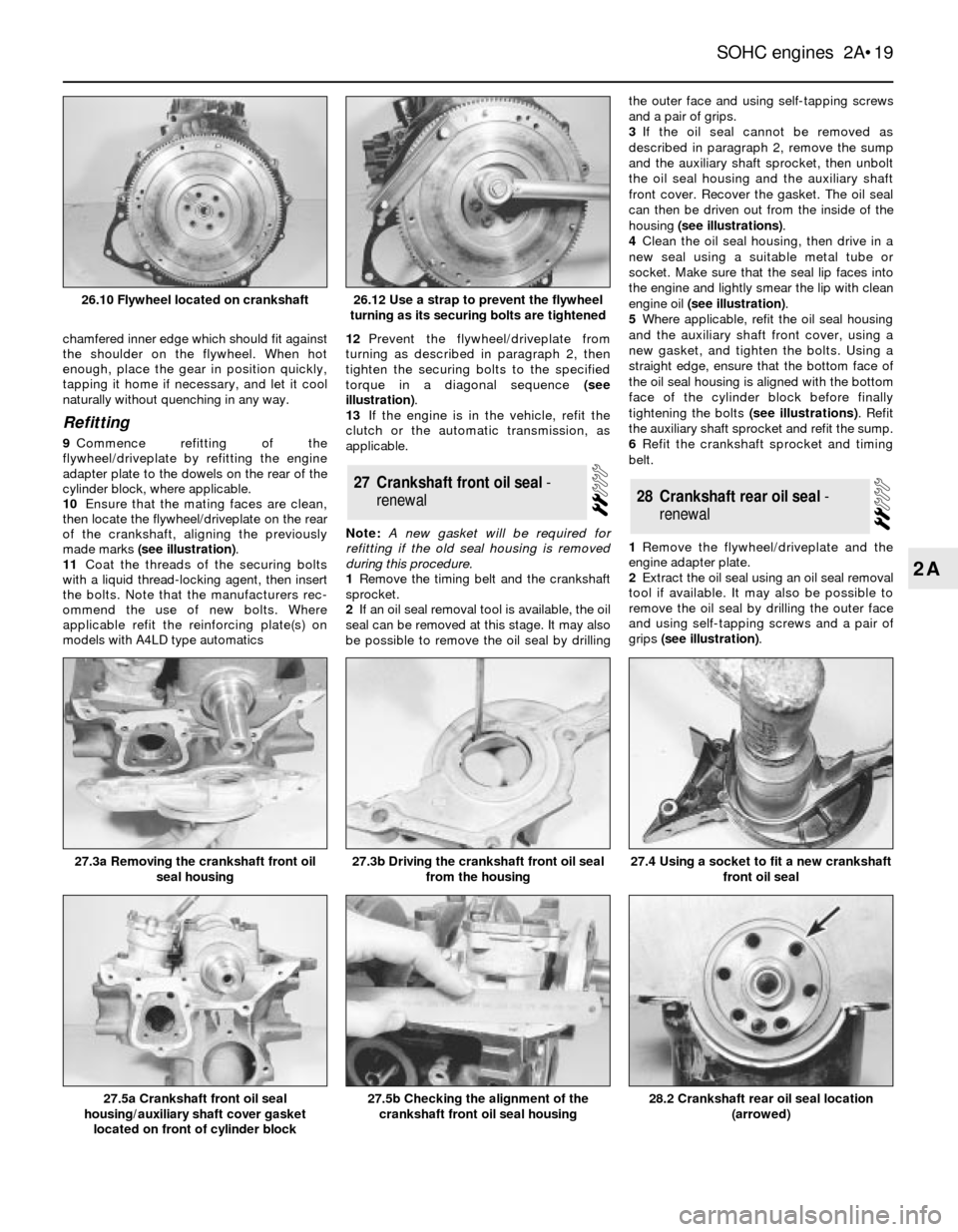

chamfered inner edge which should fit against

the shoulder on the flywheel. When hot

enough, place the gear in position quickly,

tapping it home if necessary, and let it cool

naturally without quenching in any way.

Refitting

9Commence refitting of the

flywheel/driveplate by refitting the engine

adapter plate to the dowels on the rear of the

cylinder block, where applicable.

10Ensure that the mating faces are clean,

then locate the flywheel/driveplate on the rear

of the crankshaft, aligning the previously

made marks (see illustration).

11Coat the threads of the securing bolts

with a liquid thread-locking agent, then insert

the bolts. Note that the manufacturers rec-

ommend the use of new bolts. Where

applicable refit the reinforcing plate(s) on

models with A4LD type automatics12Prevent the flywheel/driveplate from

turning as described in paragraph 2, then

tighten the securing bolts to the specified

torque in a diagonal sequence (see

illustration).

13If the engine is in the vehicle, refit the

clutch or the automatic transmission, as

applicable.

Note: A new gasket will be required for

refitting if the old seal housing is removed

during this procedure.

1Remove the timing belt and the crankshaft

sprocket.

2If an oil seal removal tool is available, the oil

seal can be removed at this stage. It may also

be possible to remove the oil seal by drillingthe outer face and using self-tapping screws

and a pair of grips.

3If the oil seal cannot be removed as

described in paragraph 2, remove the sump

and the auxiliary shaft sprocket, then unbolt

the oil seal housing and the auxiliary shaft

front cover. Recover the gasket. The oil seal

can then be driven out from the inside of the

housing (see illustrations).

4Clean the oil seal housing, then drive in a

new seal using a suitable metal tube or

socket. Make sure that the seal lip faces into

the engine and lightly smear the lip with clean

engine oil (see illustration).

5Where applicable, refit the oil seal housing

and the auxiliary shaft front cover, using a

new gasket, and tighten the bolts. Using a

straight edge, ensure that the bottom face of

the oil seal housing is aligned with the bottom

face of the cylinder block before finally

tightening the bolts (see illustrations). Refit

the auxiliary shaft sprocket and refit the sump.

6Refit the crankshaft sprocket and timing

belt.

1Remove the flywheel/driveplate and the

engine adapter plate.

2Extract the oil seal using an oil seal removal

tool if available. It may also be possible to

remove the oil seal by drilling the outer face

and using self-tapping screws and a pair of

grips (see illustration).

28Crankshaft rear oil seal -

renewal27Crankshaft front oil seal -

renewal

SOHC engines 2A¥19

2A

27.3a Removing the crankshaft front oil

seal housing27.3b Driving the crankshaft front oil seal

from the housing

28.2 Crankshaft rear oil seal location

(arrowed)27.5b Checking the alignment of the

crankshaft front oil seal housing27.5a Crankshaft front oil seal

housing/auxiliary shaft cover gasket

located on front of cylinder block

27.4 Using a socket to fit a new crankshaft

front oil seal

26.12 Use a strap to prevent the flywheel

turning as its securing bolts are tightened26.10 Flywheel located on crankshaft

Page 23 of 24

4Before fitting the new rings to the pistons,

insert them into the cylinder bore and use a

feelerblade to check that the end gaps are

within the specified limits (see illustration).

5Clean out the piston ring groove using a

piece of old piston ring as a scraper. Be

careful not to scratch the aluminium surface

of the pistons. Protect your fingers - piston

ring edges are sharp.

6Fit the oil control ring sections with the

spreader ends abutted opposite the front of the

piston. The side ring gaps should be 25 mm (1.0

in) either side of the spreader gap. Fit the

tapered lower compression ring with the ÒTOPÓ

mark towards the top of the piston and the gap

150¼ from the spreader gap, then fit the upper

compression ring with the gap 150¼ on the

other side of the spreader gap. Note that the

compression rings are coated with a

molybdenum skin which must not be damaged.

Note also that the compression rings are made

of cast iron, and will snap if expanded too far.

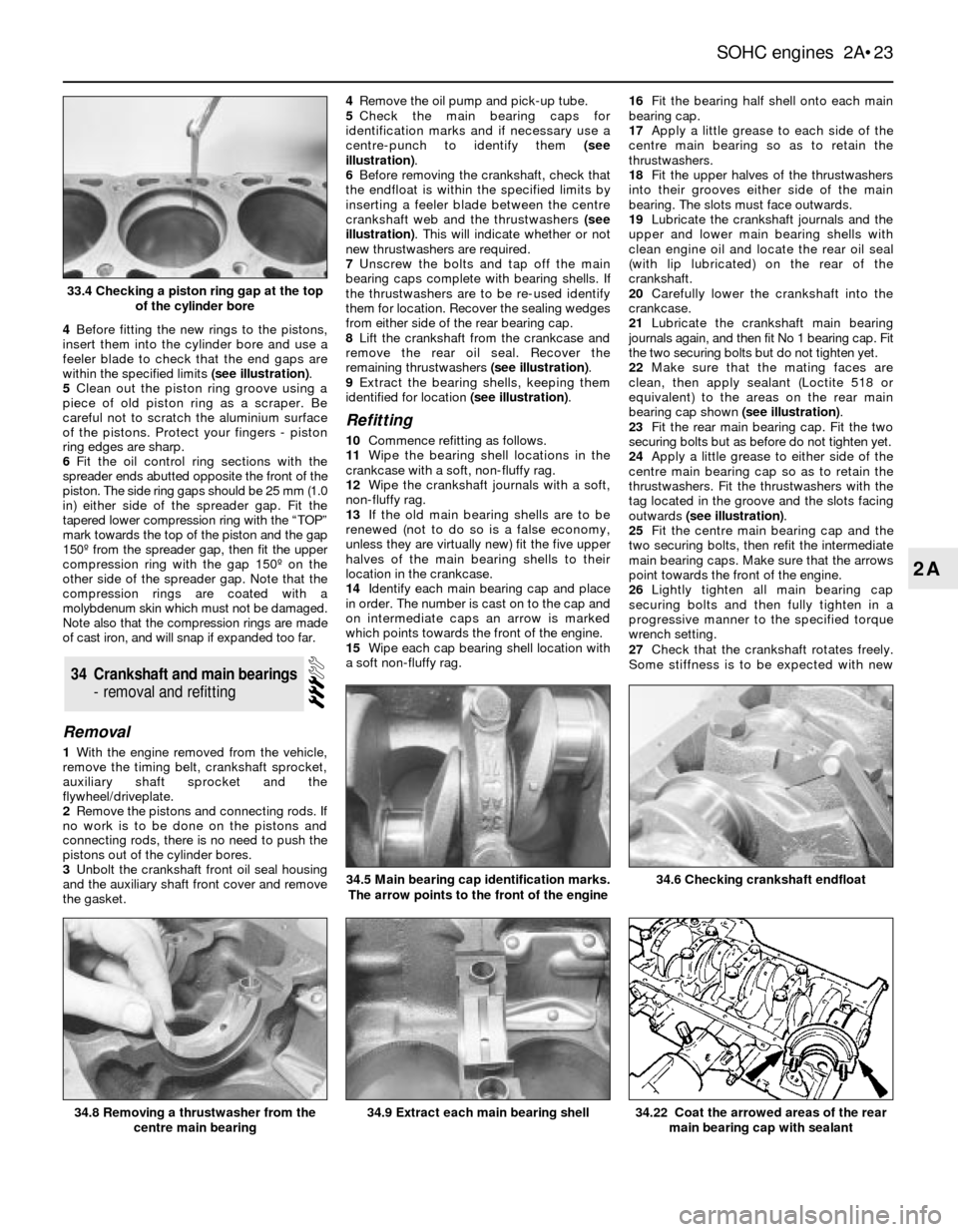

Removal

1With the engine removed from the vehicle,

remove the timing belt, crankshaft sprocket,

auxiliary shaft sprocket and the

flywheel/driveplate.

2Remove the pistons and connecting rods. If

no work is to be done on the pistons and

connecting rods, there is no need to push the

pistons out of the cylinder bores.

3Unbolt the crankshaft front oil seal housing

and the auxiliary shaft front cover and remove

the gasket.4Remove the oil pump and pick-up tube.

5Check the main bearing caps for

identification marks and if necessary use a

centre-punch to identify them (see

illustration).

6Before removing the crankshaft, check that

the endfloat is within the specified limits by

inserting a feeler blade between the centre

crankshaft web and the thrustwashers (see

illustration). This will indicate whether or not

new thrustwashers are required.

7Unscrew the bolts and tap off the main

bearing caps complete with bearing shells. If

the thrustwashers are to be re-used identify

them for location. Recover the sealing wedges

from either side of the rear bearing cap.

8Lift the crankshaft from the crankcase and

remove the rear oil seal. Recover the

remaining thrustwashers (see illustration).

9Extract the bearing shells, keeping them

identified for location (see illustration).

Refitting

10Commence refitting as follows.

11Wipe the bearing shell locations in the

crankcase with a soft, non-fluffy rag.

12Wipe the crankshaft journals with a soft,

non-fluffy rag.

13If the old main bearing shells are to be

renewed (not to do so is a false economy,

unless they are virtually new) fit the five upper

halves of the main bearing shells to their

location in the crankcase.

14Identify each main bearing cap and place

in order. The number is cast on to the cap and

on intermediate caps an arrow is marked

which points towards the front of the engine.

15Wipe each cap bearing shell location with

a soft non-fluffy rag. 16Fit the bearing half shell onto each main

bearing cap.

17Apply a little grease to each side of the

centre main bearing so as to retain the

thrustwashers.

18Fit the upper halves of the thrustwashers

into their grooves either side of the main

bearing. The slots must face outwards.

19Lubricate the crankshaft journals and the

upper and lower main bearing shells with

clean engine oil and locate the rear oil seal

(with lip lubricated) on the rear of the

crankshaft.

20Carefully lower the crankshaft into the

crankcase.

21Lubricate the crankshaft main bearing

journals again, and then fit No 1 bearing cap. Fit

the two securing bolts but do not tighten yet.

22Make sure that the mating faces are

clean, then apply sealant (Loctite 518 or

equivalent) to the areas on the rear main

bearing cap shown (see illustration).

23Fit the rear main bearing cap. Fit the two

securing bolts but as before do not tighten yet.

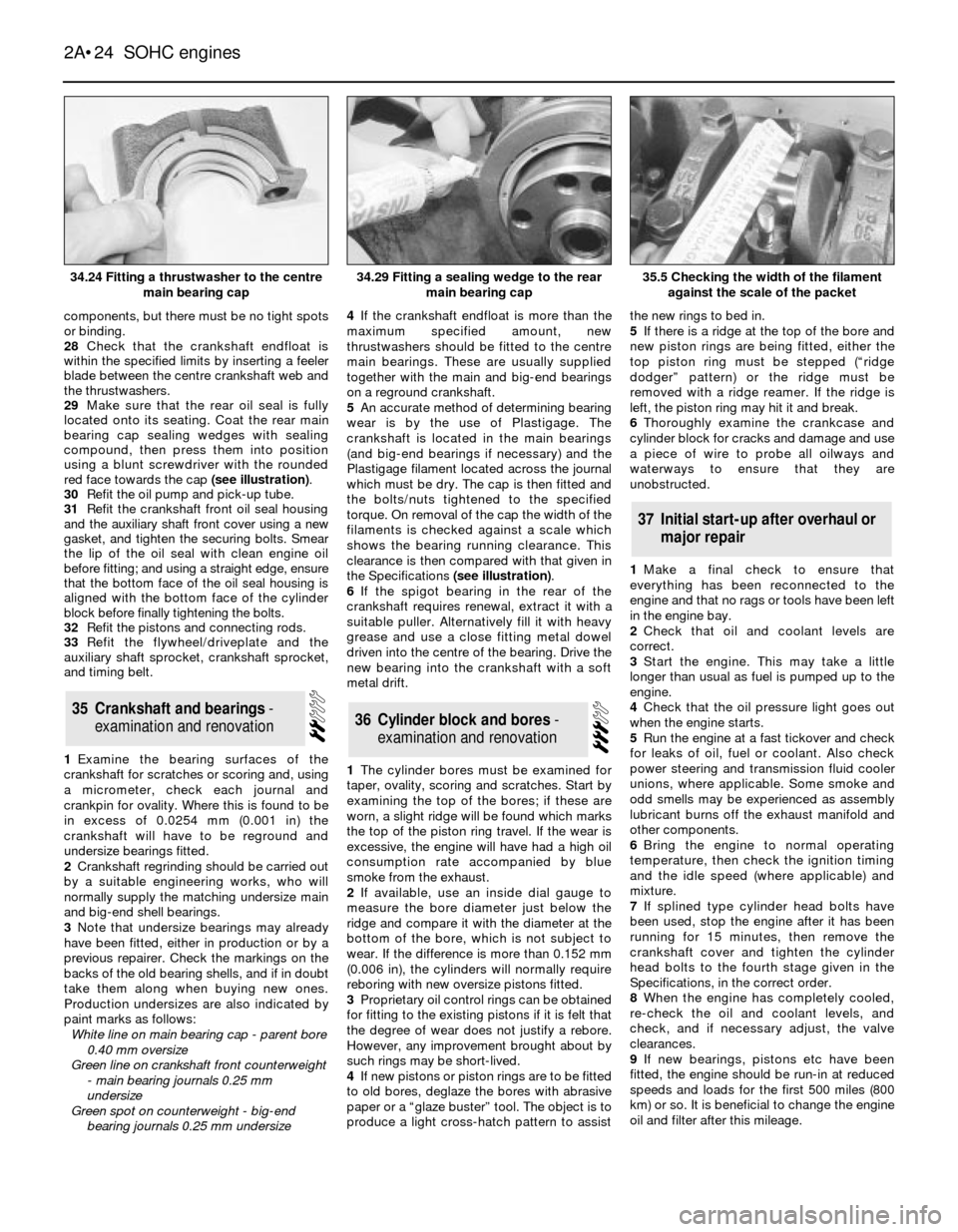

24Apply a little grease to either side of the

centre main bearing cap so as to retain the

thrustwashers. Fit the thrustwashers with the

tag located in the groove and the slots facing

outwards (see illustration).

25Fit the centre main bearing cap and the

two securing bolts, then refit the intermediate

main bearing caps. Make sure that the arrows

point towards the front of the engine.

26Lightly tighten all main bearing cap

securing bolts and then fully tighten in a

progressive manner to the specified torque

wrench setting.

27Check that the crankshaft rotates freely.

Some stiffness is to be expected with new

34Crankshaft and main bearings

- removal and refitting

SOHC engines 2A¥23

2A

34.6 Checking crankshaft endfloat

34.22 Coat the arrowed areas of the rear

main bearing cap with sealant34.9 Extract each main bearing shell34.8 Removing a thrustwasher from the

centre main bearing

34.5 Main bearing cap identification marks.

The arrow points to the front of the engine

33.4 Checking a piston ring gap at the top

of the cylinder bore

Page 24 of 24

components, but there must be no tight spots

or binding.

28Check that the crankshaft endfloat is

within the specified limits by inserting a feeler

blade between the centre crankshaft web and

the thrustwashers.

29Make sure that the rear oil seal is fully

located onto its seating. Coat the rear main

bearing cap sealing wedges with sealing

compound, then press them into position

using a blunt screwdriver with the rounded

red face towards the cap (see illustration).

30Refit the oil pump and pick-up tube.

31Refit the crankshaft front oil seal housing

and the auxiliary shaft front cover using a new

gasket, and tighten the securing bolts. Smear

the lip of the oil seal with clean engine oil

before fitting; and using a straight edge, ensure

that the bottom face of the oil seal housing is

aligned with the bottom face of the cylinder

block before finally tightening the bolts.

32Refit the pistons and connecting rods.

33Refit the flywheel/driveplate and the

auxiliary shaft sprocket, crankshaft sprocket,

and timing belt.

1Examine the bearing surfaces of the

crankshaft for scratches or scoring and, using

a micrometer, check each journal and

crankpin for ovality. Where this is found to be

in excess of 0.0254 mm (0.001 in) the

crankshaft will have to be reground and

undersize bearings fitted.

2Crankshaft regrinding should be carried out

by a suitable engineering works, who will

normally supply the matching undersize main

and big-end shell bearings.

3Note that undersize bearings may already

have been fitted, either in production or by a

previous repairer. Check the markings on the

backs of the old bearing shells, and if in doubt

take them along when buying new ones.

Production undersizes are also indicated by

paint marks as follows:

White line on main bearing cap - parent bore

0.40 mm oversize

Green line on crankshaft front counterweight

- main bearing journals 0.25 mm

undersize

Green spot on counterweight - big-end

bearing journals 0.25 mm undersize4If the crankshaft endfloat is more than the

maximum specified amount, new

thrustwashers should be fitted to the centre

main bearings. These are usually supplied

together with the main and big-end bearings

on a reground crankshaft.

5An accurate method of determining bearing

wear is by the use of Plastigage. The

crankshaft is located in the main bearings

(and big-end bearings if necessary) and the

Plastigage filament located across the journal

which must be dry. The cap is then fitted and

the bolts/nuts tightened to the specified

torque. On removal of the cap the width of the

filaments is checked against a scale which

shows the bearing running clearance. This

clearance is then compared with that given in

the Specifications (see illustration).

6If the spigot bearing in the rear of the

crankshaft requires renewal, extract it with a

suitable puller. Alternatively fill it with heavy

grease and use a close fitting metal dowel

driven into the centre of the bearing. Drive the

new bearing into the crankshaft with a soft

metal drift.

1The cylinder bores must be examined for

taper, ovality, scoring and scratches. Start by

examining the top of the bores; if these are

worn, a slight ridge will be found which marks

the top of the piston ring travel. If the wear is

excessive, the engine will have had a high oil

consumption rate accompanied by blue

smoke from the exhaust.

2If available, use an inside dial gauge to

measure the bore diameter just below the

ridge and compare it with the diameter at the

bottom of the bore, which is not subject to

wear. If the difference is more than 0.152 mm

(0.006 in), the cylinders will normally require

reboring with new oversize pistons fitted.

3Proprietary oil control rings can be obtained

for fitting to the existing pistons if it is felt that

the degree of wear does not justify a rebore.

However, any improvement brought about by

such rings may be short-lived.

4If new pistons or piston rings are to be fitted

to old bores, deglaze the bores with abrasive

paper or a Òglaze busterÓ tool. The object is to

produce a light cross-hatch pattern to assistthe new rings to bed in.

5If there is a ridge at the top of the bore and

new piston rings are being fitted, either the

top piston ring must be stepped (Òridge

dodgerÓ pattern) or the ridge must be

removed with a ridge reamer. If the ridge is

left, the piston ring may hit it and break.

6Thoroughly examine the crankcase and

cylinder block for cracks and damage and use

a piece of wire to probe all oilways and

waterways to ensurethatthey are

unobstructed.

1Make a final check to ensure that

everything has been reconnected to the

engine and that no rags or tools have been left

in the engine bay.

2Check that oil and coolant levels are

correct.

3Start the engine. This may take a little

longer than usual as fuel is pumped up to the

engine.

4Check that the oil pressure light goes out

when the engine starts.

5Run the engine at a fast tickover and check

for leaks of oil, fuel or coolant. Also check

power steering and transmission fluid cooler

unions, where applicable. Some smoke and

odd smells may be experienced as assembly

lubricant burns off the exhaust manifold and

other components.

6Bring the engine to normal operating

temperature, then check the ignition timing

and the idle speed (where applicable) and

mixture.

7If splined type cylinder head bolts have

been used, stop the engine after it has been

running for 15 minutes, then remove the

crankshaft cover and tighten the cylinder

head bolts to the fourth stage given in the

Specifications, in the correct order.

8When the engine has completely cooled,

re-check the oil and coolant levels, and

check, and if necessary adjust, the valve

clearances.

9If new bearings, pistons etc have been

fitted, the engine should be run-in at reduced

speeds and loads for the first 500 miles (800

km) or so. It is beneficial to change the engine

oil and filter after this mileage.

37Initial start-up after overhaul or

major repair

36Cylinder block and bores -

examination and renovation35Crankshaft and bearings -

examination and renovation

2A¥24SOHC engines

34.24 Fitting a thrustwasher to the centre

main bearing cap35.5 Checking the width of the filament

against the scale of the packet34.29 Fitting a sealing wedge to the rear

main bearing cap