wheel GEELY CK 2008 User Guide

[x] Cancel search | Manufacturer: GEELY, Model Year: 2008, Model line: CK, Model: GEELY CK 2008Pages: 392, PDF Size: 38.86 MB

Page 64 of 392

57Section 1 Clutch ReplacementHoist the engine from the compartment. See "Provison 20, Section 2, Chapter 2".

1. Remove manual transaxle assembly

2. Remove the clutch release fork. See (Figure 132)

3. Detach clutch release fork boot.

4. Detach clutch release bearing

5. Detach clutch release bearing fixed clamp

6. Remove clutch fork pivot pin

7. Align the clutch cover to the mark on the flywheel. Detach clutch cover. See (Figure 133)

8. Remove clutch plate

9. Check and remove clutch plate assembly. See (Figure 134)

10. Check clutch cover. See (Figure 135)

Depth wear: A: 0.6mm

Width wear: B: 5mm

Figure 132 Figure 133

Figure 134 Figure 135

Page 65 of 392

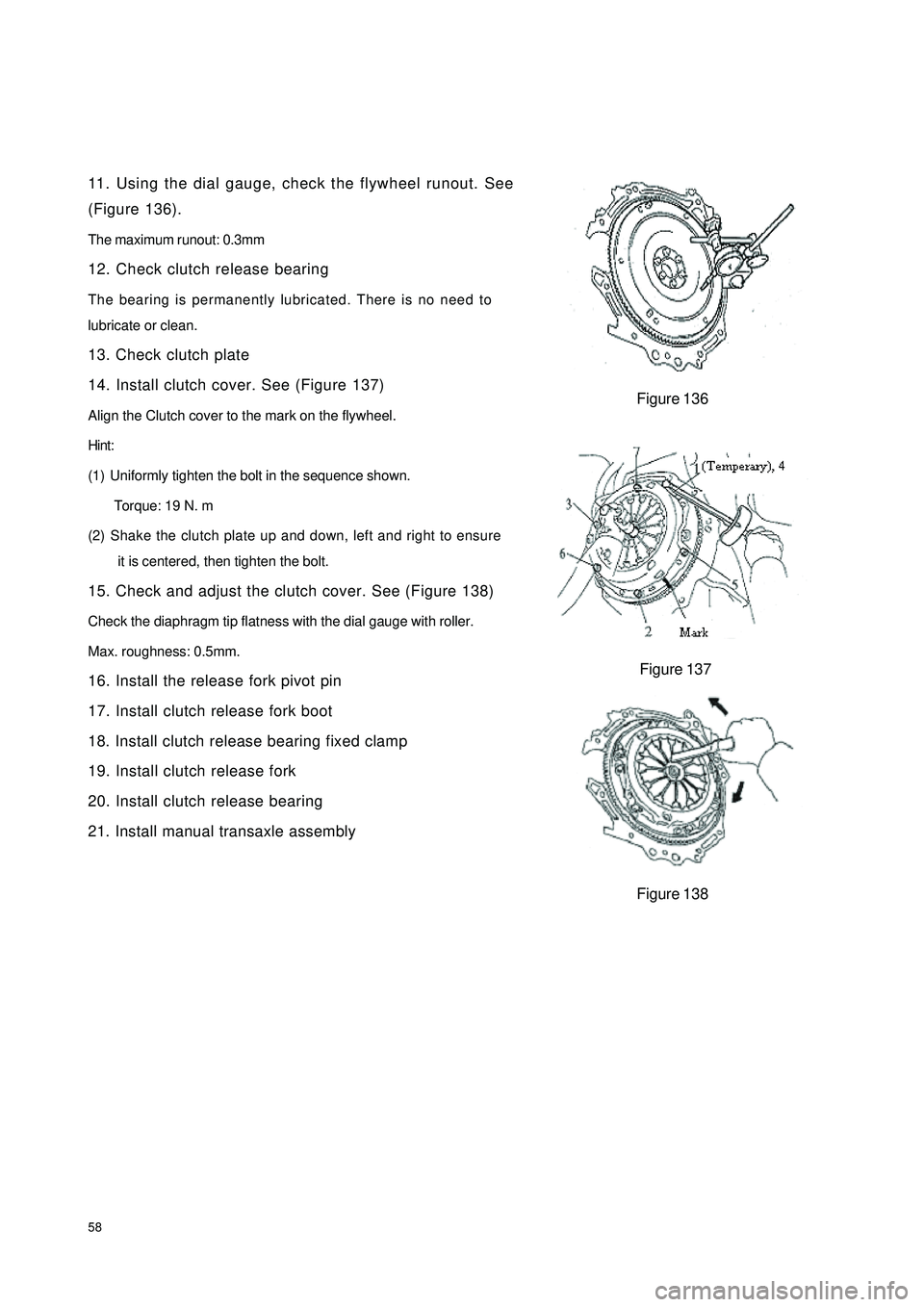

5811. Using the dial gauge, check the flywheel runout. See

(Figure 136).

The maximum runout: 0.3mm

12. Check clutch release bearing

The bearing is permanently lubricated. There is no need to

lubricate or clean.

13. Check clutch plate

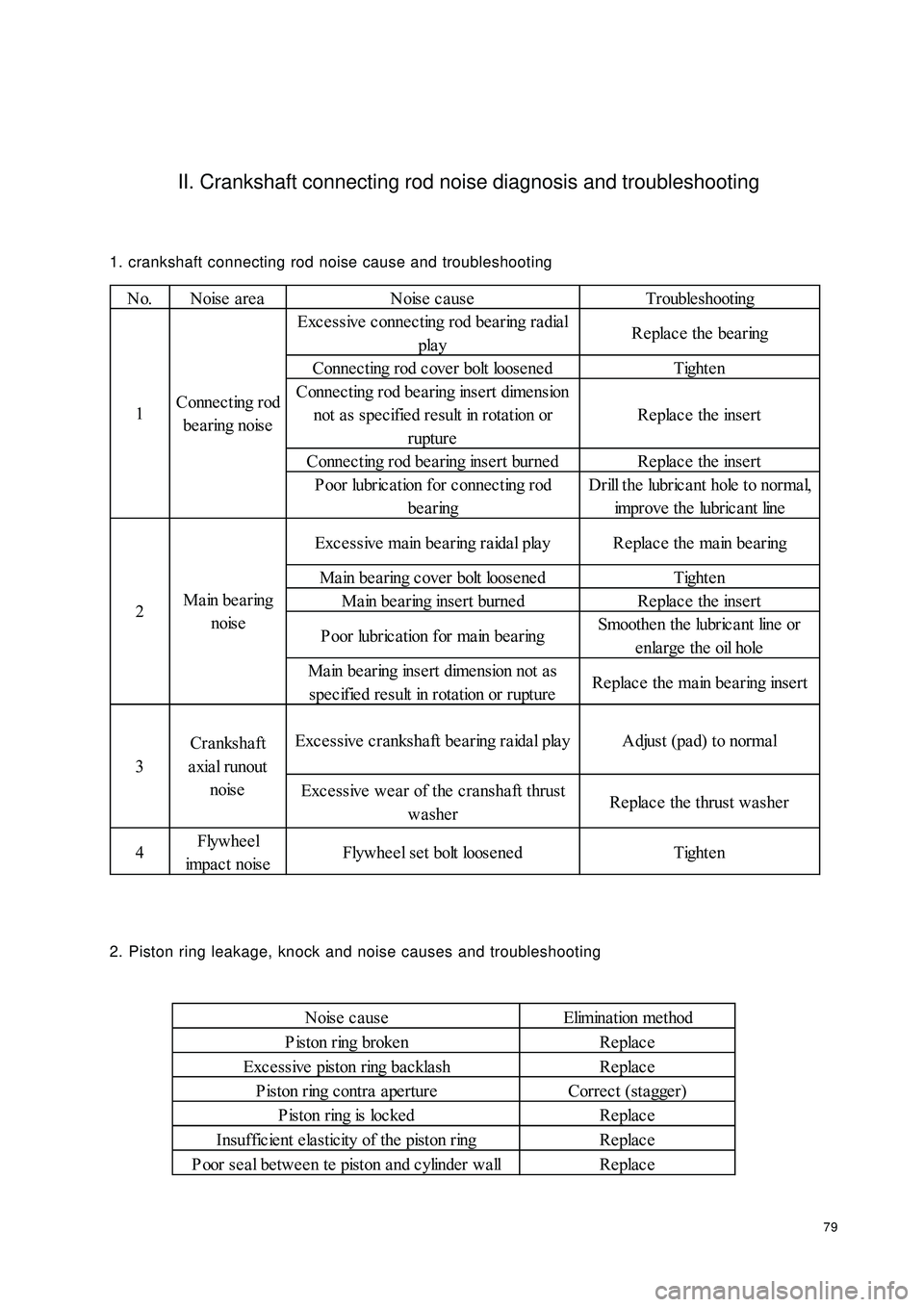

14. Install clutch cover. See (Figure 137)

Align the Clutch cover to the mark on the flywheel.

Hint:

(1) Uniformly tighten the bolt in the sequence shown.

Torque: 19 N. m

(2) Shake the clutch plate up and down, left and right to ensure

it is centered, then tighten the bolt.

15. Check and adjust the clutch cover. See (Figure 138)

Check the diaphragm tip flatness with the dial gauge with roller.

Max. roughness: 0.5mm.

16. Install the release fork pivot pin

17. Install clutch release fork boot

18. Install clutch release bearing fixed clamp

19. Install clutch release fork

20. Install clutch release bearing

21. Install manual transaxle assemblyFigure 136

Figure 137

Figure 138

Page 67 of 392

60Section 1 Manual Transaxle Replacement1. Open the engine hood

2. Remove the battery

3. Remove clutch cylinder sub-assembly. See (Figure 140)

4. Detach transmission shift cable assembly. See (Figure 141)

5. Remove the connector and turn on the back-up lamp switch connector.

6. Disconnect vehicle speed sensor

Disconnect vehicle speed sensor connector.

7. Detach the front exhaust pipe

8. Drain transmission oil

9. Detach left & right front wheel hub nut

10. Detach left & right front wheel speed sensor (ABS)

11. Detach front balance rod

12. Detach left & right tie-rod with ball stud pin

13. Detach front balance rod

14. Detach left & right lower swing arm

15. Detach left & right front propeller assembly

16. Hoist the engine from compartment. See "Provision 20, Section 2, Chapter 2"

17. Detach starter assembly

18. Detach engine mounting bracket

19. Detach manual transaxle assembly

20. Install engine mounting bracket

21. Install manual transaxle assembly

22. Connect engine vibration insulating cushions

23. Install starter assembly

24. Install left & right front propeller assembly

25. Connect left & right lower swing arm

26. Connect left & right tie-rod with ball stud pin

27. Connect front balance rod

28. Connect left & right front speed sensor (ABS)

29. Installleft & right front shaft nut

30. Install front exhaust pipe

31. Connect speedometer sensor connector.

32. Connect back-up lamp switch connector.

33. Connect transmission shift cable assembly. See (Figure 141)

34. Install clutch sub-pump assembly. See (Figure 140)Figure 140

Figure 141

Page 86 of 392

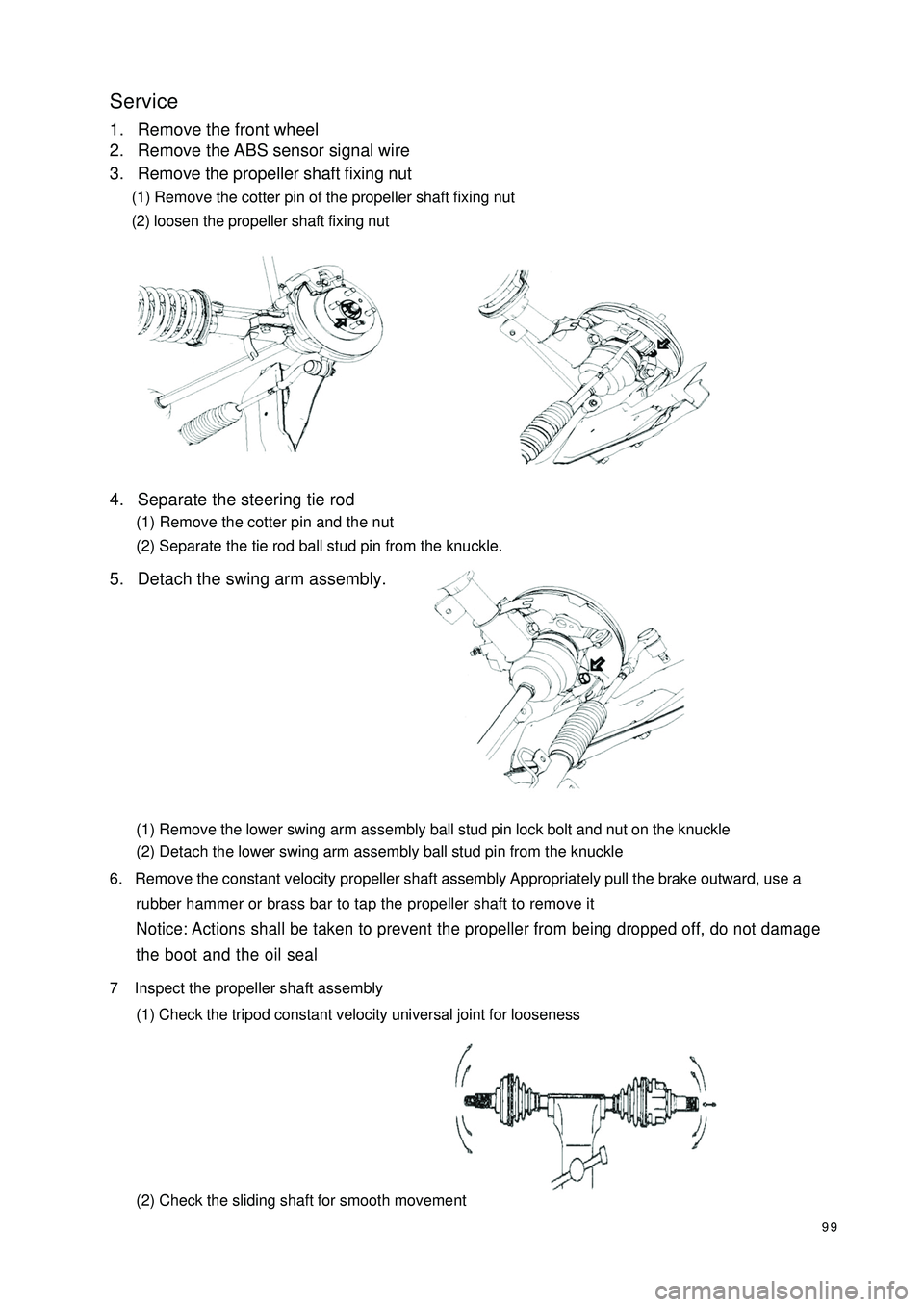

79II. Crankshaft connecting rod noise diagnosis and troubleshooting1. crankshaft connecting rod noise cause and troubleshooting

2. Piston ring leakage, knock and noise causes and troubleshootingNoise cause Elimination method

P iston ring broke n Re plac e

Exc e ssive piston ring ba ckla sh Re plac e

P iston ring contra a pe rture Corre ct (sta gge r)

P iston ring is loc ked Re plac e

Insuffic ient e lasticity of the piston ring Re plac e

P oor se al be twe e n te piston a nd c ylinder wa ll Re plac eNo.Noise areaNoise c a use Trouble shootingExcessive connecting rod bearing radialplayReplace the bearing

Conne c ting rod c ove r bolt loose nedTightenConne cting rod be a ring inse rt dimension

not a s s pe c if ie d r e s ult in r ot a t ion or

ruptureReplace the insert

Connecting rod bearing insert burnedReplace the insert

P oor lubric a tion for connec ting rodbearingDrill the lubric a nt hole to normal,

improve the lubric a nt line

Excessive main bearing raidal play Replace the main bearing

Main bearing cover bolt loosened Tighten

Main bearing insert burned Replace the insert

P oor lubr ic a t ion f or ma in be a r ingSmoothen the lubricant line or

e nla r ge t he oil hole

Ma in be aring inse rt dime nsion not a s

specified result in rotation or ruptureReplace the main bearing insert

Exc essive cranksha ft be a ring ra idal play Adjust (pa d) to norma l

Excessive wear of the cranshaft thrust

washerReplace the thrust washer

4Flywheel

impac t noiseFlywheel set bolt loosened Tighten 3Crankshaft

a xia l r unout

noise Connecting rod

bea ring noise 1

M a in be a r ing

noise 2

Page 104 of 392

97Chapter 4 Propeller ShaftSection 1 Propeller ShaftPropeller shaft is constant velocity propeller shaft, consisting of tripod constant velocity universal joint and

Rzeppa constant velocity univeral joint, where the tripod one is on the differential side and the Rzeppa one is

on the wheel side.Structure

Symptom TableThe table below is helpful to find the cause of the problem. The numbers indicate the priority of the likely

cause of the problem. Check each part in order. Repair or replace these parts or assemblies if necessary.Symptom Inspe c tion A re a

1.

R ze ppa C onsta nt ve loc ity unive rsa l joint (w orn)

2.

Tripod c onsta nt ve loc ity unive rsa l joint (w orn) NoiseRzeppa TypeTripod TypeRzeppa Constant Velocity Joint Tripod Constant Velocity Joint

1. Case 2.Steel Ball 3.Rzeppa

4.Inner Star Race 5.Semi-shaft1.Case 2.Tripod Assembly

3.Semi-shaft

Page 106 of 392

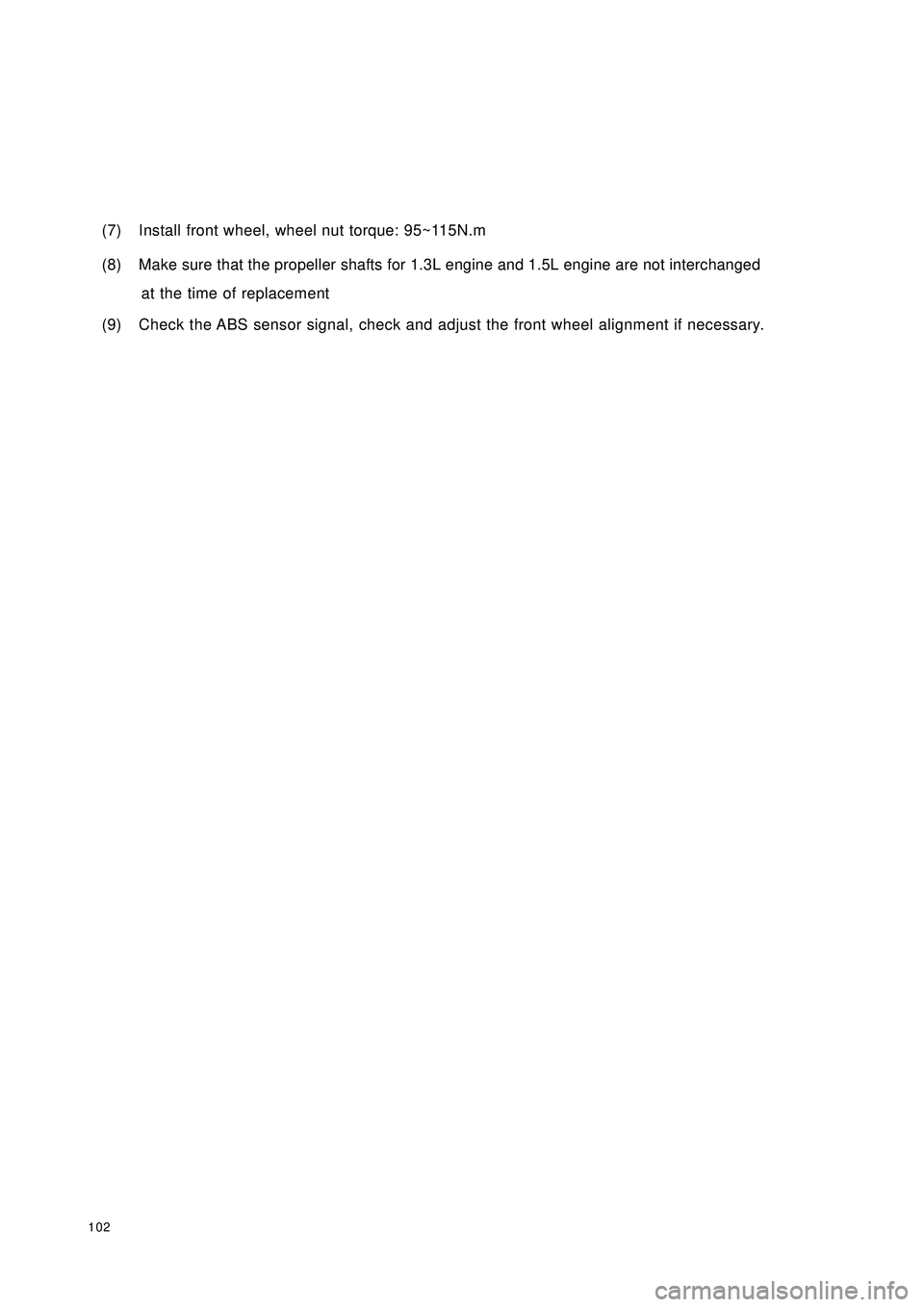

99Service1. Remove the front wheel

2. Remove the ABS sensor signal wire

3. Remove the propeller shaft fixing nut

(1) Remove the cotter pin of the propeller shaft fixing nut

(2) loosen the propeller shaft fixing nut

4. Separate the steering tie rod

(1) Remove the cotter pin and the nut

(2) Separate the tie rod ball stud pin from the knuckle.

5. Detach the swing arm assembly.

(1) Remove the lower swing arm assembly ball stud pin lock bolt and nut on the knuckle

(2) Detach the lower swing arm assembly ball stud pin from the knuckle

6. Remove the constant velocity propeller shaft assembly Appropriately pull the brake outward, use a

rubber hammer or brass bar to tap the propeller shaft to remove itNotice: Actions shall be taken to prevent the propeller from being dropped off, do not damage

the boot and the oil seal7 Inspect the propeller shaft assembly

(1) Check the tripod constant velocity universal joint for looseness

(2) Check the sliding shaft for smooth movement

Page 109 of 392

102(7) Install front wheel, wheel nut torque: 95~115N.m

(8) Make sure that the propeller shafts for 1.3L engine and 1.5L engine are not interchanged

at the time of replacement

(9) Check the ABS sensor signal, check and adjust the front wheel alignment if necessary.

Page 110 of 392

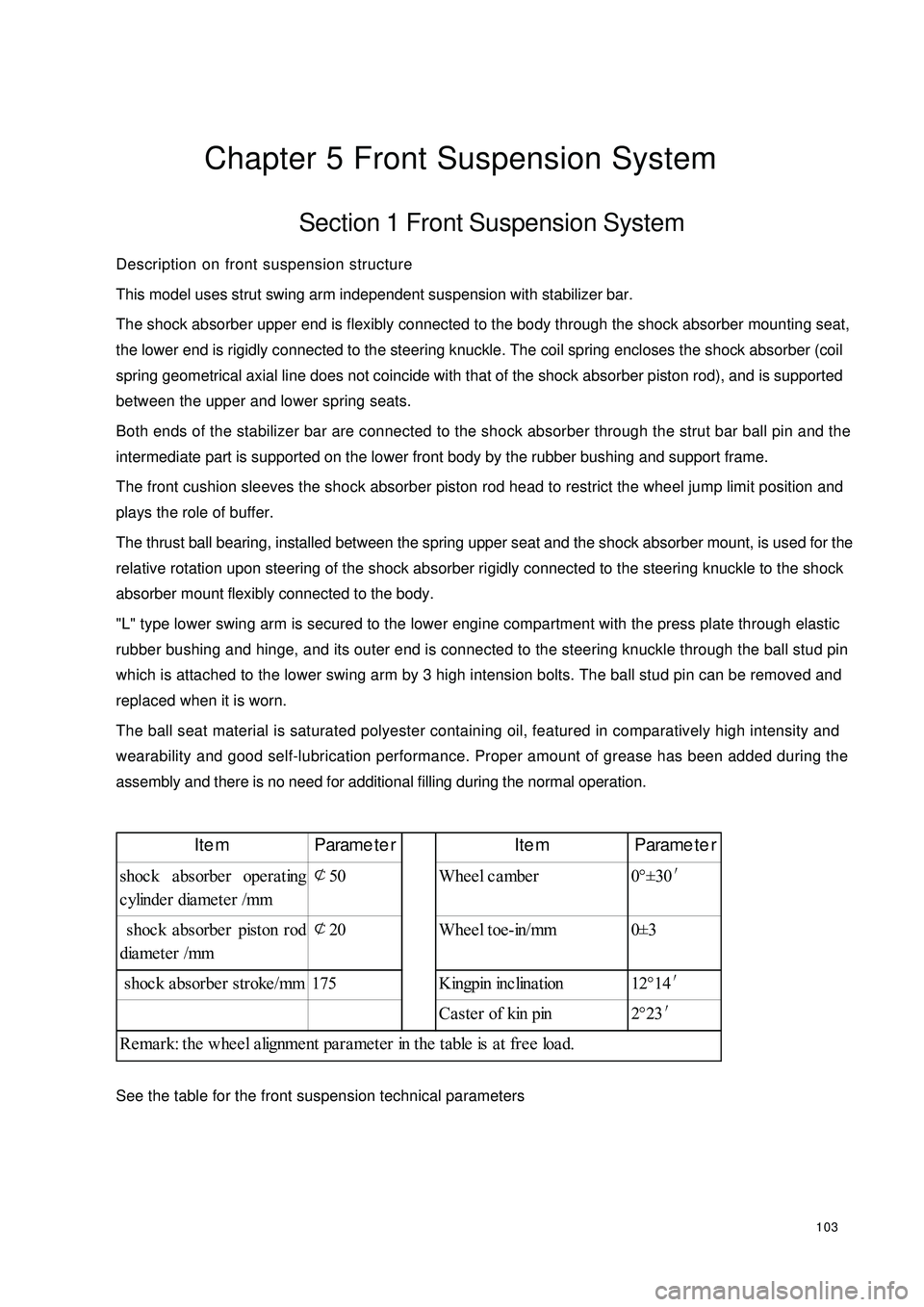

103Chapter 5 Front Suspension SystemSection 1 Front Suspension SystemDescription on front suspension structure

This model uses strut swing arm independent suspension with stabilizer bar.

The shock absorber upper end is flexibly connected to the body through the shock absorber mounting seat,

the lower end is rigidly connected to the steering knuckle. The coil spring encloses the shock absorber (coil

spring geometrical axial line does not coincide with that of the shock absorber piston rod), and is supported

between the upper and lower spring seats.

Both ends of the stabilizer bar are connected to the shock absorber through the strut bar ball pin and the

intermediate part is supported on the lower front body by the rubber bushing and support frame.

The front cushion sleeves the shock absorber piston rod head to restrict the wheel jump limit position and

plays the role of buffer.

The thrust ball bearing, installed between the spring upper seat and the shock absorber mount, is used for the

relative rotation upon steering of the shock absorber rigidly connected to the steering knuckle to the shock

absorber mount flexibly connected to the body.

"L" type lower swing arm is secured to the lower engine compartment with the press plate through elastic

rubber bushing and hinge, and its outer end is connected to the steering knuckle through the ball stud pin

which is attached to the lower swing arm by 3 high intension bolts. The ball stud pin can be removed and

replaced when it is worn.

The ball seat material is saturated polyester containing oil, featured in comparatively high intensity and

wearability and good self-lubrication performance. Proper amount of grease has been added during the

assembly and there is no need for additional filling during the normal operation.

See the table for the front suspension technical parametersItem Parameter Item Parameter

shoc k a bsorbe r ope ra ting

cylinder diameter /mm¢

50 Wheel camber 0°±30′

shoc k a bsorbe r piston rod

diameter /mm¢

20 Wheel toe-in/mm 0±3

shoc k a bsorbe r stroke /mm 175 Kingpin inc lina tion 12°14′

Ca ste r of kin pin 2°23′

Remark: the wheel alignment parameter in the table is at free load.

Page 111 of 392

104PROBLEM SYMPTOMS TABLEUse the table below to help you find the cause of the problem. The numbers indicate the priority of the likely

cause of the problem. Check each part in order. If necessary, replace parts.Sympto m Sus pe cte d Are a

1. Tires (Worn or imprope rly infla te d)

2. Wheel alignment (Incorrect)

3. Steering system joint(Loose or worn)

4. Hub be a ring (Worn)

5. Ste e ring ge a r (Out of adjustme nt or worn)

6. Suspe nsion pa rts (Worn or da ma ge d)

1. Ve hic le (Ove rloa de d)

2. Spring (stiffne ss not comply with or da ma ge )

3. Shoc k a bsorbe r (Worn)

1. Tire (Worn or imprope rly infla te d)

2. Stee ring linka ge (Loose or dama ged)

3. Sta bilize r ba r (Be nt or broke n)

4. Shoc k a bsorbe r (Worn or da mage d)

1. Tire (Worn or imprope rly infla te d)

2. T ir e ( D yna mic ba la nc e is not a s s pe c if ie d)

3. Shock a bsorber (Worn or da ma ge d)

4. Wheel alignment (Incorrect)

5. Ball stud pin (Worn or da mage d)

6. Hub be aring (Worn or da mage d)

7. Ste ering linka ge (Loose or worn)

8. Ste e ring ge a r (Out of adjustme nt or worn)

1. Tire (Worn or imprope rly infla ted)

2. Wheel alignment (Incorrect)

3. Shoc k a bsorbe r (Worn or da mage d)

4. Suspe nsion pa rts (Worn or da ma ge d) Abnormal tire wearDeviation

Body Desc ent

Sways

F r ont w he e l s himmy

Page 113 of 392

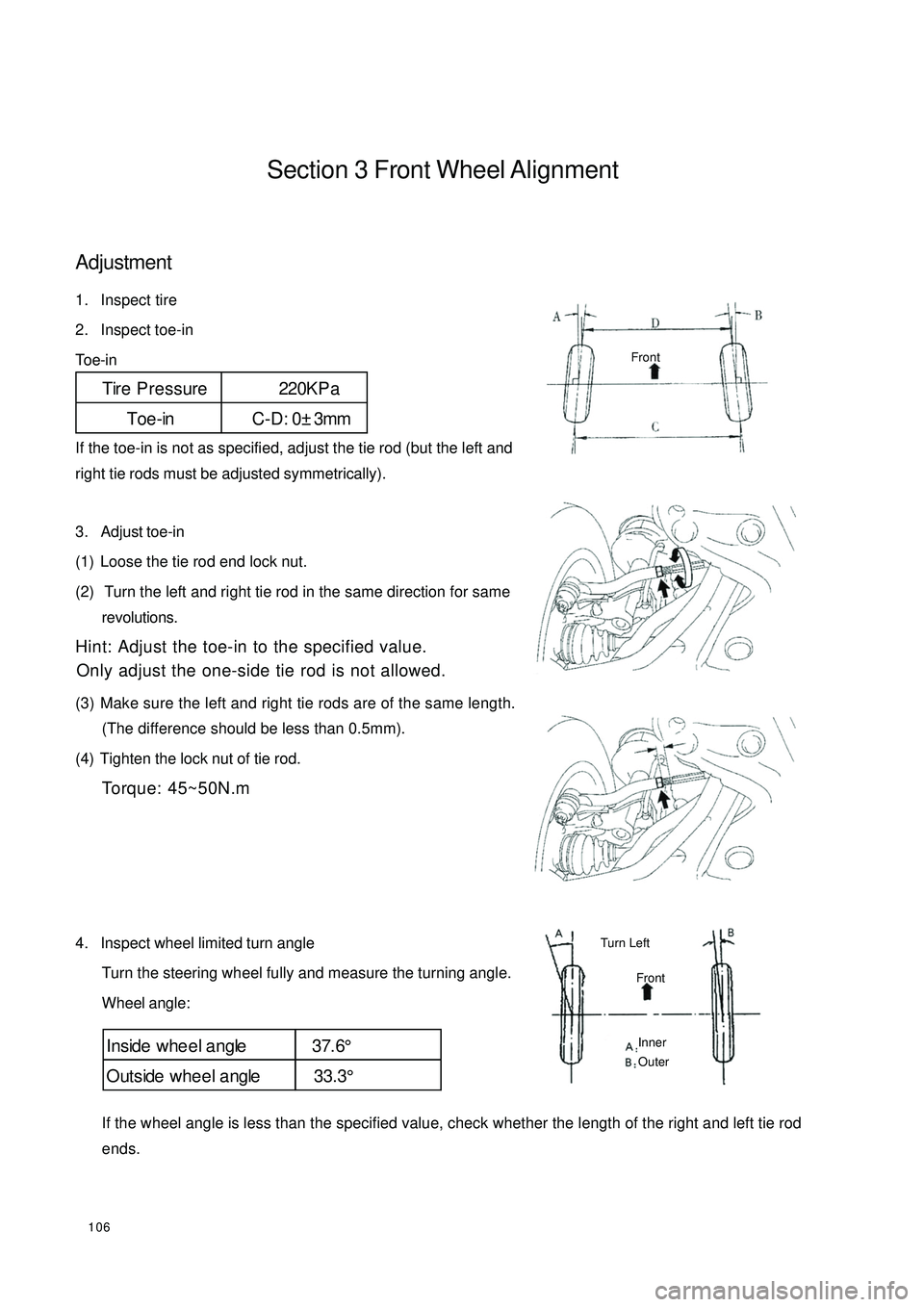

106Section 3 Front Wheel AlignmentAdjustment1. Inspect tire

2. Inspect toe-in

Toe-in

If the toe-in is not as specified, adjust the tie rod (but the left and

right tie rods must be adjusted symmetrically).

3. Adjust toe-in

(1) Loose the tie rod end lock nut.

(2) Turn the left and right tie rod in the same direction for same

revolutions.

Hint: Adjust the toe-in to the specified value.

Only adjust the one-side tie rod is not allowed.

(3) Make sure the left and right tie rods are of the same length.

(The difference should be less than 0.5mm).

(4) Tighten the lock nut of tie rod.

Torque: 45~50N.m

4. Inspect wheel limited turn angle

Turn the steering wheel fully and measure the turning angle.

Wheel angle:

If the wheel angle is less than the specified value, check whether the length of the right and left tie rod

ends.Tire Pressure 220KP a

Toe-in C-D: 0±3mmInside whe e l a ngle 37.6°

Outside whee l a ngle 33.3°FrontFrontTurn Left Inner

Outer