low oil pressure GEELY CK 2008 User Guide

[x] Cancel search | Manufacturer: GEELY, Model Year: 2008, Model line: CK, Model: GEELY CK 2008Pages: 392, PDF Size: 38.86 MB

Page 147 of 392

140Section 2 Brake FluidBleeding1. Fill brake reservoir with brake fluid

Brake fluid: JG4 GB10830

2. Bleed brake pipeline system

(1) Connect the vinyl pipe to the wheel cylinder bleeder plug port

(2) Depress the brake pedal several times, and then loosen the bleeder plug with the pedal held down.

(3) At the point when fluid stops flowing out, tighten the bleeder plug, and then release the brake pedal.

(4) Repeat (2) and (3) until all the air in the fluid has been bled out.

(5) Repeat the above procedure to bleed the brake pipeline of the air for each wheel cylinder.

Notice: Fill brake fluid into the reservoir all the time when bleeding.

3. Check fluid level in reservoir

Check the fluid level and fill fluid if necessary.Symptom Suspe ct a re a

1. Whee l cylinder piston (stuck)

2. Bra ke shoe lining (oily)

3. Disc (scratched)

4. Bra ke shoe s or lining (c ra cke d or distorte d)

5. Whee l hub be a ring (worn or da mage d)

Tire pressure (not as specified)

1. Bra ke shoe lining (da mage d)

2. Insta lla tion bolt (loose )

3. Disc (scratched)

4. Bra ke shoe (ba d in qua lity)

5. Bra ke shoe s lining (oily)

6. Sound isolating shim da mage d

7. Hold spring of bra ke shoe (da mage ) Brake Deviation

Noise from brake

Page 180 of 392

1732. DEFINITION OF MULTIPIN PLUG-IN TERMINALDefinition of Terminal Color of Harness

1Empty

2EPS VG

3Empty

4Empty

5Empty

6Empty

7Empty

8 Combination switch (Position lamp P

9 Speed sensor groun B

10 Speed sensor power sourc RY

11 Speed sensor signal outpu YR

12 Fuel senso B

13 Alte rna tor WR

14 Brake fluid level switc GR

15 Oil pressure switc YG

16 Re a r de frost YB

1 Rear fog lamp Gr

2 Engine ma lfunc tion GY

3 S e a t be lt s w it c h R

4 P owe r sourc e Y

5 Engine coolant temperature senso YW

6 Park switch G

7 Power source groun B

8 Power source groun B

9ABS R

10 SRS (Ma in) RY

11 Engine re volution signa l BBl

12 Live wire (Fire wire) WG

13 High be am la mp + RB

14 Low bea m - RW

15 SRS (Sub) RG

16 Empty Terminal No.

A

B

Page 311 of 392

304Section 4 Service Caution & NoticeI. Service CautionRefrigerant Treatment

•During the treatment, the operator shall be careful not to inhale A/C refrigerant or lubricant vapor. Long-

term exposure to the A/C environment will cause the operator's eye, nose and throat liable to stimulation.

In addition, based on the consideration on the environment influence, when discharging the HFC-134a

from the A/C system, we suggest using the recyclable and rechargeable devices. If sudden system fault

occurs, it is recommended to place the device on a ventilated place before starting service.

•For HFC-134a service equipment, it is recommended not to perform the pressurization check or leakage

inspection. If these mixture combust, it may result in severe human injury or property loss.

•Please be noticed not to let the refrigerant leak near the spark or other hot objects. If the refrigerant gas

contacts the spark or similar heat source (e.g. cigarette or heater), it may generate poisonous gas. The

refrigerant is extremely liable to leakage during the transportation. In this case, please eliminate or remove

the heat source mentioned above and keep good ventilation.

•It is very dangerous to handle the liquid refrigerant. Only a drop of refrigerant can result in local frostbite

on skin if dropped on the skin of the operator. Therefore, it is specified that the operator shall always

wear glove and eye protection during the handling of the liquid refrigerant. If liquid refrigerant gets in

your eyes or on your skin, Wash the area with much cool water. Go immediately to hospital for professional

treatment.

Refrigerant Preservation

• Refrigerant preservation container is a high pressure resistant equipment. If it is put in hot treatment, the

explosion may arise, and the resulting metal fragments and the splashed liquid refrigerant will result in

severe human injury. It is recommended to preserve the refrigerant below 40°C.II. Service NoticeInsufficient Refrigerant Handling

•If the refrigerant is founded to be insufficient during the fault diagnosis, it is recommended not to add

refrigerant because of the following facts: the pressure readings indicated by different pressure gauge

are different, thus you will be unable to determine the exact amount of the refrigerant to be added, and

excessive or insufficient refrigerant may cause a series of chained negative effects such as damaged

refrigerant circulation parts or deteriorated refrigeration effect. Therefore, if the refrigerant is found to

be insufficient, it is recommended to drain the refrigerant from the refrigerant circulation pipeline and fill

specified amount of the refrigerant.

Compressor Oil Handling

•For this type of vehicle, it is recommended to use SW-100 type compressor oil. Use of PAG compressor

oil other than the SW-100 type may cause the A/C compressor to be damaged.

•During the operation, please be noticed not to splash the SW-100 type compressor oil onto the vehicle

surface. Therefore, if this happens, please wipe it off immediately, otherwise the compressor oil will

damage the paint on the vehicle surface.

Page 312 of 392

305•Compared with the early used mineral oil, the SW-100 type compressor oil is of comparatively high

moisture absorption performance. If you mix the moisture object with the SW-100 type compressor oil, it

will damage the Refrigeration system. Therefore, after treating the compressor oil or removing the

refrigeration system components, the lid shall be covered immediately to prevent the SW-100 type

compressor oil from absorbing the moisture.Section 5 The Refrigeration System Operation ProcedureI. Refill RefrigerantNotice:•During the filling of refrigerant into the refrigeration system, be careful that it is required to

have the professionals operate under the specified standard and procedure, otherwise it will

reduce the A/C efficiency greatly and even damage the refrigeration system components.

Refill the HFC-134a refrigerant

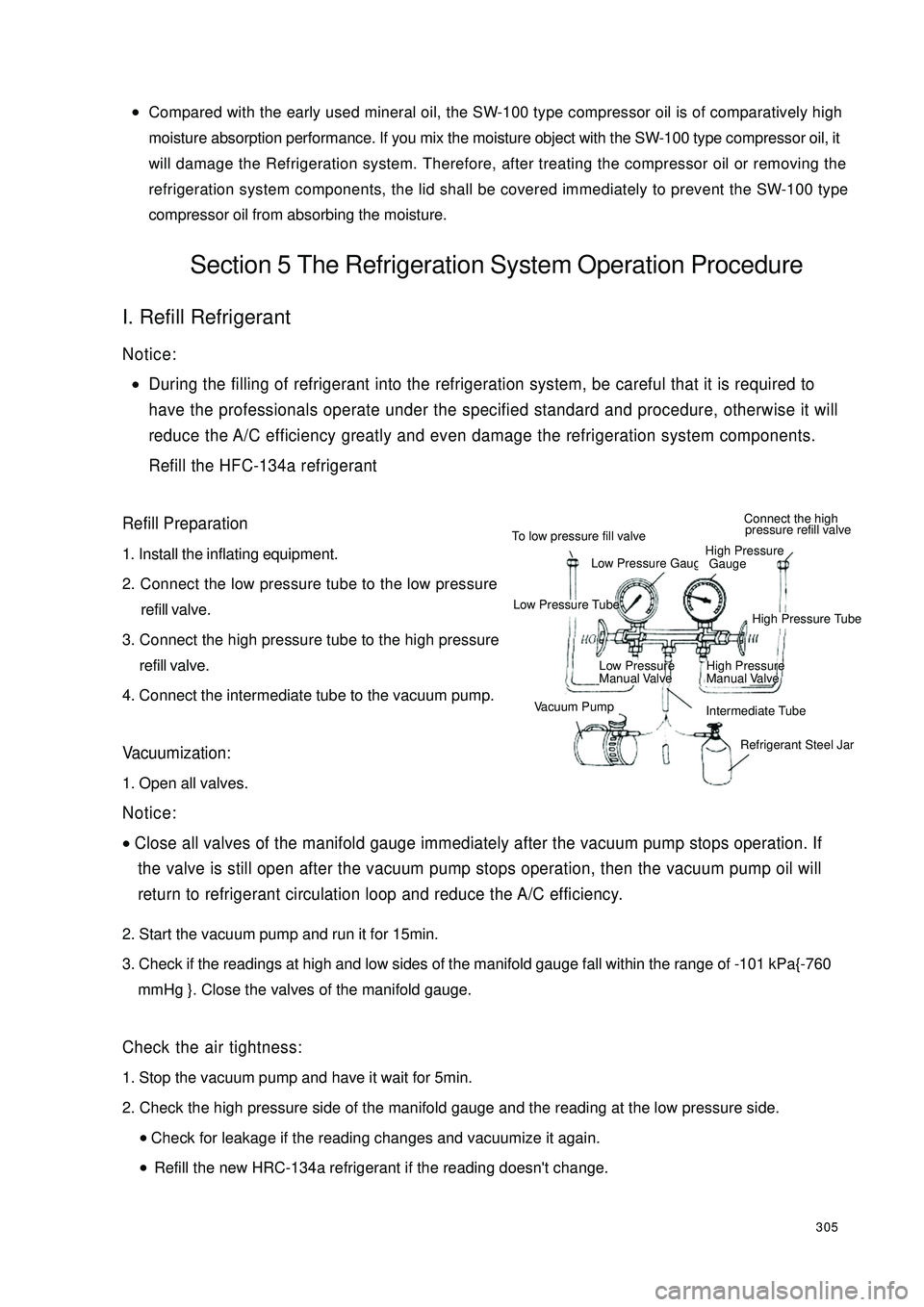

Refill Preparation1. Install the inflating equipment.

2. Connect the low pressure tube to the low pressure

refill valve.

3. Connect the high pressure tube to the high pressure

refill valve.

4. Connect the intermediate tube to the vacuum pump.Vacuumization:1. Open all valves.Notice:•Close all valves of the manifold gauge immediately after the vacuum pump stops operation. If

the valve is still open after the vacuum pump stops operation, then the vacuum pump oil will

return to refrigerant circulation loop and reduce the A/C efficiency.2. Start the vacuum pump and run it for 15min.

3. Check if the readings at high and low sides of the manifold gauge fall within the range of -101 kPa{-760

mmHg }. Close the valves of the manifold gauge.Check the air tightness:1. Stop the vacuum pump and have it wait for 5min.

2. Check the high pressure side of the manifold gauge and the reading at the low pressure side.

•Check for leakage if the reading changes and vacuumize it again.

•Refill the new HRC-134a refrigerant if the reading doesn't change.To low pressure fill valveLow Pressure GaugeHigh Pressure

GaugeConnect the high

pressure refill valveLow Pressure TubeHigh Pressure TubeLow Pressure

Manual ValveHigh Pressure

Manual ValveVacuum PumpIntermediate Tube

Refrigerant Steel Jar

Page 320 of 392

313Section 7 A/C System Faults Check & TroubleshootingI. A/C System Faults CheckInspection shall be made to isolate the fault area and its cause when the fault of A/C system occurs, and then

specific service could be performed. Inspect the whole system before re-using A/C system after a long term

of storage.

First step is initial inspection by direct "see, listen and touch". Test the system with the leak detector if

necessary.

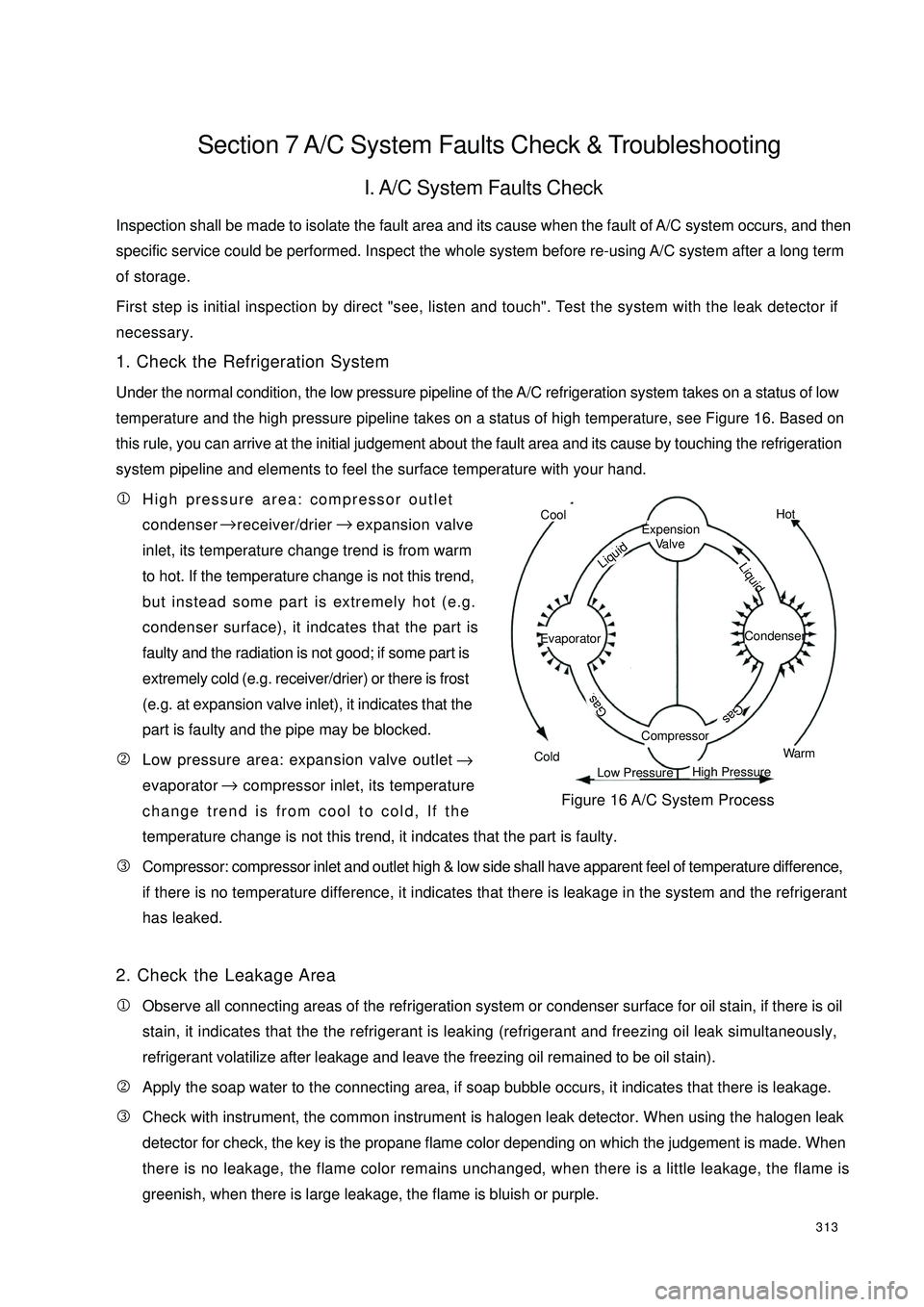

1. Check the Refrigeration System

Under the normal condition, the low pressure pipeline of the A/C refrigeration system takes on a status of lowtemperature and the high pressure pipeline takes on a status of high temperature, see Figure 16. Based onthis rule, you can arrive at the initial judgement about the fault area and its cause by touching the refrigeration

system pipeline and elements to feel the surface temperature with your hand.

1High pressure area: compressor outlet

condenser receiver/drier expansion valve

inlet, its temperature change trend is from warm

to hot. If the temperature change is not this trend,

but instead some part is extremely hot (e.g.

condenser surface), it indcates that the part is

faulty and the radiation is not good; if some part is

extremely cold (e.g. receiver/drier) or there is frost

(e.g. at expansion valve inlet), it indicates that the

part is faulty and the pipe may be blocked.

2Low pressure area: expansion valve outlet

evaporator compressor inlet, its temperature

change trend is from cool to cold, If the

temperature change is not this trend, it indcates that the part is faulty.

3Compressor: compressor inlet and outlet high & low side shall have apparent feel of temperature difference,

if there is no temperature difference, it indicates that there is leakage in the system and the refrigerant

has leaked.

2. Check the Leakage Area

1Observe all connecting areas of the refrigeration system or condenser surface for oil stain, if there is oil

stain, it indicates that the the refrigerant is leaking (refrigerant and freezing oil leak simultaneously,

refrigerant volatilize after leakage and leave the freezing oil remained to be oil stain).

2Apply the soap water to the connecting area, if soap bubble occurs, it indicates that there is leakage.

3Check with instrument, the common instrument is halogen leak detector. When using the halogen leak

detector for check, the key is the propane flame color depending on which the judgement is made. When

there is no leakage, the flame color remains unchanged, when there is a little leakage, the flame is

greenish, when there is large leakage, the flame is bluish or purple.CoolColdHotWarmExpension

Va l v eCompressorEvaporator Condenser Gas

GasLiquid LiquidLow PressureHigh PressureFigure 16 A/C System Process → →

→→

Page 322 of 392

315II. A/C System Diagnosis and TroubleshootingTable 1 Abnormal high pressure of the high pressure pipelineAbnormal low pressure of the high pressure pipeline Abnormal high pressure of the low pressure pipelineAbnormal low pressure of the low pressure pipelineHigh and low pressure can not be establishedSight glass has air bubble Compressor inlet side is frosted Compressor noise Abnormal heating on the compressorEvaporator is frostedDrier filter ices up A/C does not refrigerate or the cold air is insufficient× × × × Excessive refill of refrigerantDrain p rop er amount of

refrigerant

× × × × T oo lit t le refill of refrigerantRep air t he gas leak area, refill

p rop er amount of refrigerant

× × × × Refrigerant is leaked allRep air t he gas leak area, refill

p rop er amount of refrigerant

×× ××× ×T here is non-clot t ed gas in

the sy stemLoos en receiver and

condenser inlet connect or,

discharge t he non-clot t ed gas

××Excessive freez ing oil in t he

sy stemCheck comp ressor freez ing

oil level, adjus t it

× Excessive high t emp erat ure

of condenser inletPerform t he check at t he

p lace w it h good vent ilat ion

T here is dus t in t he

condens er core, air channel

w it hin t he condens er is

blocked or suffocat edU s e comp res s ed air or w at er

t o flush and remove t he dirt

on t he condenser

Condenser fan faulty or

brokenCheck the wiring status and

t he fan mot or, correct or

rep lace it

×× Exces s ively low t emp erat ure

of condenser inletStop the op eration of the

refrigerat ion sy st em

× × × Drier blocked Clean

A ir channel in t he evap orat or

blocked or suffocat edRemove t he dirt on t he

evap orat or

Evap orat or fan fault , p oor

blower mot or w ire connect ionCheck the wiring status and

t he fan mot or, correct or

rep lace it

×× ×T here is dirt in evap orat or

coreU s e t he comp res s ed air t o

clean t he evap orat or core × ×

××××

× P roblem Sy mp t om

Possible Cause T roubleshoot ing

×