flat tire FORD SUPER DUTY 2023 Owner's Guide

[x] Cancel search | Manufacturer: FORD, Model Year: 2023, Model line: SUPER DUTY, Model: FORD SUPER DUTY 2023Pages: 738, PDF Size: 18.49 MB

Page 506 of 738

When the malfunction indicator isilluminated, the system may not be ableto detect or signal low tire pressure asintended. TPMS malfunctions may occurfor a variety of reasons, including theinstallation of replacement or alternatetires or wheels on the vehicle that preventthe TPMS from functioning properly.Always check the TPMS malfunctiontelltale after replacing one or more tires orwheels on your vehicle to ensure that thereplacement or alternate tires and wheelsallow the TPMS to continue to functionproperly.

WARNING: Changes ormodifications not expressively approvedby the party responsible for compliancecould void the user's authority to operatethe equipment. The term "IC:" before theradio certification number only signifiesthat Industry Canada technicalspecifications were met.

This device complies with Part 15 of theFCC Rules and with License exempt RSSStandards of Industry Canada. Operationis subject to the following two conditions:

1.This device may not cause harmfulinterference, and

2.This device must accept anyinterference received, includinginterference that may cause undesiredoperation.

TIRE PRESSURE MONITORING

SYSTEM PRECAUTIONS

WARNING: The tire pressuremonitoring system is not a substitute formanually checking tire pressures. Youshould periodically check tire pressuresusing a pressure gauge. Failure tocorrectly maintain tire pressures couldincrease the risk of tire failure, loss ofcontrol, vehicle rollover and personalinjury.

WARNING: Do not use the tirepressure displayed in the informationdisplay as a tire pressure gauge. Failureto follow this instruction could result inpersonal injury or death.

Note:The use of tire sealants can damagethe tire pressure monitoring system.

Note:If the tire pressure monitor sensorbecomes damaged it may not function.

TIRE PRESSURE MONITORING

SYSTEM LIMITATIONS

When the outside temperature dropssignificantly, the tire pressure coulddecrease and activate the low tire pressurewarning lamp.

The warning lamp could also illuminatewhen you use a spare wheel, or tire sealantfrom the inflator kit.

Note:Regularly checking the vehicle tirepressures can reduce the possibility for thewarning lamp to illuminate due to outsideair temperature changes.

Note:After you inflate the tires to therecommended pressure it could take up totwo minutes of driving over 20 mph(32 km/h) for the warning indicator to turnoff.

502

2023 Super Duty (TFH) Canada/United States of America, enUSA, Edition date: 202211, DOMTire Pressure Monitoring System (If Equipped)

Page 511 of 738

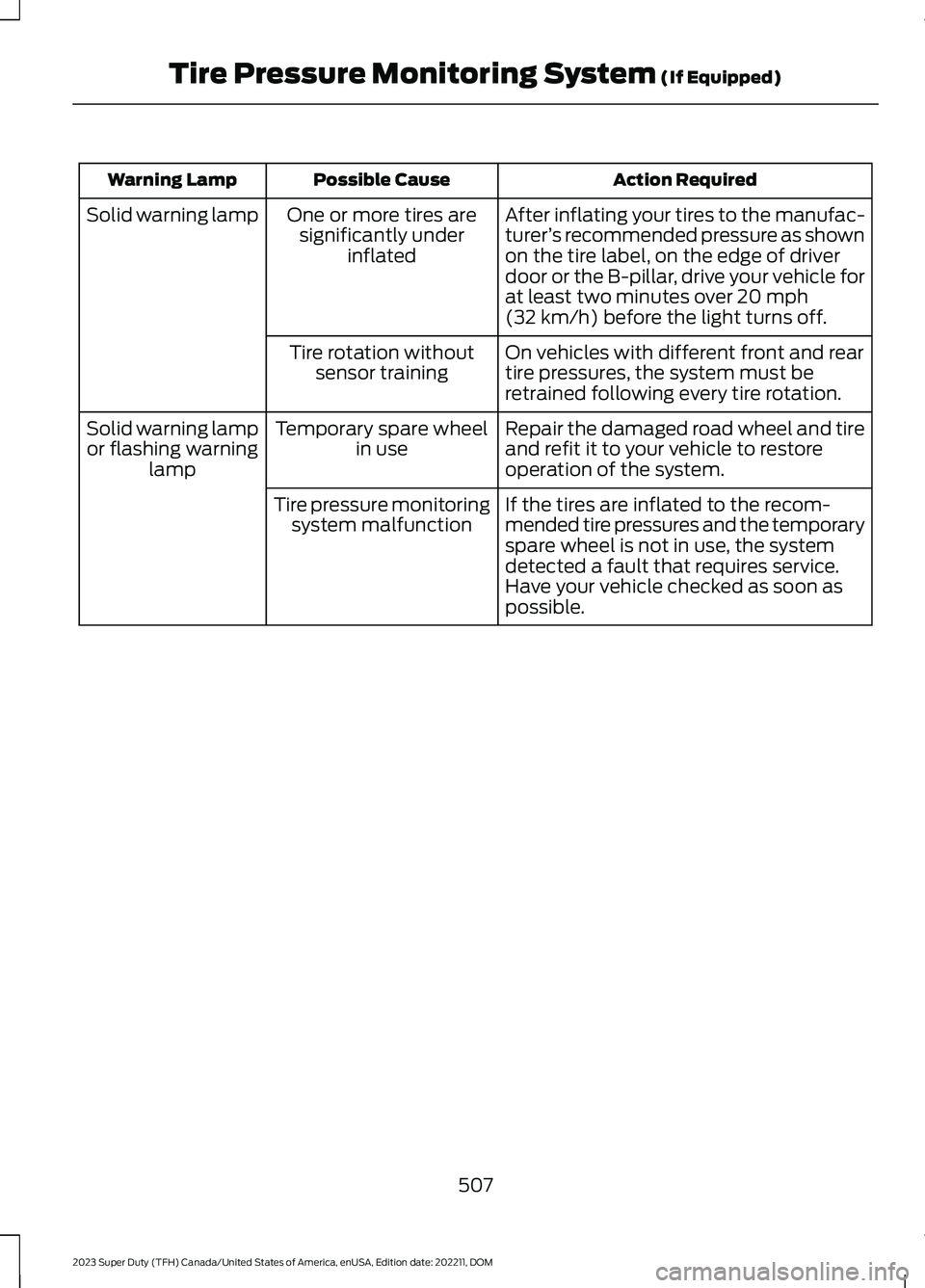

Action RequiredPossible CauseWarning Lamp

After inflating your tires to the manufac-turer’s recommended pressure as shownon the tire label, on the edge of driverdoor or the B-pillar, drive your vehicle forat least two minutes over 20 mph(32 km/h) before the light turns off.

One or more tires aresignificantly underinflated

Solid warning lamp

On vehicles with different front and reartire pressures, the system must beretrained following every tire rotation.

Tire rotation withoutsensor training

Repair the damaged road wheel and tireand refit it to your vehicle to restoreoperation of the system.

Temporary spare wheelin useSolid warning lampor flashing warninglamp

If the tires are inflated to the recom-mended tire pressures and the temporaryspare wheel is not in use, the systemdetected a fault that requires service.Have your vehicle checked as soon aspossible.

Tire pressure monitoringsystem malfunction

507

2023 Super Duty (TFH) Canada/United States of America, enUSA, Edition date: 202211, DOMTire Pressure Monitoring System (If Equipped)

Page 512 of 738

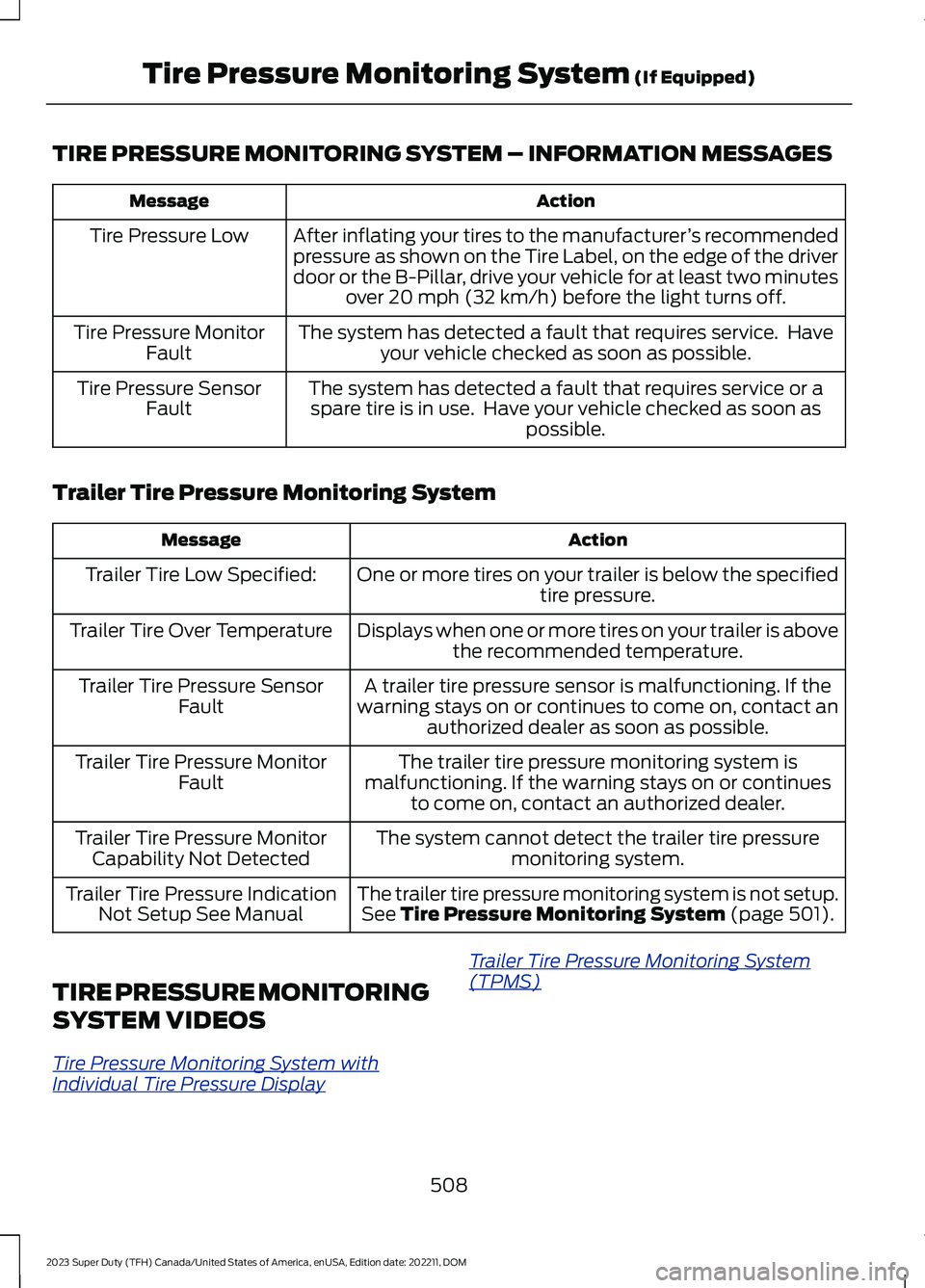

TIRE PRESSURE MONITORING SYSTEM – INFORMATION MESSAGES

ActionMessage

After inflating your tires to the manufacturer’s recommendedpressure as shown on the Tire Label, on the edge of the driverdoor or the B-Pillar, drive your vehicle for at least two minutesover 20 mph (32 km/h) before the light turns off.

Tire Pressure Low

The system has detected a fault that requires service. Haveyour vehicle checked as soon as possible.Tire Pressure MonitorFault

The system has detected a fault that requires service or aspare tire is in use. Have your vehicle checked as soon aspossible.

Tire Pressure SensorFault

Trailer Tire Pressure Monitoring System

ActionMessage

One or more tires on your trailer is below the specifiedtire pressure.Trailer Tire Low Specified:

Displays when one or more tires on your trailer is abovethe recommended temperature.Trailer Tire Over Temperature

A trailer tire pressure sensor is malfunctioning. If thewarning stays on or continues to come on, contact anauthorized dealer as soon as possible.

Trailer Tire Pressure SensorFault

The trailer tire pressure monitoring system ismalfunctioning. If the warning stays on or continuesto come on, contact an authorized dealer.

Trailer Tire Pressure MonitorFault

The system cannot detect the trailer tire pressuremonitoring system.Trailer Tire Pressure MonitorCapability Not Detected

The trailer tire pressure monitoring system is not setup.See Tire Pressure Monitoring System (page 501).Trailer Tire Pressure IndicationNot Setup See Manual

TIRE PRESSURE MONITORING

SYSTEM VIDEOS

Tire Pressure Monitoring System withIndividual Tire Pressure Display

Trailer Tire Pressure Monitoring System(TPMS)

508

2023 Super Duty (TFH) Canada/United States of America, enUSA, Edition date: 202211, DOMTire Pressure Monitoring System (If Equipped)

Page 513 of 738

CHANGING A FLAT TIRE

If you get a flat tire when driving, do notapply the brake heavily. Instead, graduallydecrease your speed. Hold the steeringwheel firmly and slowly move to a safeplace on the side of the road.

Have a flat serviced by an authorizeddealer to prevent damage to the systemsensors. See Tire Pressure MonitoringSystem Precautions (page 502).Replacethe spare tire with a road tire as soon aspossible. During repairing or replacing theflat tire, have the authorized dealer inspectthe system sensor for damage.

Note:The use of tire sealant may damageyour tire pressure monitoring system andshould only be used in roadsideemergencies.

Note:The tire pressure monitoring systemindicator light illuminates when the sparetire is in use. To restore the full function ofthe monitoring system, all road wheelsequipped with tire pressure monitoringsensors must be mounted on this vehicle.

Dissimilar Spare Wheel and TireAssembly Information

WARNING: Failure to follow theseguidelines could result in an increasedrisk of loss of vehicle control, injury ordeath.

If you have a dissimilar spare wheel andtire, then it is intended for temporary useonly. This means that if you need to use it,you should replace it as soon as possiblewith a road wheel and tire assembly thatis the same size and type as the road tiresand wheels that were originally providedby Ford. If the dissimilar spare tire or wheelis damaged, it should be replaced ratherthan repaired.

A dissimilar spare wheel and tire assemblyis defined as a spare wheel and tireassembly that is different in brand, size orappearance from the road tires andwheels.

Full-size dissimilar spare

When driving with the full-size dissimilarspare wheel and tire assembly, do not:

•Exceed 70 mph (113 km/h).

•Use more than one dissimilar sparewheel and tire assembly at a time.

•Use snow chains on the end of thevehicle with the dissimilar spare wheeland tire assembly.

•Engage any four-wheel drive mode.See Four-Wheel Drive Limitations(page 239).

When driving with the full-size dissimilarspare wheel and tire assembly, 4WDfunctionality may be limited. You mayexperience the following:

•Additional noise from the transfer caseor other drive components.

•Difficulty shifting out of a mechanicallylocked 4WD mode.

When driving with the full-size dissimilarspare wheel and tire assembly, it isrecommended that you do not:

•Engage 4WD High or 4WD Low, ifequipped, other than to get your vehicleunstuck. .

The usage of a full-size dissimilar sparewheel and tire assembly can lead toimpairment of the following:

•Handling, stability and brakingperformance.

•Comfort and noise.

•Ground clearance and parking at curbs.

•Winter weather driving capability.

•Wet weather driving capability.

•Four-wheel drive capability.

509

2023 Super Duty (TFH) Canada/United States of America, enUSA, Edition date: 202211, DOMChanging a Road Wheel (If Equipped)

Page 514 of 738

When driving with the full-size dissimilarspare wheel and tire assembly additionalcaution should be given to:

•Towing a trailer.

•Driving vehicles equipped with acamper body.

•Driving vehicles with a load on thecargo rack.

Drive cautiously when using a full-sizedissimilar spare wheel and tire assemblyand seek service as soon as possible.

Location of the Spare Tire andTools

See the following table for their locations:

LocationItem

Under the vehicle, just forward of the rearbumper.Spare tire - pick-up trucks only

Fastened to the floor pan behind the rear-most seat on the passenger side.Jack

Regular Cab: Fastened to floor behind thedriver seat.Jack handle, lug wrench, lug wrench exten-sion - only provided on dual rear wheelvehicles.Super Cab and Crew Cab: Fastened to thefloor under the rear seat on the driver's side.

Tire Change Procedure

WARNING: The jack supplied withthis vehicle is only intended for changinga flat tire in an emergency. Do notattempt to do any other work on yourvehicle when it is supported by the jack,as your vehicle could slip off the jack.Failure to follow this instruction couldresult in personal injury or death.

WARNING: To help prevent yourvehicle from moving when changing awheel, shift the transmission into park(P), set the parking brake and use anappropriate block or wheel chock tosecure the wheel diagonally opposite tothe wheel being changed. For example,when changing the front left wheel,place an appropriate block or wheelchock on the right rear wheel.

WARNING: Only use the jackprovided as original equipment with yourvehicle.

WARNING: Failure to follow theseguidelines could result in an increasedrisk of loss of vehicle control, injury ordeath.

WARNING: Never place anythingbetween the vehicle jack and yourvehicle.

510

2023 Super Duty (TFH) Canada/United States of America, enUSA, Edition date: 202211, DOMChanging a Road Wheel (If Equipped)E166722

Page 515 of 738

WARNING: Never place anythingbetween the vehicle jack and the ground.

WARNING: Do not attempt tochange a tire on the side of the vehicleclose to moving traffic. Pull far enoughoff the road to not obstruct the flow oftraffic and avoid the danger of being hitwhen operating the jack or changing thewheel.

WARNING: The jack supplied withthis vehicle is only intended for changinga flat tire in an emergency. Do notattempt to do any other work on yourvehicle when it is supported by the jack,as your vehicle could slip off the jack.Failure to follow this instruction couldresult in personal injury or death.

WARNING: Only use the sparewheel carrier to stow wheels providedwith your vehicle.

Note:Do not use impact tools or powertools operating at over 200 RPM on thespare wheel carrier winch, which may causeit to malfunction and result in the wheel andtire not being securely stowed.

Note:Passengers should not remain in thevehicle when the vehicle is being jacked.

1.Park the vehicle on a level firm groundand activate the hazard flashers.

2.Apply the parking brake, place thetransmission in park (P), switch theengine off.

3.Block the wheel diagonally oppositethe flat tire. For example, if the leftfront tire is flat, block the right rearwheel.

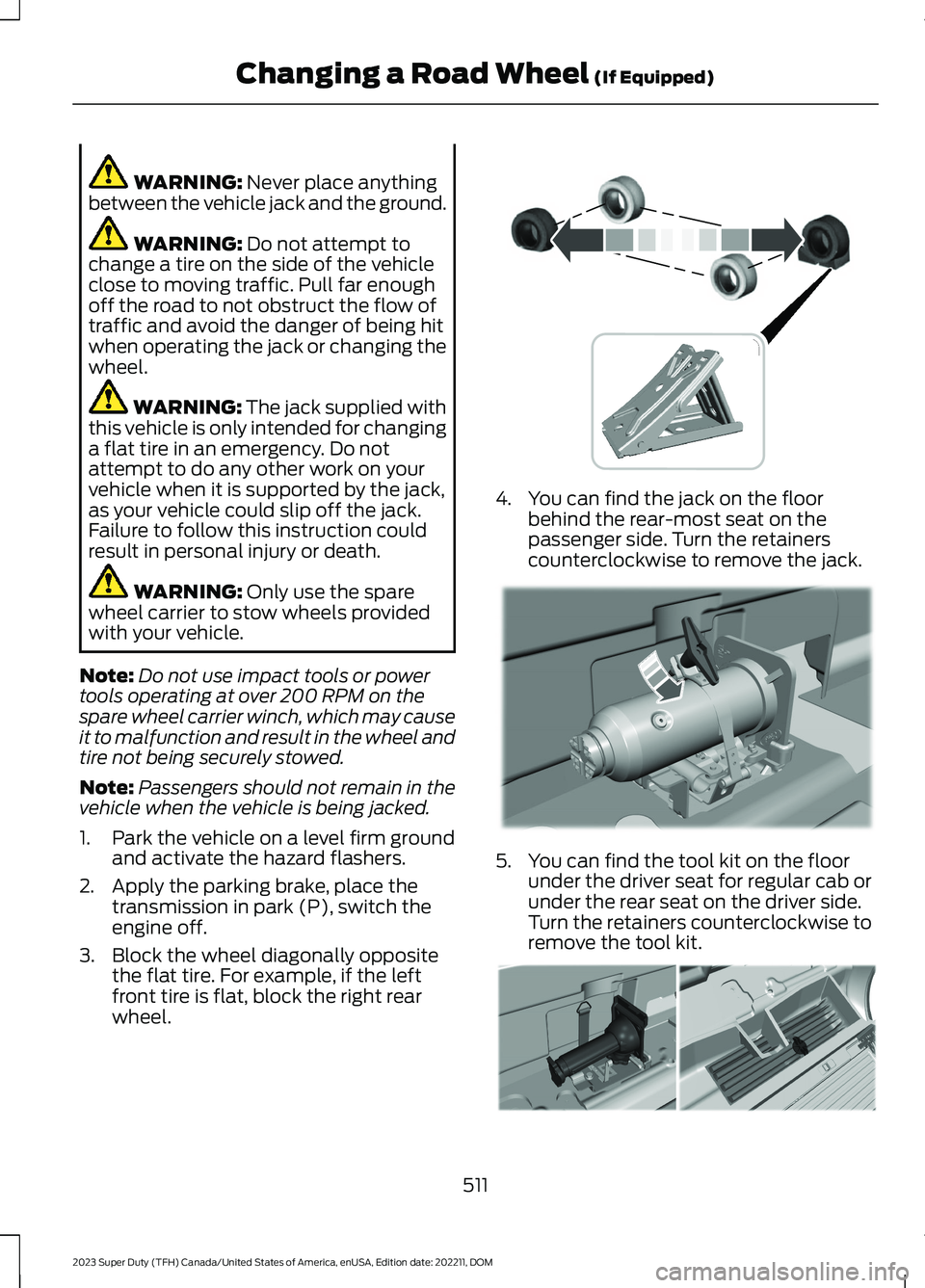

4.You can find the jack on the floorbehind the rear-most seat on thepassenger side. Turn the retainerscounterclockwise to remove the jack.

5.You can find the tool kit on the floorunder the driver seat for regular cab orunder the rear seat on the driver side.Turn the retainers counterclockwise toremove the tool kit.

511

2023 Super Duty (TFH) Canada/United States of America, enUSA, Edition date: 202211, DOMChanging a Road Wheel (If Equipped) E388040 E309424 E309795

Page 516 of 738

6.Use the ignition key to open the lock atthe rear bumper.

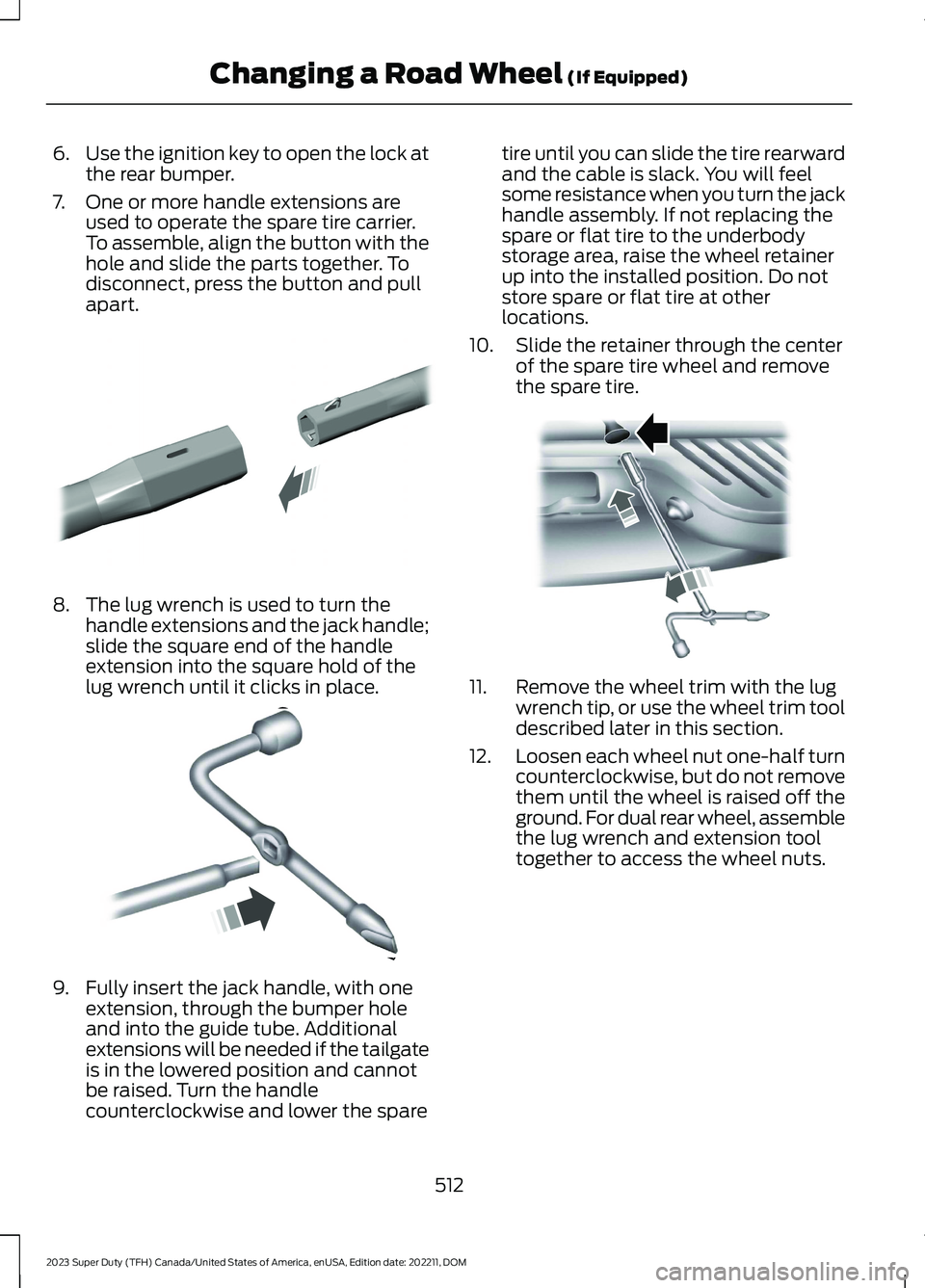

7.One or more handle extensions areused to operate the spare tire carrier.To assemble, align the button with thehole and slide the parts together. Todisconnect, press the button and pullapart.

8.The lug wrench is used to turn thehandle extensions and the jack handle;slide the square end of the handleextension into the square hold of thelug wrench until it clicks in place.

9.Fully insert the jack handle, with oneextension, through the bumper holeand into the guide tube. Additionalextensions will be needed if the tailgateis in the lowered position and cannotbe raised. Turn the handlecounterclockwise and lower the spare

tire until you can slide the tire rearwardand the cable is slack. You will feelsome resistance when you turn the jackhandle assembly. If not replacing thespare or flat tire to the underbodystorage area, raise the wheel retainerup into the installed position. Do notstore spare or flat tire at otherlocations.

10.Slide the retainer through the centerof the spare tire wheel and removethe spare tire.

11.Remove the wheel trim with the lugwrench tip, or use the wheel trim tooldescribed later in this section.

12.Loosen each wheel nut one-half turncounterclockwise, but do not removethem until the wheel is raised off theground. For dual rear wheel, assemblethe lug wrench and extension tooltogether to access the wheel nuts.

512

2023 Super Duty (TFH) Canada/United States of America, enUSA, Edition date: 202211, DOMChanging a Road Wheel (If Equipped)E308882 E162796 E310417

Page 520 of 738

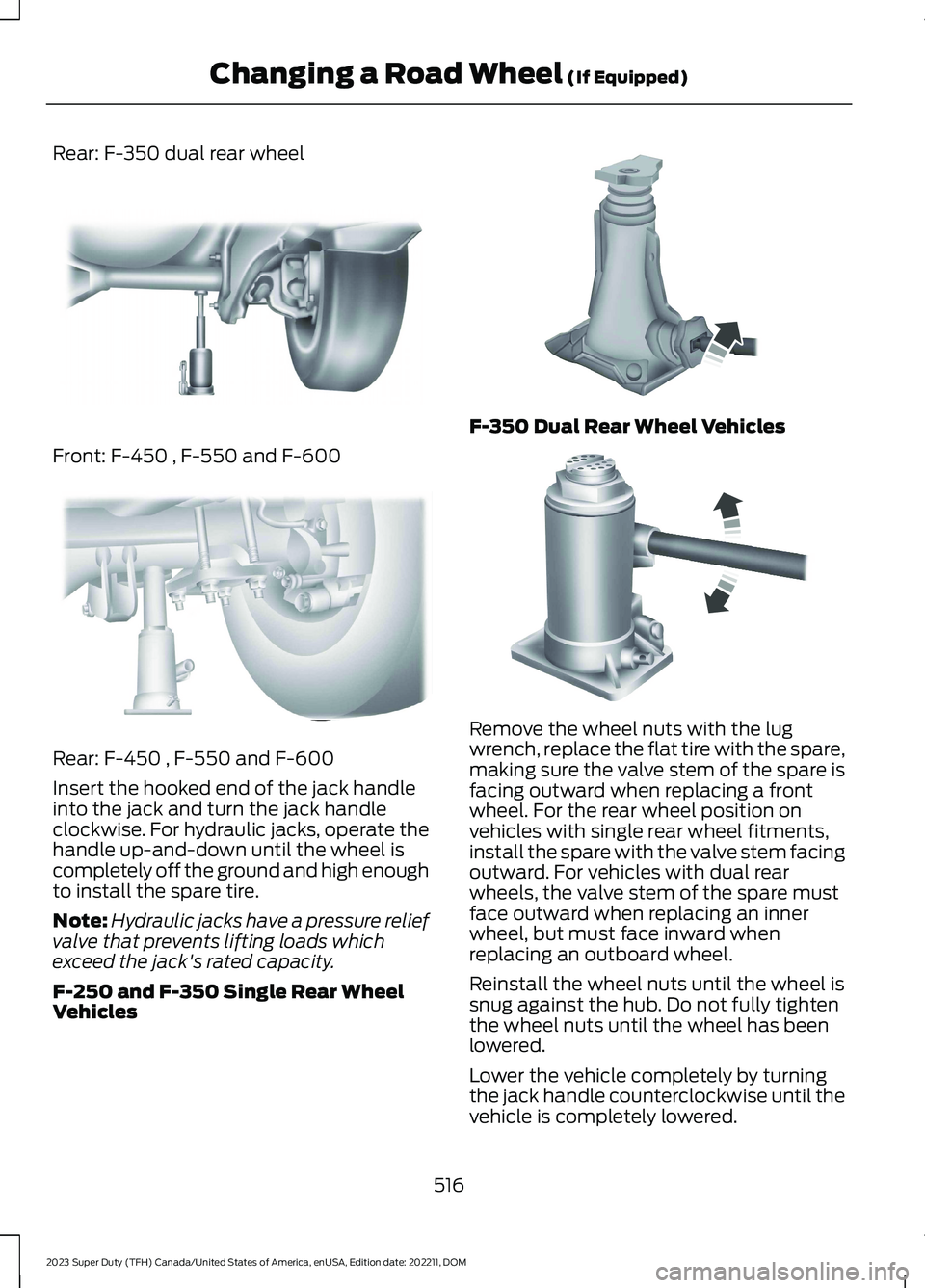

Rear: F-350 dual rear wheel

Front: F-450 , F-550 and F-600

Rear: F-450 , F-550 and F-600

Insert the hooked end of the jack handleinto the jack and turn the jack handleclockwise. For hydraulic jacks, operate thehandle up-and-down until the wheel iscompletely off the ground and high enoughto install the spare tire.

Note:Hydraulic jacks have a pressure reliefvalve that prevents lifting loads whichexceed the jack's rated capacity.

F-250 and F-350 Single Rear WheelVehicles

F-350 Dual Rear Wheel Vehicles

Remove the wheel nuts with the lugwrench, replace the flat tire with the spare,making sure the valve stem of the spare isfacing outward when replacing a frontwheel. For the rear wheel position onvehicles with single rear wheel fitments,install the spare with the valve stem facingoutward. For vehicles with dual rearwheels, the valve stem of the spare mustface outward when replacing an innerwheel, but must face inward whenreplacing an outboard wheel.

Reinstall the wheel nuts until the wheel issnug against the hub. Do not fully tightenthe wheel nuts until the wheel has beenlowered.

Lower the vehicle completely by turningthe jack handle counterclockwise until thevehicle is completely lowered.

516

2023 Super Duty (TFH) Canada/United States of America, enUSA, Edition date: 202211, DOMChanging a Road Wheel (If Equipped)E162816 E162818 E162811 E162819

Page 522 of 738

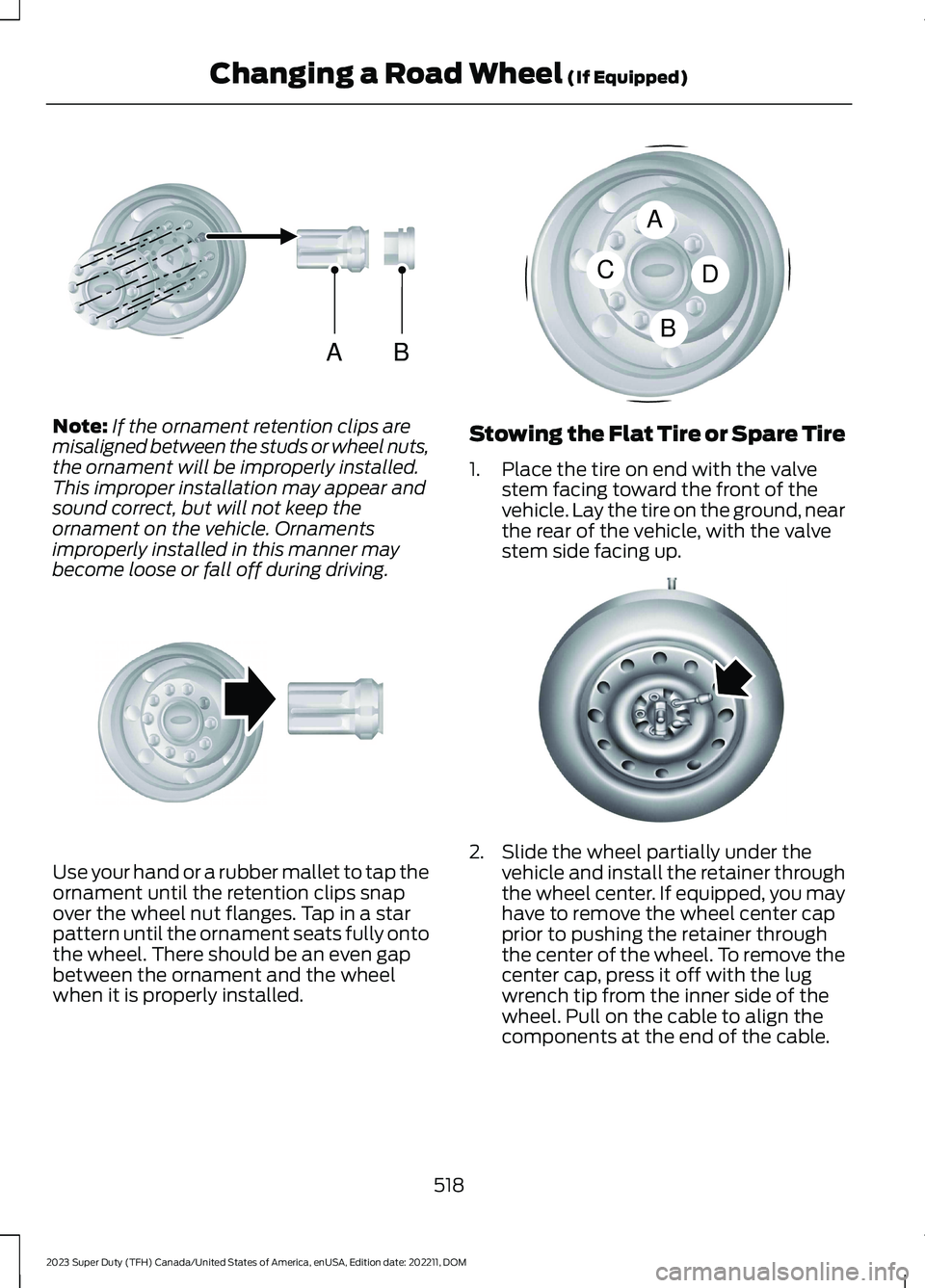

Note:If the ornament retention clips aremisaligned between the studs or wheel nuts,the ornament will be improperly installed.This improper installation may appear andsound correct, but will not keep theornament on the vehicle. Ornamentsimproperly installed in this manner maybecome loose or fall off during driving.

Use your hand or a rubber mallet to tap theornament until the retention clips snapover the wheel nut flanges. Tap in a starpattern until the ornament seats fully ontothe wheel. There should be an even gapbetween the ornament and the wheelwhen it is properly installed.

Stowing the Flat Tire or Spare Tire

1.Place the tire on end with the valvestem facing toward the front of thevehicle. Lay the tire on the ground, nearthe rear of the vehicle, with the valvestem side facing up.

2.Slide the wheel partially under thevehicle and install the retainer throughthe wheel center. If equipped, you mayhave to remove the wheel center capprior to pushing the retainer throughthe center of the wheel. To remove thecenter cap, press it off with the lugwrench tip from the inner side of thewheel. Pull on the cable to align thecomponents at the end of the cable.

518

2023 Super Duty (TFH) Canada/United States of America, enUSA, Edition date: 202211, DOMChanging a Road Wheel (If Equipped)ABE162822 E162823 ACBDE162824 E162800

Page 523 of 738

3.Reinsert the lug wrench extension(s)through the rear bumper and guidetube and turn the lug wrench clockwiseuntil the tire is raised to its stowedposition underneath the vehicle. Thewrench will become harder to turn andthe spare tire winch will ratchet or slipwhen the tire is raised to maximumtightness. You will hear a clicking soundfrom the winch indicating that the tireis properly stowed, tighten until aminimum of three clicks are heard.Check that the tire lies flat against theframe and is secure.

4.Carefully place all tools back in the toolkit bag.

5.Reinstall the tool kit bag and tightenthe wing nut.

6.Properly reinstall the jack into thebracket and tighten the wing nut.

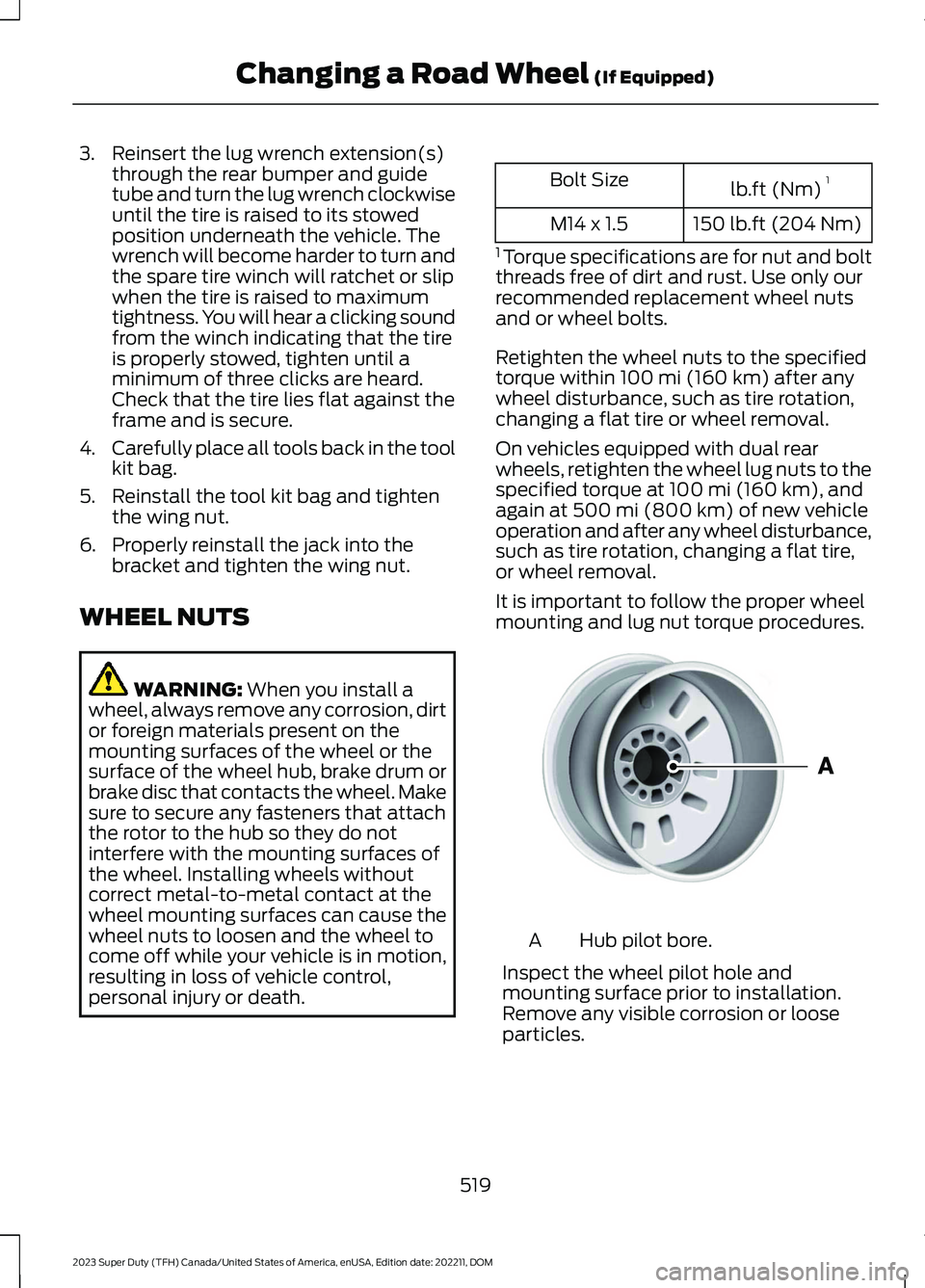

WHEEL NUTS

WARNING: When you install awheel, always remove any corrosion, dirtor foreign materials present on themounting surfaces of the wheel or thesurface of the wheel hub, brake drum orbrake disc that contacts the wheel. Makesure to secure any fasteners that attachthe rotor to the hub so they do notinterfere with the mounting surfaces ofthe wheel. Installing wheels withoutcorrect metal-to-metal contact at thewheel mounting surfaces can cause thewheel nuts to loosen and the wheel tocome off while your vehicle is in motion,resulting in loss of vehicle control,personal injury or death.

lb.ft (Nm)1Bolt Size

150 lb.ft (204 Nm)M14 x 1.5

1 Torque specifications are for nut and boltthreads free of dirt and rust. Use only ourrecommended replacement wheel nutsand or wheel bolts.

Retighten the wheel nuts to the specifiedtorque within 100 mi (160 km) after anywheel disturbance, such as tire rotation,changing a flat tire or wheel removal.

On vehicles equipped with dual rearwheels, retighten the wheel lug nuts to thespecified torque at 100 mi (160 km), andagain at 500 mi (800 km) of new vehicleoperation and after any wheel disturbance,such as tire rotation, changing a flat tire,or wheel removal.

It is important to follow the proper wheelmounting and lug nut torque procedures.

Hub pilot bore.A

Inspect the wheel pilot hole andmounting surface prior to installation.Remove any visible corrosion or looseparticles.

519

2023 Super Duty (TFH) Canada/United States of America, enUSA, Edition date: 202211, DOMChanging a Road Wheel (If Equipped)E145950