washer fluid GEELY CK 2008 Workshop Manual

[x] Cancel search | Manufacturer: GEELY, Model Year: 2008, Model line: CK, Model: GEELY CK 2008Pages: 392, PDF Size: 38.86 MB

Page 102 of 392

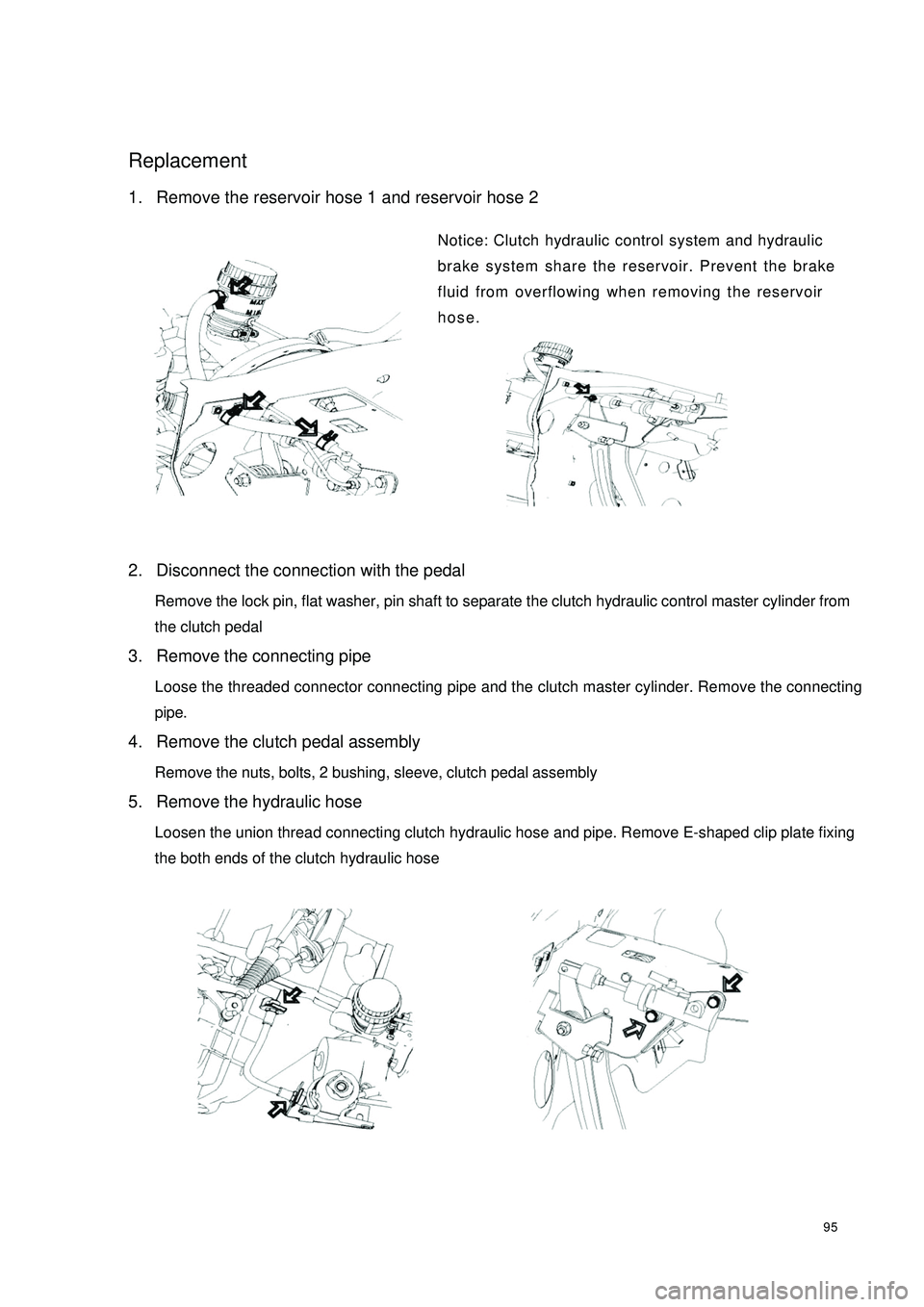

95Replacement1. Remove the reservoir hose 1 and reservoir hose 2

Notice: Clutch hydraulic control system and hydraulic

brake system share the reservoir. Prevent the brake

fluid from overflowing when removing the reservoir

hose.

2. Disconnect the connection with the pedal

Remove the lock pin, flat washer, pin shaft to separate the clutch hydraulic control master cylinder from

the clutch pedal

3. Remove the connecting pipe

Loose the threaded connector connecting pipe and the clutch master cylinder. Remove the connecting

pipe.

4. Remove the clutch pedal assembly

Remove the nuts, bolts, 2 bushing, sleeve, clutch pedal assembly

5. Remove the hydraulic hose

Loosen the union thread connecting clutch hydraulic hose and pipe. Remove E-shaped clip plate fixing

the both ends of the clutch hydraulic hose

Page 154 of 392

147Section 6 Rear BrakeComponents

Repairing1. Remove rear wheel

2. Drain the brake fluid

3. Remove the brake drum

(1) loose the parking brake handle

(2) Remove the cotter pin with a long nose pliers

(3) loose the spindle slot nut

Lower Return Spring

Oil Baffle Plate

Anchor Plate

Brake Bottom Plates

Left Cable Plate

Left Torsion Spring

Adjusting Pawl Shaft

Pin

Left Adjusting

Pawl

Left Adjusting

Plate

Brake Shoe I

Wheel Hub Bearing II

Rear Spindle Cap

Wheel Hub

Bearing I

Stop Washer

Wheel Hub

Bolt

Rear Ring Gear

Rear Brake Drum

Rear Spindle Cover

Brake Shoe I

Shoe Guide

Friction Shoe

Boot

Cup

Piston

Wheel Cylinder

Spring

Piston

BootCup

Parking Brake

Left Swing Arm

Rear Brake

Auto

Adjusting Lever

Adjusting Lever Spring

Return Spring

Page 200 of 392

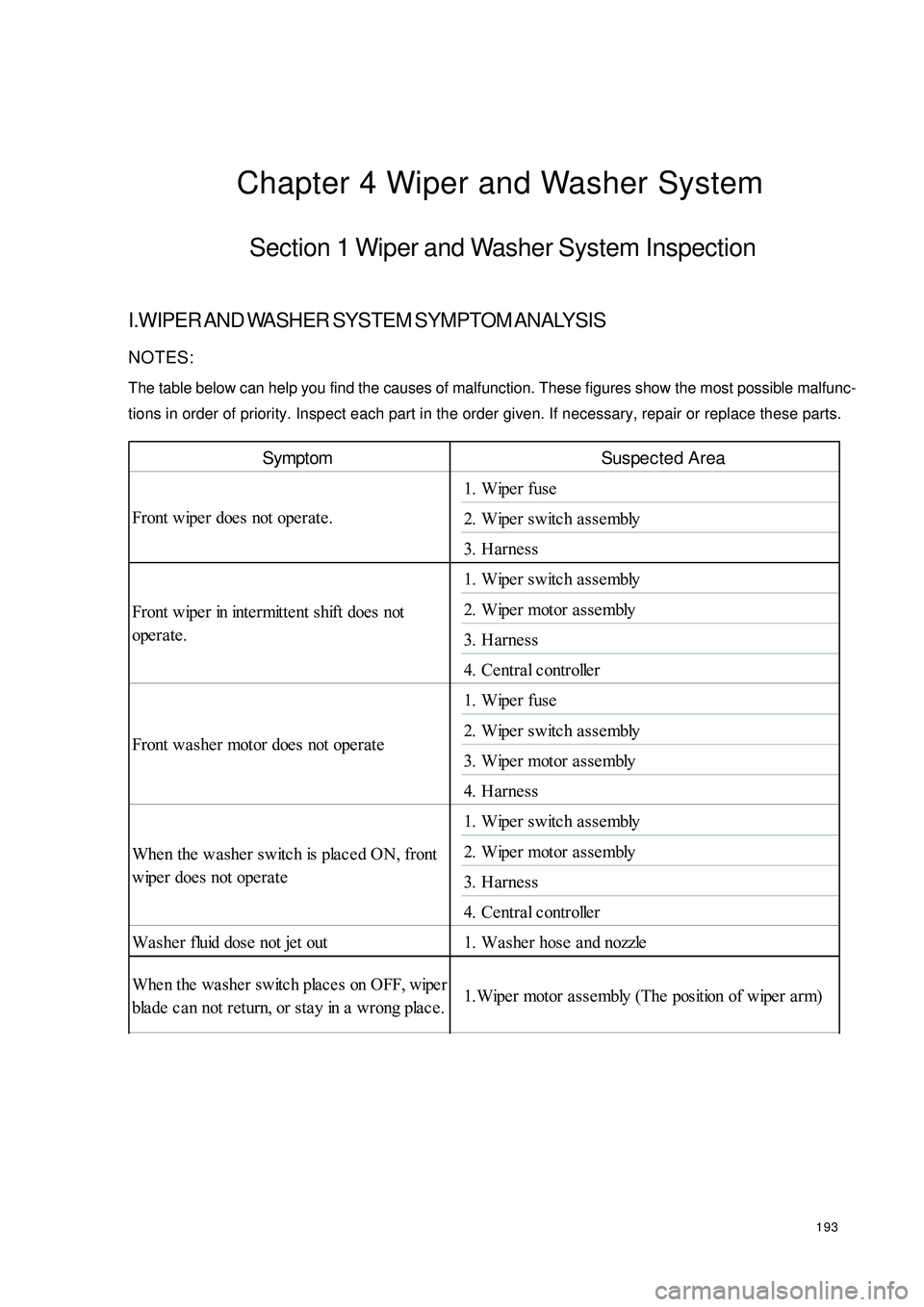

193Chapter 4 Wiper and Washer SystemSection 1 Wiper and Washer System InspectionI.WIPER AND WASHER SYSTEM SYMPTOM ANALYSISNOTES:

The table below can help you find the causes of malfunction. These figures show the most possible malfunc-

tions in order of priority. Inspect each part in the order given. If necessary, repair or replace these parts.Symptom Suspected Area

1. Wipe r fuse

2. Wipe r switc h a sse mbly

3. Harne ss

1. Wipe r switc h a sse mbly

2. Wipe r motor a sse mbly

3. Harne ss

4. Ce ntra l controlle r

1. Wipe r fuse

2. Wipe r switc h a sse mbly

3. Wipe r motor a sse mbly

4. Harne ss

1. Wipe r switc h a sse mbly

2. Wipe r motor a sse mbly

3. Harne ss

4. Ce ntra l controlle r

Wa she r fluid dose not jet out 1. Wa she r hose a nd nozzleWhen the washer switch places on OFF, wiperbla de ca n not return, or sta y in a wrong pla ce .1.Wipe r motor a sse mbly (The position of wipe r a rm) Front wipe r doe s not operate .

Front wipe r in inte rmitte nt shift does not

operate.

Front wa she r motor doe s not operate

When the washer switch is placed ON, front

wipe r does not ope ra te

Page 201 of 392

194II. MALFUNCTION INSPECTION1. WASHER PUMP INSPECTION

(1) Mount washer pump on the can system. Pour washer fluid into the can.

(2) Disconnect the connector of washer pump.

(3) Connect the terminal 1 of washer pump to the battery positive (+) and the terminal 2 to the negative (-),

as shown below. Inspect that the washer fluid flows out of the can.

(4) If not, replace the washer pump.

2. WIPER SWITCH ASSEMBLY

(a) Inspect the continuity

�yInspect each terminal on connector for continuity.

Standard:Switch position Tested terminal Specified condition

MIST 8(

+)

—10(

+)

Continuity

OFF 3(

+)

—10(

+)

Continuity

INT 8(

+)

—6(

+)

3(

+)

—10(

+)

Continuity

LO 8(

+)

—10(

+)

Continuity

HI 8(

+)

—11(

-)

Continuity

Page 203 of 392

196Section 2 Replacement and AdjustmentI WIPER MOTOR ASSEMBLY REPLACEMENT1. REMOVE WIPER MOTOR

(a) Disconnect the connector.

(b) Remove the 4 mounting bolts.

(c) Separate the shaft of the motor crankshaft arm and the wiper link with special tools.

2. INSTALL A NEW WIPER MOTOR

(a) Press the shaft of the motor crankshaft arm and the wiper link in its position with special tools.

(b) Lock the 4 bolts in the specified torque.

(c) Connect the connector.

(d) Operate the wiper, make the washer fluid spraying on the windshield, check if the operation of wiper and

its starting position is normal. If not, remove the wiper arm blades assembly and make some proper

adjustment.

Hint: Make the top of the new shaft of the wiper motor crankshaft arm filled with lubricating oil.II. WIPER BLADES REPLACEMENT1. REMOVE BLADES FROM WIPER BLADES ASSEMBLY 1, 2

�yRemove blades from wiper blades assembly 1, 2 respectively.

2. INSTALL NEW BLADES

�yInstall new blades on wiper blades assembly 1, 2 respectively.4 Mounting Bolts

Page 204 of 392

197III. WIPER SWITCH ASSEMBLY REPLACEMENT1. DETACH STEERING WHEEL ASSEMBLY

(a) Disconnect the main power source of the vehicle.

(b) Remove the passenger SRS module assembly, and cautiously put it in a safe place.

(c) Loosen steering wheel lock-bolts and remove the assembly.

2. REMOVE WIPER SWITCH

(a) Disconnect the connector.

(b) Remove the 2 tapping screws that are for mounting the wiper switch, take out the wiper switch from the

bracket of the combination switch.IV. WASHER NOZZLEADJUSTMENT

1. INSPECT WASHER NOZZLE

(a) Start the engine, check if the position where the washer fluid from the nozzle sprays the windshield is in

the central or upper of the area wiped by the blades.

(b) Change the direction (horizontal) of the nozzle hole to adjust the point where washer fluid sprays the

windshield.