lock FORD TRANSIT CONNECT 2020 Owners Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2020, Model line: TRANSIT CONNECT, Model: FORD TRANSIT CONNECT 2020Pages: 509, PDF Size: 7.73 MB

Page 295 of 509

2.

Hold the bulb holder and turn the lamp

counterclockwise and remove it.

3. Remove the bulb by pulling it straight out.

Front Fog Lamps 1. Disconnect the electrical connector.

2.

Turn the bulb holder counterclockwise

and remove it.

Note: Do not touch the glass of the bulb.

Note: You cannot separate the bulb from

the bulb holder. Rear Lamps

1. Remove the screws.

2.

Turn the bulb holders counterclockwise

to remove them.

3. Remove the bulbs by pulling them straight out.

291

2020 Transit Connect (CHC) Canada/United States of America, CG3739en enUSA, Edition date: 201903, First-Printing MaintenanceE165496

2

3 E71062

1

2 1

E165484 23

E165485

Page 296 of 509

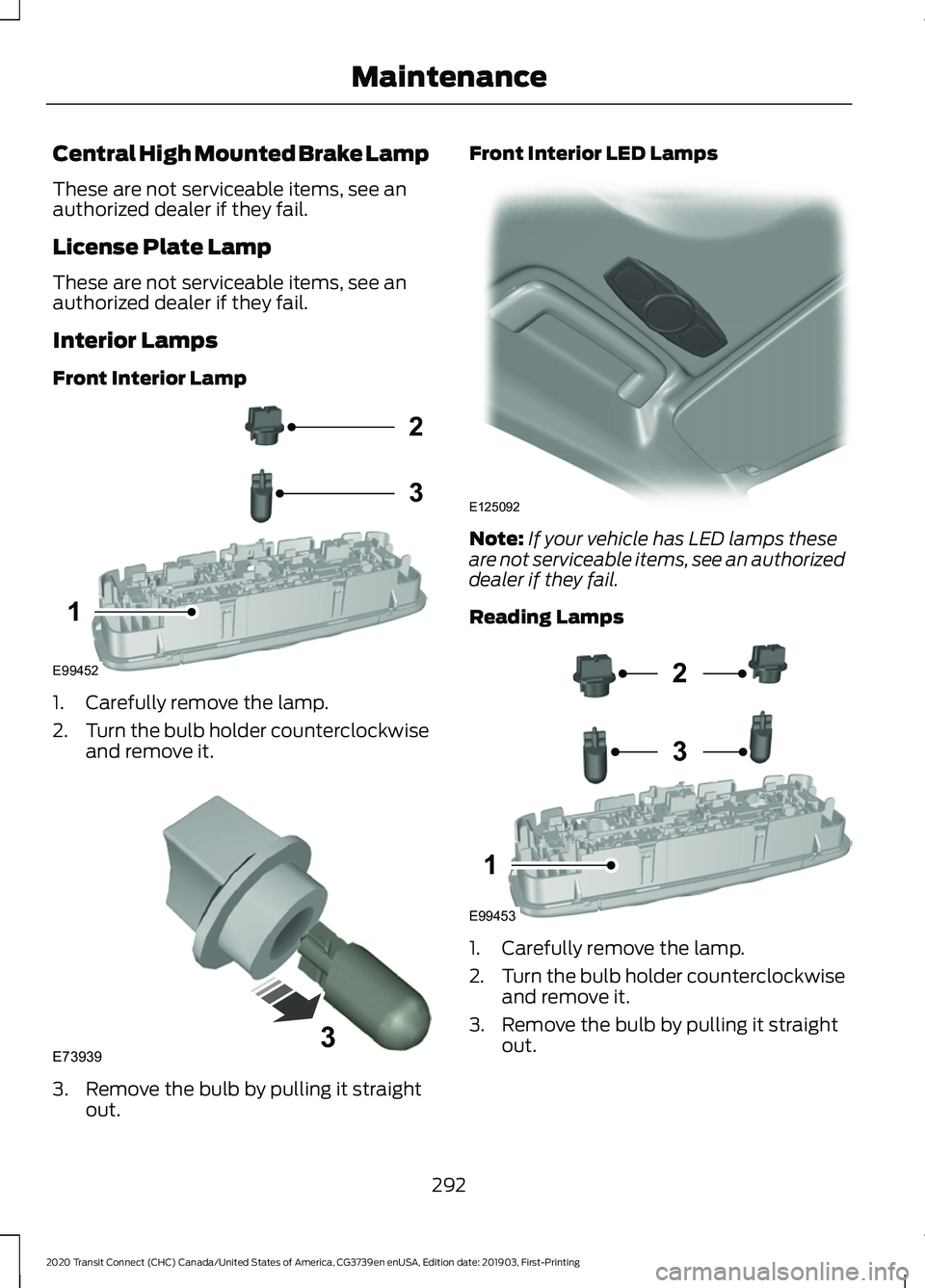

Central High Mounted Brake Lamp

These are not serviceable items, see an

authorized dealer if they fail.

License Plate Lamp

These are not serviceable items, see an

authorized dealer if they fail.

Interior Lamps

Front Interior Lamp

1. Carefully remove the lamp.

2.

Turn the bulb holder counterclockwise

and remove it. 3. Remove the bulb by pulling it straight

out. Front Interior LED Lamps

Note:

If your vehicle has LED lamps these

are not serviceable items, see an authorized

dealer if they fail.

Reading Lamps 1. Carefully remove the lamp.

2.

Turn the bulb holder counterclockwise

and remove it.

3. Remove the bulb by pulling it straight out.

292

2020 Transit Connect (CHC) Canada/United States of America, CG3739en enUSA, Edition date: 201903, First-Printing MaintenanceE99452

2

3

1 E739393 E125092 E99453

2

3

1

Page 312 of 509

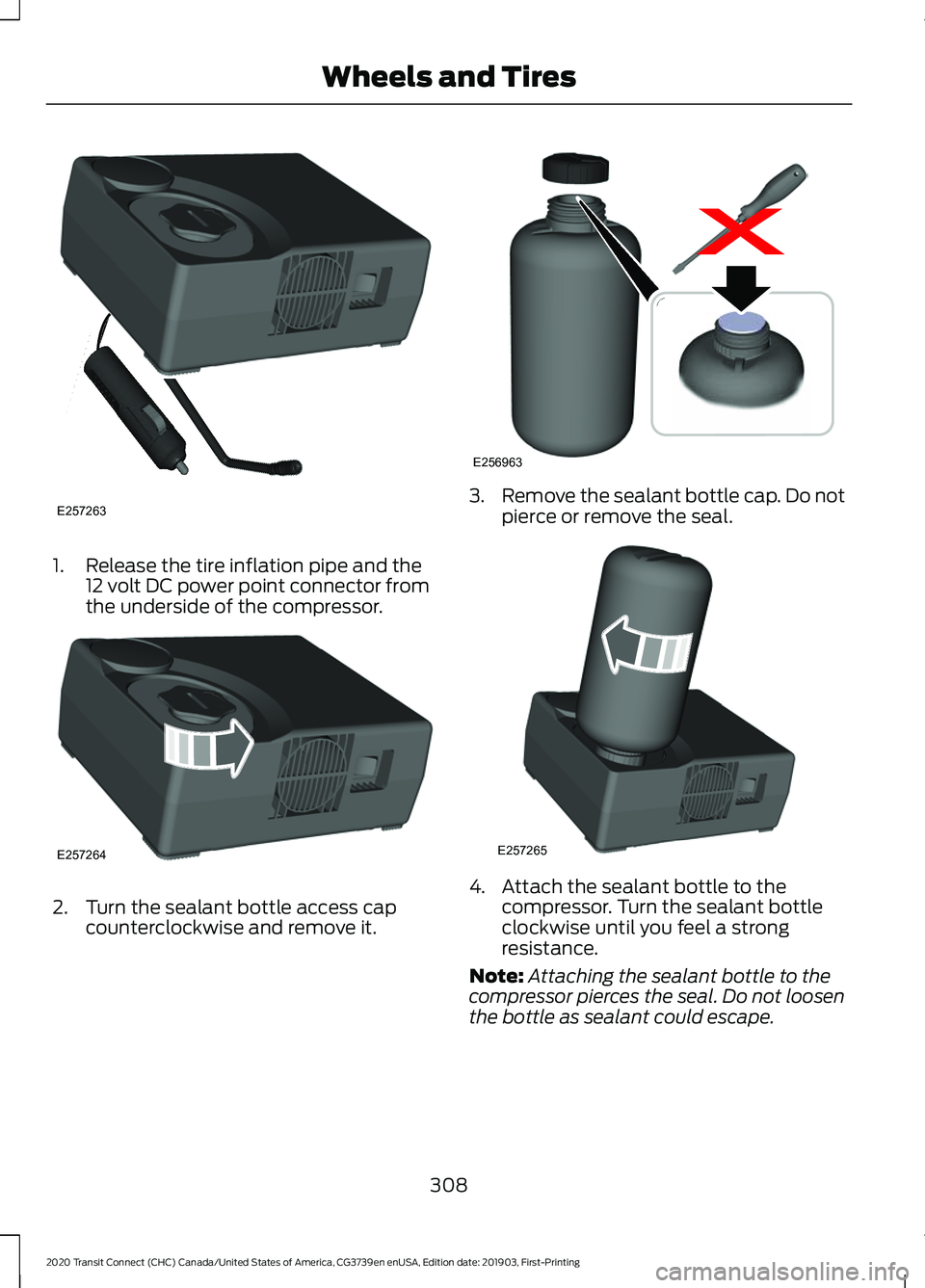

1. Release the tire inflation pipe and the

12 volt DC power point connector from

the underside of the compressor. 2. Turn the sealant bottle access cap

counterclockwise and remove it. 3.

Remove the sealant bottle cap. Do not

pierce or remove the seal. 4. Attach the sealant bottle to the

compressor. Turn the sealant bottle

clockwise until you feel a strong

resistance.

Note: Attaching the sealant bottle to the

compressor pierces the seal. Do not loosen

the bottle as sealant could escape.

308

2020 Transit Connect (CHC) Canada/United States of America, CG3739en enUSA, Edition date: 201903, First-Printing Wheels and TiresE257263 E257264 x

E256963 E257265

Page 330 of 509

Vehicles with Stability Control

When stability control is on, your vehicle

may exhibit some unusual driving

characteristics. To reduce this, switch

traction control off. See Stability Control

(page 185).

Note: The anti-lock brake system continues

to correctly operate.

TIRE PRESSURE MONITORING

SYSTEM WARNING:

The tire pressure

monitoring system is not a substitute for

manually checking tire pressures. You

should periodically check tire pressures

using a pressure gauge. Failure to

correctly maintain tire pressures could

increase the risk of tire failure, loss of

control, vehicle rollover and personal

injury.

Note: You should only use tire sealants in

roadside emergencies as they may cause

damage to the tire pressure monitoring

system sensor.

Note: If the tire pressure monitoring system

sensor becomes damaged, it may not

function. Each tire, including the spare (if

provided), should be checked

monthly when cold and inflated

to the inflation pressure recommended by

the vehicle manufacturer on the vehicle

placard or tire inflation pressure label. (If

your vehicle has tires of a different size

than the size indicated on the vehicle

placard or tire inflation pressure label, you

should determine the proper tire inflation

pressure for those tires). As an added safety feature, your vehicle

has been equipped with a Tire Pressure

Monitoring System (TPMS) that

illuminates a low tire pressure telltale

when one or more of your tires is

significantly under-inflated. Accordingly,

when the low tire pressure telltale

illuminates, you should stop and check

your tires as soon as possible, and inflate

them to the proper pressure. Driving on a

significantly under-inflated tire causes the

tire to overheat and can lead to tire failure.

Under-inflation also reduces fuel efficiency

and tire tread life, and may affect the

vehicle

’s handling and stopping ability.

Please note that the TPMS is not a

substitute for proper tire maintenance, and

it is the driver ’s responsibility to maintain

correct tire pressure, even if under-inflation

has not reached the level to trigger

illumination of the TPMS low tire pressure

telltale.

Your vehicle has also been equipped with

a TPMS malfunction indicator to indicate

when the system is not operating properly.

The TPMS malfunction indicator is

combined with the low tire pressure

telltale. When the system detects a

malfunction, the telltale will flash for

approximately one minute and then remain

continuously illuminated. This sequence

will continue upon subsequent vehicle

start-ups as long as the malfunction exists.

When the malfunction indicator is

illuminated, the system may not be able

to detect or signal low tire pressure as

intended. TPMS malfunctions may occur

for a variety of reasons, including the

installation of replacement or alternate

tires or wheels on the vehicle that prevent

the TPMS from functioning properly.

Always check the TPMS malfunction

telltale after replacing one or more tires or

wheels on your vehicle to ensure that the

replacement or alternate tires and wheels

allow the TPMS to continue to function

properly.

326

2020 Transit Connect (CHC) Canada/United States of America, CG3739en enUSA, Edition date: 201903, First-Printing Wheels and Tires

Page 335 of 509

•

Use commercial car washing

equipment.

• Try to repair the dissimilar spare tire.

Use of one of the dissimilar spare tires

listed above at any one wheel location can

lead to impairment of the following:

• Handling, stability and braking

performance.

• Comfort and noise.

• Ground clearance and parking at curbs.

• Winter weather driving capability.

• Wet weather driving capability.

• All-wheel driving capability (if

applicable).

3. Full-size dissimilar spare without

label on wheel

When driving with the full-size dissimilar

spare wheel and tire assembly, do not:

• Exceed 70 mph (113 km/h).

• Use more than one dissimilar spare

wheel and tire assembly at a time.

• Use commercial car washing

equipment.

• Use snow chains on the end of the

vehicle with the dissimilar spare wheel

and tire assembly.

The usage of a full-size dissimilar spare

wheel and tire assembly can lead to

impairment of the following:

• Handling, stability and braking

performance.

• Comfort and noise.

• Ground clearance and parking at curbs.

• Winter weather driving capability.

• Wet weather driving capability.

• All-wheel driving capability. When driving with the full-size dissimilar

spare wheel and tire assembly additional

caution should be given to:

•

Towing a trailer.

• Driving vehicles equipped with a

camper body.

• Driving vehicles with a load on the

cargo rack.

Drive cautiously when using a full-size

dissimilar spare wheel and tire assembly

and seek service as soon as possible.

Changing a Road Wheel WARNING: When one of the front

wheels is off the ground, the

transmission alone will not prevent the

vehicle from moving or slipping off the

jack, even if the transmission selector

lever is in park (P). WARNING:

To help prevent your

vehicle from moving when you change

a tire, be sure to place the transmission

selector lever in park (P), set the parking

brake and block (in both directions) the

wheel that is diagonally opposite (other

side and end of the vehicle) to the tire

being changed. WARNING:

Never get underneath

a vehicle that is supported only by a jack.

If your vehicle slips off the jack, you or

someone else could be seriously injured. WARNING:

Do not attempt to

change a tire on the side of the vehicle

close to moving traffic. Pull far enough

off the road to avoid the danger of being

hit when operating the jack or changing

the wheel.

331

2020 Transit Connect (CHC) Canada/United States of America, CG3739en enUSA, Edition date: 201903, First-Printing Wheels and Tires

Page 336 of 509

WARNING: Always use the jack

provided as original equipment with your

vehicle. If using a jack other than the one

provided as original equipment with your

vehicle, make sure the jack capacity is

adequate for the vehicle weight,

including any vehicle cargo or

modifications.

Note: The jack and tools are located behind

a cover in the sidewall at the left rear of the

cargo area. Remove the retention straps and

wing nut before removing the jack.

The jack and tools are located behind a

cover in the left rear of the cargo area.

Remove the wing nut to remove the jack.

Remove the lug nut wrench from the clips

by pulling straight out.

1. Park on a level surface, set the parking

brake and activate the hazard flashers.

2. Move the transmission selector lever to the park (P) position and switch the

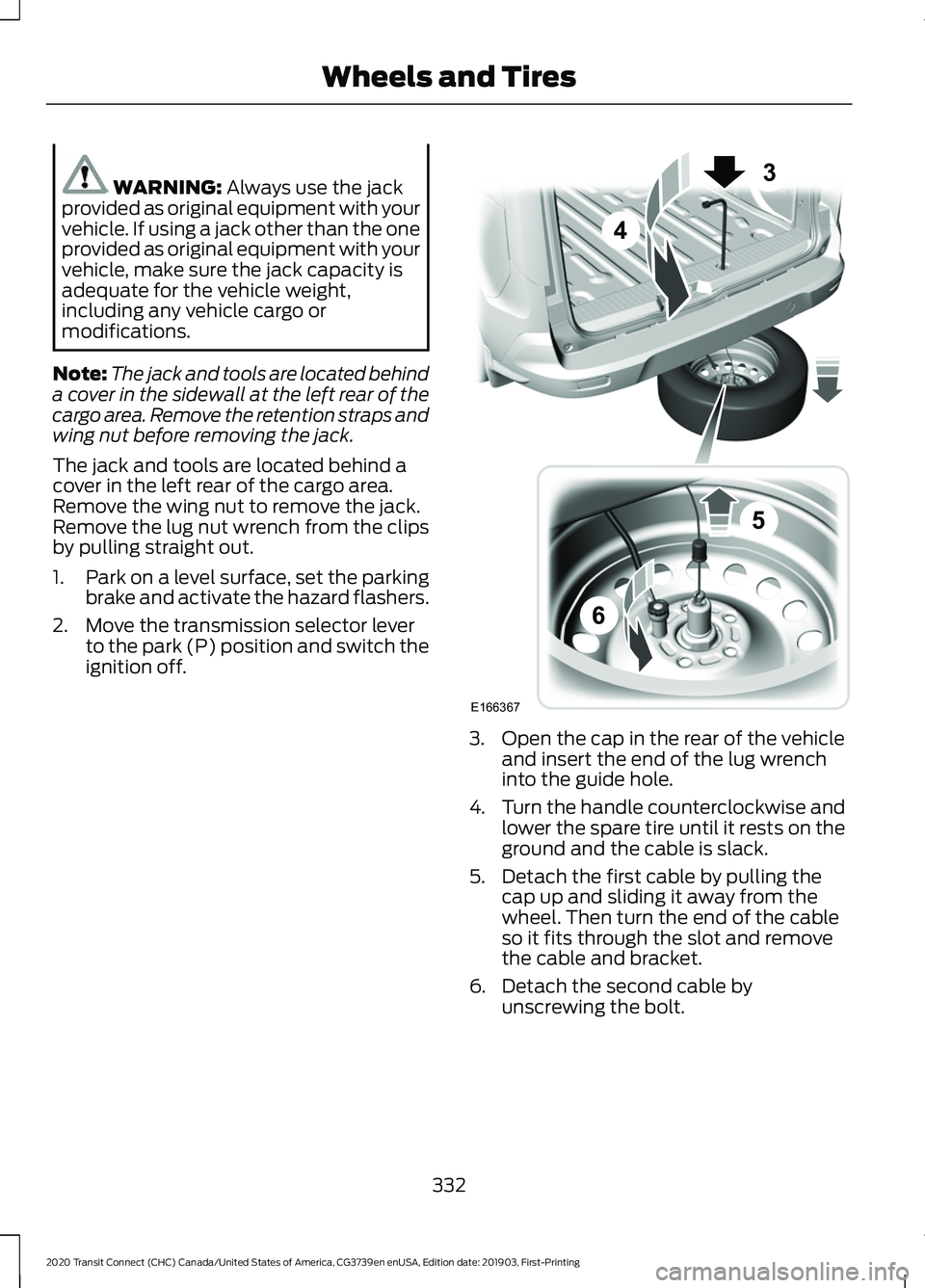

ignition off. 3. Open the cap in the rear of the vehicle

and insert the end of the lug wrench

into the guide hole.

4. Turn the handle counterclockwise and

lower the spare tire until it rests on the

ground and the cable is slack.

5. Detach the first cable by pulling the cap up and sliding it away from the

wheel. Then turn the end of the cable

so it fits through the slot and remove

the cable and bracket.

6. Detach the second cable by unscrewing the bolt.

332

2020 Transit Connect (CHC) Canada/United States of America, CG3739en enUSA, Edition date: 201903, First-Printing Wheels and TiresE166367

3

4

5

6

Page 337 of 509

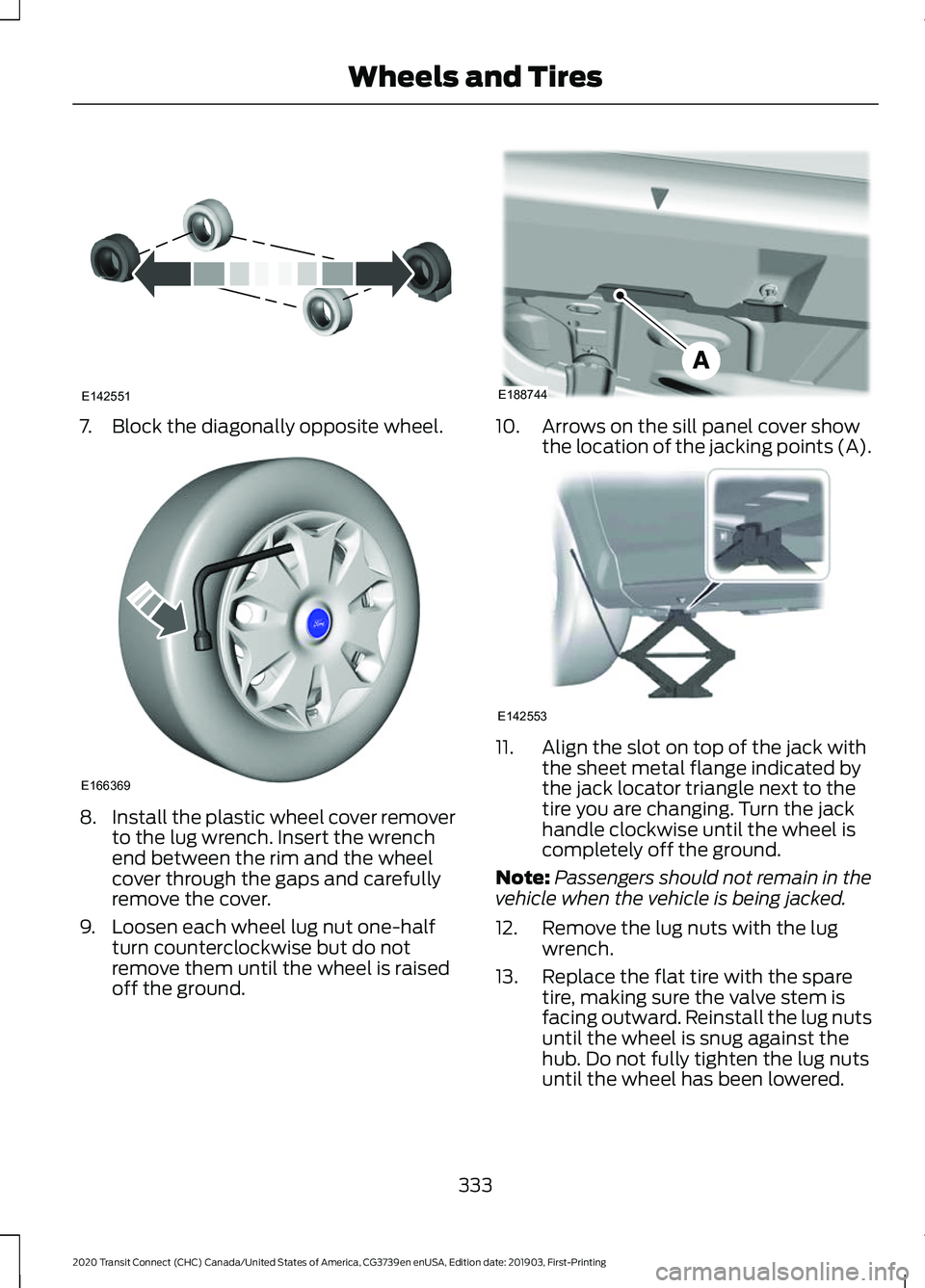

7. Block the diagonally opposite wheel.

8.

Install the plastic wheel cover remover

to the lug wrench. Insert the wrench

end between the rim and the wheel

cover through the gaps and carefully

remove the cover.

9. Loosen each wheel lug nut one-half turn counterclockwise but do not

remove them until the wheel is raised

off the ground. 10. Arrows on the sill panel cover show

the location of the jacking points (A). 11. Align the slot on top of the jack with

the sheet metal flange indicated by

the jack locator triangle next to the

tire you are changing. Turn the jack

handle clockwise until the wheel is

completely off the ground.

Note: Passengers should not remain in the

vehicle when the vehicle is being jacked.

12. Remove the lug nuts with the lug wrench.

13. Replace the flat tire with the spare tire, making sure the valve stem is

facing outward. Reinstall the lug nuts

until the wheel is snug against the

hub. Do not fully tighten the lug nuts

until the wheel has been lowered.

333

2020 Transit Connect (CHC) Canada/United States of America, CG3739en enUSA, Edition date: 201903, First-Printing Wheels and TiresE142551 E166369 E188744 E142553

Page 338 of 509

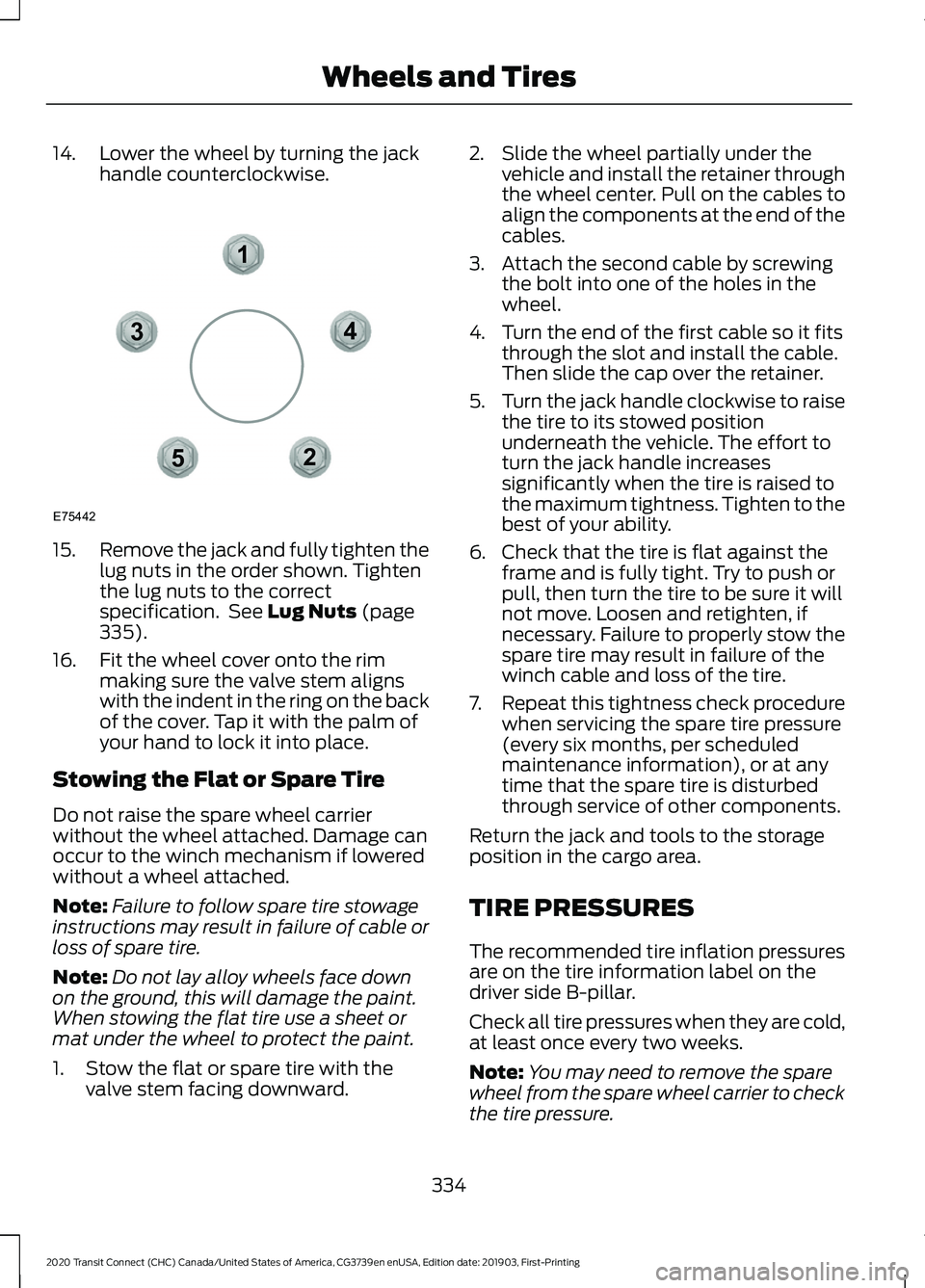

14. Lower the wheel by turning the jack

handle counterclockwise.15.

Remove the jack and fully tighten the

lug nuts in the order shown. Tighten

the lug nuts to the correct

specification. See Lug Nuts (page

335).

16. Fit the wheel cover onto the rim making sure the valve stem aligns

with the indent in the ring on the back

of the cover. Tap it with the palm of

your hand to lock it into place.

Stowing the Flat or Spare Tire

Do not raise the spare wheel carrier

without the wheel attached. Damage can

occur to the winch mechanism if lowered

without a wheel attached.

Note: Failure to follow spare tire stowage

instructions may result in failure of cable or

loss of spare tire.

Note: Do not lay alloy wheels face down

on the ground, this will damage the paint.

When stowing the flat tire use a sheet or

mat under the wheel to protect the paint.

1. Stow the flat or spare tire with the valve stem facing downward. 2. Slide the wheel partially under the

vehicle and install the retainer through

the wheel center. Pull on the cables to

align the components at the end of the

cables.

3. Attach the second cable by screwing the bolt into one of the holes in the

wheel.

4. Turn the end of the first cable so it fits through the slot and install the cable.

Then slide the cap over the retainer.

5. Turn the jack handle clockwise to raise

the tire to its stowed position

underneath the vehicle. The effort to

turn the jack handle increases

significantly when the tire is raised to

the maximum tightness. Tighten to the

best of your ability.

6. Check that the tire is flat against the frame and is fully tight. Try to push or

pull, then turn the tire to be sure it will

not move. Loosen and retighten, if

necessary. Failure to properly stow the

spare tire may result in failure of the

winch cable and loss of the tire.

7. Repeat this tightness check procedure

when servicing the spare tire pressure

(every six months, per scheduled

maintenance information), or at any

time that the spare tire is disturbed

through service of other components.

Return the jack and tools to the storage

position in the cargo area.

TIRE PRESSURES

The recommended tire inflation pressures

are on the tire information label on the

driver side B-pillar.

Check all tire pressures when they are cold,

at least once every two weeks.

Note: You may need to remove the spare

wheel from the spare wheel carrier to check

the tire pressure.

334

2020 Transit Connect (CHC) Canada/United States of America, CG3739en enUSA, Edition date: 201903, First-Printing Wheels and Tires12

3

4

5

E75442

Page 354 of 509

Materials

Specification

Name

WSS-M2C949-AMERCON® ULV

Motorcraft® MERCON® ULV Automatic Transmis-

sion Fluid (U.S.)

Motorcraft® MERCON® ULV Automatic Transmis-

sion Fluid / MERCON® ULV huile pour boîtes auto-

matique Motorcraft® (Canada)

XT-12-QULV (U.S. & Canada)

Locks

Materials Specification

Name

-

Motorcraft® Penetrating and Lock Lubricant (U.S.)

Motorcraft® Penetrating Fluid / Liquide dégrippant

Motorcraft® (Canada)

XL-1 (U.S.)

CXC-51-A (Canada)

Grease

Materials Specification

Name

ESB-M1C93-B

Motorcraft® Multi-Purpose Grease Spray (U.S.)

Motorcraft® Multi-Purpose Grease Spray / Graisse

tout usage en aérosol Motorcraft® (Canada)

XL-5-A (U.S. & Canada)

CAPACITIES AND

SPECIFICATIONS - 2.0L

DURATEC-HE (MI4)/2.0L FLEX

FUEL

Use oil and fluid that meets the defined

specification and viscosity grade. If you do not use oil and fluid that meets

the defined specification and viscosity

grade, it could result in:

•

Component damage not covered by

the vehicle Warranty.

• Longer engine cranking periods.

• Increased emission levels.

• Reduced engine performance.

• Reduced fuel economy.

• Reduced brake performance.

350

2020 Transit Connect (CHC) Canada/United States of America, CG3739en enUSA, Edition date: 201903, First-Printing Capacities and Specifications

Page 358 of 509

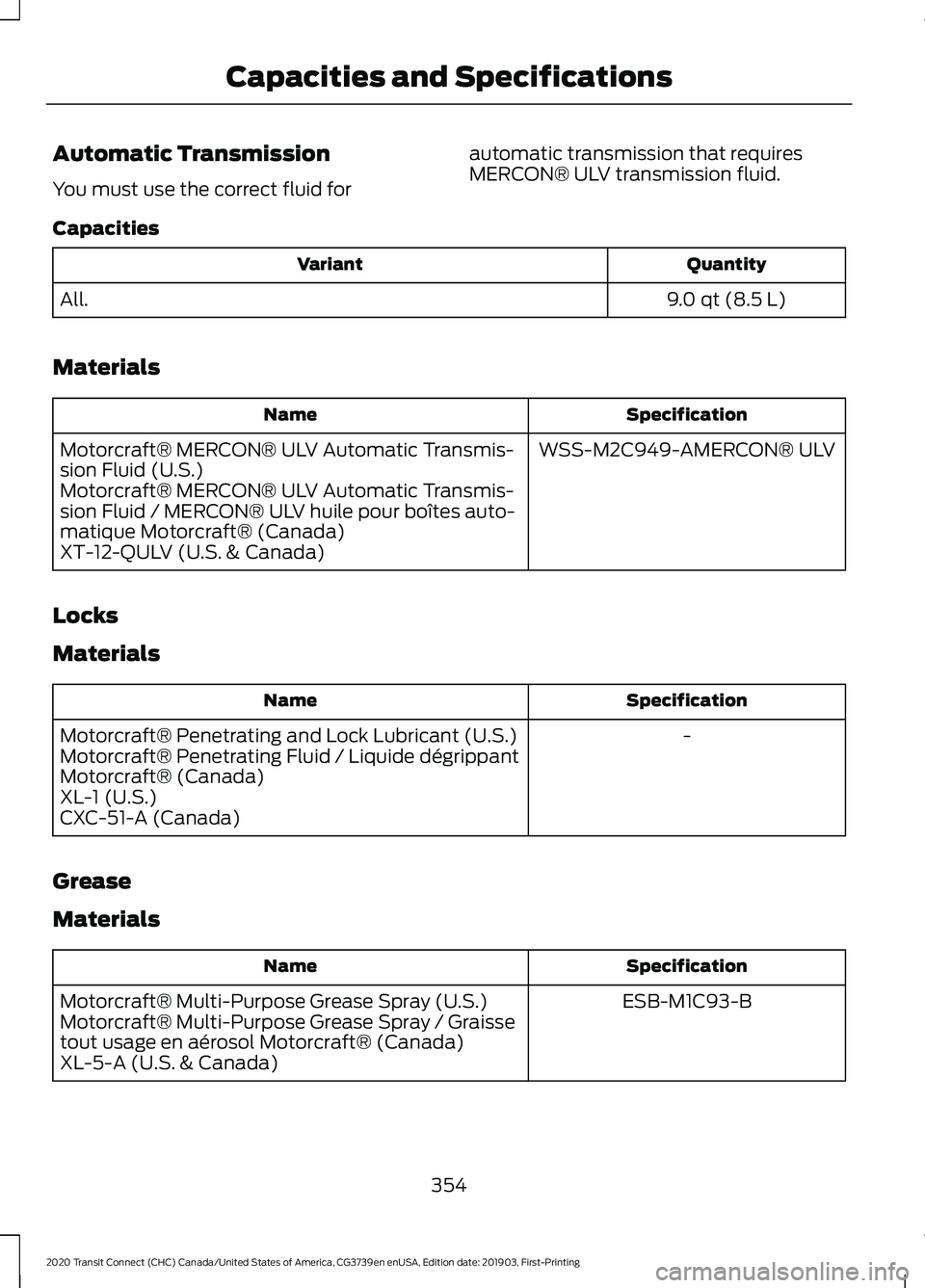

Automatic Transmission

You must use the correct fluid for

automatic transmission that requires

MERCON® ULV transmission fluid.

Capacities Quantity

Variant

9.0 qt (8.5 L)

All.

Materials Specification

Name

WSS-M2C949-AMERCON® ULV

Motorcraft® MERCON® ULV Automatic Transmis-

sion Fluid (U.S.)

Motorcraft® MERCON® ULV Automatic Transmis-

sion Fluid / MERCON® ULV huile pour boîtes auto-

matique Motorcraft® (Canada)

XT-12-QULV (U.S. & Canada)

Locks

Materials Specification

Name

-

Motorcraft® Penetrating and Lock Lubricant (U.S.)

Motorcraft® Penetrating Fluid / Liquide dégrippant

Motorcraft® (Canada)

XL-1 (U.S.)

CXC-51-A (Canada)

Grease

Materials Specification

Name

ESB-M1C93-B

Motorcraft® Multi-Purpose Grease Spray (U.S.)

Motorcraft® Multi-Purpose Grease Spray / Graisse

tout usage en aérosol Motorcraft® (Canada)

XL-5-A (U.S. & Canada)

354

2020 Transit Connect (CHC) Canada/United States of America, CG3739en enUSA, Edition date: 201903, First-Printing Capacities and Specifications