radiator GEELY CK 2008 Workshop Manual

[x] Cancel search | Manufacturer: GEELY, Model Year: 2008, Model line: CK, Model: GEELY CK 2008Pages: 392, PDF Size: 38.86 MB

Page 3 of 392

Chapter 6 Cooling System Inspection

(MR7131A, MR7151A, MR7161A).................................................................52Section 1 System Check

Section 2 Water Pump, Thermostat and Radiator Replacement.................................... 54Chapter 7 Clutch (MR7131A, MR7151A, MR7161A)....................................56Section 1 Clutch Replacement...................................................................................57Chapter 8 Maunal Transaxle Assembly

(MR7131A, MR7151A, MR7161A)................................................................59Section 1 Manual Transaxle Replacement..................................................................60

Section 2 Vehicle Speed Sensor Replacement

Section 3 Transmission Case Oil Seal..........................................................................62

Section 4 Transaxle Case Oil Seal Replacement........................................................63Chapter 9 General Engine Troubles and Their Troubleshooting....................64Section 1 Overview........................................................................................................64

Section 2 General Engine Fault and Troubleshooting.......................................................64

Section 3 Engine Noise Diagnosis and Troubleshooting................................................77Chapter 10 Engine Management Unit..............................................................81Section 1 System Description.........................................................................................81

Section 2 System Component and Working Principle......................................................82Part II Chassis............................................................................85Chapter 1 Transmission Control Device.........................................................85Section 1 Transmission Control Device.........................................................................85

Section 2 Lever Type Transmission Control Device......................................................85

Section 3 Cable Type Transmission Control Module......................................................87Chapter 2 Accelerator Pedal............................................................................90Section 1 Accelerator Pedal..........................................................................................90Chapter 3 Clutch Control System....................................................................91Section 1 Clutch Control System....................................................................................91

Section 2 Clutch Cable Control Mechanism.....................................................................91

Section 3 Clutch hydraulic Control Device.......................................................................94Chapter 4 Propeller Shaft...............................................................................97...............................................................................................52

..............................................................61

Page 17 of 392

10Chapter 2 Engine Components Replacement

(MR479Q, MR479QA, MR481QA)Section 1 Engine ComponentsComponent 1Air Filter Assembly W/ Hose

Accelerator Control

Cable Assembly

Heater Inlet Hose

Heater Outlet Hose

Fuel Sub-Assembly

Efi Fuel Pipe Clamp

MT:

Transmission

Control Cable

Assembly

AT :

Transmission Control Cable Assembly MT:

Clutch Release

Cylinder Assembly

Radiator Outlet Pipe Radiator Inlet Pipe

Starter AssemblyAT: Oil Cooler Outlet Pipe

AT: Oil Cooler Inlet Pipe

Radiator Assembly

BatteryFront Exhaust

Pipe Assy.3-way catalytic

converterMufflerTail PipeFigure 20

Page 21 of 392

1421. Remove radiator assembly

22. Remove engine V-belt

23. Remove No. 1 V- belt (A/C compressor to crankshaft pulley)

24. Remove generator assembly

25. Remove A/C compressor

26. Remove compressor installing No. 1 bracket. Remove 4 bolts and compressor installing No.

1 bracket.

27. Remove starter assembly

28. Remove power steering pump V- belt

29. Detach power steering pump assembly

30. Remove power steering pump, adjust the bracket

31. Detach manual transaxle assembly (Separate automatic transaxle assembly)

32. Detach clutch cover panel assembly.

33. Detach clutch pressure plate assembly.

34. Detach flywheel sub-assembly.

35. Remove engine rear end cover.

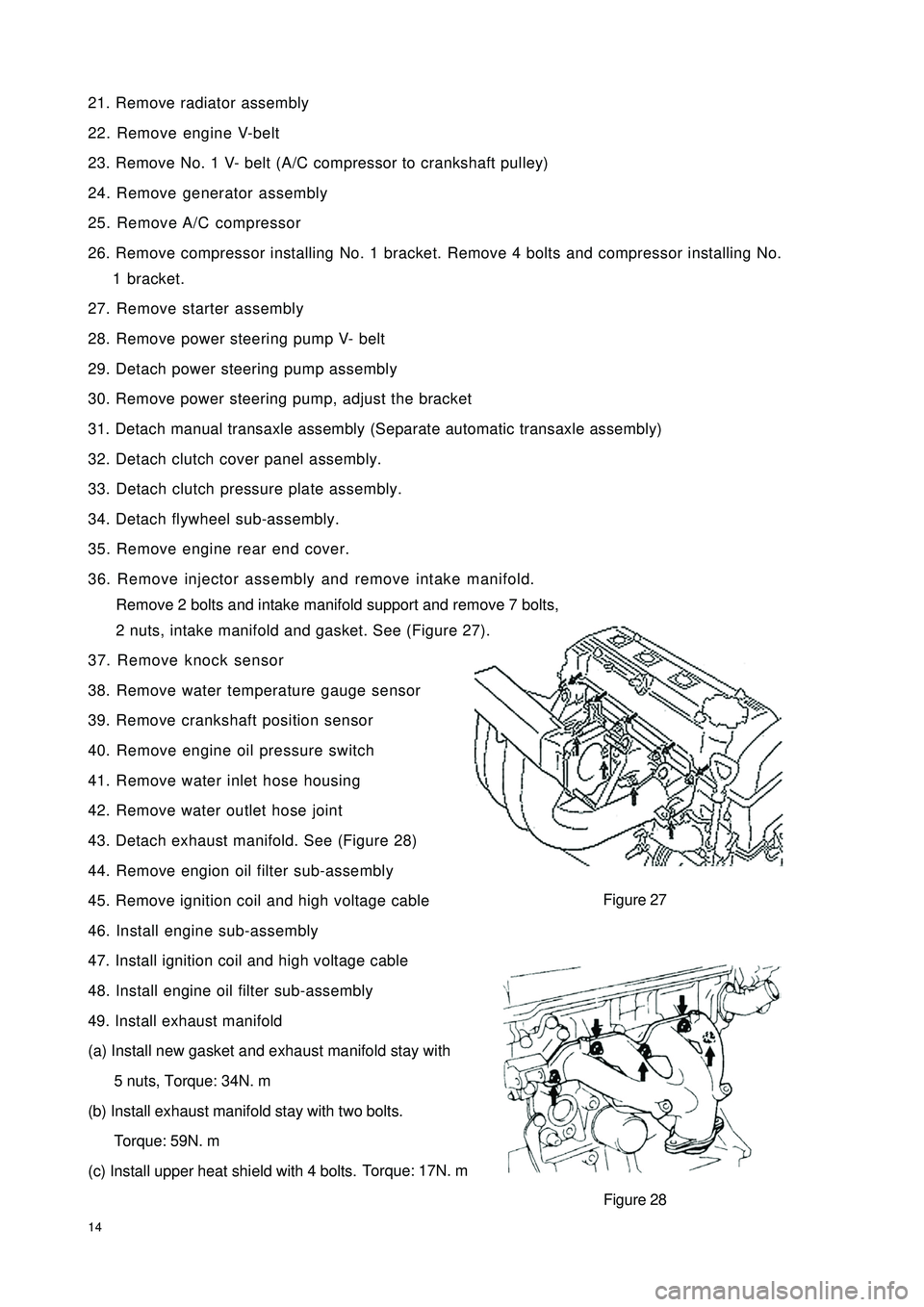

36. Remove injector assembly and remove intake manifold.

Remove 2 bolts and intake manifold support and remove 7 bolts,

2 nuts, intake manifold and gasket. See (Figure 27).

37. Remove knock sensor

38. Remove water temperature gauge sensor

39. Remove crankshaft position sensor

40. Remove engine oil pressure switch

41. Remove water inlet hose housing

42. Remove water outlet hose joint

43. Detach exhaust manifold. See (Figure 28)

44. Remove engion oil filter sub-assembly

45. Remove ignition coil and high voltage cable

46. Install engine sub-assembly

47. Install ignition coil and high voltage cable

48. Install engine oil filter sub-assembly

49. Install exhaust manifold

(a) Install new gasket and exhaust manifold stay with

5 nuts, Torque: 34N. m

(b) Install exhaust manifold stay with two bolts.

Torque: 59N. m

(c) Install upper heat shield with 4 bolts.Torque: 17N. mFigure 27

Figure 28

Page 23 of 392

16(c) Install and uniformly tighten connecting bolt in the sequence shown inthe figure.

Torque: 64N. m

62. Install manual transaxle assembly

63. Install starter assembly

64. Install power steering pump bracket

65. Install power steering pump adjusting bracket with 2 bolts.

66. Connect power steering pump assembly

67. Install engine assembly and transaxle

68. Connect left, right, front and rear lower suspension arm sub-assembly

69. Connect left and right tie rod ball stud pin assembly

70. Connect left, right and front vehicle speed sensor (with ABS)

71. Install left & right nuts on the front shaft hub

72. Install front exhaust pipe assembly

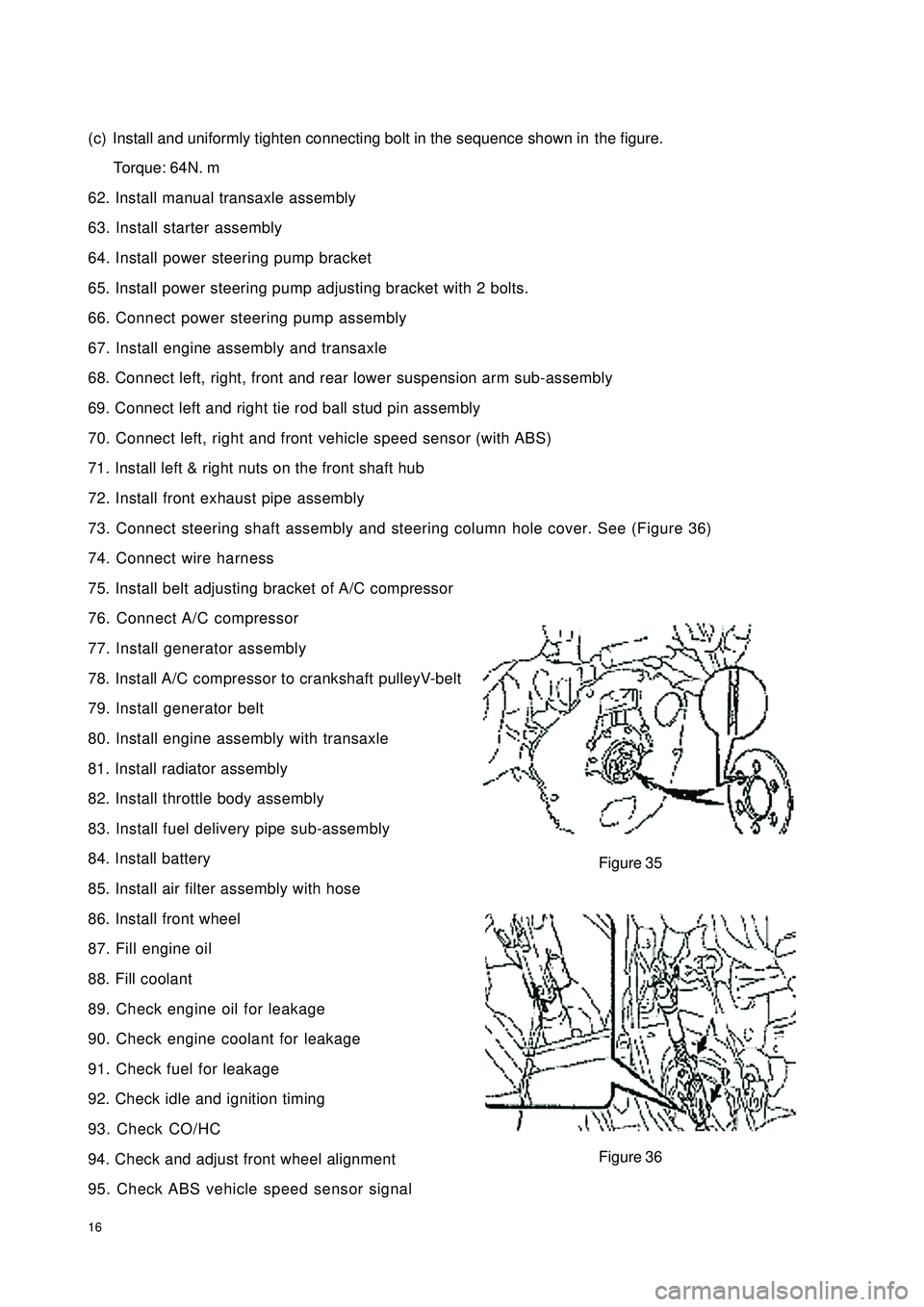

73. Connect steering shaft assembly and steering column hole cover. See (Figure 36)

74. Connect wire harness

75. Install belt adjusting bracket of A/C compressor

76. Connect A/C compressor

77. Install generator assembly

78. Install A/C compressor to crankshaft pulleyV-belt

79. Install generator belt

80. Install engine assembly with transaxle

81. Install radiator assembly

82. Install throttle body assembly

83. Install fuel delivery pipe sub-assembly

84. Install battery

85. Install air filter assembly with hose

86. Install front wheel

87. Fill engine oil

88. Fill coolant

89. Check engine oil for leakage

90. Check engine coolant for leakage

91. Check fuel for leakage

92. Check idle and ignition timing

93. Check CO/HC

94. Check and adjust front wheel alignment

95. Check ABS vehicle speed sensor signalFigure 35

Figure 36

Page 37 of 392

30Component 3Figure 70Air Filter Assembly W/ HoseEngine Hood

Right Wiper Arm

Left Wiper Arm

Right Scuttle Ventilation Grille

Left Scuttle Ventilation Grille Right Engine Mounting Bracket

Generator

AssemblyAccelerator Cable AssemblyWiper Arm Subassembly

EFI Fuel Hose Clamp

Fuel Pipe Sub-Assembly

Heater Outlet Hose A

Radiator Outlet Hose Radiator Inlet HoseHeater Inlet Hose

Vane-Type Pump

V-Belt V/ Power Steering

V-Belt No.1Fan & Generator V-Belt

Page 59 of 392

52Chapter 6 Cooling System Inspection

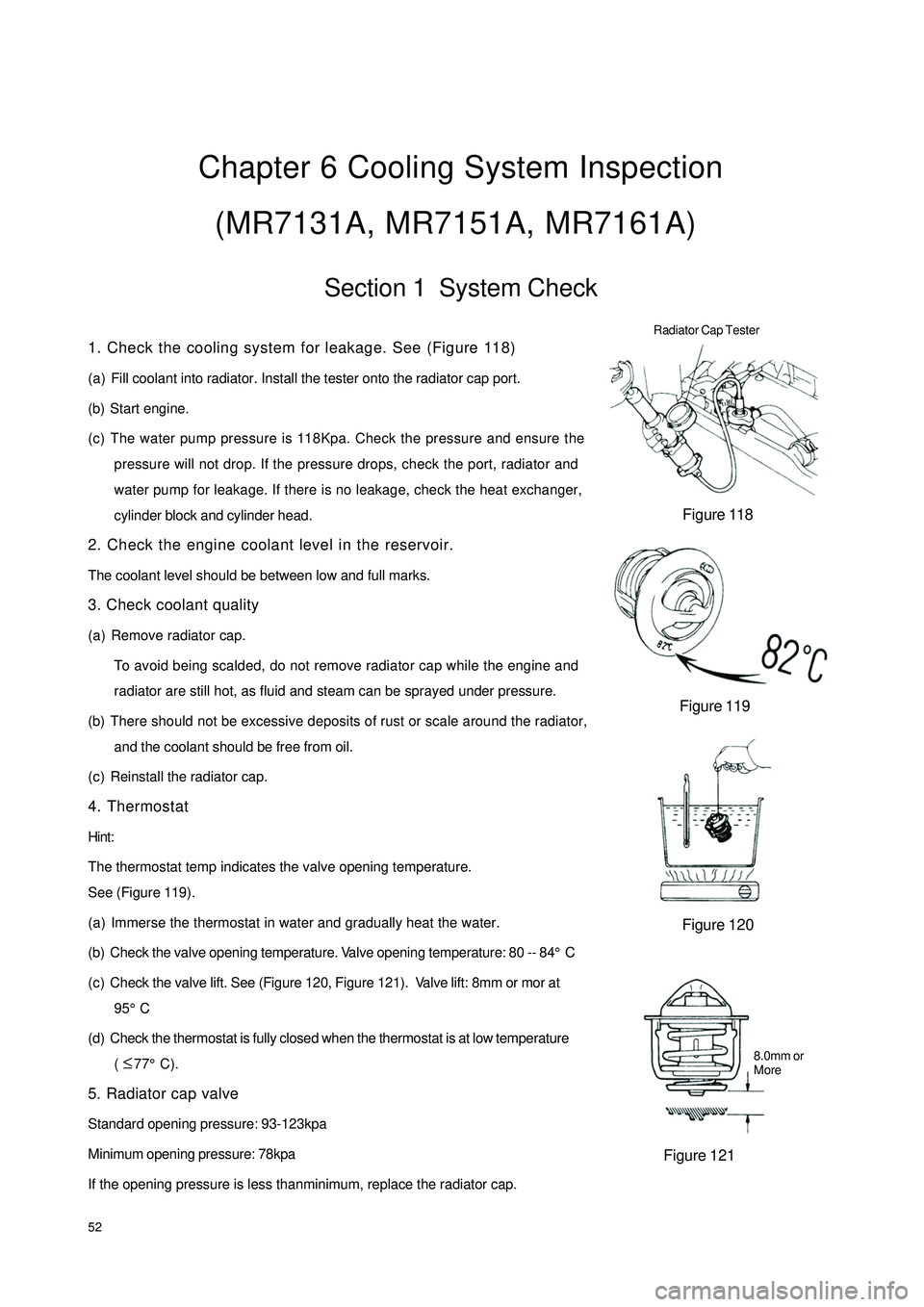

(MR7131A, MR7151A, MR7161A)Section 1 System Check1. Check the cooling system for leakage. See (Figure 118)

(a) Fill coolant into radiator. Install the tester onto the radiator cap port.

(b) Start engine.

(c) The water pump pressure is 118Kpa. Check the pressure and ensure the

pressure will not drop. If the pressure drops, check the port, radiator and

water pump for leakage. If there is no leakage, check the heat exchanger,

cylinder block and cylinder head.

2. Check the engine coolant level in the reservoir.

The coolant level should be between low and full marks.

3. Check coolant quality

(a) Remove radiator cap.

To avoid being scalded, do not remove radiator cap while the engine and

radiator are still hot, as fluid and steam can be sprayed under pressure.

(b) There should not be excessive deposits of rust or scale around the radiator,

and the coolant should be free from oil.

(c) Reinstall the radiator cap.

4. Thermostat

Hint:

The thermostat temp indicates the valve opening temperature.

See (Figure 119).

(a) Immerse the thermostat in water and gradually heat the water.

(b) Check the valve opening temperature. Valve opening temperature: 80 -- 84°C

(c) Check the valve lift. See (Figure 120, Figure 121). Valve lift: 8mm or mor at

95°C

(d) Check the thermostat is fully closed when the thermostat is at low temperature

( 77°C).

5. Radiator cap valve

Standard opening pressure: 93-123kpa

Minimum opening pressure: 78kpa

If the opening pressure is less thanminimum, replace the radiator cap.Figure 118

Figure 119

Figure 120

Figure 121 Radiator Cap Tester8.0mm or

More ≤

Page 61 of 392

54Section 2 Water Pump, Thermostat and Radiator ReplacementHoist the engine from the compartment. See "Provison 20, Section 2, Chapter 2".

1. Replace water pump. See (Figure 125)

(1) Drain the coolant.

(2) Detach timing belt.

(3) Detach power steering pump assembly.

(4) Remove the oil dipstick guide.

(5) Detach water pump assembly.

(6) Install water pump assembly.

(7) The installation is in the reverse order of the removal.

2. Replace thermostat

(1) Remove thermostat (See Figure 126).

(2) Install thermostat.

a. Install a new gasket to the thermostat. See (Figure 127).

b.Align the main valve of the thermostat to the top of the

stud. Insert the thermostat into the water inlet case.

Hint:

The main valve is set at around 10°C as shown in the figure. See (Figure 128).

(3) Install inlet connector.

Figure 127 Figure 128

3. Replace radiator

(1) Open radiator cap.

(2) Open the drain valve and drain the coolant.

(3) Detach radiator water inlet hose.

(4) Detach radiator water outlet hose.Figure 125

Figure 126

Page 62 of 392

55(5) Disconnect auto-transmission oil cooler input pipe (Auto-transmission).

(6) Disconnect auto-transmission oil cooler output pipe (Auto-transmission).

(7) Remove 4 bolts from the radiator mounting bracket. See (Figure 129).

(8) Detach radiator assembly, Remove 3 bolts. Detach the fan and fan shroud. See (Figure 130).

Figure 127 Figure 128

(9) Install the cooling fan assembly

(a) Fix the reservoir assembly on the cooling fan bracket with the bolt. Torque: 16 N. m.

(b) Install the fan and fan shroud with 3 bolts. Torque: 7.5N. m.

(c) Install the cooling fan assembly to radiator assembly with 3 bolts. Torque: 16N. m.

(d) Connect the overflow pipe on the reservoir assembly and radiator assembly. Fix it with the spring

band.

(f) The installation of the radiator assembly is in the reverse order of the removal.

Page 82 of 392

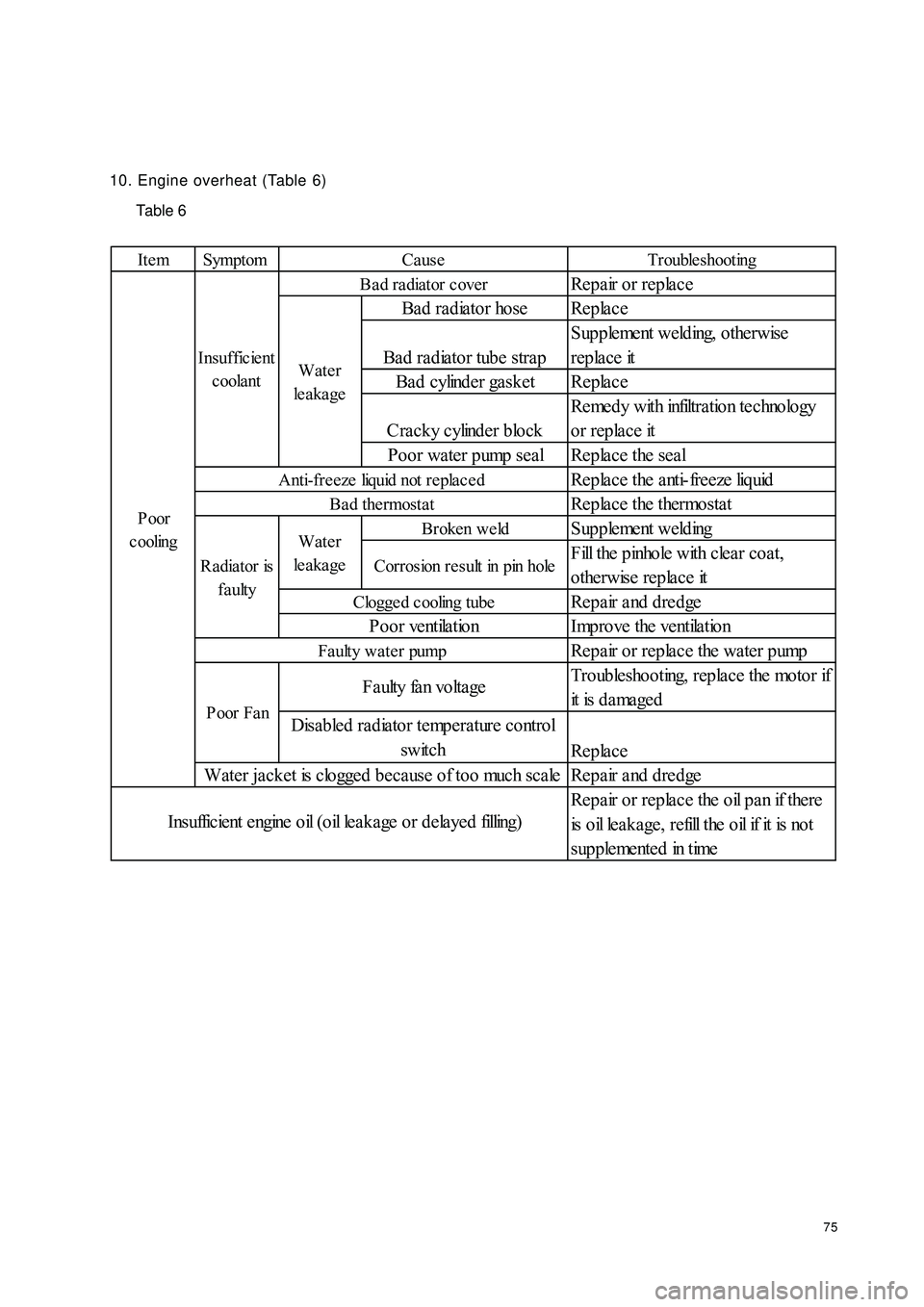

7510. Engine overheat (Table 6)

Table 6Ite m Symptom Trouble shootingRepair or replace

Bad radiator hose Replace

Bad radiator tube strapSupplement welding, otherwise

replace it

Bad cylinder gasket Replace

Cracky cylinder blockRemedy with infiltration technology

or replace it

Poor water pump seal Replace the seal

Replace the anti-freeze liquid

Replace the thermostatBroken we ldSupplement weldingCorrosion result in pin holeFill the pinhole with clear coat,

otherwise replace it

Repair and dredge

Improve the ventilation

Repair or replace the water pump

Troubleshooting, replace the motor if

it is d a ma ge d

Replace

Repair and dredge

Repair or replace the oil pan if there

is o il le a k a ge , r e fill t he o il if it is no t

s up p le me nt e d in t imeCause

Ba d ra diator c over

Clogge d cooling tubePoor ventilationWater

le a ka ge

Anti-fre eze liquid not repla ce d

Bad thermostat

Radiator is

faultyWater

le a ka ge Insufficient

coolantF a ulty fa n vo lta ge

Disabled radiator temperature control

switch

Water jacket is clogged because of too much scale

I ns uffic ie nt e ngine o il ( o il le a k a ge o r d e la ye d filling)P oor

c ooling

Poor FanFaulty water pump

Page 166 of 392

1594Make a simulation test in a way of symptom simulation

5Inspect DTC

6Confirm symptomV. SYMPTOM SIMULATIONNOTES:

The most difficult conditions to handle in the fault troubleshooting are that the fault symptom dose not appear.

Under the circumstances, make sure first to make a comprehensive analysis to the fault described by the

customer, then to simulate an environment that is similar or the same with the conditions when the fault of the

customer's vehicle occurred. No matter how rich the experience of the technician is and how skillful he is, if

he make a fault troubleshooting analysis without confirm the fault symptom, it is inevitable for him to neglect

some important factors and incorrectly guess, which may cause barriers to repair. For example, if a fault

occurs only when the engine is cool or if a fault occurs only caused by a vibration from pavement and so on,

when the engine is checked in the hot or static state, it is no way to confirm. Because of vibration, high-

temperature or seeping water (Vapor) often causes some faults that are difficult to reappear. So, here are

some effective symptom simulation tests.

KEY POINTS OF SYMPTOM SIMULATION TEST:

In the symptom simulation test, no doubt it is important to confirm the fault symptom, but the fault position or

fault components must be also found out. So, before the test and the pre-inspection of connection, narrow the

range of the circuit where faults may occur according to the fault symptom. Then make a symptom simula-

tion test to see if the circuit measured is normal; the fault symptom is also verified at the same time.

1. Way of Vibration: When vibration may be the major cause of the fault.

For example:

(a) Use your hand to gently vibrate the sensor that is considered the cause of the fault, in order to check if it

is ineffective.

(b) Softly rock the connector and harness in horizontal and vertical direction.

Notes: Hard rock may cause the relay circuit open.

2. Way of Spraying Water: When rainy weather or wet environment may be the major cause of the fault.

(a) Spray water on the vehicle to check if the fault occurs.

NOTES:

�yBe sure not to directly spray water into the engine compartment. Spray the water on the face of the

radiator to change the temperature and humidity indirectly.

�yBe sure not to spray water onto electronic devices and controllers.