horn FORD SUPER DUTY 2023 User Guide

[x] Cancel search | Manufacturer: FORD, Model Year: 2023, Model line: SUPER DUTY, Model: FORD SUPER DUTY 2023Pages: 738, PDF Size: 18.49 MB

Page 418 of 738

Maximum WadingCapabilityModel

22 in (560 mm)1Vehicles withoutTremor or XL Off-Road Packages

30 in (762 mm)XL Off-RoadPackage

33 in (838 mm)Tremor Package

1 Bottom of the doors.

When you are driving through water do notexceed 4 mph (7 km/h).

Never stop or shut a vehicle off whencrossing deep water unless your vehicleingested water into the engine air intake.If the engine stalls, do not attempt torestart it. Keep the doors fully closed duringa water crossing.

Extra care must be taken crossing any typeof water. Do not drive into water unlessnecessary. Only drive through areas thatare designated and approved. Determineexit points that are downstream of yourentry point to allow for drifting. If there areother vehicles ahead, wait until they haveleft the water. Unsettled water can makea safe passage more challenging.

High currents even in shallow water canwash the dirt out from around your tires orpush your vehicle across slippery rocks orsurfaces. Never attempt to cross flowingwater that is deeper than your vehicle'sground clearance. Even in low currents yourvehicle's body surface area can be pusheddownstream and out of control. Do notcross any body of water that is fast flowingand rising, wait for the flow rate to reduce.

Vehicles used to traverse water regularlyshould be periodically inspected for signsof water ingestion in all of the vehicle'sfluids. If water is found inside your vehiclefluids, service your vehicle or see anauthorized dealer.

After driving through water and as soon asit is safe to do so, check the brakes, horn,lights, and steering wheel to make sureeverything is still in working order.

AFTER DRIVING YOUR VEHICLEOFF-ROAD

WARNING: After off-road use,before returning to the road, check thewheels and tires for damage. Off-roaduse may cause damage to your wheelsand tires that can lead to tire failure, lossof vehicle control, serious injury or death.

WARNING: Always re-inflate tiresto recommended tire pressures beforethe vehicle is operated on-road. Therecommended pressure is located on thetire label or safety certification label,located on the B-pillar, inside the driver'sdoor.

Driving off-road places more stress on yourvehicle than most on-road driving. Afterdriving off-road check for damage to yourvehicle and, if necessary, have your vehiclefixed as soon as possible.

Inspect the underbody of your vehicle bychecking tires, body structure, steering,suspension, and exhaust system fordamage.

Check the radiator for mud and debris andclean as needed.

Remove accumulations of plants or brush.These things could be a fire hazard or hidedamage to the fuel lines, brake hoses, andpropeller shafts.

414

2023 Super Duty (TFH) Canada/United States of America, enUSA, Edition date: 202211, DOMDriving Hints

Page 427 of 738

POST-CRASH ALERT SYSTEM

WHAT IS THE POST-CRASHALERT SYSTEM

The system helps draw attention to yourvehicle in the event of a serious impact.

HOW DOES THE POST-CRASHALERT SYSTEM WORK

The system is designed to turn the hazardflashers on, turn the courtesy lamps on,intermittently sound the horn and unlockall doors in the event of a serious impactthat deploys an airbag or the seatbeltpretensioners.

POST-CRASH ALERT SYSTEMLIMITATIONS

Depending on applicable laws in thecountry your vehicle was built for, the horndoes not sound in the event of a seriousimpact.

SWITCHING THE POST-CRASHALERT SYSTEM OFF

Press the hazard flasher switch, the unlockbutton on the remote control, the panicbutton on the remote control or cycle theignition to switch the system off.

Note:The alert turns off when the vehiclebattery runs out of charge.

AUTOMATIC CRASH SHUTOFF

WHAT IS AUTOMATIC CRASHSHUTOFF

The automatic crash shutoff is designedto stop the fuel going to the engine in theevent of a moderate or severe crash.

Note:Not every impact causes a shutoff.

AUTOMATIC CRASH SHUTOFFPRECAUTIONS

WARNING: If your vehicle has beeninvolved in a crash, have the fuel systemchecked. Failure to follow this instructioncould result in fire, personal injury ordeath.

RE-ENABLING YOUR VEHICLE

1.Switch the ignition off.

2.Attempt to start your vehicle.

3.Switch the ignition off.

4.Attempt to start your vehicle.

Note:If your vehicle does not start after thethird attempt, have your vehicle checked assoon as possible.

RECOVERY TOWING

ACCESSING THE FRONT TOWINGPOINT

WARNING: Using recovery hooksis dangerous and should only be done bya person familiar with proper vehiclerecovery safety practices. Improper useof recovery hooks may cause hook failureor separation from the vehicle and couldresult in serious injury or death.

WARNING: Slowly remove theslack from the recovery strap prior topulling. Failure to do so can introducesignificantly higher loads which cancause the recovery hooks to break off, orthe recovery strap to fail which can causeserious injury or death.

423

2023 Super Duty (TFH) Canada/United States of America, enUSA, Edition date: 202211, DOMCrash and Breakdown Information

Page 438 of 738

Protected ComponentRatingItem

Compressed natural gasmodule power.10 A65

Trailer brake control.30 A74Aftermarket e-brake access.

Compressed natural gaspowered at all times.30 A75

Trailer tow lighting modulebattery charge.25 A76

Vehicle battery 1.30 A77

Power point 2.20 A78

Power point 1.20 A79

Horn.20 A84

Heated rear windshield.40 A85

Headlamp control module.5 A91

Left-hand headlamp.15 A92

Right-hand headlamp.15 A93

Power point 3.20 A94

Power point 4.20 A95Smart charge module.

Tailgate release.10 A98

Customer interface module.50 A101

Rain sensor.5 A102

Front wiper motor.30 A103

Fuel pump.30 A105

Body control module RP1bus.30 A106

Trailer tow park lamps.25 A107

434

2023 Super Duty (TFH) Canada/United States of America, enUSA, Edition date: 202211, DOMFuses

Page 507 of 738

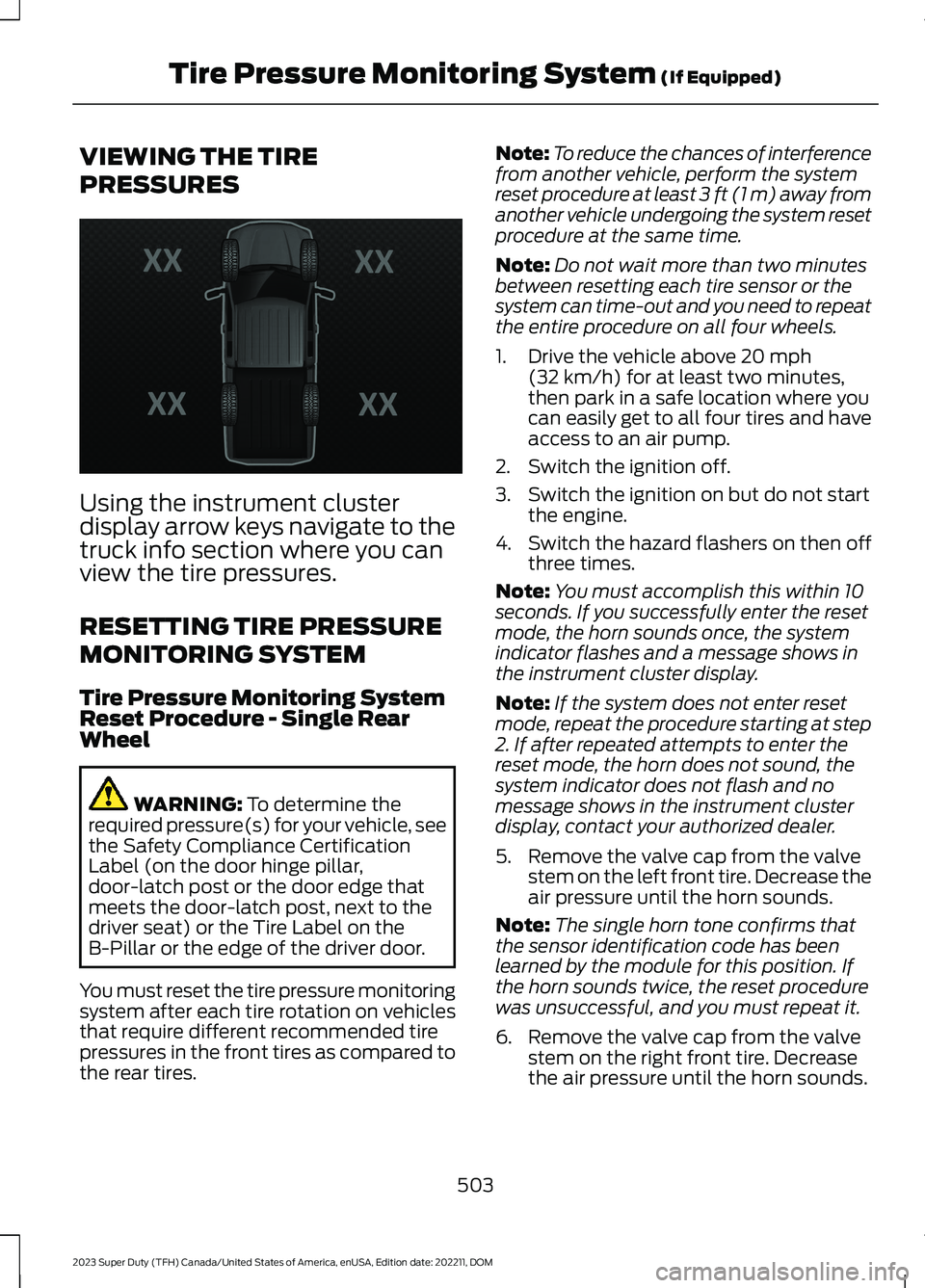

VIEWING THE TIRE

PRESSURES

Using the instrument clusterdisplay arrow keys navigate to thetruck info section where you canview the tire pressures.

RESETTING TIRE PRESSURE

MONITORING SYSTEM

Tire Pressure Monitoring SystemReset Procedure - Single RearWheel

WARNING: To determine therequired pressure(s) for your vehicle, seethe Safety Compliance CertificationLabel (on the door hinge pillar,door-latch post or the door edge thatmeets the door-latch post, next to thedriver seat) or the Tire Label on theB-Pillar or the edge of the driver door.

You must reset the tire pressure monitoringsystem after each tire rotation on vehiclesthat require different recommended tirepressures in the front tires as compared tothe rear tires.

Note:To reduce the chances of interferencefrom another vehicle, perform the systemreset procedure at least 3 ft (1 m) away fromanother vehicle undergoing the system resetprocedure at the same time.

Note:Do not wait more than two minutesbetween resetting each tire sensor or thesystem can time-out and you need to repeatthe entire procedure on all four wheels.

1.Drive the vehicle above 20 mph(32 km/h) for at least two minutes,then park in a safe location where youcan easily get to all four tires and haveaccess to an air pump.

2.Switch the ignition off.

3.Switch the ignition on but do not startthe engine.

4.Switch the hazard flashers on then offthree times.

Note:You must accomplish this within 10seconds. If you successfully enter the resetmode, the horn sounds once, the systemindicator flashes and a message shows inthe instrument cluster display.

Note:If the system does not enter resetmode, repeat the procedure starting at step2. If after repeated attempts to enter thereset mode, the horn does not sound, thesystem indicator does not flash and nomessage shows in the instrument clusterdisplay, contact your authorized dealer.

5.Remove the valve cap from the valvestem on the left front tire. Decrease theair pressure until the horn sounds.

Note:The single horn tone confirms thatthe sensor identification code has beenlearned by the module for this position. Ifthe horn sounds twice, the reset procedurewas unsuccessful, and you must repeat it.

6.Remove the valve cap from the valvestem on the right front tire. Decreasethe air pressure until the horn sounds.

503

2023 Super Duty (TFH) Canada/United States of America, enUSA, Edition date: 202211, DOMTire Pressure Monitoring System (If Equipped)E224333

Page 508 of 738

7.Repeat the previous step on the rightrear tire and then on the left rear tire.

8.Switch the ignition off.

Note:If the horn sounds twice again afterswitching the ignition off, and repeating theprocedure, contact your authorized dealerand have your vehicle checked as soon aspossible.

9.Set all four tires to the recommendedair pressure as indicated on the SafetyCompliance Certification Label.

Tire Pressure Monitoring SystemReset Procedure - Dual Rear Wheel

For further information seeUnderstanding Your Tire PressureMonitoring System and refer to DualRear Wheel, earlier in this section.

Read the entire procedure beforeattempting.

1.Drive the vehicle above 20 mph(32 km/h) for at least two minutes,then park in a safe location where youcan easily get to all six tires and haveaccess to an air pump.

2.Place the ignition in the off position andkeep the key in the ignition.

3.Cycle the ignition to the on positionwith the engine off.

4.Turn the hazard flashers on then offthree times. You must accomplish thiswithin 10 seconds. If you successfullyenter the reset mode, the horn soundsonce, the system indicator flashes anda message shows in the instrumentcluster display. If this does not occur,repeat the procedure starting at step2. If after repeated attempts to enterthe reset mode, the horn does notsound, the system indicator does notflash and no message shows in theinstrument cluster display, contact yourauthorized dealer as soon as possible.

5.Train the tire pressure monitoringsystem sensors in the tires using thefollowing system reset sequencestarting with the left front tire in thefollowing order: Left front - driver sidefront tire, Right front - passenger sidefront tire, Right outer rear -passengerside rear outer tire, Right inner rear -passenger side rear inner tire, Left outerrear - driver side rear outer tire, Leftinner rear - driver side rear inner tire.

6.Remove the valve cap from the valvestem on the left front tire. Decrease theair pressure until the horn sounds.

Note:The single horn chirp confirms thatthe sensor identification code has beenlearned by the module for this position. If adouble horn is heard, the reset procedurewas unsuccessful, and you must repeat it.

7.Remove the valve cap from the valvestem on the right front tire. Decreasethe air pressure until the horn sounds.

8.Remove the valve cap from the valvestem on the right outer rear tire.Decrease the air pressure until the hornsounds.

9.Remove the valve cap from the valvestem on the right inner rear tire.Decrease the air pressure until the hornsounds.

10.Remove the valve cap from the valvestem on the left outer rear tire.Decrease the air pressure until thehorn sounds.

11.Remove the valve cap from the valvestem on the left inner rear tire.Decrease the air pressure until thehorn sounds. Training is completeafter the horn sounds for the last tiretrained, the system indicator stopsflashing, and a message is shown inthe instrument cluster display.

504

2023 Super Duty (TFH) Canada/United States of America, enUSA, Edition date: 202211, DOMTire Pressure Monitoring System (If Equipped)

Page 509 of 738

12.Turn the ignition off. If two short hornbeeps are heard, the reset procedurewas unsuccessful and you mustrepeat it. If after repeating theprocedure and two short beeps areheard when the ignition is turned tooff, contact your authorized dealer assoon as possible.

13.Set all six tires to the recommendedair pressure as indicated on theSafety Compliance CertificationLabel, affixed to either the door hingepillar, door-latch post, or the dooredge that meets the door-latch post,next to the driver seating position ortire label located on the B-pillar orthe edge of the driver door.

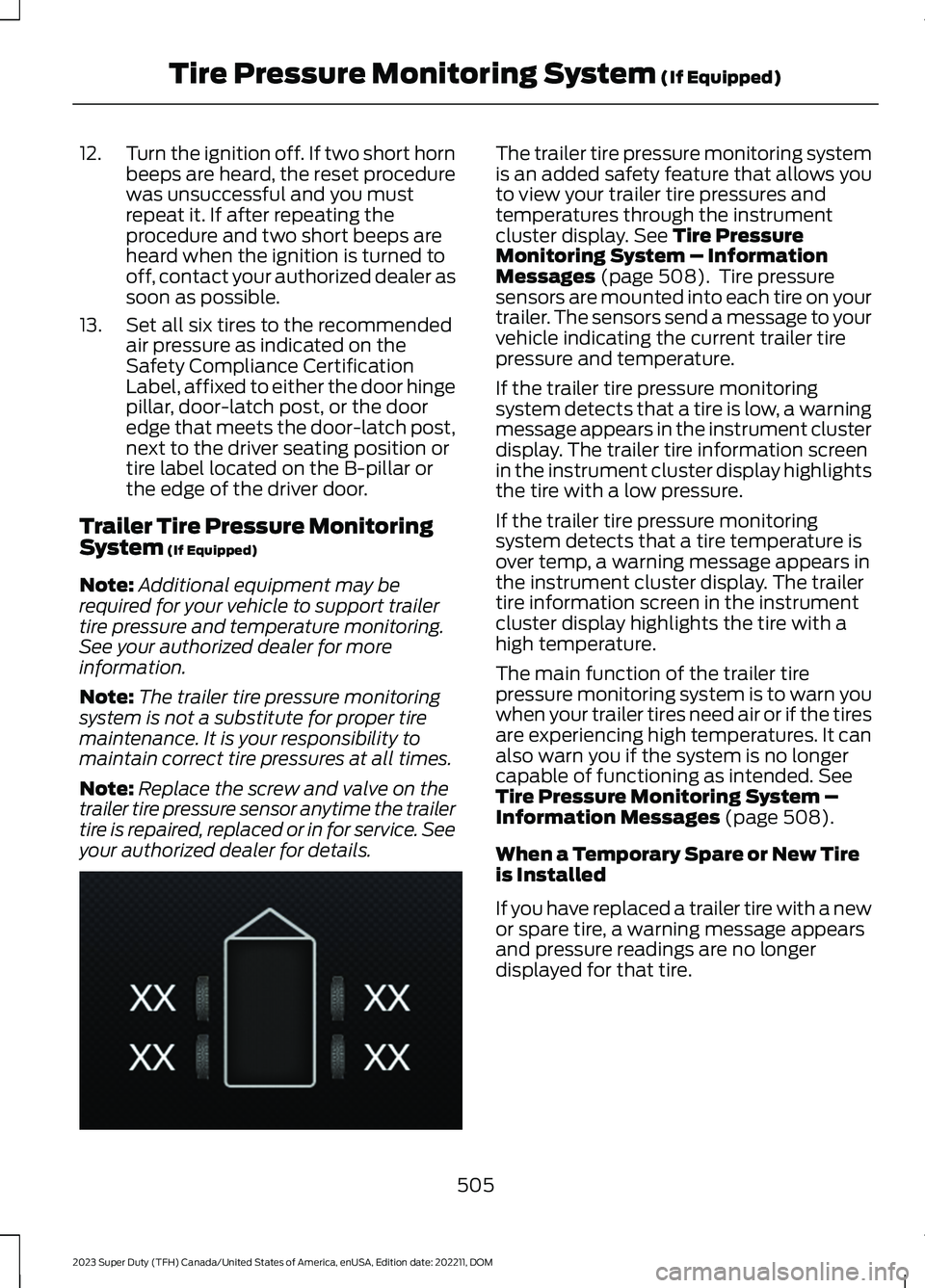

Trailer Tire Pressure MonitoringSystem (If Equipped)

Note:Additional equipment may berequired for your vehicle to support trailertire pressure and temperature monitoring.See your authorized dealer for moreinformation.

Note:The trailer tire pressure monitoringsystem is not a substitute for proper tiremaintenance. It is your responsibility tomaintain correct tire pressures at all times.

Note:Replace the screw and valve on thetrailer tire pressure sensor anytime the trailertire is repaired, replaced or in for service. Seeyour authorized dealer for details.

The trailer tire pressure monitoring systemis an added safety feature that allows youto view your trailer tire pressures andtemperatures through the instrumentcluster display. See Tire PressureMonitoring System – InformationMessages (page 508). Tire pressuresensors are mounted into each tire on yourtrailer. The sensors send a message to yourvehicle indicating the current trailer tirepressure and temperature.

If the trailer tire pressure monitoringsystem detects that a tire is low, a warningmessage appears in the instrument clusterdisplay. The trailer tire information screenin the instrument cluster display highlightsthe tire with a low pressure.

If the trailer tire pressure monitoringsystem detects that a tire temperature isover temp, a warning message appears inthe instrument cluster display. The trailertire information screen in the instrumentcluster display highlights the tire with ahigh temperature.

The main function of the trailer tirepressure monitoring system is to warn youwhen your trailer tires need air or if the tiresare experiencing high temperatures. It canalso warn you if the system is no longercapable of functioning as intended. SeeTire Pressure Monitoring System –Information Messages (page 508).

When a Temporary Spare or New Tireis Installed

If you have replaced a trailer tire with a newor spare tire, a warning message appearsand pressure readings are no longerdisplayed for that tire.

505

2023 Super Duty (TFH) Canada/United States of America, enUSA, Edition date: 202211, DOMTire Pressure Monitoring System (If Equipped)E235807

Page 597 of 738

Check Every Six Months

The door weatherstrips for wear. Lubricate if necessary.

The hinges, latches and outside locks for proper operation. Lubricate if necessary.

The parking brake for proper operation.

The seatbelts and seat latches for wear and function.

Safety warning lamps, brake, ABS, airbag and seatbelt for operation.

The washer spray and wiper operation. Clean or replace blades as necessary.

Multi-Point Inspection

It is important to have the systems on yourvehicle regularly checked. This can helpidentify potential issues and prevent majorproblems. We recommend having thefollowing multi-point inspection performedat every scheduled maintenance intervalto help make sure your vehicle keepsrunning great.

Multi-Point Inspection

Hazard warning system operationAccessory drive belt or belts

Horn operationBattery performance

Radiator, cooler, heater and air conditioninghosesEngine air filter

Suspension components for leaks ordamageExhaust system

Steering and linkageExterior lamps operation

Tires including the spare for wear and

proper pressure2Fluid levels1; fill if necessary

Windshield for cracks, chips or pitsFor oil and fluid leaks

Washer spray and wiper operationHalfshaft dust boots

1 Brake, coolant recovery reservoir, automatic transmission and window washer.2If your vehicle has a temporary mobility kit, check the tire sealant expiration Use By dateon the canister. Replace as needed.

593

2023 Super Duty (TFH) Canada/United States of America, enUSA, Edition date: 202211, DOMScheduled Maintenance

Page 600 of 738

Check Every Month

The fuel and water separator. Drain if necessary or if indicated by the instrument cluster

display.1

The holes and slots in the tail pipe to make sure they are functional and clear of debris.1

1 Diesel vehicles only.

Check Every Six Months

The battery connections. Clean if necessary.

The body and door drain holes for obstructions. Clean if necessary.

The cooling system fluid level and the coolant system strength.

The door weatherstrips for wear. Lubricate if necessary.

The hinges, latches and outside locks for proper operation. Lubricate if necessary.

The parking brake for proper operation.

The seatbelts and seat latches for wear and function.

Safety warning lamps, brake, ABS, airbag and seatbelt for operation.

The washer spray and wiper operation. Clean or replace blades as necessary.

Multi-Point Inspection

It is important to have the systems on yourvehicle regularly checked. This can helpidentify potential issues and prevent majorproblems. We recommend having thefollowing multi-point inspection performedat every scheduled maintenance intervalto help make sure your vehicle keepsrunning great.

Multi-Point Inspection

Hazard warning system operationAccessory drive belt or belts

Horn operationBattery performance

Radiator, cooler, heater and air conditioninghosesEngine air filter

596

2023 Super Duty (TFH) Canada/United States of America, enUSA, Edition date: 202211, DOMScheduled Maintenance

Page 721 of 738

H

Headlamp AdjustingSee: Adjusting the Headlamps....................460Headlamps.......................................................117Adjusting the Level of the Headlamps.........117Headlamp Indicators..........................................117Using the High Beam Headlamps.................117Headlamps – Troubleshooting.................117Headlamps – Frequently AskedQuestions...........................................................117Head Up Display............................................147Head Up Display – Troubleshooting...........148Head Up Display Settings..........................147Head Up Display –Troubleshooting.........................................148Head Up Display – InformationMessages..........................................................148Heated Seats.................................................168Heated Seat Precautions................................168Switching the Heated Seats On andOff.......................................................................168HeatingSee: Climate Control - Vehicles With:Automatic Temperature Control..............152See: Climate Control - Vehicles With: ManualTemperature Control....................................156Hill Descent Control....................................277Hill Descent Control –Troubleshooting............................................278Hill Descent Control Indicator..................277Hill Descent Control Precautions...........277Hill Descent Control –Troubleshooting........................................278Hill Descent Control – InformationMessages.........................................................278Hill Descent Control Videos.....................278Hill Start Assist.............................................265Hill Start Assist – Troubleshooting.............265Hill Start Assist Precautions....................265Hill Start Assist –Troubleshooting........................................265Hill Start Assist – InformationMessages.........................................................265Hill Start Assist Videos..............................265Hitches.............................................................359Fifth-Wheel Trailer Hitch.................................361

Hooking Up a Trailer Using aWeight-Distributing Hitch.........................360Installing a Hitch................................................359Hood LockSee: Opening and Closing the Hood.........440Horn....................................................................110How Does 911 Assist Work..........................67How Does Adaptive Cruise Control WithStop and Go Work....................................296How Does Auto Hold Work......................266How Does Blind Spot InformationSystem Work...............................................327How Does Cross Traffic AlertWork...............................................................335How Does Cross Traffic BrakingWork...............................................................262How Does Drive Mode ControlWork.................................................................311How Does Driver Alert Work....................346How Does Easy Entry and ExitWork................................................................90How Does Exit Warning Work.................332How Does Four-Wheel Drive Work.......238How Does Hill Descent ControlWork...............................................................277How Does Hill Start Assist Work...........265How Does Onboard Scales Work..........384How Does Pre-Collision AssistWork..............................................................338How Does Reverse Brake AssistWork..............................................................258How Does Smart Hitch Work..................382How Does Speed Sign RecognitionWork..............................................................348How Does Stability Control Work..........270How Does the 360 Degree CameraWork..............................................................290How Does the Diesel Particulate FilterWork................................................................221How Does the Electronic LockingDifferential Work.......................................245How Does the Lane Keeping SystemWork................................................................317How Does the Rear Occupant AlertSystem Work................................................174How Does the Safety Canopy™Work.................................................................58

717

2023 Super Duty (TFH) Canada/United States of America, enUSA, Edition date: 202211, DOMIndex