FORD SUPER DUTY 2008 2.G Special Off-Road Package Supplement Manual

Manufacturer: FORD, Model Year: 2008, Model line: SUPER DUTY, Model: FORD SUPER DUTY 2008 2.GPages: 25, PDF Size: 0.2 MB

Page 21 of 25

Inspection and lubrication

When servicing any driveline components on a vehicle equipped

with a locking rear differential, ensure that the engine is off and

all wheels are off the ground to prevent the vehicle from moving. Axles

equipped with a locking rear differential deliver power to both wheels,

even when only one wheel is on the ground. Failure to observe these

cautionary measures may cause the vehicle to move which can result

in property damage, personal injury, even death.

This differential is designed to operate in the lubricant recommended by

the vehicle/axle manufacturer; no special lubricant is needed. Refer to

theMaintenance Product Specifications and Capacitiesin your

Owner’s Guidefor the proper axle lubricant. For very cold weather

applications, use the lightest oil the axle manufacturer will allow to

overcome possible sluggish re-engagement of the driven clutch

assemblies.

No adjustments or alterations should be made to the differential. Refer to

the vehicle/axle manufacturer’s instructions for adjustments to other

components in the axle.

SAND INGESTION

When driving through sand, traction or brake capability may be limited.

Also, sand may enter your engine’s air intake and severely damage your

engine or your vehicle may stall. Driving through sand where the

transmission vent tube or external breather kit is submerged may allow

sand into the transmission and cause internal transmission damage.

2008 F-250/350/450/550(f23)

Supplement

USA(fus)

Driving

21

Page 22 of 25

WHEELS

Your vehicle may be equipped with two-piece bolt-together beadlock

rims. Beadlock rims allow the tires to survive operating at lower air

pressure which provide greater traction due to the larger tire-to-ground

contact area during slow, off-road operation. Always reinflate the tires to

the tire manufacturer’s recommendations when no longer in slow,

off-road driving conditions. The beadlock also acts as a safety device

ensuring that the tire does not unseat from the rim or rotate on the

wheel when tire pressure is reduced, while also preventing the entry of

foreign objects, debris or water into the tire’s air chamber.

Note:The wheel/tire assemblies should be serviced only by trained

personnel who have read and understand the wheel

assembly/disassembly information contained within theWorkshop

Manual.

TIRES

Your vehicle’s tires may be equipped with a Variable Function Insert

(VFI) which is mounted into each tire. The VFI inserts and tires are then

fitted around the beadlock rim assembly, providing a higher level of tire

protection due to the dense rubber material in the tire assembly and

maximum all-terrain mobility.

SNOW CHAINS

Tire chains cannot be used on vehicles equipped with M/TR tires.

ON-BOARD AIR SYSTEM

Your vehicle is equipped with an on-board air system which has been

designed to provide compressed air for multiple uses, including the

addition of air to the vehicle’s tires. The system uses a 25 ft. (7.6m)

length of air hose equipped with a clamp-on style air chuck. When not in

use, this hose is secured to the floor of the truck. A compressor,

mounted to the frame under the truck on the passenger side frame rail,

is included along with an air reservoir on the driver side. When the

compressor is on, the output pressure at the air tank is limited to 80 psi

(552 kPa).

2008 F-250/350/450/550(f23)

Supplement

USA(fus)

Tires, Wheels and Loading

22

Page 23 of 25

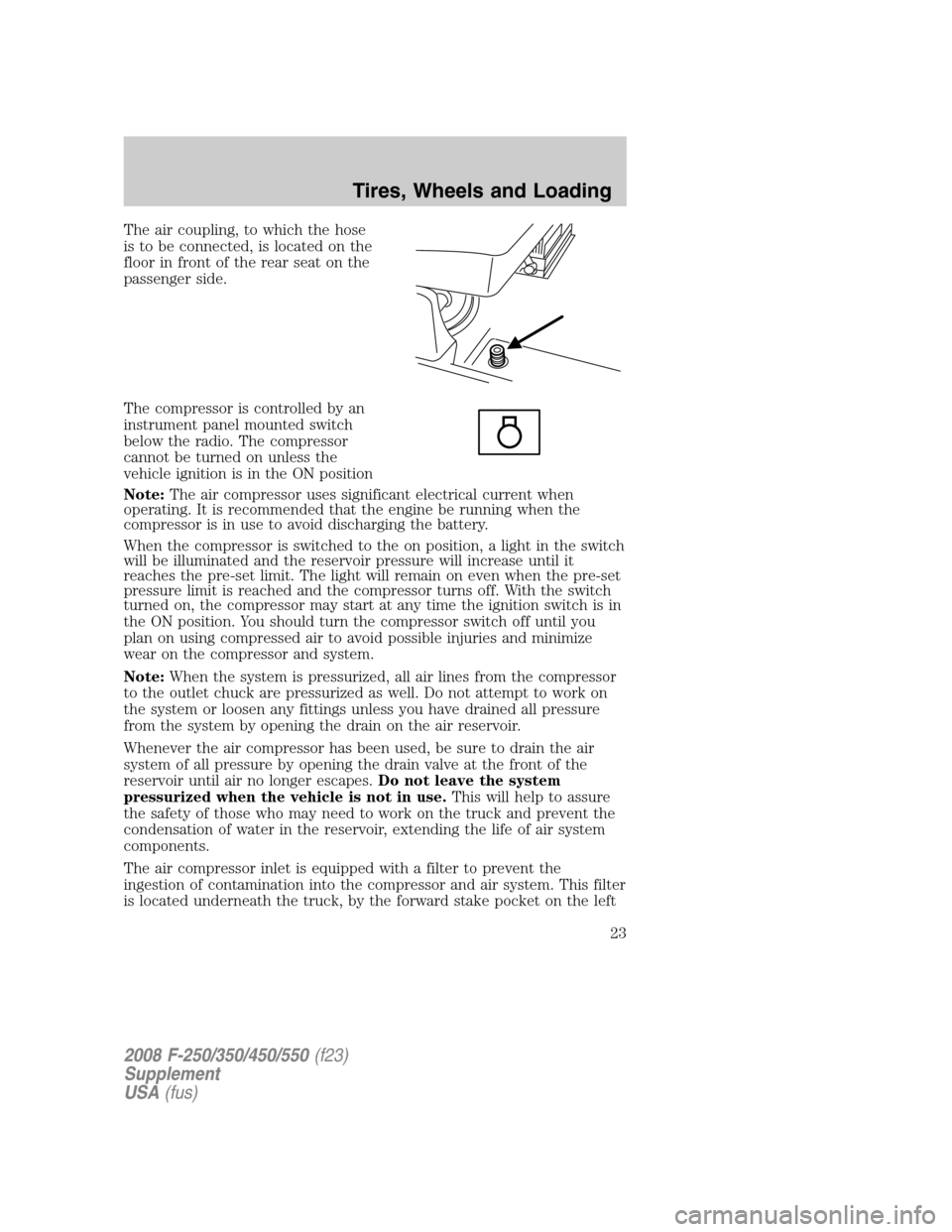

The air coupling, to which the hose

is to be connected, is located on the

floor in front of the rear seat on the

passenger side.

The compressor is controlled by an

instrument panel mounted switch

below the radio. The compressor

cannot be turned on unless the

vehicle ignition is in the ON position

Note:The air compressor uses significant electrical current when

operating. It is recommended that the engine be running when the

compressor is in use to avoid discharging the battery.

When the compressor is switched to the on position, a light in the switch

will be illuminated and the reservoir pressure will increase until it

reaches the pre-set limit. The light will remain on even when the pre-set

pressure limit is reached and the compressor turns off. With the switch

turned on, the compressor may start at any time the ignition switch is in

the ON position. You should turn the compressor switch off until you

plan on using compressed air to avoid possible injuries and minimize

wear on the compressor and system.

Note:When the system is pressurized, all air lines from the compressor

to the outlet chuck are pressurized as well. Do not attempt to work on

the system or loosen any fittings unless you have drained all pressure

from the system by opening the drain on the air reservoir.

Whenever the air compressor has been used, be sure to drain the air

system of all pressure by opening the drain valve at the front of the

reservoir until air no longer escapes.Do not leave the system

pressurized when the vehicle is not in use.This will help to assure

the safety of those who may need to work on the truck and prevent the

condensation of water in the reservoir, extending the life of air system

components.

The air compressor inlet is equipped with a filter to prevent the

ingestion of contamination into the compressor and air system. This filter

is located underneath the truck, by the forward stake pocket on the left

2008 F-250/350/450/550(f23)

Supplement

USA(fus)

Tires, Wheels and Loading

23

Page 24 of 25

side of the bed. If operating the air system in dusty areas, periodically

inspect this filter and replace it if found to be clogged or damaged, or if

the time needed to pressurize the system starts to become extended.

Using the air system to fill tires

To fill your tires, first be sure to stop the truck in a safe place. You

should be far enough off the road that passing traffic will not be a danger

to you. You should have an accurate tire pressure gauge to measure the

pressure in the tires and inflate them to the settings on the tire pressure

placard, which is usually inside the door on the truck.

Remove the air hose from under the clamp on the floor of the truck.

Attach the connector end of the hose to the coupling in the trim panel

behind the driver’s seat by using one hand to slide the coupling collar

toward the trim panel and the other to insert the fitting on the end of

the hose into the coupling. When the fitting is seated in the coupling,

slide the collar back to its original position.

Extend the hose to reach the tire needing air. Remove the cap from the

tire valve stem and attach the clamp-on air chuck by squeezing the

locking mechanism while placing the chuck over the valve stem. Release

the locking mechanism when the air chuck is seated on the stem. Air will

flow from the system to the tire until you remove the chuck. Be sure to

use your gauge to set the pressure according to the placard. When the

tire pressure is correct, disconnect the hose and re-stow it under the

clamp on the floor behind the passenger seat. Do not forget to re-install

the cap on the valve stem.

TIRE PRESSURE MONITORING SYSTEM (TPMS) (IF EQUIPPED)

If your vehicle is equipped with a Tire Pressure Monitoring System

(TPMS), refer to yourOwner’s Guidefor complete details on system

operation.

2008 F-250/350/450/550(f23)

Supplement

USA(fus)

Tires, Wheels and Loading

24

Page 25 of 25

CHANGING A FLAT TIRE

Refer to yourOwner’s Guidefor the tire changing procedure. Follow the

F-350 Dual Rear Wheel (DRW) jacking instructions.

FUSING

Note:Fuse 29 in the instrument panel box, located below and to the left

of the steering wheel, should be a 15A mini fuse. Always replace the fuse

you removed with a fuse with the same amperage rating.

2008 F-250/350/450/550(f23)

Supplement

USA(fus)

Roadside emergencies

25