lock FORD TRANSIT CONNECT 2016 2.G Repair Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2016, Model line: TRANSIT CONNECT, Model: FORD TRANSIT CONNECT 2016 2.GPages: 439, PDF Size: 6.96 MB

Page 206 of 439

Set the windshield wipers in the service

position to change the wiper blades. The

windshield wipers return to the starting

position when you switch the ignition on.

Note:

You cannot move the wiper arms to

the service position manually when you

switch the ignition on.

Note: You can use the service position to

provide easier access to the wiper blades

for freeing them from snow and ice.

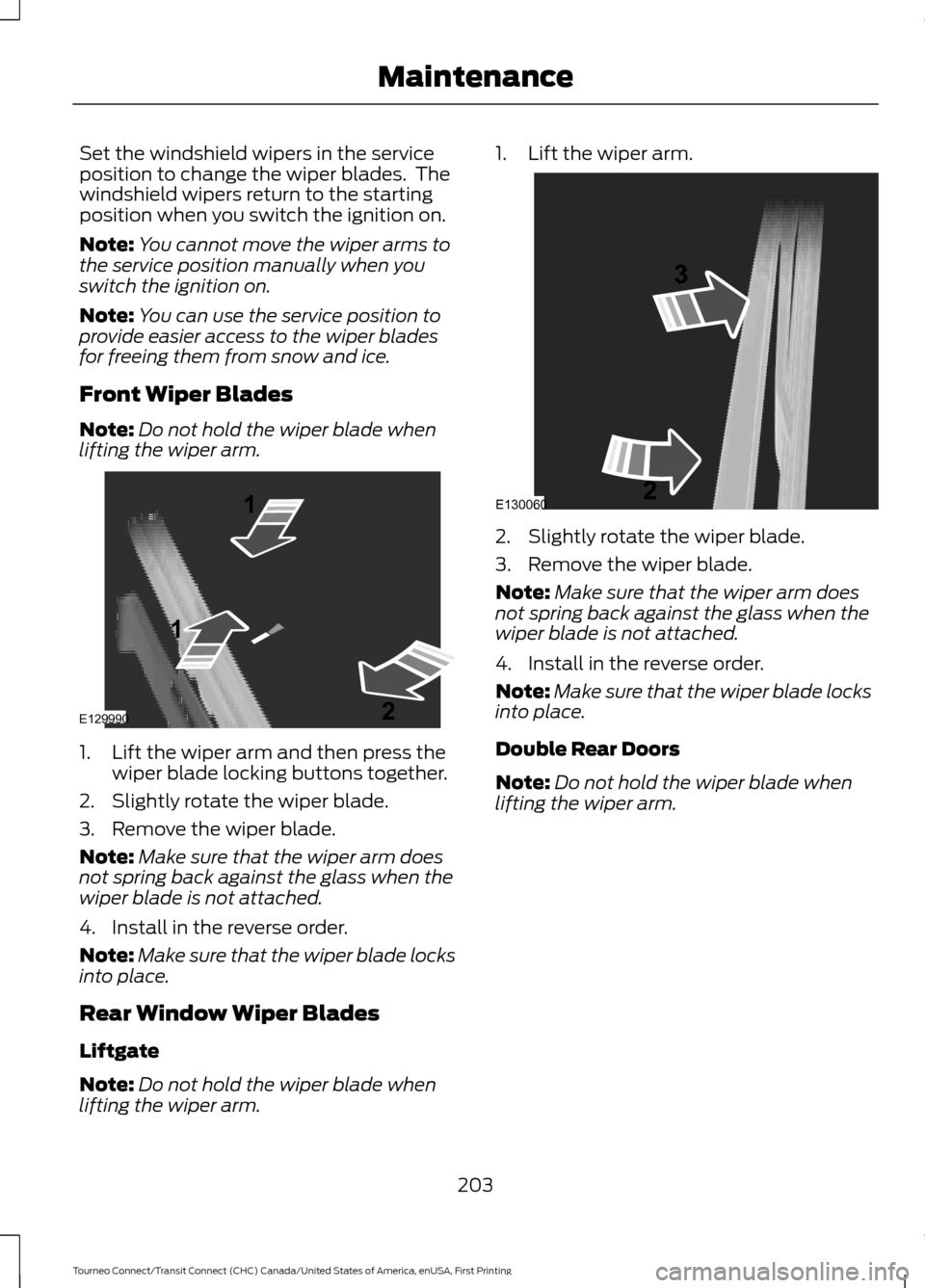

Front Wiper Blades

Note: Do not hold the wiper blade when

lifting the wiper arm. 1. Lift the wiper arm and then press the

wiper blade locking buttons together.

2. Slightly rotate the wiper blade.

3. Remove the wiper blade.

Note: Make sure that the wiper arm does

not spring back against the glass when the

wiper blade is not attached.

4. Install in the reverse order.

Note: Make sure that the wiper blade locks

into place.

Rear Window Wiper Blades

Liftgate

Note: Do not hold the wiper blade when

lifting the wiper arm. 1. Lift the wiper arm.

2. Slightly rotate the wiper blade.

3. Remove the wiper blade.

Note:

Make sure that the wiper arm does

not spring back against the glass when the

wiper blade is not attached.

4. Install in the reverse order.

Note: Make sure that the wiper blade locks

into place.

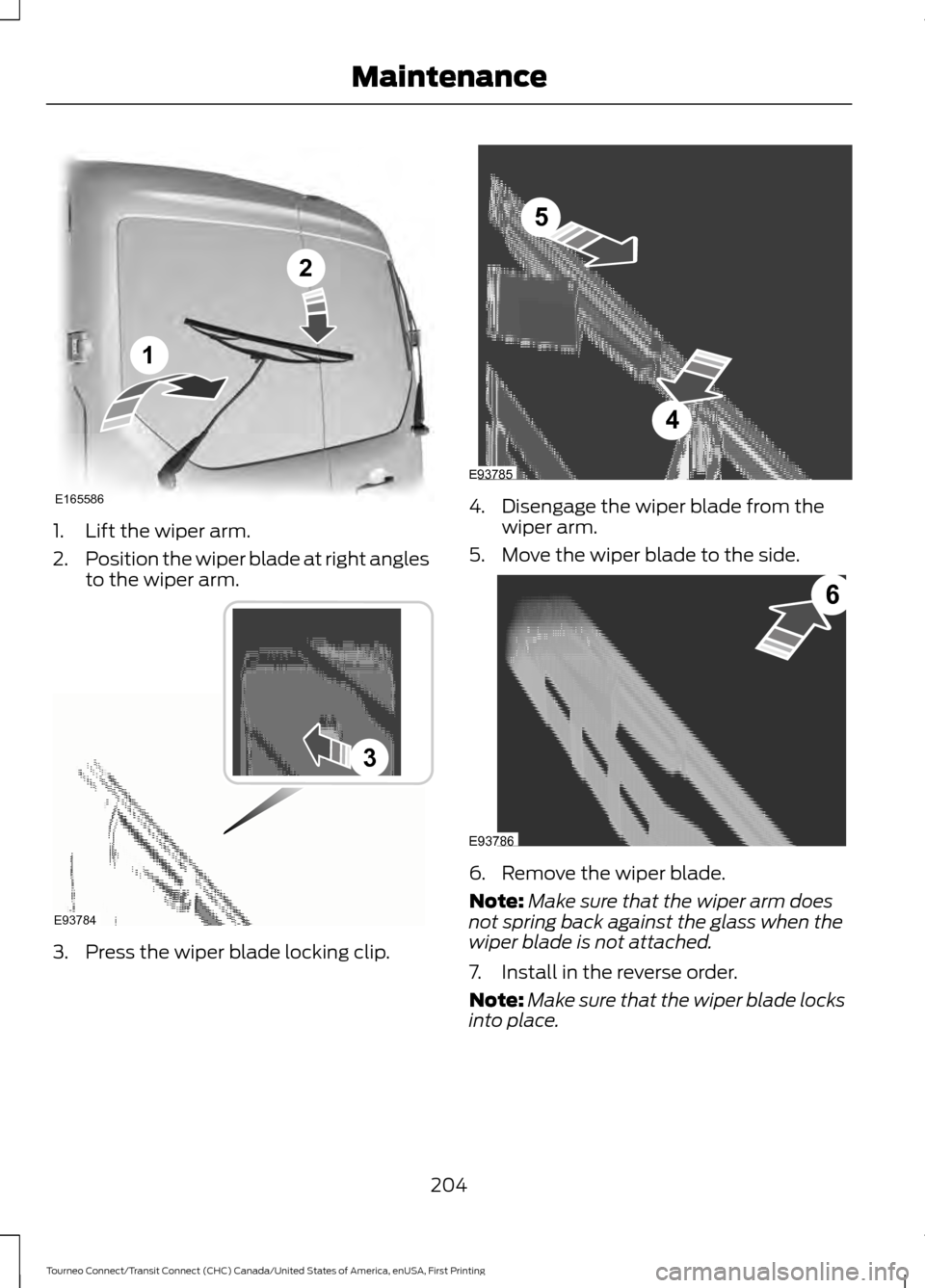

Double Rear Doors

Note: Do not hold the wiper blade when

lifting the wiper arm.

203

Tourneo Connect/Transit Connect (CHC) Canada/United States of America, enUSA, First Printing MaintenanceE129990

1

1 2 E130060

3

2

Page 207 of 439

1. Lift the wiper arm.

2.

Position the wiper blade at right angles

to the wiper arm. 3. Press the wiper blade locking clip. 4. Disengage the wiper blade from the

wiper arm.

5. Move the wiper blade to the side. 6. Remove the wiper blade.

Note:

Make sure that the wiper arm does

not spring back against the glass when the

wiper blade is not attached.

7. Install in the reverse order.

Note: Make sure that the wiper blade locks

into place.

204

Tourneo Connect/Transit Connect (CHC) Canada/United States of America, enUSA, First Printing MaintenanceE165586

1

2 E93784

3 5

4

E93785 6

E93786

Page 208 of 439

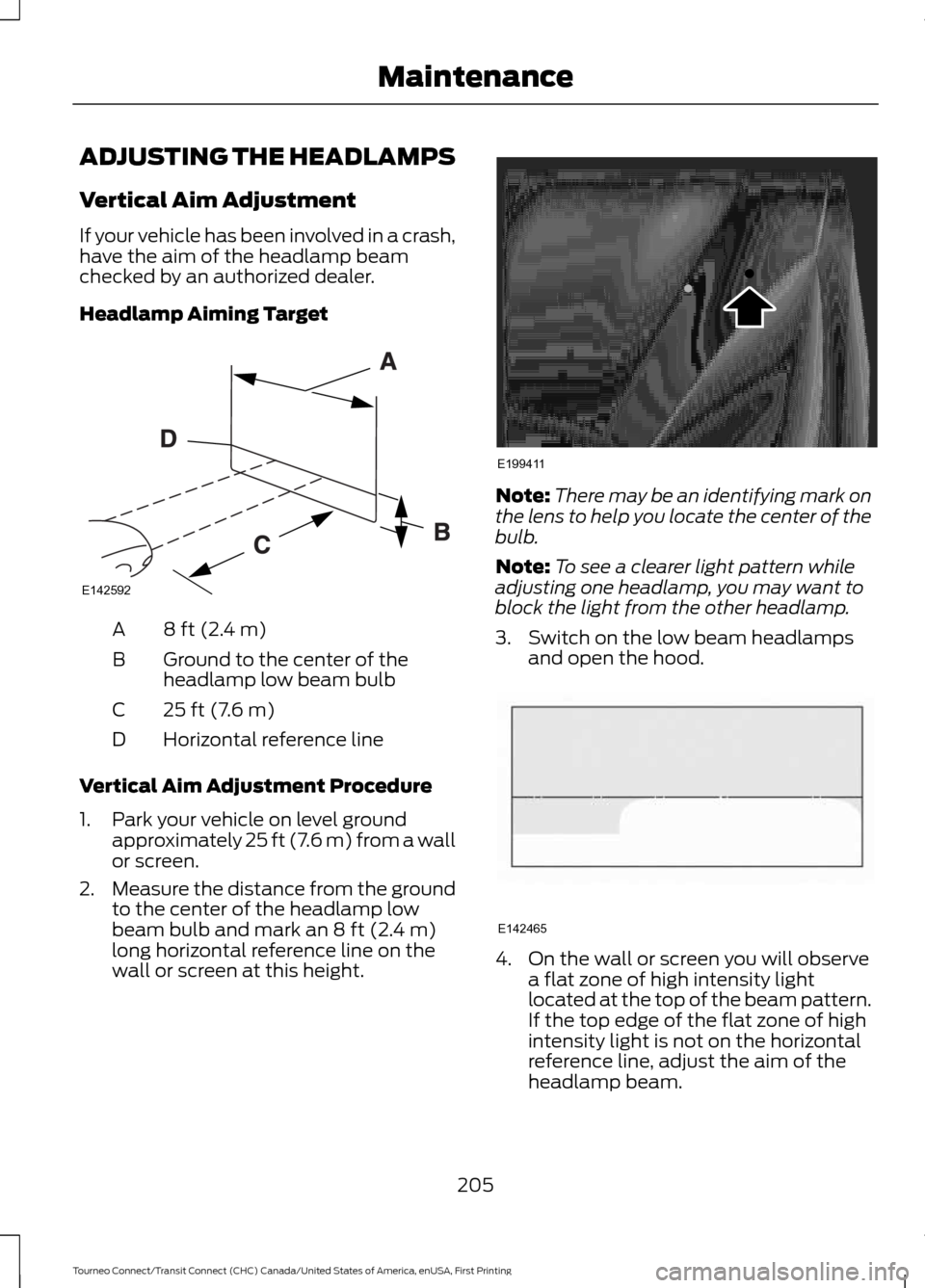

ADJUSTING THE HEADLAMPS

Vertical Aim Adjustment

If your vehicle has been involved in a crash,

have the aim of the headlamp beam

checked by an authorized dealer.

Headlamp Aiming Target

8 ft (2.4 m)

A

Ground to the center of the

headlamp low beam bulb

B

25 ft (7.6 m)

C

Horizontal reference line

D

Vertical Aim Adjustment Procedure

1. Park your vehicle on level ground approximately 25 ft (7.6 m) from a wall

or screen.

2. Measure the distance from the ground

to the center of the headlamp low

beam bulb and mark an

8 ft (2.4 m)

long horizontal reference line on the

wall or screen at this height. Note:

There may be an identifying mark on

the lens to help you locate the center of the

bulb.

Note: To see a clearer light pattern while

adjusting one headlamp, you may want to

block the light from the other headlamp.

3. Switch on the low beam headlamps and open the hood. 4. On the wall or screen you will observe

a flat zone of high intensity light

located at the top of the beam pattern.

If the top edge of the flat zone of high

intensity light is not on the horizontal

reference line, adjust the aim of the

headlamp beam.

205

Tourneo Connect/Transit Connect (CHC) Canada/United States of America, enUSA, First Printing MaintenanceE142592 E199411 E142465

Page 209 of 439

5. Locate the vertical adjuster on each

headlamp. Use a suitable tool, for

example a screwdriver or hexagonal

socket, to turn the adjuster clockwise

or counterclockwise to adjust the

vertical aim of the headlamp. The

horizontal edge of the brighter light

should touch the horizontal reference

line.

6. Close the hood and switch off the lamps.

Horizontal Aim Adjustment

The horizontal aim of the headlamp beam

on your vehicle is not adjustable.

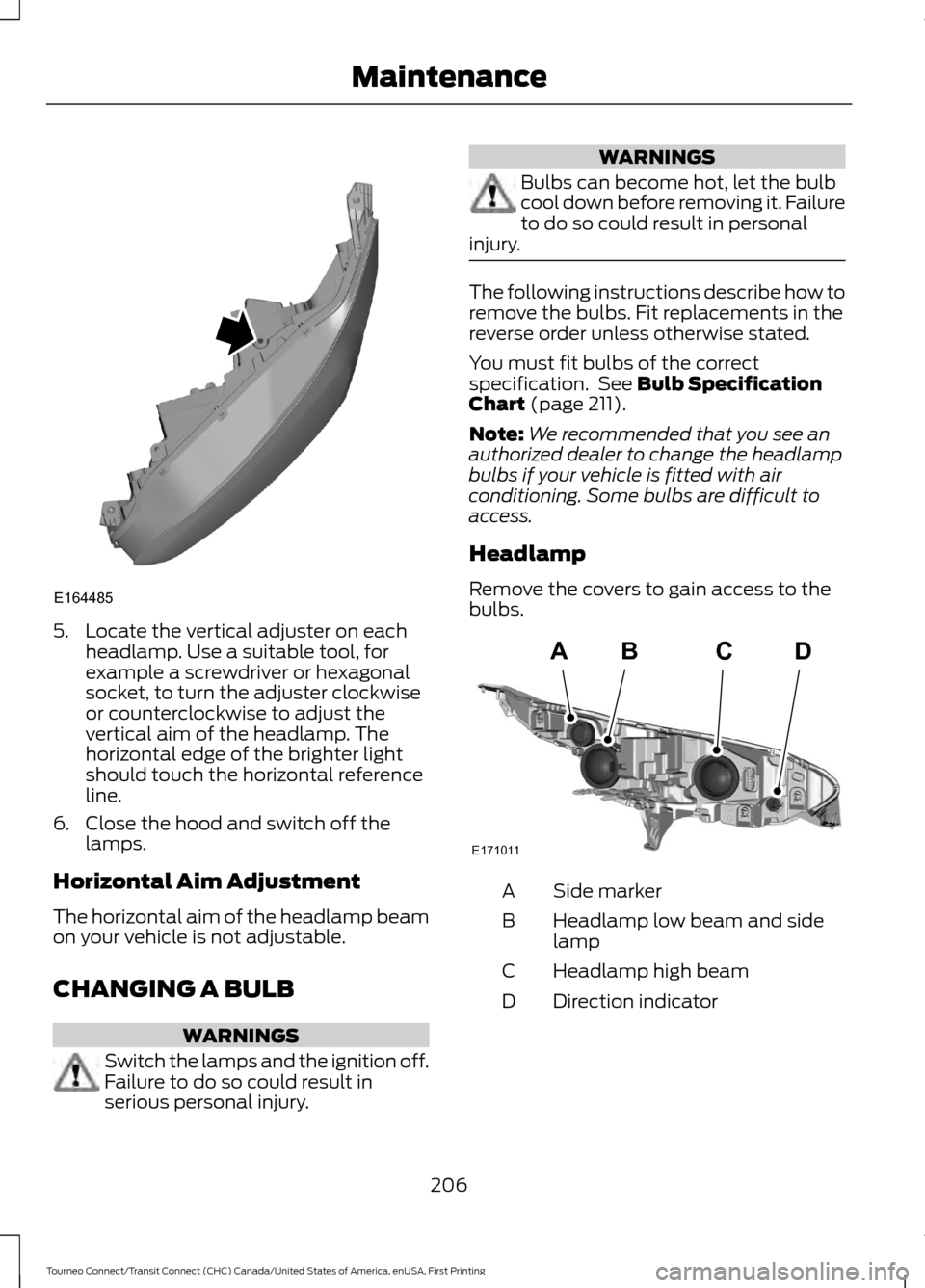

CHANGING A BULB WARNINGS

Switch the lamps and the ignition off.

Failure to do so could result in

serious personal injury. WARNINGS

Bulbs can become hot, let the bulb

cool down before removing it. Failure

to do so could result in personal

injury. The following instructions describe how to

remove the bulbs. Fit replacements in the

reverse order unless otherwise stated.

You must fit bulbs of the correct

specification. See Bulb Specification

Chart (page 211).

Note: We recommended that you see an

authorized dealer to change the headlamp

bulbs if your vehicle is fitted with air

conditioning. Some bulbs are difficult to

access.

Headlamp

Remove the covers to gain access to the

bulbs. Side marker

A

Headlamp low beam and side

lamp

B

Headlamp high beam

C

Direction indicator

D

206

Tourneo Connect/Transit Connect (CHC) Canada/United States of America, enUSA, First Printing MaintenanceE164485 ABCD

E171011

Page 210 of 439

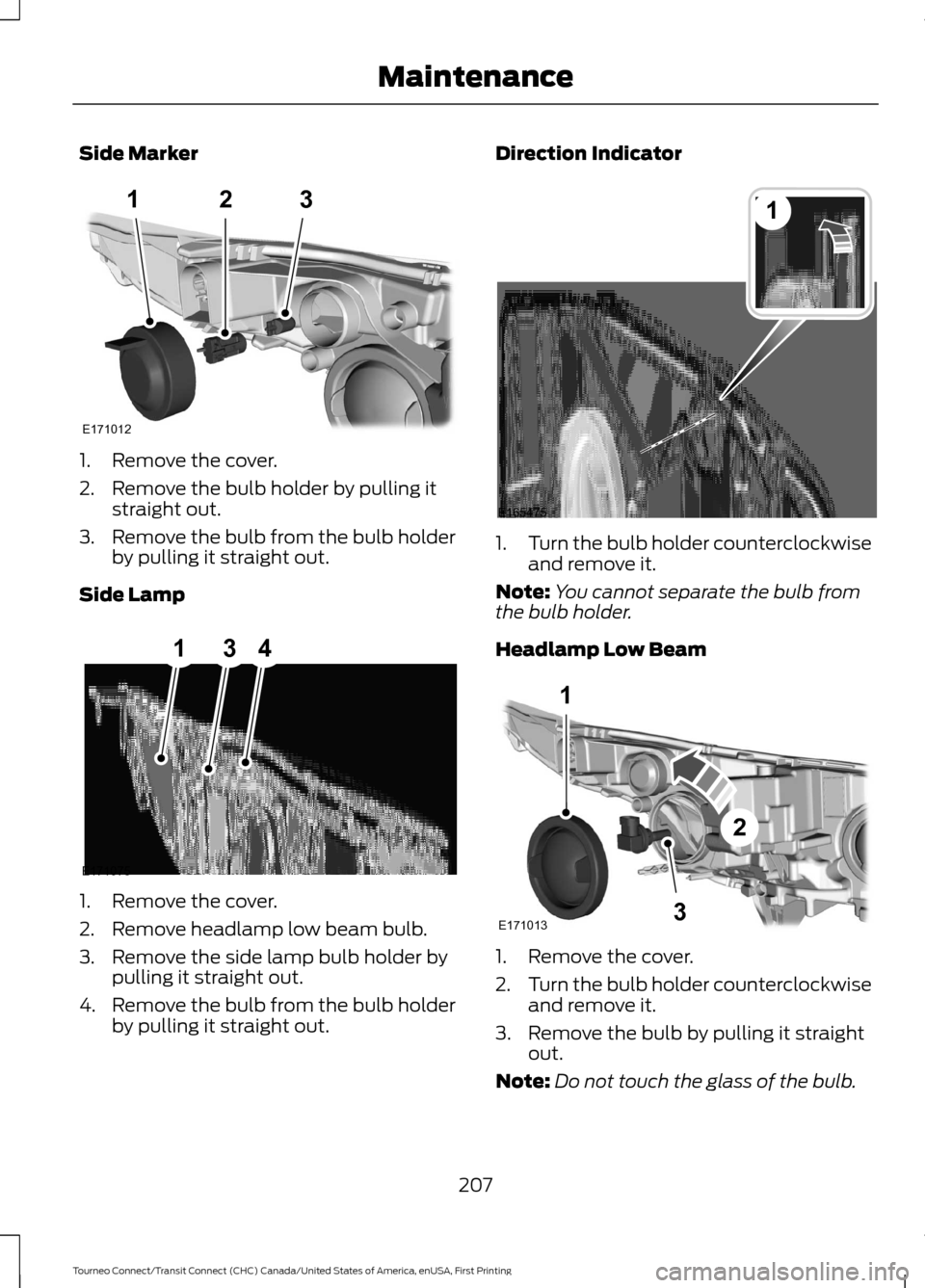

Side Marker

1. Remove the cover.

2. Remove the bulb holder by pulling it

straight out.

3. Remove the bulb from the bulb holder

by pulling it straight out.

Side Lamp 1. Remove the cover.

2. Remove headlamp low beam bulb.

3. Remove the side lamp bulb holder by

pulling it straight out.

4. Remove the bulb from the bulb holder

by pulling it straight out. Direction Indicator

1.

Turn the bulb holder counterclockwise

and remove it.

Note: You cannot separate the bulb from

the bulb holder.

Headlamp Low Beam 1. Remove the cover.

2.

Turn the bulb holder counterclockwise

and remove it.

3. Remove the bulb by pulling it straight out.

Note: Do not touch the glass of the bulb.

207

Tourneo Connect/Transit Connect (CHC) Canada/United States of America, enUSA, First Printing Maintenance123

E171012 E171075

314 1

E165475 1

3

2

E171013

Page 211 of 439

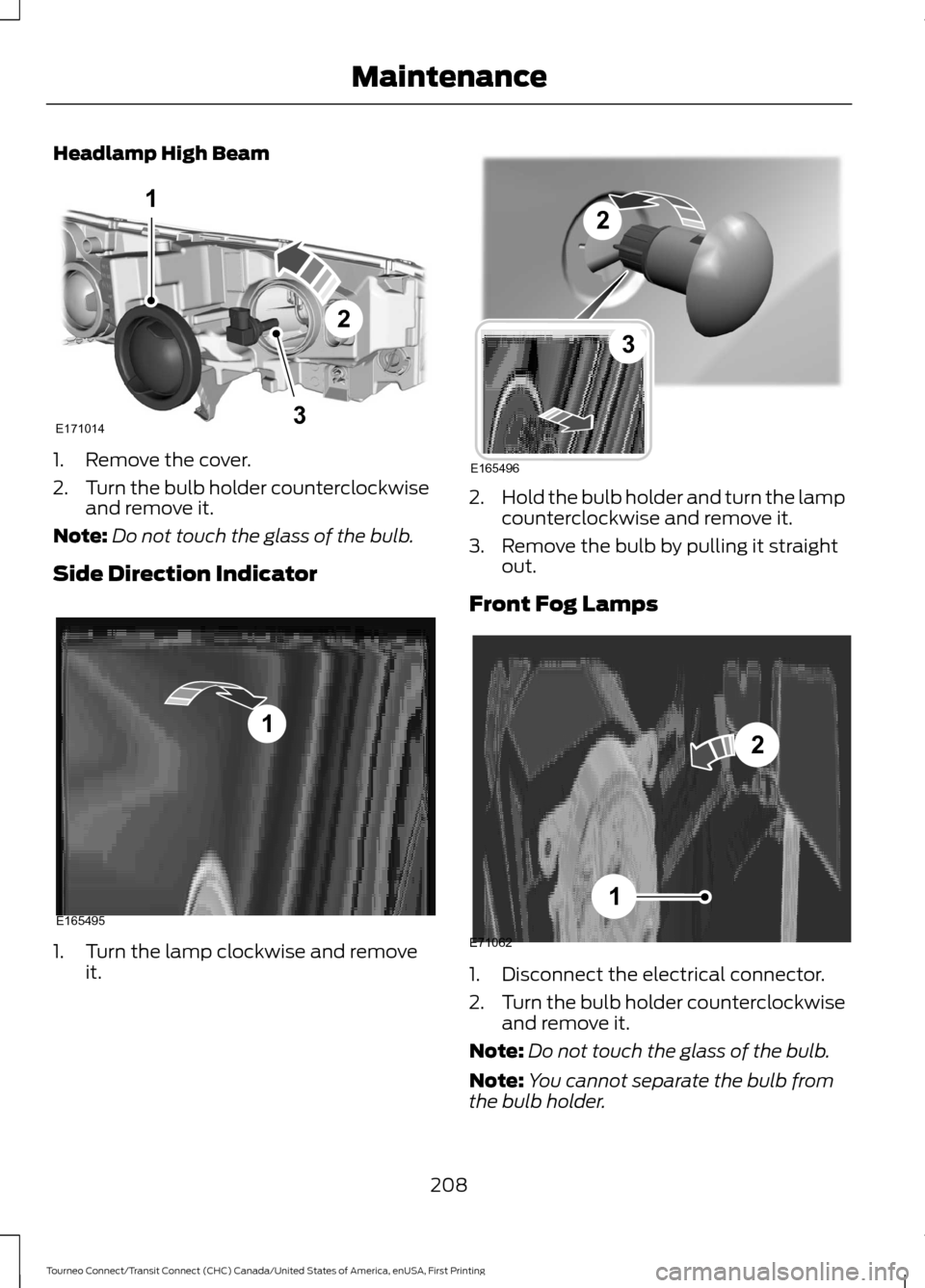

Headlamp High Beam

1. Remove the cover.

2.

Turn the bulb holder counterclockwise

and remove it.

Note: Do not touch the glass of the bulb.

Side Direction Indicator 1. Turn the lamp clockwise and remove

it. 2.

Hold the bulb holder and turn the lamp

counterclockwise and remove it.

3. Remove the bulb by pulling it straight out.

Front Fog Lamps 1. Disconnect the electrical connector.

2.

Turn the bulb holder counterclockwise

and remove it.

Note: Do not touch the glass of the bulb.

Note: You cannot separate the bulb from

the bulb holder.

208

Tourneo Connect/Transit Connect (CHC) Canada/United States of America, enUSA, First Printing Maintenance1

3

2

E171014 1

E165495 E165496

2

3 E71062

1

2

Page 212 of 439

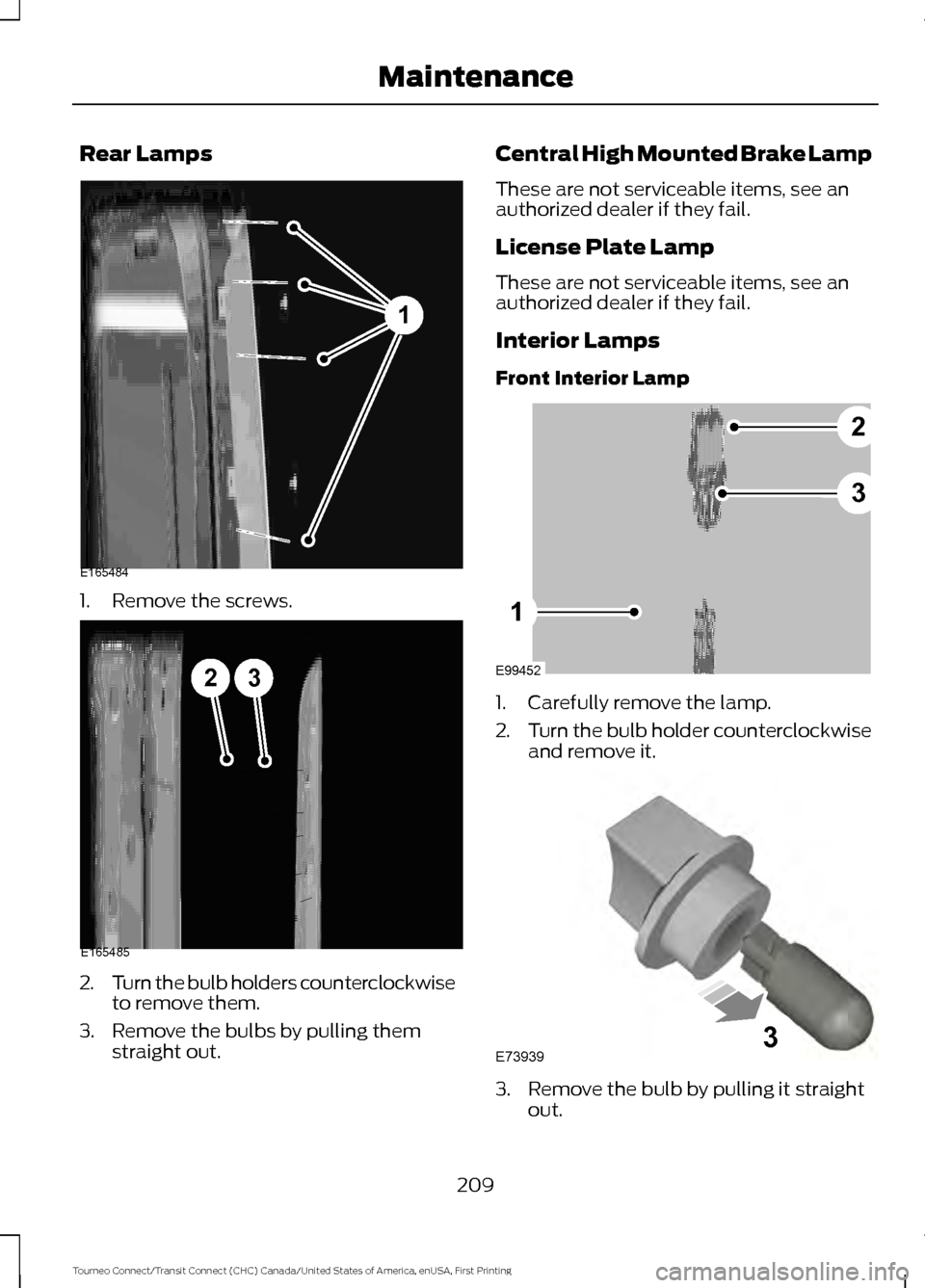

Rear Lamps

1. Remove the screws.

2.

Turn the bulb holders counterclockwise

to remove them.

3. Remove the bulbs by pulling them straight out. Central High Mounted Brake Lamp

These are not serviceable items, see an

authorized dealer if they fail.

License Plate Lamp

These are not serviceable items, see an

authorized dealer if they fail.

Interior Lamps

Front Interior Lamp

1. Carefully remove the lamp.

2.

Turn the bulb holder counterclockwise

and remove it. 3. Remove the bulb by pulling it straight

out.

209

Tourneo Connect/Transit Connect (CHC) Canada/United States of America, enUSA, First Printing Maintenance1

E165484 23

E165485 E99452

2

3

1 E739393

Page 213 of 439

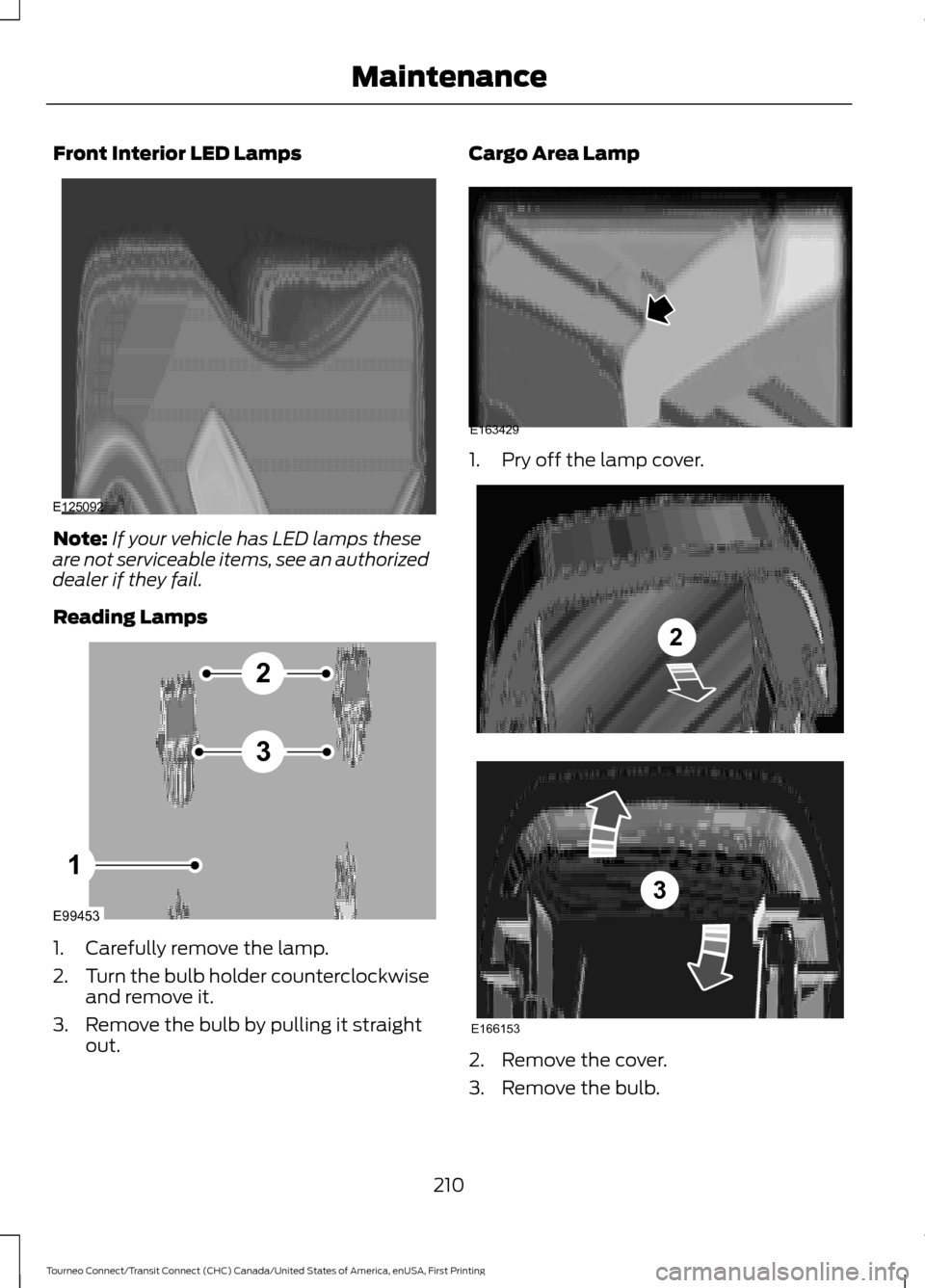

Front Interior LED Lamps

Note:

If your vehicle has LED lamps these

are not serviceable items, see an authorized

dealer if they fail.

Reading Lamps 1. Carefully remove the lamp.

2.

Turn the bulb holder counterclockwise

and remove it.

3. Remove the bulb by pulling it straight out. Cargo Area Lamp

1. Pry off the lamp cover.

2. Remove the cover.

3. Remove the bulb.

210

Tourneo Connect/Transit Connect (CHC) Canada/United States of America, enUSA, First Printing MaintenanceE125092 E99453

2

3

1 E163429 E166153

2

3

Page 218 of 439

Exterior Plastic Parts

For routine cleaning we recommend

Motorcraft Detail Wash. If tar or grease

spots are present, we recommend

Motorcraft Bug and Tar Remover.

Stripes or Graphics (If Equipped)

Do not use a commercial or high-pressure

sprayer on the surface or edge of stripes

and graphics. This can damage them and

cause the edges to peel away from the

vehicle surface.

Underbody

Flush the complete underside of your

vehicle frequently. Keep body and door

drain holes free of debris or foreign

material.

WAXING

Regular waxing is necessary to protect your

car's paint from the elements. We

recommend that you wash and wax the

painted surface once or twice a year.

When washing and waxing, park your

vehicle in a shaded area out of direct

sunlight. Always wash your vehicle before

applying wax.

• Use a quality wax that does not contain

abrasives.

• Follow the manufacturer ’s instructions

to apply and remove the wax.

• Apply a small amount of wax in a

back-and-forth motion, not in circles. •

Do not allow wax to come in contact

with any non-body (low-gloss black)

colored trim. The wax will discolor or

stain the parts over time.

•Roof racks.

• Bumpers.

• Grained door handles.

• Side moldings.

• Mirror housings.

• Windshield cowl area.

• Do not apply wax to glass areas.

• After waxing, your car's paint should

feel smooth, and be free of streaks and

smudges.

CLEANING THE ENGINE

Engines are more efficient when they are

clean because grease and dirt buildup keep

the engine warmer than normal.

When washing:

• Take care when using a power washer

to clean the engine. The high-pressure

fluid could penetrate the sealed parts

and cause damage.

• Do not spray a hot engine with cold

water to avoid cracking the engine

block or other engine components.

• Spray Motorcraft Engine Shampoo and

Degreaser on all parts that require

cleaning and pressure rinse clean. In

Canada, use Motorcraft Engine

Shampoo.

• Never wash or rinse the engine while it

is hot or running; water in the running

engine may cause internal damage.

215

Tourneo Connect/Transit Connect (CHC) Canada/United States of America, enUSA, First Printing Vehicle Care

Page 245 of 439

Carrying Out the System Reset

Procedure

Read the entire procedure before carrying

out a system reset.

1. Drive your vehicle above 20 mph (32

km/h) for at least two minutes and

then park in a safe location where you

can easily get to all four tires and have

access to a tire inflation pump.

2. Switch the ignition off.

3. Switch the ignition on with the engine off.

4. Turn the hazard flashers on then off three times, this must be completed

within 10 seconds. If the reset mode

has been entered successfully, the horn

will chirp once and the system indicator

will flash. If this does not occur, repeat

the procedure from step 2. If after

repeated attempts to enter the reset

mode, the horn does not chirp and the

system indicator does not flash, have

your vehicle checked by an authorized

dealer as soon as possible.

5. Train the system sensors in the tires using the following reset sequence

starting with the left front tire and

following a clockwise order: Left front,

right front, right rear, left rear.

6. Remove the valve cap from the valve stem on the left front tire. Decrease the

air pressure until the horn chirps.

Note: The single horn chirp confirms that

the sensor identification code has been

learned by your vehicle for this position. If a

double horn chirp is heard, the reset

procedure was unsuccessful and must be

repeated.

7. Remove the valve cap from the valve stem on the right front tire. Decrease

the air pressure until the horn chirps.

8. Remove the valve cap from the valve stem on the right rear tire. Decrease the

air pressure until the horn chirps. 9. Remove the valve cap from the valve

stem on the left rear tire. Decrease the

air pressure until the horn chirps.

Training is complete when the horn

chirps after the last system sensor (left

rear) has been trained and the system

indicator stops flashing.

10. Switch the ignition off. If two short horn chirps are heard, the reset

procedure was unsuccessful and

must be repeated.

Note: If after repeating the procedure two

short horn chirps are heard again, have your

vehicle checked by an authorized dealer as

soon as possible.

11. Set all four tires to the correct pressure See Maintenance (page

193). or the tire inflation pressure label

(located on the edge of driver door or

the B-Pillar).

CHANGING A ROAD WHEEL WARNINGS

The use of tire sealants may damage

your tire pressure monitoring system

and should only be used in roadside

emergencies. If you must use a sealant, the

Ford Tire Mobility Kit sealant should be

used. The tire pressure monitoring system

sensor and valve stem on the wheel must

be replaced by an authorized dealer after

use of the sealant. If the tire pressure monitor sensor

becomes damaged, it will no longer

function.

See Tire Pressure

Monitoring System (page 238). Note:

The tire pressure monitoring system

indicator light will illuminate when the spare

tire is in use. To restore the full function of

the monitoring system, all road wheels

equipped with tire pressure monitoring

sensors must be mounted on the vehicle.

242

Tourneo Connect/Transit Connect (CHC) Canada/United States of America, enUSA, First Printing Wheels and Tires