FORD TRANSIT 2006 7.G Body And Equipment Mounting Section Manual

Manufacturer: FORD, Model Year: 2006, Model line: TRANSIT, Model: FORD TRANSIT 2006 7.GPages: 234, PDF Size: 33.19 MB

Page 21 of 234

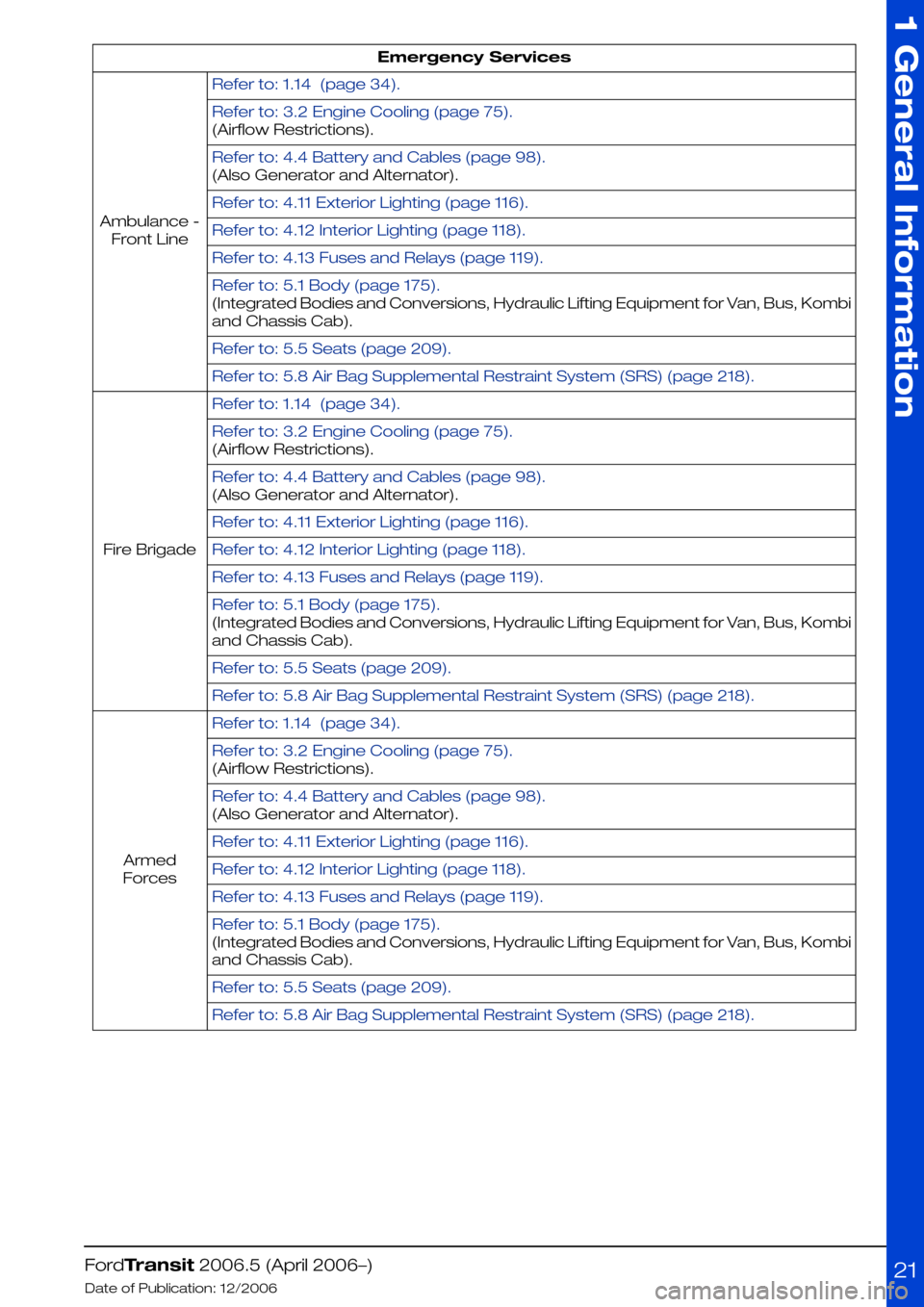

Emergency Services

Refer to: 1.14 (page 34).

Ambulance -

Front Line

Refer to: 3.2 Engine Cooling (page 75).

(Airflow Restrictions).

Refer to: 4.4 Battery and Cables (page 98).

(Also Generator and Alternator).

Refer to: 4.11 Exterior Lighting (page 116).

Refer to: 4.12 Interior Lighting (page 118).

Refer to: 4.13 Fuses and Relays (page 119).

Refer to: 5.1 Body (page 175).

(Integrated Bodies and Conversions, Hydraulic Lifting Equipment for Van, Bus, Kombi

and Chassis Cab).

Refer to: 5.5 Seats (page 209).

Refer to: 5.8 Air Bag Supplemental Restraint System (SRS) (page 218).

Refer to: 1.14 (page 34).

Fire Brigade

Refer to: 3.2 Engine Cooling (page 75).

(Airflow Restrictions).

Refer to: 4.4 Battery and Cables (page 98).

(Also Generator and Alternator).

Refer to: 4.11 Exterior Lighting (page 116).

Refer to: 4.12 Interior Lighting (page 118).

Refer to: 4.13 Fuses and Relays (page 119).

Refer to: 5.1 Body (page 175).

(Integrated Bodies and Conversions, Hydraulic Lifting Equipment for Van, Bus, Kombi

and Chassis Cab).

Refer to: 5.5 Seats (page 209).

Refer to: 5.8 Air Bag Supplemental Restraint System (SRS) (page 218).

Refer to: 1.14 (page 34).

Armed

Forces

Refer to: 3.2 Engine Cooling (page 75).

(Airflow Restrictions).

Refer to: 4.4 Battery and Cables (page 98).

(Also Generator and Alternator).

Refer to: 4.11 Exterior Lighting (page 116).

Refer to: 4.12 Interior Lighting (page 118).

Refer to: 4.13 Fuses and Relays (page 119).

Refer to: 5.1 Body (page 175).

(Integrated Bodies and Conversions, Hydraulic Lifting Equipment for Van, Bus, Kombi

and Chassis Cab).

Refer to: 5.5 Seats (page 209).

Refer to: 5.8 Air Bag Supplemental Restraint System (SRS) (page 218).

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

1 General Information

21

Page 22 of 234

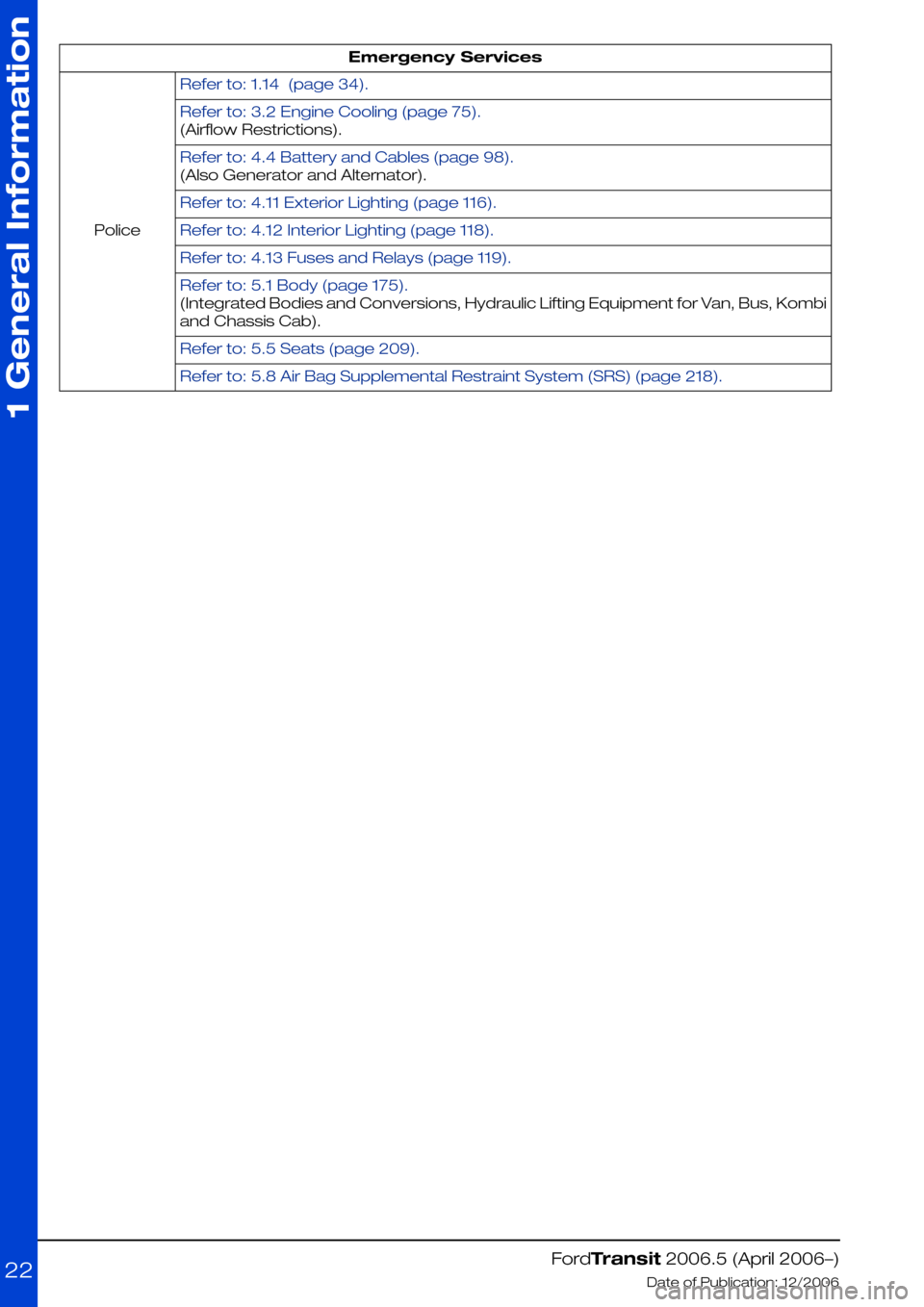

Emergency Services

Refer to: 1.14 (page 34).

Police

Refer to: 3.2 Engine Cooling (page 75).

(Airflow Restrictions).

Refer to: 4.4 Battery and Cables (page 98).

(Also Generator and Alternator).

Refer to: 4.11 Exterior Lighting (page 116).

Refer to: 4.12 Interior Lighting (page 118).

Refer to: 4.13 Fuses and Relays (page 119).

Refer to: 5.1 Body (page 175).

(Integrated Bodies and Conversions, Hydraulic Lifting Equipment for Van, Bus, Kombi

and Chassis Cab).

Refer to: 5.5 Seats (page 209).

Refer to: 5.8 Air Bag Supplemental Restraint System (SRS) (page 218).

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

1 General Information

22

Page 23 of 234

1.5 Conversion Homologation

The Vehicle Converter must observe any

statutory rules and regulations. When the

conversion needs a new approval the following

information must be quoted.

•All dimensional, weight and centre of gravity

data.

•The fixing of the body to the donor vehicle.

•Operating conditions.

The responsible Technical Service may require

additional information and/or testing.

NOTE: For further information please contact

your local National Sales Company

representative, or Local Ford Dealer. If they are

unable to help you then please contact the

Vehicle Converter Advisory Service at

[email protected].

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

1 General Information

23

Page 24 of 234

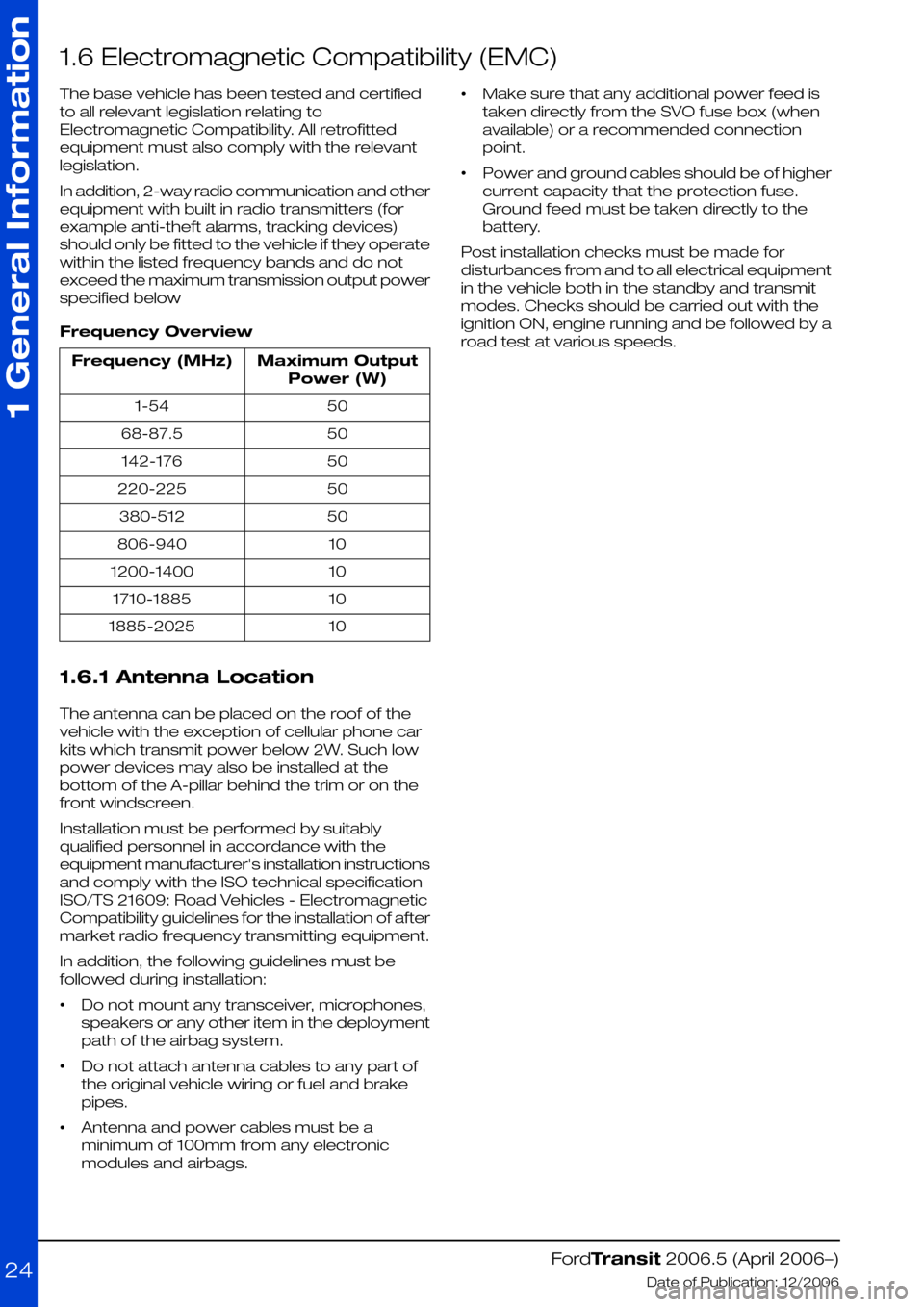

1.6 Electromagnetic Compatibility (EMC)

The base vehicle has been tested and certified

to all relevant legislation relating to

Electromagnetic Compatibility. All retrofitted

equipment must also comply with the relevant

legislation.

In addition, 2-way radio communication and other

equipment with built in radio transmitters (for

example anti-theft alarms, tracking devices)

should only be fitted to the vehicle if they operate

within the listed frequency bands and do not

exceed the maximum transmission output power

specified below

Frequency Overview

Maximum Output

Power (W)

Frequency (MHz)

501-54

5068-87.5

50142-176

50220-225

50380-512

10806-940

101200-1400

101710-1885

101885-2025

1.6.1 Antenna Location

The antenna can be placed on the roof of the

vehicle with the exception of cellular phone car

kits which transmit power below 2W. Such low

power devices may also be installed at the

bottom of the A-pillar behind the trim or on the

front windscreen.

Installation must be performed by suitably

qualified personnel in accordance with the

equipment manufacturer's installation instructions

and comply with the ISO technical specification

ISO/TS 21609: Road Vehicles - Electromagnetic

Compatibility guidelines for the installation of after

market radio frequency transmitting equipment.

In addition, the following guidelines must be

followed during installation:

•Do not mount any transceiver, microphones,

speakers or any other item in the deployment

path of the airbag system.

•Do not attach antenna cables to any part of

the original vehicle wiring or fuel and brake

pipes.

•Antenna and power cables must be a

minimum of 100mm from any electronic

modules and airbags.

•Make sure that any additional power feed is

taken directly from the SVO fuse box (when

available) or a recommended connection

point.

•Power and ground cables should be of higher

current capacity that the protection fuse.

Ground feed must be taken directly to the

battery.

Post installation checks must be made for

disturbances from and to all electrical equipment

in the vehicle both in the standby and transmit

modes. Checks should be carried out with the

ignition ON, engine running and be followed by a

road test at various speeds.

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

1 General Information

24

Page 25 of 234

1.7 Vehicle Duty Cycle Guidelines

It is necessary to take into account the customer

usage profile and the anticipated vehicle duty

cycles of the modified vehicle in order to choose

the appropriate specification of the base vehicle.

It is necessary to select the appropriate drive,

engine, gear ratio, gross vehicle mass, gross train

mass, axle plates and payloads of the base

vehicle to match the customer requirements.

Where possible make sure that the base vehicle

is ordered with any necessary plant fit options.

NOTE: For further information please contact

your local National Sales Company

representative, or Local Ford Dealer. If they are

unable to help you then please contact the

Vehicle Converter Advisory Service at

[email protected].

A high numeric gear ratio is recommended for

vehicles with customer requirements for:

•high payload

•trailer tow

•frequent stop-and-go cycles

•high altitude and gradients

•terrain conditions such as found on building

and construction sites

Rear wheel drive is recommended for high

traction in combination with a high trailer weight

Front wheel drive is recommended for low

conversion weight

1.7.1 Conversion Affect on Fuel

Economy and Performance

Any conversion may effect the fuel consumption

and performance depending on the

aerodynamics and the weight added by the

conversion. The published information for fuel

consumption and performance of the base

vehicle therefore may not be valid. It is advisable

to control the weight, but without deteriorating

other vehicle attributes and functions (especially

those related to safety and durability).

1.7.2 Vehicle Ride and Handling

Attributes

CAUTION: Do not exceed the axle

plate, gross vehicle mass, trailer

plate and gross trailer mass limits.

Due to the displacement of the center of gravity

occurred by the conversion the ride and handling

attributes may be different to the base vehicle.

NOTE: This vehicle should be evaluated for safe

operation prior to sale

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

1 General Information

25

Page 26 of 234

1.8 End of Life Vehicle (ELV) Directive

The EU End-of-Life Vehicle (ELV) directive

requires that environmental and recycling aspects

are integrated in the development process of

new components and vehicles. This includes

requirements with aspect to:

•The overall recyclability (85%) / recoverability

(95%) of vehicles.

•Limited use of hazardous substances including

the elimination of prohibited substances such

as lead, hexavalent chromium cadmium and

mercury).

•Publication of dismantling information.

•Parts Marking according to the corresponding

ISO Standards: ISO 1043-1, 1043-2 and 11469

for plastics and ISO 1629 for rubber materials.

•Increasing use of recycled materials.

•Producers meet all, or a significant part of, the

costs to take back End-of-Life Vehicles

In addition to the requirements resulting from the

End-of-Life directive other environmental targets

should be taken into consideration such as:

•minimizing costs and environmental burden

along the product life-cycle.

•Maximizing use of renewable materials e.g.

natural fibres.

•minimizing the presence of substances

impacting vehicle interior air quality / clean

compartment or allergenic reactions (please

refer to 'Technischer Überwachungsverein

TÜV TOXPROOF). This refers to aspects like

smell, fogging, toxicity and allergy coming from

material in the interior.

•eliminate use of prohibited substances which

are listed in the Global Automotive Declarable

Substance List (GADSL) at

http://www.gadsl.org.

For continued legal compliance and

environmental performance of all Ford products

it is essential that any conversion of the vehicles

is in compliance with the requirements listed

above.

This is not a complete list of all legal requirements

to be met by every converted vehicle.

NOTE: For further information please contact

your local National Sales Company representative,

or Local Ford Dealer. If they are unable to help

you then please contact the Vehicle Converter

Advisory Service at [email protected].

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

1 General Information

26

Page 27 of 234

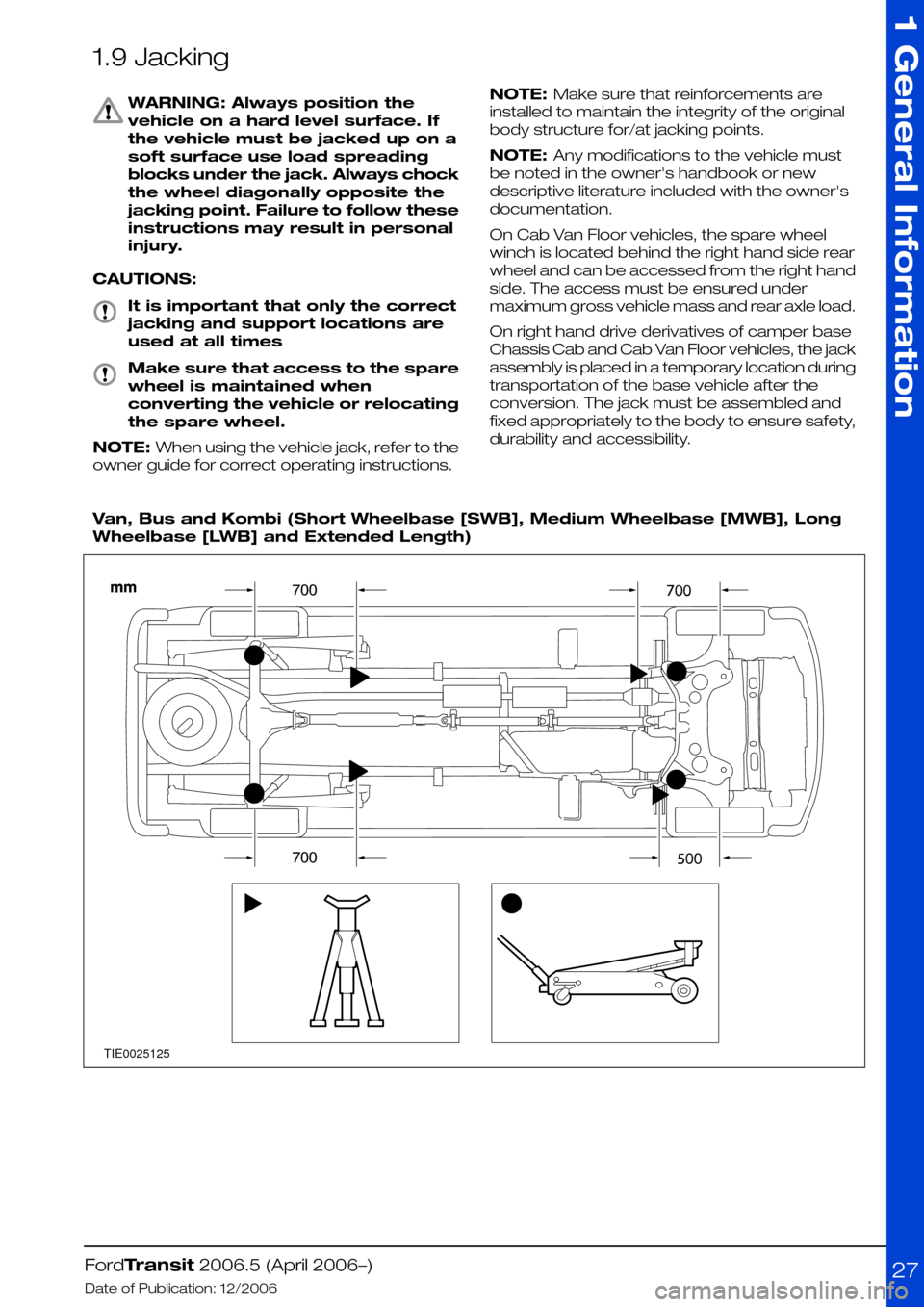

1.9 Jacking

WARNING: Always position the

vehicle on a hard level surface. If

the vehicle must be jacked up on a

soft surface use load spreading

blocks under the jack. Always chock

the wheel diagonally opposite the

jacking point. Failure to follow these

instructions may result in personal

injury.

CAUTIONS:

It is important that only the correct

jacking and support locations are

used at all times

Make sure that access to the spare

wheel is maintained when

converting the vehicle or relocating

the spare wheel.

NOTE: When using the vehicle jack, refer to the

owner guide for correct operating instructions.

NOTE: Make sure that reinforcements are

installed to maintain the integrity of the original

body structure for/at jacking points.

NOTE: Any modifications to the vehicle must

be noted in the owner's handbook or new

descriptive literature included with the owner's

documentation.

On Cab Van Floor vehicles, the spare wheel

winch is located behind the right hand side rear

wheel and can be accessed from the right hand

side. The access must be ensured under

maximum gross vehicle mass and rear axle load.

On right hand drive derivatives of camper base

Chassis Cab and Cab Van Floor vehicles, the jack

assembly is placed in a temporary location during

transportation of the base vehicle after the

conversion. The jack must be assembled and

fixed appropriately to the body to ensure safety,

durability and accessibility.

Van, Bus and Kombi (Short Wheelbase [SWB], Medium Wheelbase [MWB], Long

Wheelbase [LWB] and Extended Length)

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

1 General Information

27TIE0025125

Page 28 of 234

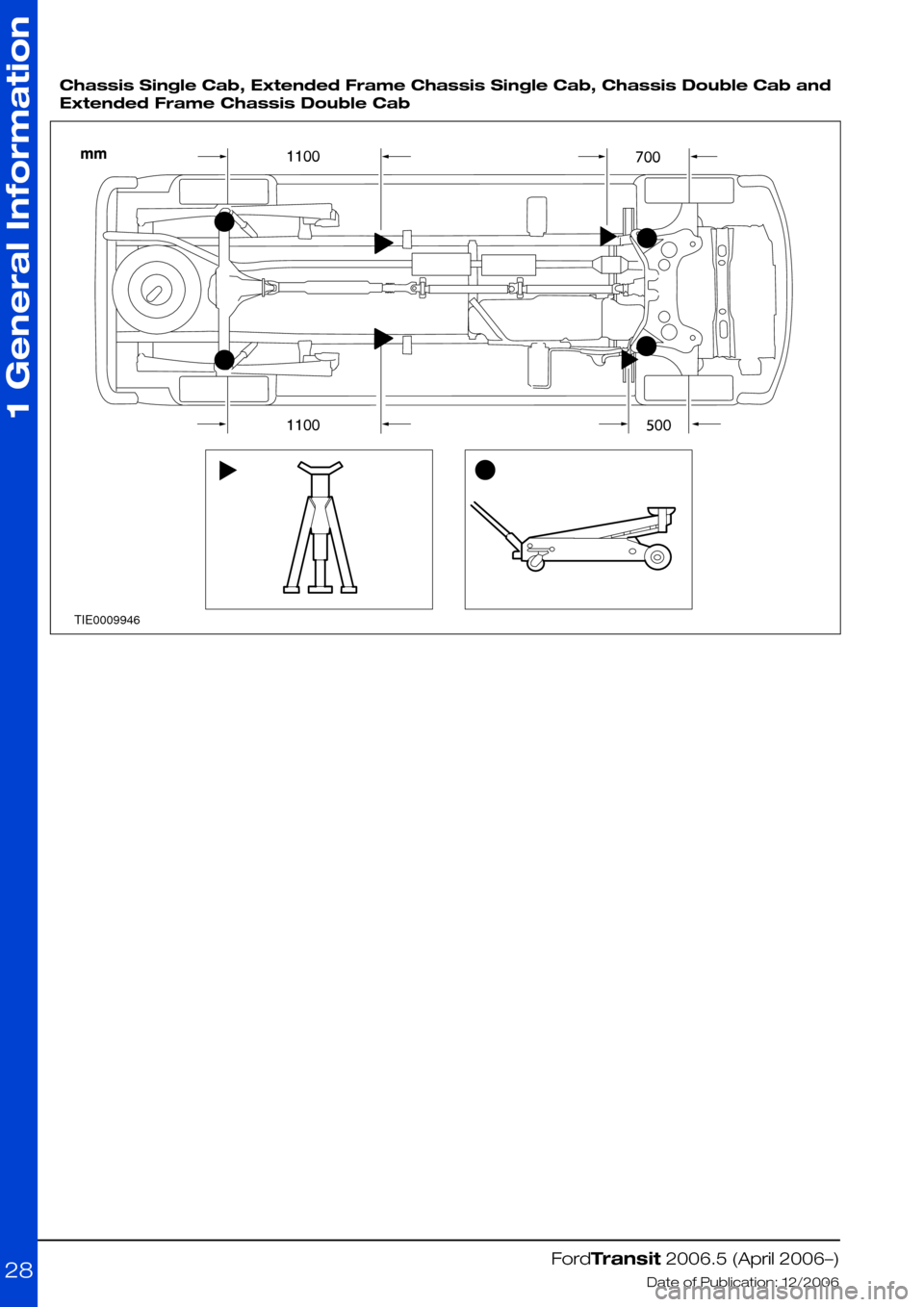

Chassis Single Cab, Extended Frame Chassis Single Cab, Chassis Double Cab and

Extended Frame Chassis Double Cab

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

1 General Information

28TIE0009946

Page 29 of 234

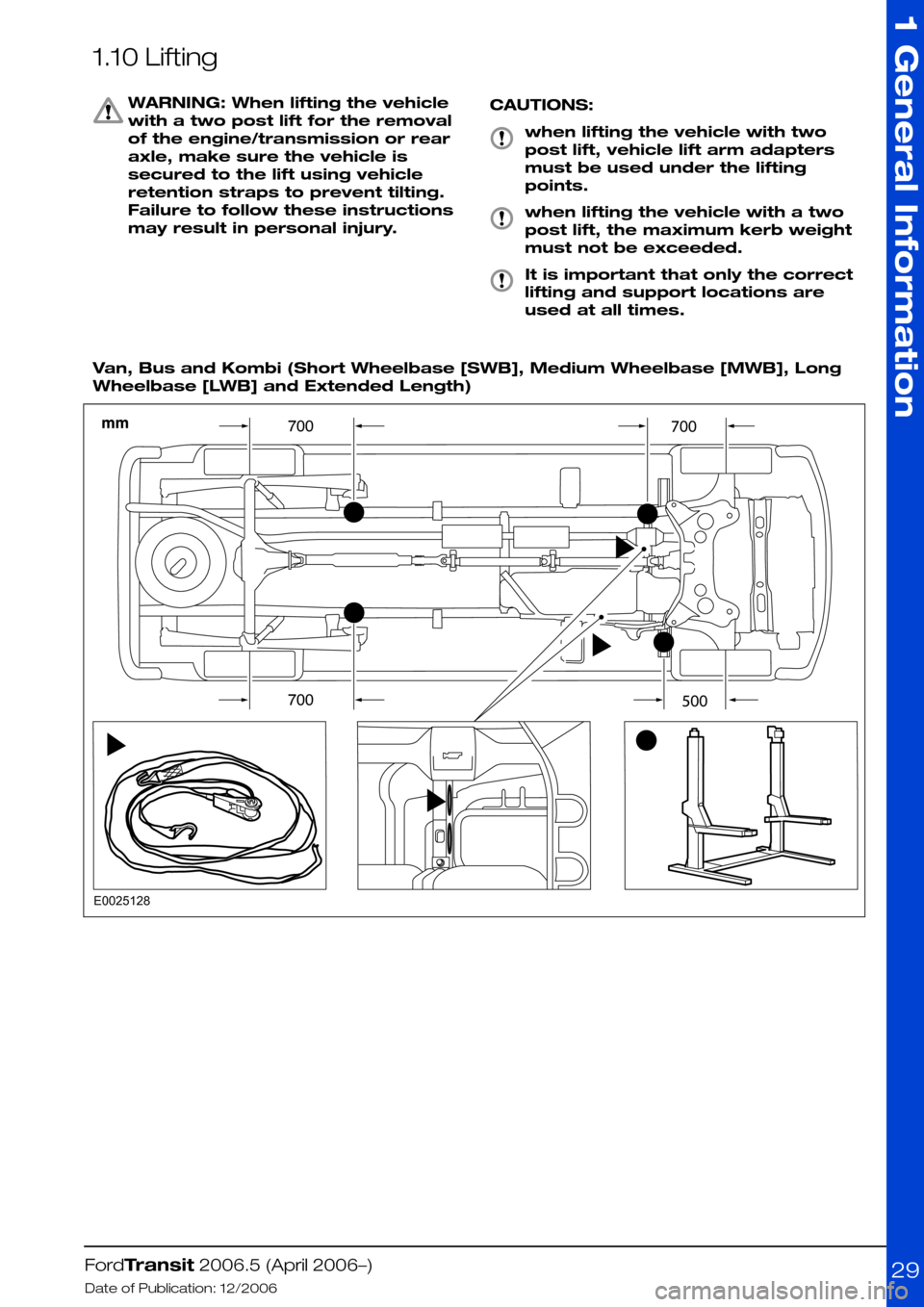

1.10 Lifting

WARNING: When lifting the vehicle

with a two post lift for the removal

of the engine/transmission or rear

axle, make sure the vehicle is

secured to the lift using vehicle

retention straps to prevent tilting.

Failure to follow these instructions

may result in personal injury.

CAUTIONS:

when lifting the vehicle with two

post lift, vehicle lift arm adapters

must be used under the lifting

points.

when lifting the vehicle with a two

post lift, the maximum kerb weight

must not be exceeded.

It is important that only the correct

lifting and support locations are

used at all times.

Van, Bus and Kombi (Short Wheelbase [SWB], Medium Wheelbase [MWB], Long

Wheelbase [LWB] and Extended Length)

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

1 General Information

29E0025128

Page 30 of 234

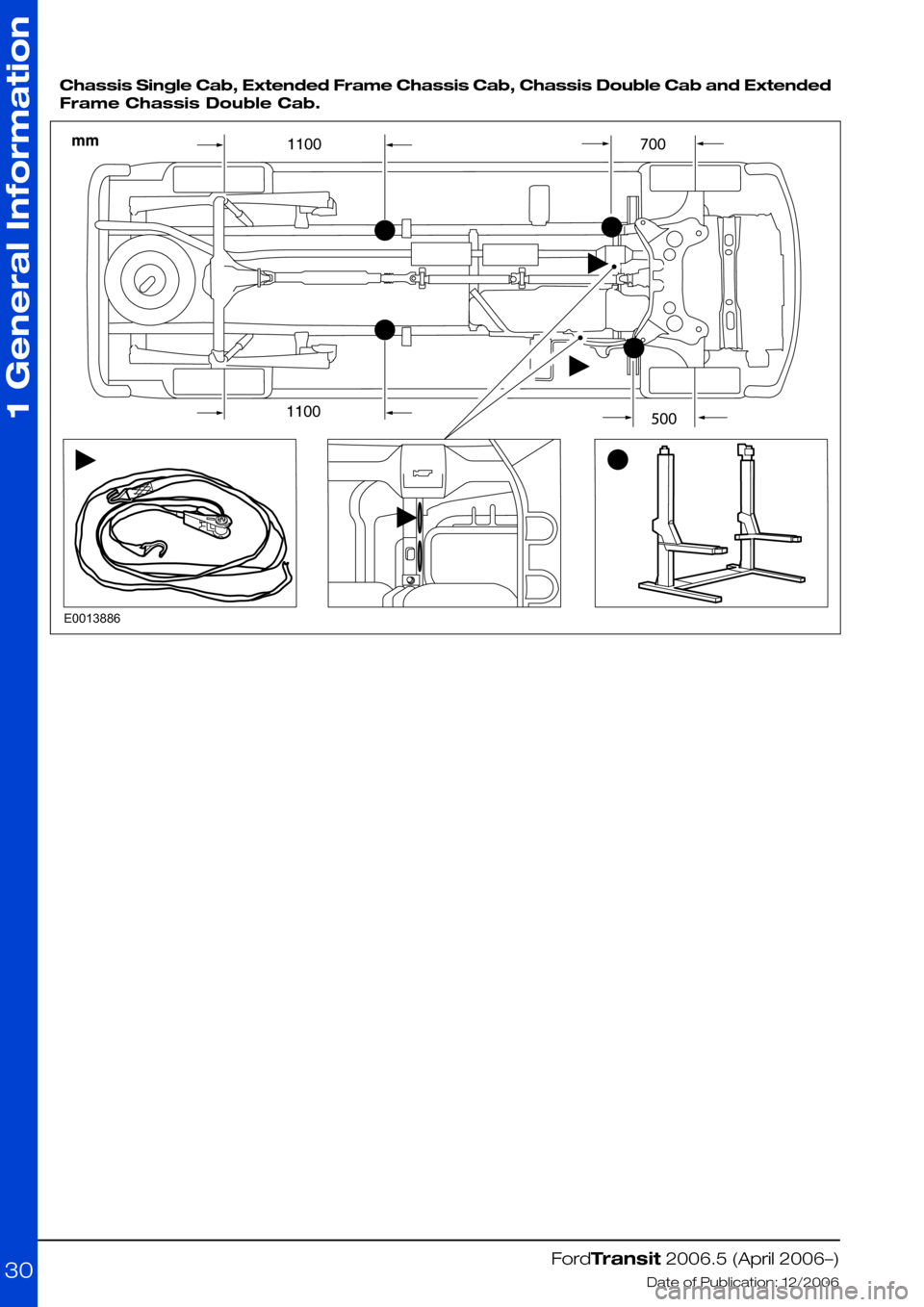

Chassis Single Cab, Extended Frame Chassis Cab, Chassis Double Cab and Extended

Frame Chassis Double Cab.

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

1 General Information

30E0013886