suspension GEELY CK 2008 Workshop Manual

[x] Cancel search | Manufacturer: GEELY, Model Year: 2008, Model line: CK, Model: GEELY CK 2008Pages: 392, PDF Size: 38.86 MB

Page 4 of 392

Section 1 Propeller Shaft.................................................................................................. 97Chapter 5 Front Suspension System............................................................... 1 0 3Section 1 Front Suspension System................................................................................ 103

Section 2 Front Suspension............................................................................................105

Section 3 Front Wheel Alignment.......................................................................................106

Section 4 Front Strut Assembly....................................................................................... 107

Section 5 Lower Swing Arm Assembly............................................................................ 110

Section 6 Front Stabilizer Bar and Link Rod Assembly.....................................................113Chapter 6 Rear Suspension System................................................................116Section 1 Rear Suspension System

Section 2 Rear Suspension............................................................................................117

Section 3 Rear Wheel Alignment.................................................................................... 118

Section 4 Left & Right Rear Strut Assembly.....................................................................119

Section 5 Rear stabilizer bar assembly, strut rod components..........................................121

Section 6 Left & Right Trailing Rod Assembly.............................................................. 123

Section 7 No. 1 Transverse Arm Assembly..................................................................... 124

Section 8 No. 2 Transverse Arm Assembly..................................................................... 125Chapter 7 Wheel................................................................................................126Section 1 Tire Inspection................................................................................................. 126

Section 2 Wheel Replacement......................................................................................... 127Chapter 8 Power Steering System.................................................................. 1 2 8Section 1 Power Steering System.................................................................................... 128

Section 2 Steering Drive and Control Mechanism......................................................... 130

Section 3 Steering Pipeline Component.......................................................................... 133

Section 4 Power Steering Gear Retaining DeviceChapter 9 Brake System.................................................................................. 1 3 9Section 1 Brake System ................................................................................................... 139

Section 2 Brake Fluid....................................................................................................... 140

Section 3 Brake Pedal...................................................................................................... 141

Section 4 Vacuum Booster with Brake Master Cylinder Assembly....................................143

Section 5 Front Brake Assembly..................................................................................... 144

Section 6 Rear Brake

Section 7 Brake Line ....................................................................................................... 151..................................................................................116

.....................................................................................................147..........................................................136

Page 23 of 392

16(c) Install and uniformly tighten connecting bolt in the sequence shown inthe figure.

Torque: 64N. m

62. Install manual transaxle assembly

63. Install starter assembly

64. Install power steering pump bracket

65. Install power steering pump adjusting bracket with 2 bolts.

66. Connect power steering pump assembly

67. Install engine assembly and transaxle

68. Connect left, right, front and rear lower suspension arm sub-assembly

69. Connect left and right tie rod ball stud pin assembly

70. Connect left, right and front vehicle speed sensor (with ABS)

71. Install left & right nuts on the front shaft hub

72. Install front exhaust pipe assembly

73. Connect steering shaft assembly and steering column hole cover. See (Figure 36)

74. Connect wire harness

75. Install belt adjusting bracket of A/C compressor

76. Connect A/C compressor

77. Install generator assembly

78. Install A/C compressor to crankshaft pulleyV-belt

79. Install generator belt

80. Install engine assembly with transaxle

81. Install radiator assembly

82. Install throttle body assembly

83. Install fuel delivery pipe sub-assembly

84. Install battery

85. Install air filter assembly with hose

86. Install front wheel

87. Fill engine oil

88. Fill coolant

89. Check engine oil for leakage

90. Check engine coolant for leakage

91. Check fuel for leakage

92. Check idle and ignition timing

93. Check CO/HC

94. Check and adjust front wheel alignment

95. Check ABS vehicle speed sensor signalFigure 35

Figure 36

Page 110 of 392

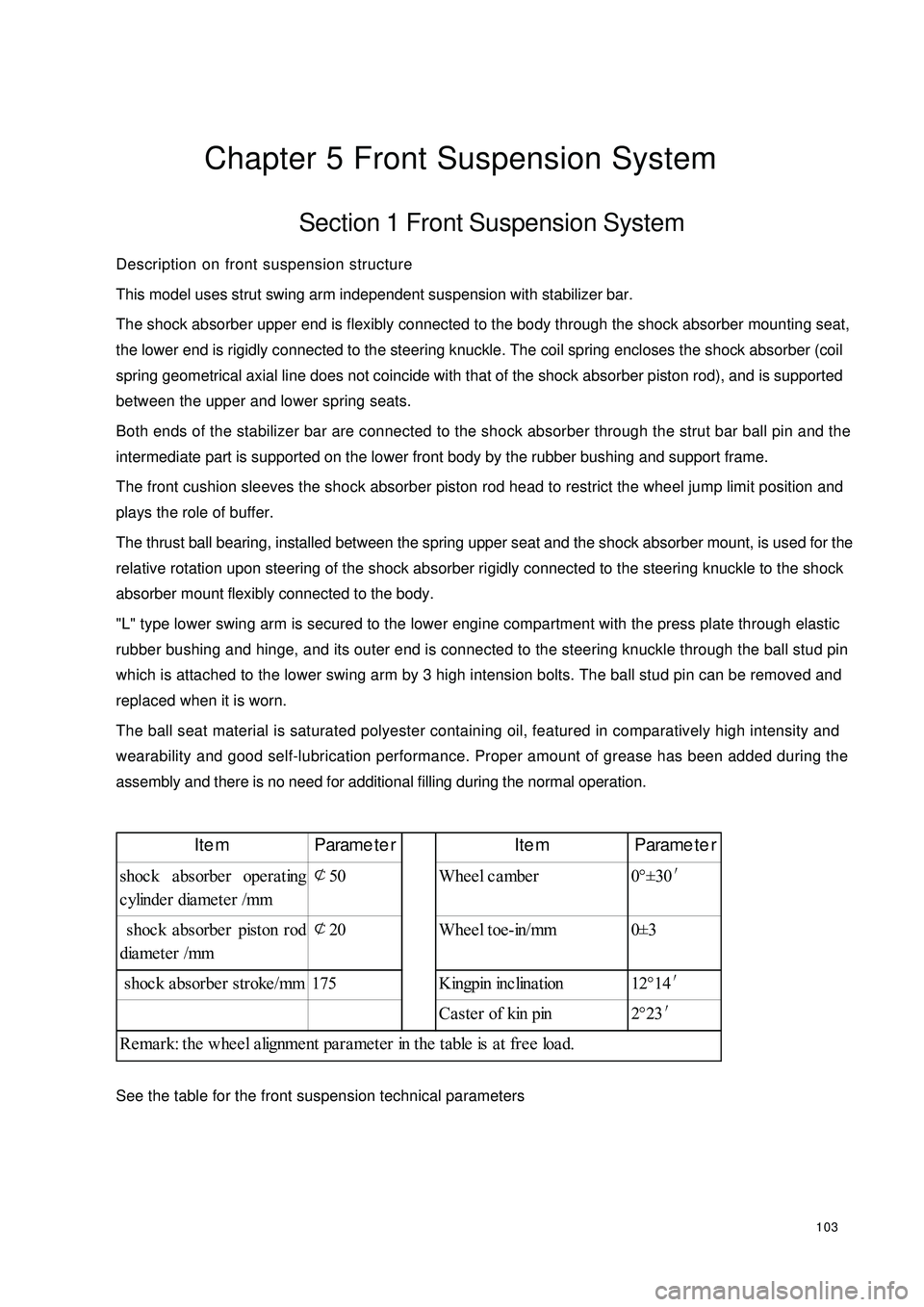

103Chapter 5 Front Suspension SystemSection 1 Front Suspension SystemDescription on front suspension structure

This model uses strut swing arm independent suspension with stabilizer bar.

The shock absorber upper end is flexibly connected to the body through the shock absorber mounting seat,

the lower end is rigidly connected to the steering knuckle. The coil spring encloses the shock absorber (coil

spring geometrical axial line does not coincide with that of the shock absorber piston rod), and is supported

between the upper and lower spring seats.

Both ends of the stabilizer bar are connected to the shock absorber through the strut bar ball pin and the

intermediate part is supported on the lower front body by the rubber bushing and support frame.

The front cushion sleeves the shock absorber piston rod head to restrict the wheel jump limit position and

plays the role of buffer.

The thrust ball bearing, installed between the spring upper seat and the shock absorber mount, is used for the

relative rotation upon steering of the shock absorber rigidly connected to the steering knuckle to the shock

absorber mount flexibly connected to the body.

"L" type lower swing arm is secured to the lower engine compartment with the press plate through elastic

rubber bushing and hinge, and its outer end is connected to the steering knuckle through the ball stud pin

which is attached to the lower swing arm by 3 high intension bolts. The ball stud pin can be removed and

replaced when it is worn.

The ball seat material is saturated polyester containing oil, featured in comparatively high intensity and

wearability and good self-lubrication performance. Proper amount of grease has been added during the

assembly and there is no need for additional filling during the normal operation.

See the table for the front suspension technical parametersItem Parameter Item Parameter

shoc k a bsorbe r ope ra ting

cylinder diameter /mm¢

50 Wheel camber 0°±30′

shoc k a bsorbe r piston rod

diameter /mm¢

20 Wheel toe-in/mm 0±3

shoc k a bsorbe r stroke /mm 175 Kingpin inc lina tion 12°14′

Ca ste r of kin pin 2°23′

Remark: the wheel alignment parameter in the table is at free load.

Page 112 of 392

105Section 2 Front SuspensionComponents

LF Strut Assembly

Front

Brake Hose Clip

Connected to Brake

Connected

to Brake

LF Brake Assembly

Stabilizer Bar

Left Link Rod

Assembly

Left lower Swing

Arm Assembly

Lower Swing

Arm LF Bracket

Lower Swing Arm

RF Bracket

Front Stabilizer Bar Assembly

Stabilizer Bar

Right Link Rod Assembly

RF Brake Assembly

Connected to Brake

Clip

Front Brake Hose

RF Strut Assembly

Connected

to Brake

BodyBody

Right Lower

Swing Arm

Assembly

Lower Trailing

Arm Rear Elastic Hinge

Fixed to Shock

Absorber

ABS Sensor Wire Harness

Shock Absorber

Page 123 of 392

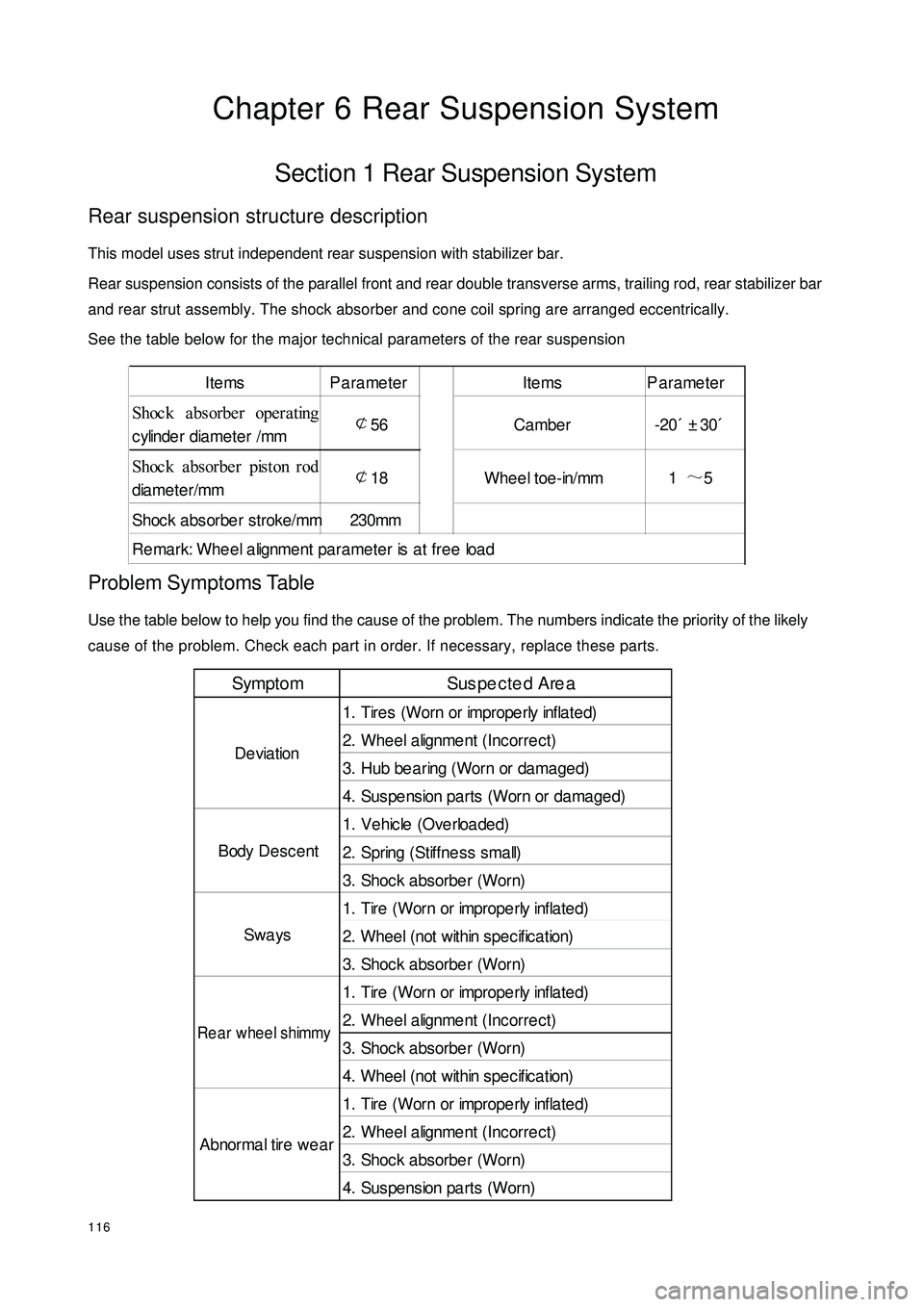

116Chapter 6 Rear Suspension SystemSection 1 Rear Suspension SystemRear suspension structure descriptionThis model uses strut independent rear suspension with stabilizer bar.

Rear suspension consists of the parallel front and rear double transverse arms, trailing rod, rear stabilizer bar

and rear strut assembly. The shock absorber and cone coil spring are arranged eccentrically.

See the table below for the major technical parameters of the rear suspensionProblem Symptoms TableUse the table below to help you find the cause of the problem. The numbers indicate the priority of the likely

cause of the problem. Check each part in order. If necessary, replace these parts.Items Parameter Items Parameter

Shoc k a bsorbe r operating

cylinder diameter /mm¢

56 Cambe r -20´±30´

Shoc k a bsorbe r piston rod

diameter/mm¢

18 Wheel toe-in/mm 1~

5

Shoc k absorbe r stroke/mm 230mm

Remark: Wheel alignment parameter is at free loadSympto m Sus pe cte d Are a

1. Tires (Worn or imprope rly infla te d)

2. Wheel alignment (Incorrect)

3. Hub be a ring (Worn or da ma ge d)

4. Suspe nsion pa rts (Worn or da ma ge d)

1. Ve hic le (Ove rloa de d)

2. Spring (Stiffness small)

3. Shoc k a bsorbe r (Worn)

1. Tire (Worn or imprope rly inflate d)

2. W he e l ( not w it hin s pe c if ic a t ion)

3. Shoc k a bsorbe r (Worn)

1. Tire (Worn or imprope rly inflate d)

2. Wheel alignment (Incorrect)

3. Shoc k a bsorbe r (Worn)

4. W he e l ( not w it hin s pe c if ic a t ion)

1. Tire (Worn or imprope rly inflate d)

2. Wheel alignment (Incorrect)

3. Shoc k a bsorbe r (Worn)

4. Sus pe nsion pa rts (Worn) Abnormal tire wearDeviation

Body Desc ent

SwaysRear wheel shimmy

Page 124 of 392

117Section 2 Rear SuspensionComponents

LR Strut Assembly

LR ABS Sensor Wire Harness

LR Brake

LR Brake Pipe

Clip

Clip

RR Strut Assembly

Clip

RR ABS Sensor Wire Harness

RR Brake Hosex2

No. 2 Transverse Arm

Left Trailing Rod Assembly

Body

Body

Body Body

No. 1 Transverse Arm

No. 1 Rocker Arm

Clip

RR Brake Pipe

RR Brake Hose

RR Brake

Right Trailing Rod Assembly

Rear Stabilizer Bar Assembly

No. 2 Transverse Arm

Rear Stabilizer Bar Retainer

Rod Components

Page 125 of 392

118Section 3 Rear Wheel AlignmentInspection1. Inspect tire

Standard inflation pressure: 220 Kpa

2. Inspect rear wheel toe-in

If the rear wheel toe-in is not within the specification, adjust it via rear

wheel toe-in adjusting cam.

3. Inspect the camber

Notice: If the camber is not within the specification, check the suspension parts for damage/low

performance. Replace it if necessary.Toe-in C - D: 1~

5 mmC a m ber -20´± 30´FrontNo. 2 Transverse Arm Assembly Rear Wheel Toe-In

Adjusting PanelRear Wheel Toe-In

Adjusting PlateNo. 2 Transverse

Arm Assembly No. 1 Transverse

Arm Assembly No. 1 Transverse

Arm Assembly Rear Wheel Toe-In

Adjusting CamRear Wheel Toe-In

Adjusting CamBody Bottom Plate

Page 126 of 392

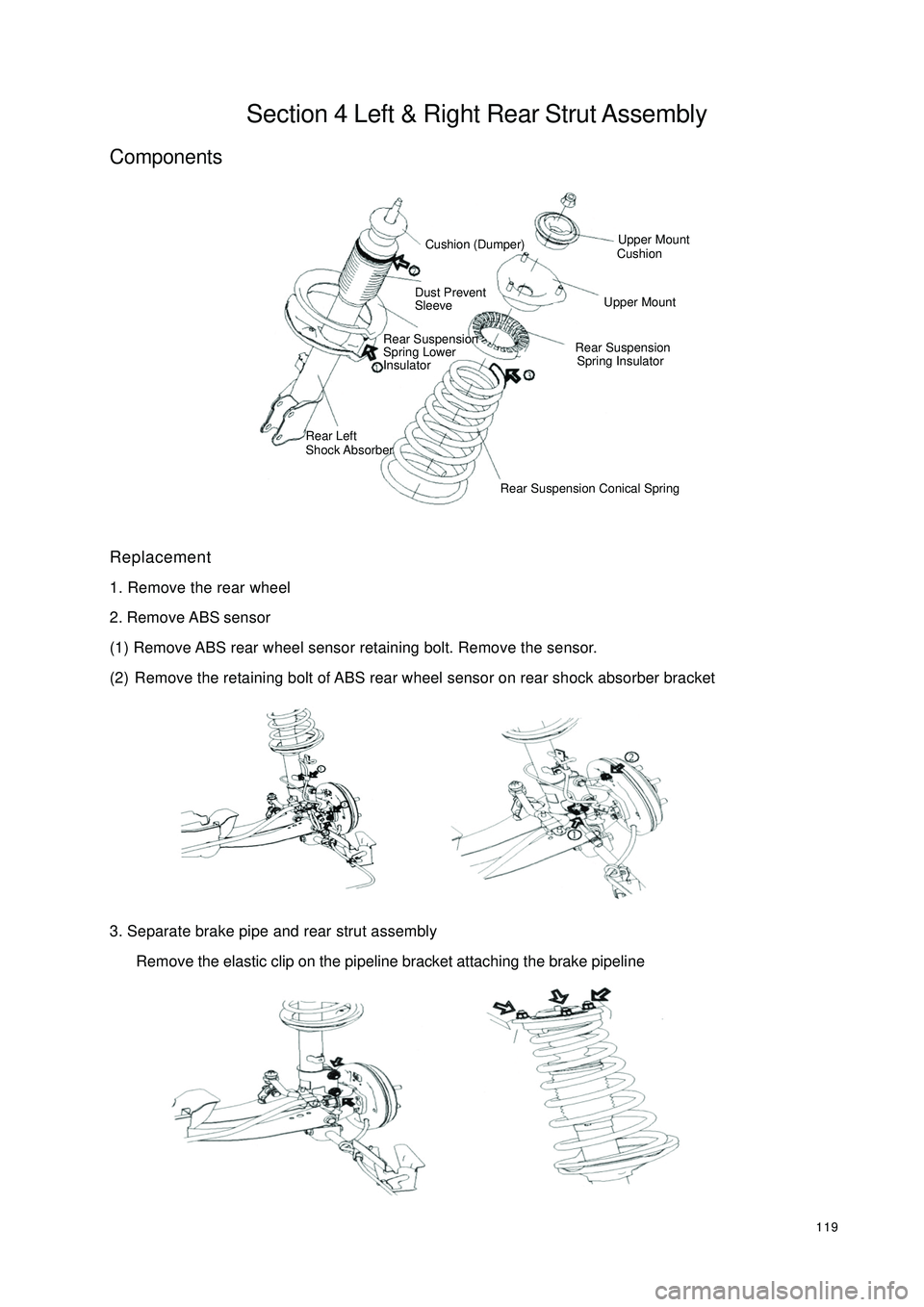

119Section 4 Left & Right Rear Strut AssemblyComponentsReplacement

1. Remove the rear wheel

2. Remove ABS sensor

(1) Remove ABS rear wheel sensor retaining bolt. Remove the sensor.

(2) Remove the retaining bolt of ABS rear wheel sensor on rear shock absorber bracket

3. Separate brake pipe and rear strut assembly

Remove the elastic clip on the pipeline bracket attaching the brake pipelineCushion (Dumper)Dust Prevent

SleeveRear Suspension

Spring Lower

InsulatorRear Left

Shock Absorber Upper Mount

CushionUpper MountRear Suspension

Spring Insulator

Rear Suspension Conical Spring

Page 127 of 392

1204. Remove the left and right rear strut assembly

(1) Remove the threaded connect of the rear strut assembly and rear brake assembly

(2) Remove the 3 nuts attaching the rear suspension upper mount to the body

Caution: reliable object shall be used to support the rear brake assembly! Make sure that the

brake pipeline is not affected or damaged!

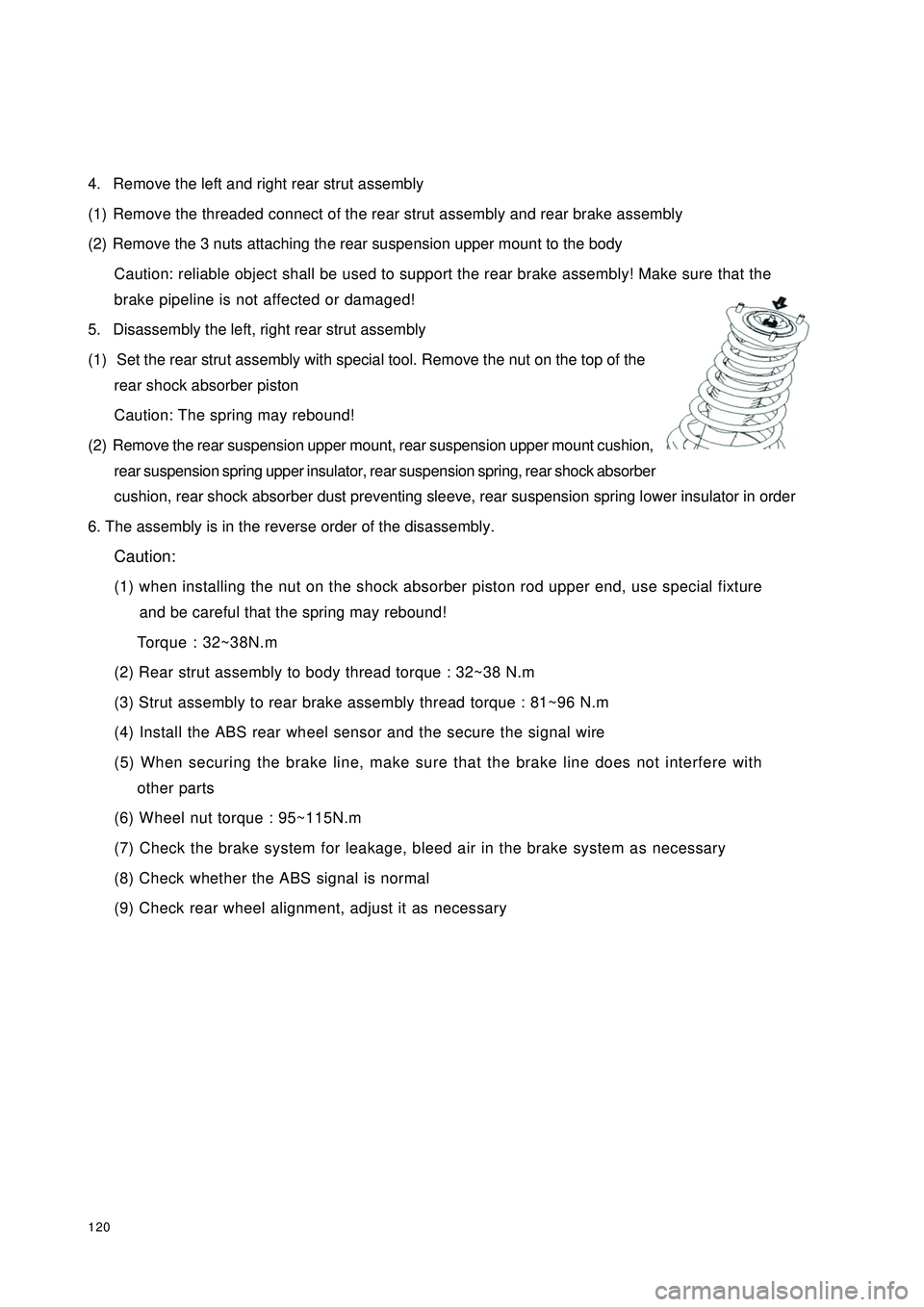

5. Disassembly the left, right rear strut assembly

(1) Set the rear strut assembly with special tool. Remove the nut on the top of the

rear shock absorber piston

Caution: The spring may rebound!

(2) Remove the rear suspension upper mount, rear suspension upper mount cushion,

rear suspension spring upper insulator, rear suspension spring, rear shock absorber

cushion, rear shock absorber dust preventing sleeve, rear suspension spring lower insulator in order

6. The assembly is in the reverse order of the disassembly.

Caution:

(1) when installing the nut on the shock absorber piston rod upper end, use special fixture

and be careful that the spring may rebound!

Torque : 32~38N.m

(2) Rear strut assembly to body thread torque : 32~38 N.m

(3) Strut assembly to rear brake assembly thread torque : 81~96 N.m

(4) Install the ABS rear wheel sensor and the secure the signal wire

(5) When securing the brake line, make sure that the brake line does not interfere with

other parts

(6) Wheel nut torque : 95~115N.m

(7) Check the brake system for leakage, bleed air in the brake system as necessary

(8) Check whether the ABS signal is normal

(9) Check rear wheel alignment, adjust it as necessary

Page 367 of 392

360(I) Front Sheet Metal, Cowl PartsThe main function of the front sheet metal and the cowl parts is forming an engine compartment to supply the

engine and accessories with a protective cover and to absorb the most energy when vehicle encounters

frontal impaction, protecting mud from being splashed by the front wheels, and meeting the requirements of

body design in appearance. It is mainly composed of front cross member assembly, LH/RH front mud guard

and front side member assembly, engine hood front support plate assembly, hood lock bracket assembly,

cowl assembly, cowl upper assembly.

1. Front Cross Member Assembly

The front cross member assembly is mainly composed of the front cross member welding sub-assembly,

front cross member bottom plate assembly, LH/RH side member end plate by welding them together, and its

dismantle diagram as shown in the Figure 5-2.

2. Lh/Rh Front Mudguard And Front Side Member Assembly

LH/RH front mud guard and front side member assembly is mainly composed of LH/RH front mudguards

and LH/RH side members by welding them together.

It is mainly used to mount some mounting brackets such as the engine LH/RH side suspension bracket, LH/

RH front suspension shock absorber bracket, etc. and to mount the LH/RH front fenders.

3. Engine Hood Front Support Plate Assembly

Engine hood front support plate is mainly composed of LH/RH headlamp mounting bracket assembly, hood

front support plate sub-assembly, and LH/RH front support plate reinforcement, by welding them together.

Engine hood front support plate assembly is used to mount radiator, engine hood lock, radiator grille, front

bumper, and headlamp.

4. Engine Hood Lock Bracket Assembly

Engine hood lock bracket assembly is used to mount the engine hood lock, also to strengthen the intensity and

rigidity of the front body by connecting the engine hood front support plate and front cross member.

5. Cowl Assembly

Cowl assembly is mainly composed of cowl inner and outer plate assembly and cowl lower cross member, by

welding them together.

Cowl assembly and front floor, LH/RH front mud guard (LH/RH front pillar), cowl upper baffle is welded

together, which forms a framework with great torsional strength. It generates great resistance to lateral

impact and rolled deformation.

Cowl inner and outer plate assembly is sandwich structure. 3mm of asphalt plate lies in the interlayer, which

is to cut off the noise and heat generated from the engine.