FORD SUPER DUTY 2015 3.G Diesel Supplement Manual

Manufacturer: FORD, Model Year: 2015, Model line: SUPER DUTY, Model: FORD SUPER DUTY 2015 3.GPages: 84, PDF Size: 13.36 MB

Page 51 of 84

10.

Engine cooling system: Repeat

Step 5 until the coolant level has

stabilized (is no longer dropping after

each step) AND the upper radiator

hose at the radiator is warm to the

touch (indicating that the engine

thermostat is open and coolant is

flowing through the radiator).

Secondary cooling system: Repeat

Step 5 until the coolant level has

stabilized (is no longer dropping after

each step) AND the lower passenger

side of the secondary radiator is

warm to the touch (indicating

secondary thermostat is open and

coolant is flowing through the entire

system).

11. Reinstall the pressure relief cap. Shut

the engine off and let it cool.

12. Check the coolant level in the reservoir before you drive your vehicle

the next few times (with the engine

cool).

13. If necessary, add prediluted engine coolant to the coolant reservoir until

the coolant level is within the COLD

FILL RANGE as listed on the reservoir.

After any coolant has been added,

check the coolant concentration. See

Adding Engine Coolant

earlier in

the chapter for more information.

Whenever coolant has been added, the

coolant level in the reservoir should be

checked the next few times you drive the

vehicle. If needed, add prediluted engine

coolant to bring the coolant level to the

proper level on the reservoir.

Recycled Engine Coolant

Ford Motor Company does not recommend

the use of recycled engine coolant since a

Ford-approved recycling process is not yet

available. Used engine coolant should be disposed

of in an appropriate manner. Follow your

community

’s regulations and standards

for recycling and disposing of automotive

fluids.

Severe Climates

If you drive in extremely cold climates:

• It may be necessary to have a Ford

authorized dealer increase the coolant

concentration above 50%.

• A coolant concentration of 60% will

provide improved freeze point

protection. Engine coolant

concentrations above 60% will

decrease the overheat protection

characteristics of the engine coolant

and may cause engine damage.

If you drive in extremely hot climates:

• It may be necessary to have a Ford

authorized dealer decrease the coolant

concentration to 40%.

• A coolant concentration of 40% will

provide improved overheat protection.

Engine coolant concentrations below

40% will decrease the corrosion/freeze

protection characteristics of the engine

coolant and may cause engine

damage.

Vehicles driven year-round in non-extreme

climates should use prediluted engine

coolant for optimum cooling system and

engine protection.

Checking Coolant Corrosion

Inhibitor Additive Strength

At specific mileage intervals of 15000

miles (24000 km), as listed in the

scheduled maintenance information

chapter, the coolant corrosion inhibitor

additive should be checked. The optional

information display, if equipped, will also

display the message CHECK COOLANT

ADDITIVE at this time. The purpose of

checking is to verify the correct engine

48

Super Duty (TFA) , enUSA Maintenance

Page 52 of 84

coolant concentration (freeze point

protection) and corrosion inhibitor additive

level (strength) of the coolant for

maximum engine performance and

protection. Three products are available

to confirm the life and health of the

coolant: one tool, a test kit and a coolant

inhibitor additive:

•

Rotunda tool 300–ROB75240

available from your dealer –

recommended refractometer to test

coolant concentration.

• Rotunda 328-R071–ELC (Antifreeze

Coolant ELC Contamination Kit) –

Evaluates the corrosion inhibitor

additive strength. Note the first step is

to verify the vehicle ’s coolant

concentration is in the correct range of

40 – 60%. Coolant concentrations

outside this range will not provide valid

test results. If the report results in a

pass (i.e., the cooling system does not

show excessive contamination/the

corrosion inhibitor additive strength is

sufficient), no action is required. If the

report results as insufficient (does not

pass), the corrosion inhibitor additive

strength of the coolant is too low. If the

ENGINE COOLING SYSTEM corrosion

inhibitor additive strength is low, add

48 fluid oz. of Motorcraft Specialty

Orange Engine Coolant Revitalizer. If

the SECONDARY COOLING SYSTEM

corrosion inhibitor additive strength is

low, add 16 fluid oz. of Motorcraft

Specialty Orange Engine Coolant

Revitalizer.

• Motorcraft Specialty Orange Engine

Coolant Revitalizer

– Additive to

boost the corrosion inhibitor level

based upon the test results of the

Antifreeze Coolant ELC Contamination

Kit. The Revitalizer may be added two

times over the life of the coolant. If

additional dosages are required, the

cooling system must be flushed and

refilled per the instructions in the

Workshop Manual.

See

Capacities and Specifications

(page 55). for the proper coolant and

additive specifications.

49

Super Duty (TFA) , enUSA Maintenance

Page 53 of 84

Coolant Change

At specific mileage intervals, as listed in

the scheduled maintenance information,

the coolant should be changed. The

optional information display, if equipped,

will also display the message COOLANT

CHANGE REQUIRED at this time.

See Capacities and Specifications

(page 55). for the proper coolant.

Engine-driven Cooling Fan (Fan

Clutch)

Your vehicle is equipped with an engine

driven cooling fan drive (also called a fan

clutch). This fan drive changes the fan

speed to match the vehicle ’s changing

cooling air flow requirements. Fan speed,

fan noise level and fuel consumption all

will increase based on the driving

conditions that include trailer towing, hill

climbing, heavy loads, high speed and high

ambient temperature, individually or in

combination.

The fan drive is designed to provide the

minimum fan speed (and resulting

minimum fan noise and fuel consumption)

required to meet the ever changing vehicle

cooling air flow requirements. You will hear

the amount of fan noise increasing and

decreasing as the engine power

requirements and vehicle driving conditions

change as you drive. This is to be expected

as being normal to the operation of your

vehicle. High levels of fan noise might also

be heard when your engine is first started,

and should normally decrease after driving

for a short time. CHANGING THE ENGINE AIR

FILTER

Air Filter Restriction Gauge WARNING

To reduce the risk of vehicle damage

and/or personal burn injuries do not

start your engine with the air filter

removed and do not remove it while the

engine is running. Note:

Operating your vehicle in heavy

snowfall or extreme rain conditions may

allow excessive amounts of snow or water

into the air intake system. This could plug

or soak the air filter that could cause the

engine to lose power or shut down. The restriction gauge, located on the upper

housing of the air filter assembly, measures

the vacuum inside the air filter. The more

the air filter is restricted (dirty, clogged),

the higher the vacuum reading.

Check the air filter restriction gauge

whenever you open the hood to perform

general engine maintenance or at least

every 7,500 miles (12,000 km). If you

operate your vehicle in extremely dusty

conditions, check and reset the gauge at

least every 500 miles (800 km), or two

weeks, whichever comes first. Change the

50

Super Duty (TFA) , enUSA MaintenanceE163372

Page 54 of 84

air filter when the restriction gauge reads

near the change filter line and the gauge

is yellow. If you allow the restriction gauge

to reach maximum restriction you can

affect your engine performance and fuel

economy.

Note:

Do not blow out the air filter element

with compressed air since the compressed

air could damage the filter paper.

Note: Do not rely on filter appearance

alone. A filter which appears to be dirty may

actually have several thousand miles

(kilometers) of life remaining. After installation of the new filter element,

reset the gauge by pressing the reset

button on top of the gauge.

The following actions are recommend after

operating the vehicle up to 200 miles (320

km) in heavy snowfall or extreme rain:

•

Snow: At the earliest opportunity, open

the hood and clear all the snow and ice

from the air filter housing inlet (do NOT

remove the foam filter) and reset the

air filter restriction gauge.

• Extreme rain: The air filter will dry after

about 15– 30 minutes at highway

speeds. At the earliest opportunity,

open the hood and reset the air filter

restriction gauge.

Air Filter Replacement

When replacing the air filter element, use

a Motorcraft® air filter element. See

Motorcraft Parts (page 55).

Note: Failure to use the correct air filter

element may result in severe engine

damage.

51

Super Duty (TFA) , enUSA MaintenanceE163373

Page 55 of 84

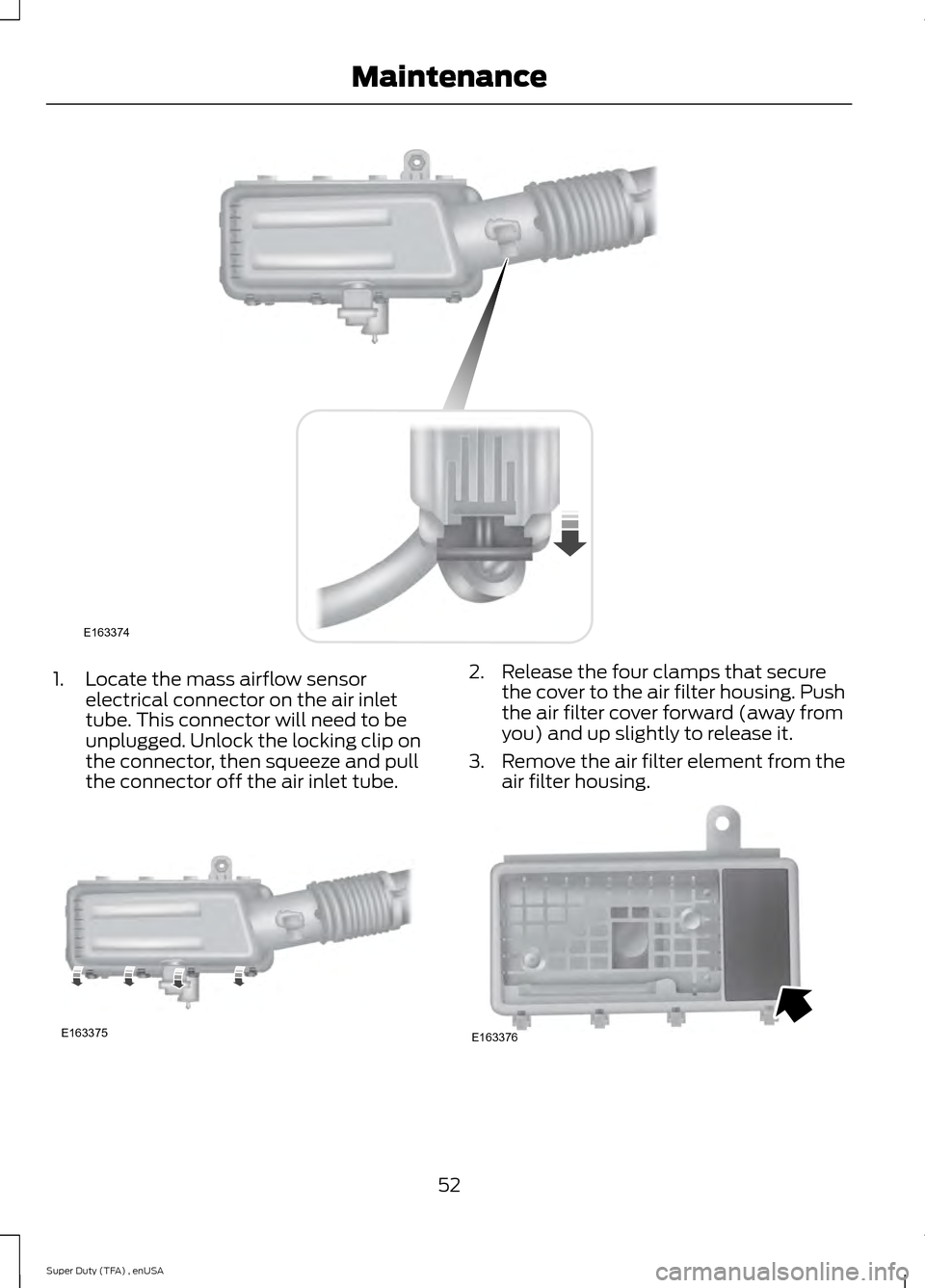

1. Locate the mass airflow sensor

electrical connector on the air inlet

tube. This connector will need to be

unplugged. Unlock the locking clip on

the connector, then squeeze and pull

the connector off the air inlet tube. 2. Release the four clamps that secure

the cover to the air filter housing. Push

the air filter cover forward (away from

you) and up slightly to release it.

3. Remove the air filter element from the

air filter housing. 52

Super Duty (TFA) , enUSA MaintenanceE163374 E163375 E163376

Page 56 of 84

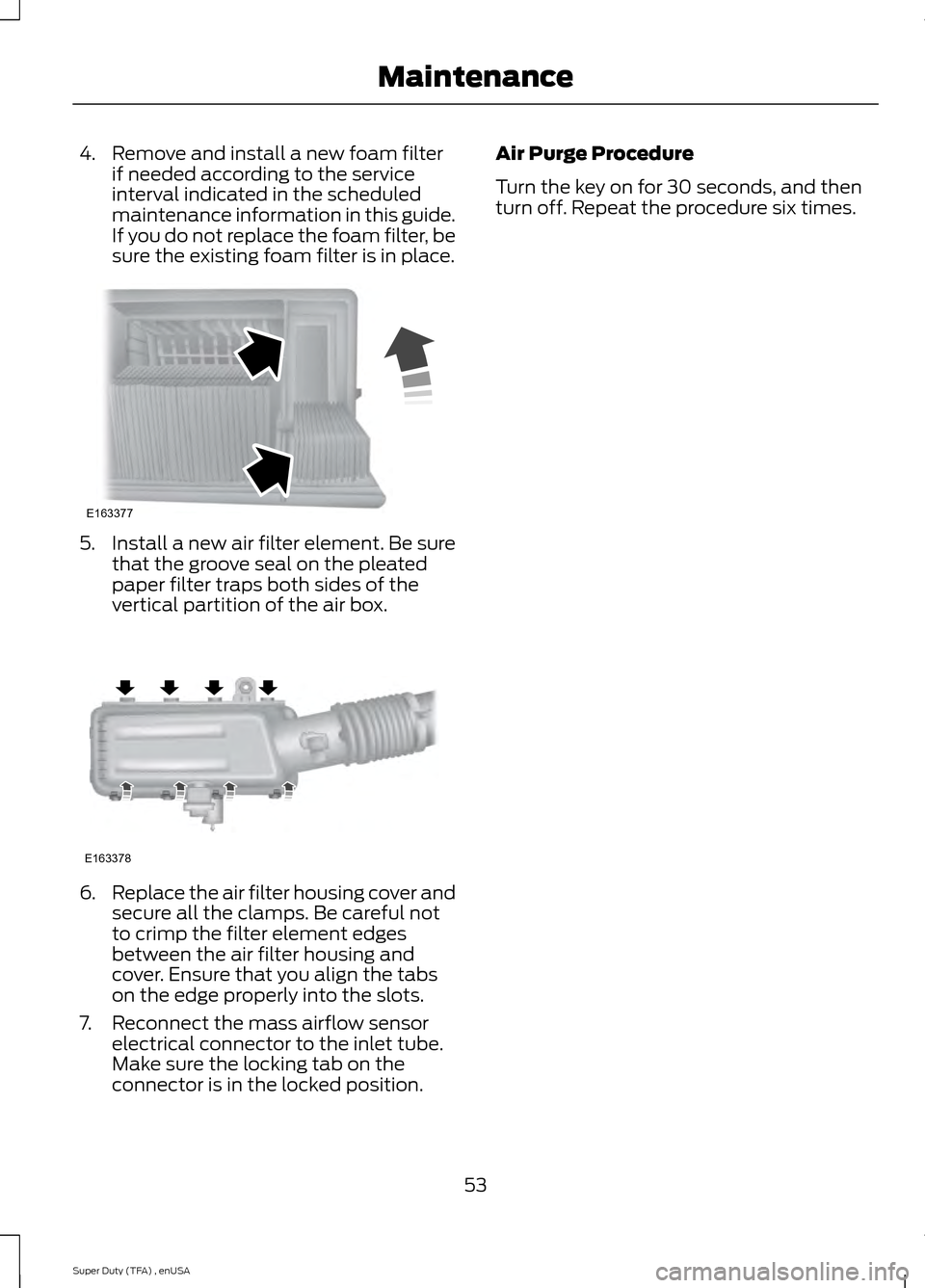

4. Remove and install a new foam filter

if needed according to the service

interval indicated in the scheduled

maintenance information in this guide.

If you do not replace the foam filter, be

sure the existing foam filter is in place. 5. Install a new air filter element. Be sure

that the groove seal on the pleated

paper filter traps both sides of the

vertical partition of the air box. 6.

Replace the air filter housing cover and

secure all the clamps. Be careful not

to crimp the filter element edges

between the air filter housing and

cover. Ensure that you align the tabs

on the edge properly into the slots.

7. Reconnect the mass airflow sensor electrical connector to the inlet tube.

Make sure the locking tab on the

connector is in the locked position. Air Purge Procedure

Turn the key on for 30 seconds, and then

turn off. Repeat the procedure six times.

53

Super Duty (TFA) , enUSA MaintenanceE163377 E163378

Page 57 of 84

CLEANING THE ENGINE

Engines are more efficient when they are

clean because grease and dirt buildup keep

the engine warmer than normal.

When washing:

•

Take care when using a power washer

to clean the engine. The high-pressure

fluid could penetrate the sealed parts

and cause damage.

• Do not spray a hot engine with cold

water to avoid cracking the engine

block or other engine components.

• Spray Motorcraft Engine Shampoo and

Degreaser on all parts that require

cleaning and pressure rinse clean. In

Canada, use Motorcraft Engine

Shampoo.

• Never wash or rinse the engine while it

is hot or running; water in the running

engine may cause internal damage.

• Never wash or rinse any ignition coil,

spark plug wire or spark plug well, or

the area in and around these locations.

• Cover the battery, power distribution

box, and air filter assembly to prevent

water damage when cleaning the

engine.

CLEANING THE EXHAUST WARNINGS

Failure to maintain the functional

holes, in the tailpipe section of the

exhaust, clean and free of debris or

foreign material may result in the holes

becoming blocked or plugged. Do not

modify or remove the tail-pipe section.

Blocked or plugged holes or

removal/modification of the system could

result in elevated exhaust gas

temperatures which may result in

vehicle/property damage or personal

injury. WARNINGS

The normal operating temperature

of the exhaust system is very high.

Never work around or attempt to

repair any part of the exhaust system until

it has cooled. Use special care when

working around the diesel oxidation

catalytic converter and/or the diesel

particulate filter (DPF). The diesel

oxidation catalytic converter and/or the

DPF heats up to a high temperature after

only a short period of engine operation and

can stay hot even after the engine is turned

off. Failure to follow these instructions may

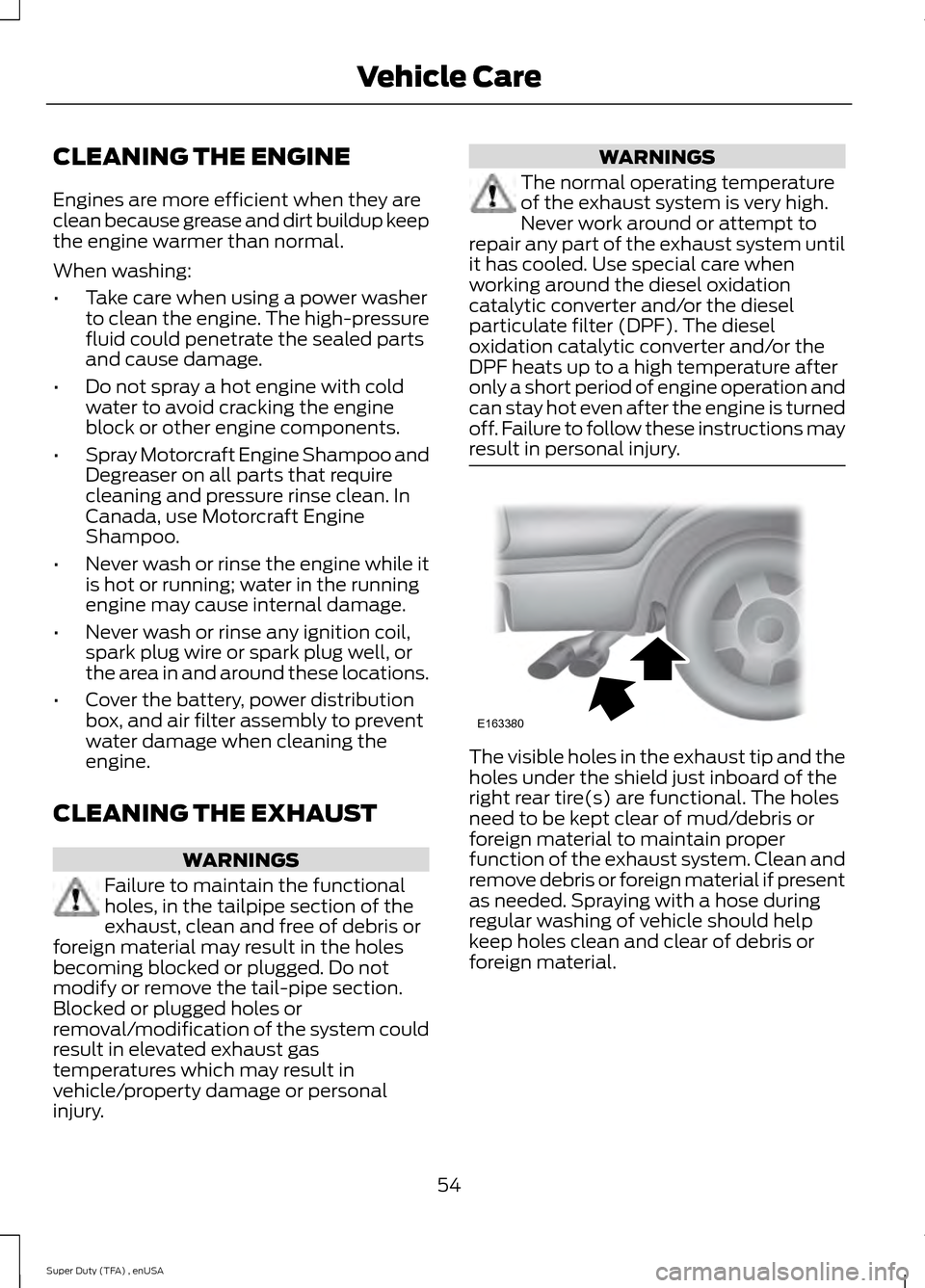

result in personal injury. The visible holes in the exhaust tip and the

holes under the shield just inboard of the

right rear tire(s) are functional. The holes

need to be kept clear of mud/debris or

foreign material to maintain proper

function of the exhaust system. Clean and

remove debris or foreign material if present

as needed. Spraying with a hose during

regular washing of vehicle should help

keep holes clean and clear of debris or

foreign material.

54

Super Duty (TFA) , enUSA Vehicle CareE163380

Page 58 of 84

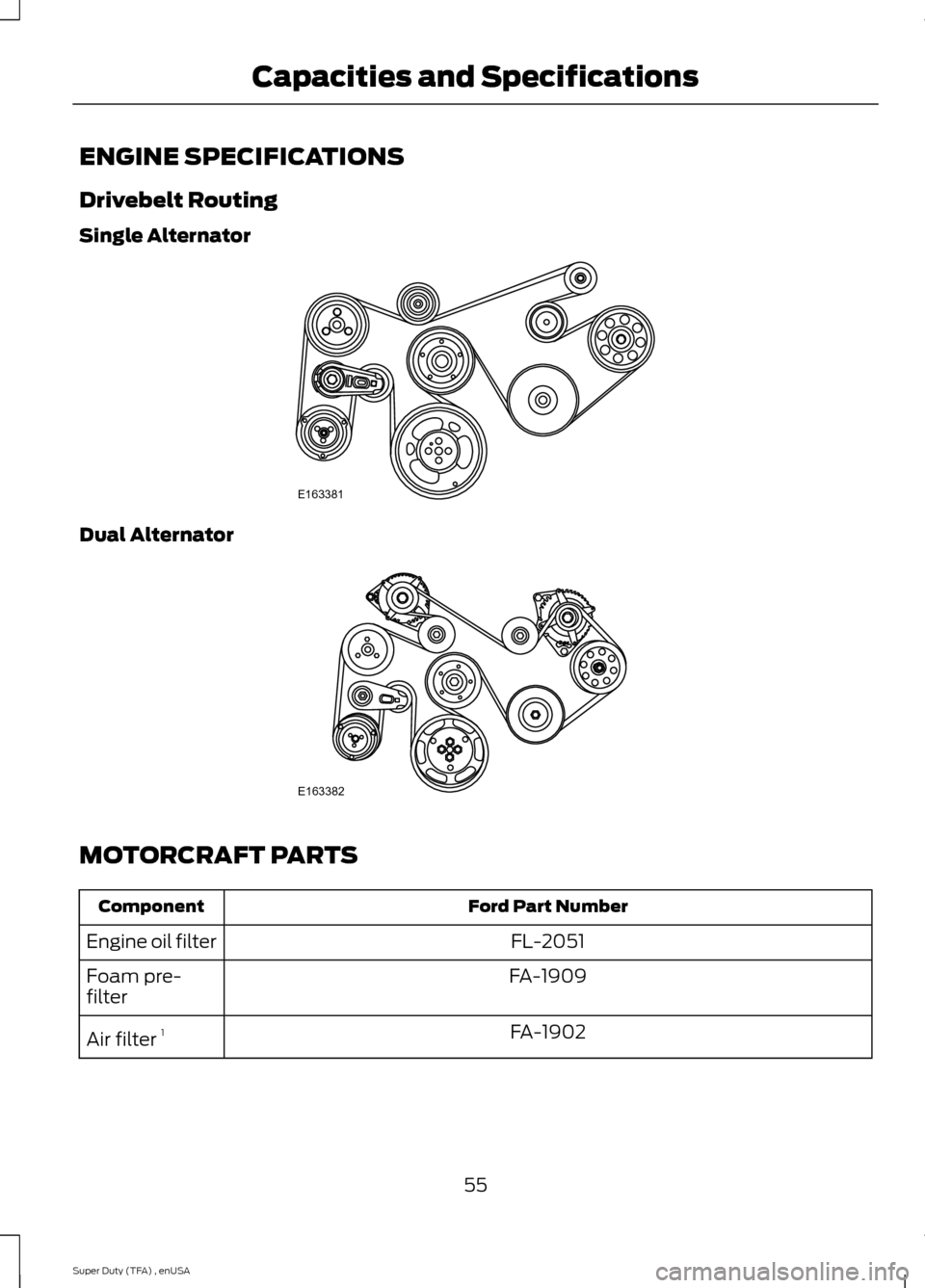

ENGINE SPECIFICATIONS

Drivebelt Routing

Single Alternator

Dual Alternator

MOTORCRAFT PARTS

Ford Part Number

Component

FL-2051

Engine oil filter

FA-1909

Foam pre-

filter

FA-1902

Air filter 1

55

Super Duty (TFA) , enUSA Capacities and SpecificationsE163381 E163382

Page 59 of 84

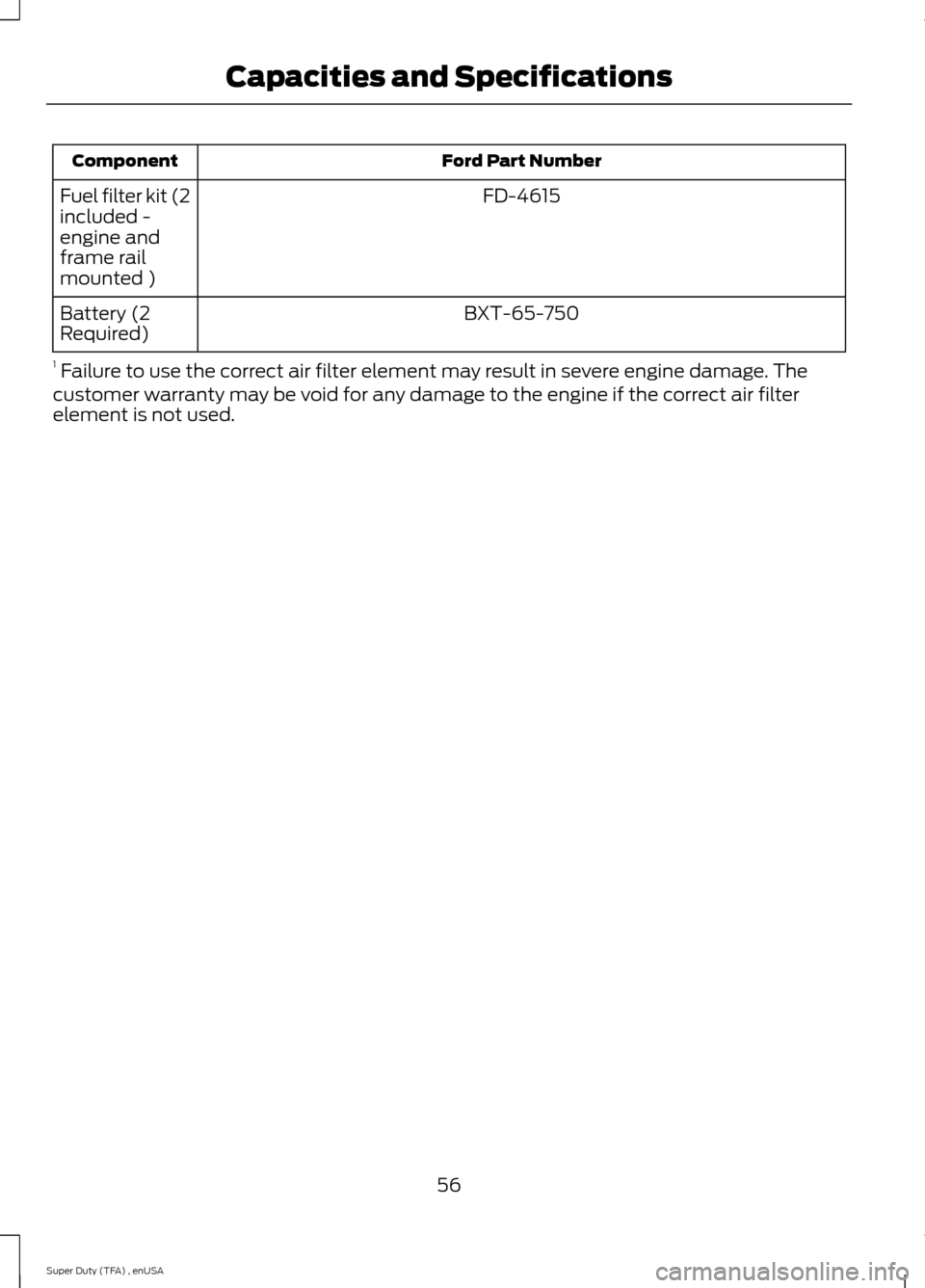

Ford Part Number

Component

FD-4615

Fuel filter kit (2

included -

engine and

frame rail

mounted )

BXT-65-750

Battery (2

Required)

1 Failure to use the correct air filter element may result in severe engine damage. The

customer warranty may be void for any damage to the engine if the correct air filter

element is not used.

56

Super Duty (TFA) , enUSA Capacities and Specifications

Page 60 of 84

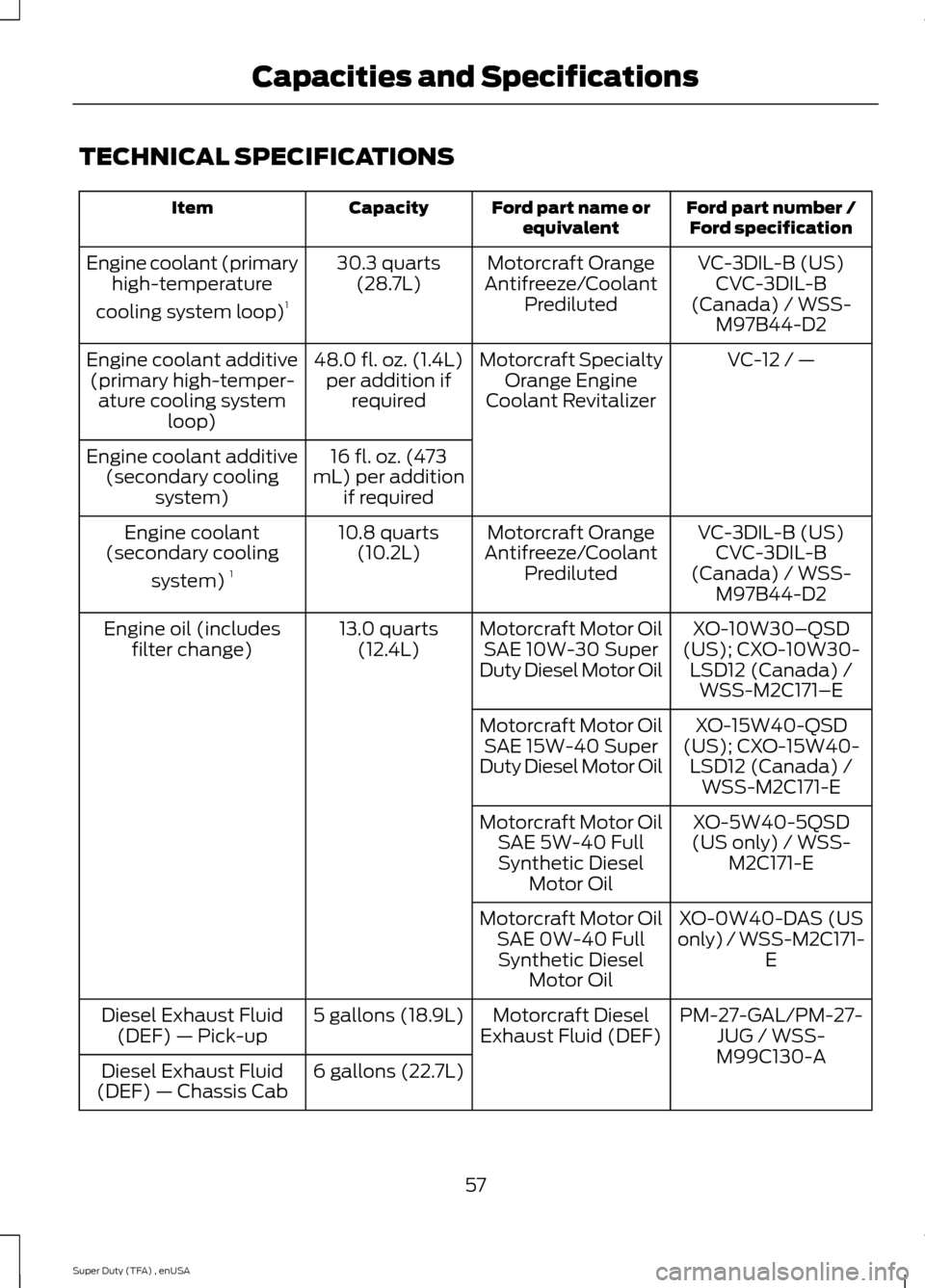

TECHNICAL SPECIFICATIONS

Ford part number /

Ford specification

Ford part name or

equivalent

Capacity

Item

VC-3DIL-B (US)CVC-3DIL-B

(Canada) / WSS- M97B44-D2

Motorcraft Orange

Antifreeze/Coolant Prediluted

30.3 quarts

(28.7L)

Engine coolant (primary

high-temperature

cooling system loop) 1

VC-12 / —

Motorcraft Specialty

Orange Engine

Coolant Revitalizer

48.0 fl. oz. (1.4L)

per addition if required

Engine coolant additive

(primary high-temper- ature cooling system loop)

16 fl. oz. (473

mL) per addition if required

Engine coolant additive

(secondary cooling system)

VC-3DIL-B (US)CVC-3DIL-B

(Canada) / WSS- M97B44-D2

Motorcraft Orange

Antifreeze/Coolant Prediluted

10.8 quarts

(10.2L)

Engine coolant

(secondary cooling

system) 1

XO-10W30–QSD

(US); CXO-10W30- LSD12 (Canada) / WSS-M2C171–E

Motorcraft Motor Oil

SAE 10W-30 Super

Duty Diesel Motor Oil

13.0 quarts

(12.4L)

Engine oil (includes

filter change)

XO-15W40-QSD

(US); CXO-15W40- LSD12 (Canada) / WSS-M2C171-E

Motorcraft Motor Oil

SAE 15W-40 Super

Duty Diesel Motor Oil

XO-5W40-5QSD

(US only) / WSS- M2C171-E

Motorcraft Motor Oil

SAE 5W-40 FullSynthetic Diesel Motor Oil

XO-0W40-DAS (US

only) / WSS-M2C171- E

Motorcraft Motor Oil

SAE 0W-40 FullSynthetic Diesel Motor Oil

PM-27-GAL/PM-27-JUG / WSS-

M99C130-A

Motorcraft Diesel

Exhaust Fluid (DEF)

5 gallons (18.9L)

Diesel Exhaust Fluid

(DEF) — Pick-up

6 gallons (22.7L)

Diesel Exhaust Fluid

(DEF) — Chassis Cab

57

Super Duty (TFA) , enUSA Capacities and Specifications