diagram GEELY CK 2008 User Guide

[x] Cancel search | Manufacturer: GEELY, Model Year: 2008, Model line: CK, Model: GEELY CK 2008Pages: 392, PDF Size: 38.86 MB

Page 235 of 392

2283. Speaker soundless in all modes

Wiring Diagram

(1) Check LCD (Liquid Crystal Display) illumination

1Turn ignition switch to ACC

2Connect radio assembly continuity

3Switch on position lamp

Standard: Radio assembly LCD light goes on

Abnormal:Go to Step (7)

Normal:Go to Next Step

(2) Control volume and adjust volume balance

�yOperate the radio assembly to adjust volume balance and find soundless speaker

Check and replace the radio assembly if all the speakers are soundless

Check and replace the soundless speakers if some of the speakers are soundlessMain Fuse BoxRadio and CDIgnition switchFusible Link BoxBatteryLeft Rear SpeakerRight Rear SpeakerLeft tweeter SpeakerRight tweeter SpeakerLeft Front Speaker

Right Front Speaker

Page 282 of 392

275VIII. ABS ECU Connector Pin LayoutABS ECU Connector (End Views)

Electrical Wiring DiagramCombination MeterABS Warning Light

Drive ModuleABS ECU

ABS RR Wheel Sensor

ABS LR Wheel Sensor ABS RF Wheel Sensor

ABS LF Wheel Sensor

Brake Lamp Switch

Page 308 of 392

301 4. Heater

Figure 5 Heater Door Control Diagram

The heater comprises the heater radiator (heat exchanger), the plastic case forming the air duct, connecting

rods adjusting different air ducts and the door. The two groups of combination doors in the heater case are

connected to the heating control mechanism by the cable. The first group is the two couple action doors

adjusting the air mix ratio that are located in the outlet and inlet each; the second group comprises 4 doors

controlling the air outlet vents, where the upper center one controls the front outlet vent, each of the upper

left and right sides controls a defogger outlet vent and lower foot outlet vent. Figure 5 shows the working

principle of temperature adjustment door. The d) , c) , e) , f) in the figure indicate the outlet air flow direction

as the result of the adjustment of the control knob in the heating control mechanism panel.Hot Wind LocationCold Wind LocationLinkageRadiator CoreRadiator CoreTemperature Adjustment

Door Working PrincipleFoot OutletTo Front OutletTo DefrosterRadiator CoreTo Front OutletRadiator CoreFoot OutletFoot OutletTo Defroster

Page 309 of 392

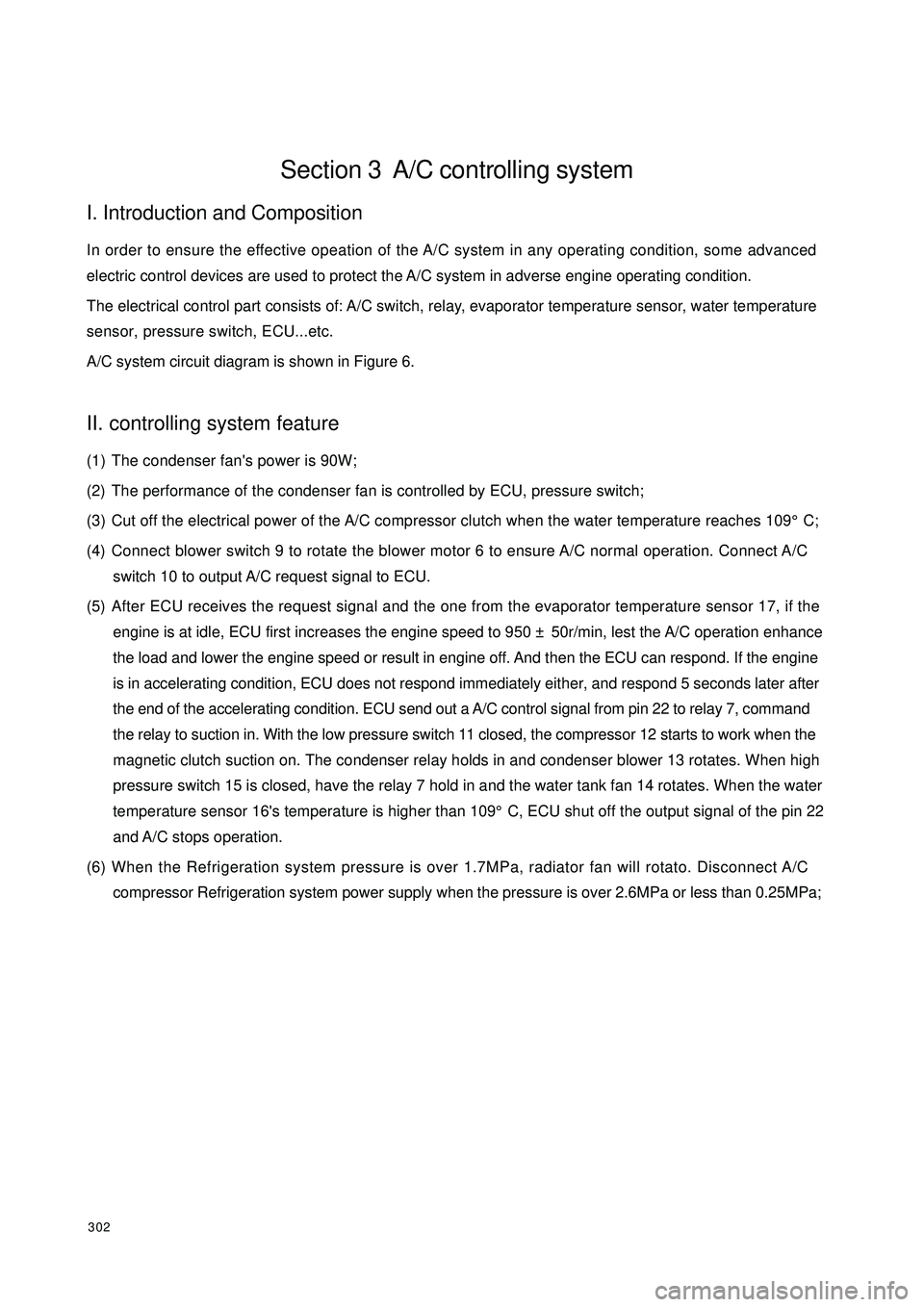

302Section 3 A/C controlling systemI. Introduction and CompositionIn order to ensure the effective opeation of the A/C system in any operating condition, some advanced

electric control devices are used to protect the A/C system in adverse engine operating condition.

The electrical control part consists of: A/C switch, relay, evaporator temperature sensor, water temperature

sensor, pressure switch, ECU...etc.

A/C system circuit diagram is shown in Figure 6.II. controlling system feature(1) The condenser fan's power is 90W;

(2) The performance of the condenser fan is controlled by ECU, pressure switch;

(3) Cut off the electrical power of the A/C compressor clutch when the water temperature reaches 109°C;

(4) Connect blower switch 9 to rotate the blower motor 6 to ensure A/C normal operation. Connect A/C

switch 10 to output A/C request signal to ECU.

(5) After ECU receives the request signal and the one from the evaporator temperature sensor 17, if the

engine is at idle, ECU first increases the engine speed to 950 ± 50r/min, lest the A/C operation enhance

the load and lower the engine speed or result in engine off. And then the ECU can respond. If the engine

is in accelerating condition, ECU does not respond immediately either, and respond 5 seconds later after

the end of the accelerating condition. ECU send out a A/C control signal from pin 22 to relay 7, command

the relay to suction in. With the low pressure switch 11 closed, the compressor 12 starts to work when the

magnetic clutch suction on. The condenser relay holds in and condenser blower 13 rotates. When high

pressure switch 15 is closed, have the relay 7 hold in and the water tank fan 14 rotates. When the water

temperature sensor 16's temperature is higher than 109°C, ECU shut off the output signal of the pin 22

and A/C stops operation.

(6) When the Refrigeration system pressure is over 1.7MPa, radiator fan will rotato. Disconnect A/C

compressor Refrigeration system power supply when the pressure is over 2.6MPa or less than 0.25MPa;

Page 310 of 392

303Figure 6 A/C System Electrical Appliance DiagramIII. Protecting Device1. Low temperature protection

Evaporator temperature sensor, when the sensed temperature is lower than 3°C, the compressor clutch

is de-energized and stops operation.

2. High temperature protection

Water temperature sensor, when the sensed water temperature reaches 109°C, the compressor clutch is

de-energized and stops operation.

3. Low pressure protection

When pressure sensed by the pressure switch is lower than 0.25MPa, the compressor clutch is de-

energized and stops operation.

4. Voltage protection

When the pressure sensed by the pressure switch reaches 1.7MPa, radiator fan rotates.

5. High pressure protection

When the pressure sensed by the pressure switch reaches 2.6MPa, the compressor clutch is de-energized

and stops operation.

6. Normal pressure

When system pressure reaches 0.25MPa~2.4MPa, control the A/C idle speed. Color of wire:R-Red Bl-Blue Y-Yellow Lg-Light green Br-Brown B-Black P-Pink G-Green W-White Gr-Gray

1. Battery 2. Main Fuse Box 3. Alternator 4. Ignition Switch 5. Idle Rise Valve 6. Blower 7. Relay

8. Blower Regulating Resistance 9. Blower Switch 10. A/C Switch 11. A/C Low Pressure Switch

12. Compressor 13. Condensor Fan 14. Radiator Fan 15. A/C High Pressure Switch

16. Water Temperature Sensor 17. Evaporator Temperature Sensor 18. Electronic Wind Door Actuator Switch

19. Electronic Wind Door Actuator 20. Revolution Sensor 21. Engine ECU

Page 336 of 392

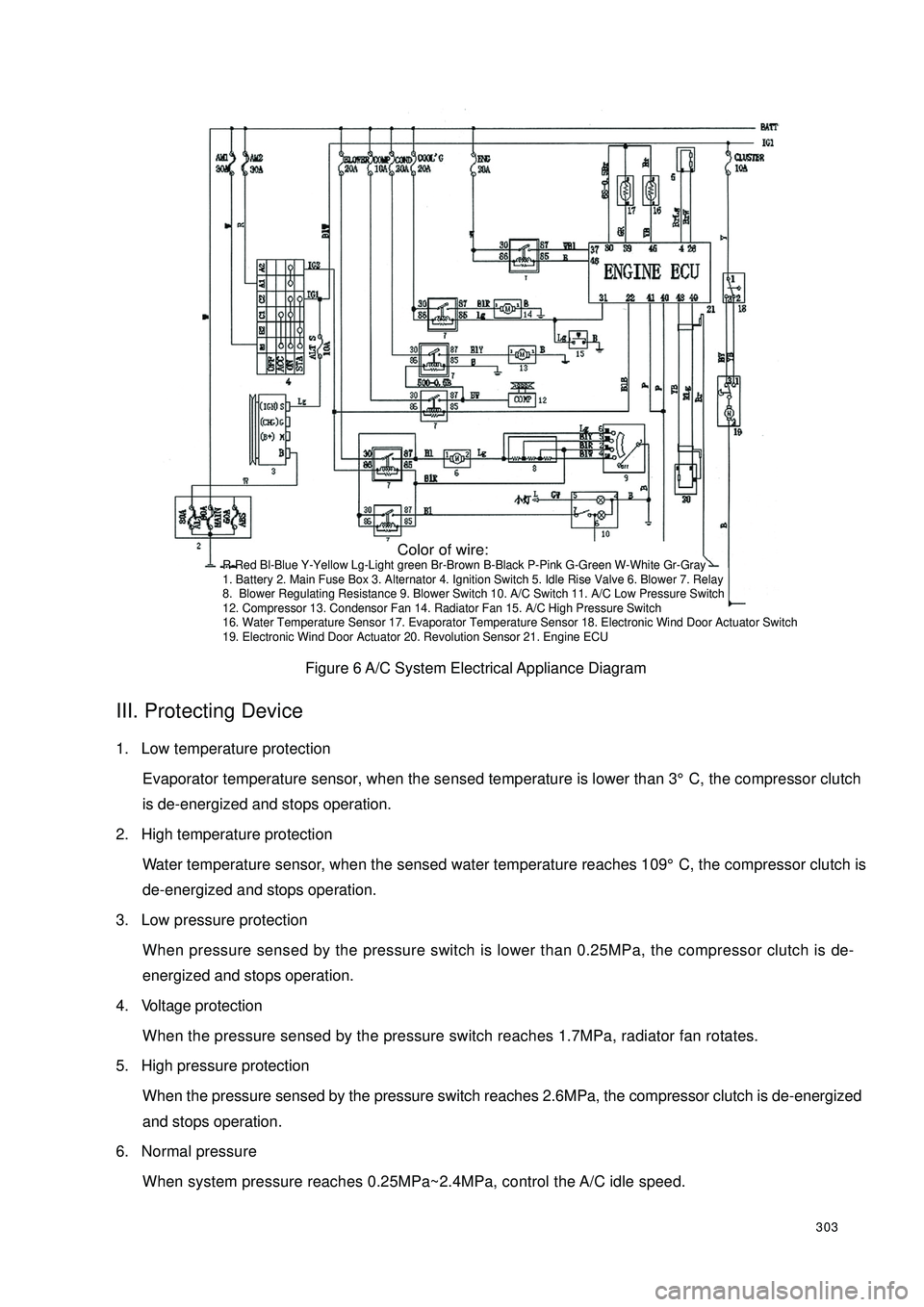

329(V) Rear BumperThe structure diagram is shown as the figure below:

1.Cross Pan Head Tapping Screw And Big Washer Set2.Cross Pan Head Screw (GB973 M6X16)

3.Cross Pan Head Screw (GB973 M6X16) 4.Rear Bumper5.Clip6.Rear Bumper Reinforce-

ment Assembly 7.Rear Bumper Mounting Bracket Assembly8.Hexigon Bolt and Spring Washer

Set 9.Hexigon Bolt Spring and Flat Gasket Set

1.Rear Bumper Removal/Installation

(1) Disconnect the negative (--) terminal cable from the battery.

(2) Remove the cross pan head tapping screw and big washer set.

(3) Remove 4 hexagon bolt on the mounting bracket.

(4) Remove 2 cross pan head screw (GB973 M6X16)

(5) Pull the rear bumper out from the body.

(6) Remove the cross pan head screw (GB973 M6X16) and hexagon bolt spring and flat gasketset. Remove

the rear bumper mounting bracket assembly.

(7) The installation is in the reverse order of the removal.

Page 350 of 392

343(IX) A pillar inside trim and front door sillA pillar inside trim and front door sill diagram

A pillar inside trim and front door sill diagram

1. Right A Pillar Inside Trim 2. Left A Pillar Inside Trim 3. Right Front Door Sill

4. Left Front Door Sill5.D-Clip 6. Steel Clip7. Cross Slot Head Self-tapping Screw

1. Removal

1Remove the installed right front door sill, left front door sill self-tapping screw cross screwdriver;

2Use an opener to remove the right A pillar inside trim, A pillar inside trim, right front door sill, left frontdoor sill.

2. Installation

1 Install the right A pillar inside trim, A pillar inside trim, right front door sill , left front door sill to the

corresponding position with clip and steel clip;

2Fix the right front door sill , left front door sill with a tapping screw. 1 2

3

6

4 57

Page 351 of 392

344(X) B pillar inside trimB pillar inside trim diagram:

B Pillar Inside Trim Diagram

1. Right B Pillar Upper Inside Trim 2. Left B Pillar Upper Inside Trim 3. Right Deflector

4. Left Deflector5. Right B Pillar Lower Inside Trim 6. Left B Pillar Lower Inside Trim

7. Right B Pillar Lower Inside Trim Sound Insulator 8. Left B Pillar Lower Inside Trim Sound Insulator

9. Cross Pan Head Tapping Screw10. Steel Clip

1.Removal

1Remove the installed left B pillar lower inside trim, right B pillar lower inside trim tapping screw with a

cross screwdriver;

2Remove the left B pillar lower inside trim, right B pillar lower inside trim with a opener ;

3Remove the seat belt swing ring;

4Remove the right B pillar upper inside trim, leftB pillar upper inside trim tapping screw with the cross

screwdriver;

5Remove the right B pillar upper inside trim, leftB pillar upper inside trim with a opener.

2.Installation

1Clip B pillar inside trim to the corresponding position with clip and steel clip in order;

2Fix the upper inside trim and lower inside trim to the vehicle body with a tapping screw.

2

453

1

6

10

8 79

Page 352 of 392

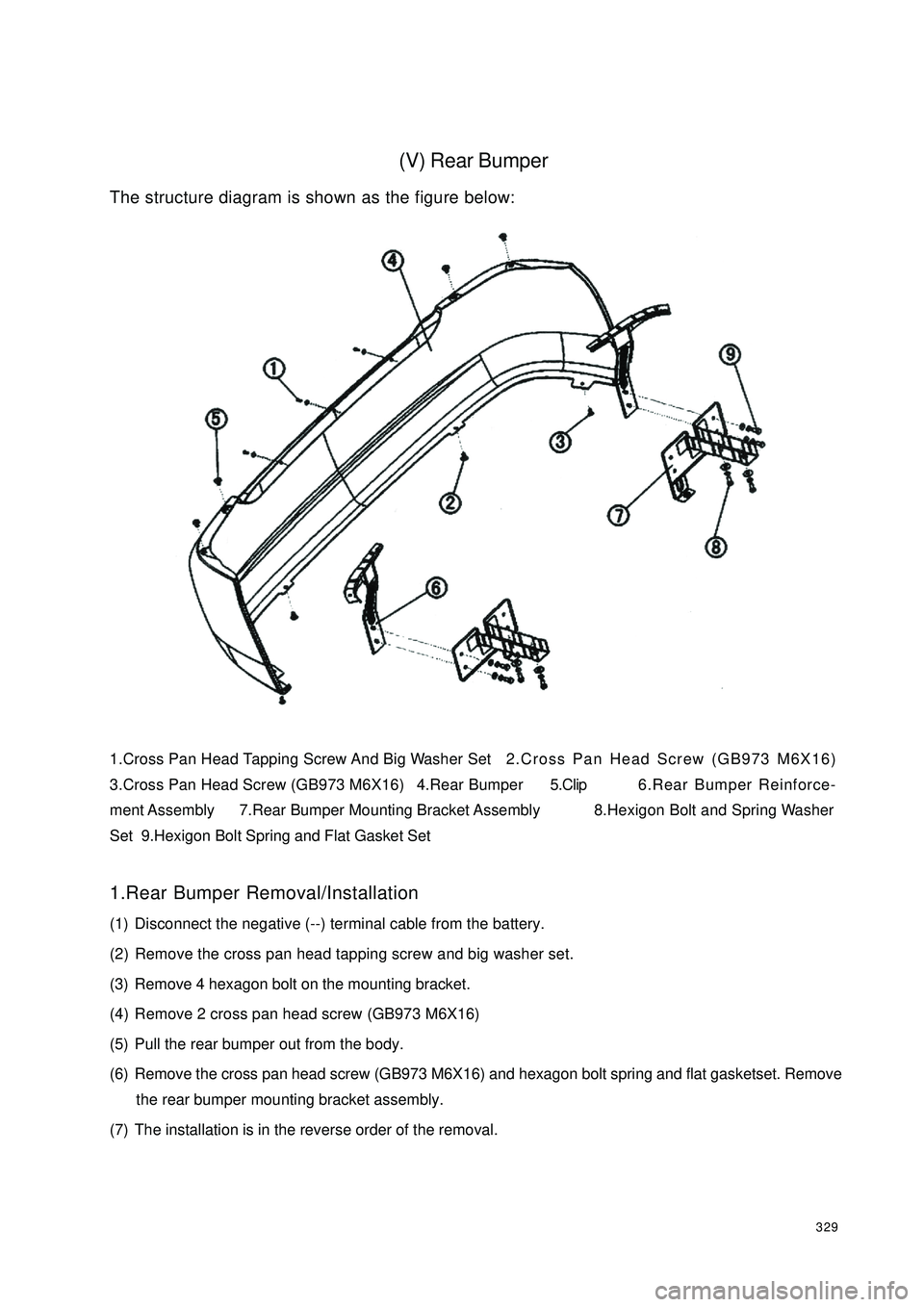

345(XI) Cpillar inside trim and rear door sillC pillar inside trim and rear door sill diagram:

C pillar inside trim& rear door sill diagramdiagram

1.Right C Pillar Upper Inside Trim 2.Left C Pillar Upper Inside Trim 3. Right C Pillar Upper Inside

Trim Sound Insulator 4. Left Sound Insulator 5. Right C Pillar Lower Inside Trim 6. Left C Pillar

Lower Inside Trim 7. Right Rear Door Sill 8. Left Rear Door Sill9. E-Clip10. Cross Pan

Head Self-tapping Screw 11. D-Clip

1. Removal

1Remove the installed door sill and C pillar lower inside trim tapping screw and E-clip with a cross

screwdriver;

2Remove C pillar upper inside trim with a opener ;

3Remove C pillar lower inside trim with a opener

2.Installation

1 Clip C pillar inside trim and rear door sill onto the corresponding position in order;

2Tap C pillar upper inside trim and C pillar lower inside trim lightly with a rubber hammer to ensure D-clip

clipped in the vehicle inner panel;

3Fix the rear door sill onto the vehicle body with a tapping screw.112 110843

57

96

Page 353 of 392

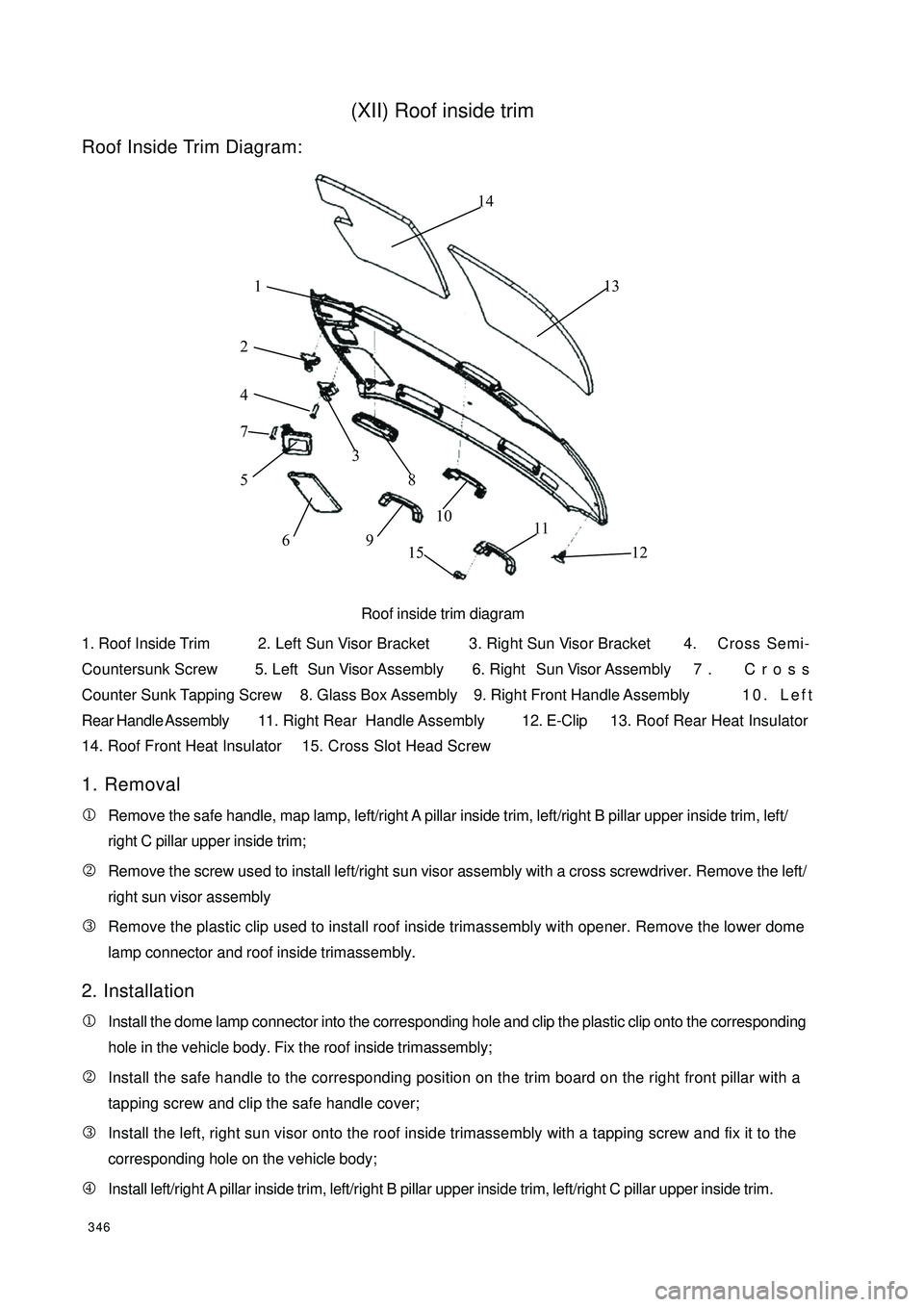

346(XII) Roof inside trimRoof Inside Trim Diagram:

Roof inside trim diagram

1. Roof Inside Trim2. Left Sun Visor Bracket 3. Right Sun Visor Bracket 4. Cross Semi-

Countersunk Screw 5. Left Sun Visor Assembly 6. Right Sun Visor Assembly 7 . Cross

Counter Sunk Tapping Screw 8. Glass Box Assembly 9. Right Front Handle Assembly10. Left

Rear Handle Assembly11. Right Rear Handle Assembly12. E-Clip13. Roof Rear Heat Insulator

14. Roof Front Heat Insulator15. Cross Slot Head Screw

1. Removal

1Remove the safe handle, map lamp, left/right A pillar inside trim, left/right B pillar upper inside trim, left/

right C pillar upper inside trim;

2Remove the screw used to install left/right sun visor assembly with a cross screwdriver. Remove the left/

right sun visor assembly

3Remove the plastic clip used to install roof inside trimassembly with opener. Remove the lower dome

lamp connector and roof inside trimassembly.

2. Installation

1Install the dome lamp connector into the corresponding hole and clip the plastic clip onto the corresponding

hole in the vehicle body. Fix the roof inside trimassembly;

2Install the safe handle to the corresponding position on the trim board on the right front pillar with a

tapping screw and clip the safe handle cover;

3Install the left, right sun visor onto the roof inside trimassembly with a tapping screw and fix it to the

corresponding hole on the vehicle body;

4Install left/right A pillar inside trim, left/right B pillar upper inside trim, left/right C pillar upper inside trim. 2 13 4

5

6 7

8

9 10

11

12 13 1415