ignition GEELY FC 2008 User Guide

[x] Cancel search | Manufacturer: GEELY, Model Year: 2008, Model line: FC, Model: GEELY FC 2008Pages: 419, PDF Size: 13.87 MB

Page 39 of 419

Engine mechanism - Engine assemblyCO HC Trouble occurrence Possible causes 28 Normal HighUnstable idle speed

Low HighUnstable idle speed

(HC readings not stable)

High HighUnstable idle speed

(black smoke emission)1. Ignition system malfunctionIgnition timing incorrect Spark plug too dirty, short circuit or clearance

incorrect

2. Valve clearance incorrect

3. Air inlet and exhaust valve leaky

4. Cylinder leaky

1. Vacuum leak:PCV hoseIntake manifoldThrottle bodyIdle speed stepping motorVacuum booster and pipelines

2. Fire caused by too thin mixing ratio

1. Air filter core blocked

2. PCV valve blocked

3. EFI system malfunctionFuel pressure regulator malfunctionWater temperature sensor malfunctionIntake pressure sensor malfunctionECU malfunctionInjection nozzle malfunctionThrottle position sensor malfunction

Page 41 of 419

![GEELY FC 2008 User Guide Engine mechanism - Valve clearanceValve clearanceAdjustment1. Remove engine plastic hood components.

2. Remove ignition coil components [4G18-3705110].

3. Remove cylinder head cover components [4G18-

GEELY FC 2008 User Guide Engine mechanism - Valve clearanceValve clearanceAdjustment1. Remove engine plastic hood components.

2. Remove ignition coil components [4G18-3705110].

3. Remove cylinder head cover components [4G18-](/img/58/57161/w960_57161-40.png)

Engine mechanism - Valve clearanceValve clearanceAdjustment1. Remove engine plastic hood components.

2. Remove ignition coil components [4G18-3705110].

3. Remove cylinder head cover components [4G18-

1003130].

4. Remove engine right bottom shield.

5. Turn crankshaft to cylinder 1 compression top dead

center position.(a) Turn crankshaft pulley to align its groove with “o” mark on

timing chain hood.

(b) Check dot marks on camshaft timing sprocket and VVT

timing sprocket, and they should be in a line on timing chain

hood surface as shown in the diagram.

Hint: if not, turn crankshaft for one circle again

and align the above marks.6. Check valve clearance.(a) Only check the valves shown in the diagram.

(1) Measure the clearance between valve tappet and cam-

shaft with plug gauge.

(2) Record valve clearance measuring value exceeding

specification, and this value will be used to determine

valve tappet thickness that needs change.

Valve clearance (cold vehicle)Intake airExhaust(b) Turn crankshaft for one circle ), and cylinder 4 is

turned to compression top dead center position.

(c) Only check the valves shown in the diagram. Measure valve

clearance (see step (a)).7. Remove drive beltSlowly turn drive belt tensioner clockwise to loosen it.

Then remove drive belt and put back drive belt tensioner slowly

and gently. 30 Mark

Mark

Mark

Timing chain

hood surface

Groove

Page 50 of 419

34. Remove power steering pump assembly.

35. Remove sub frame together with side member.(a) Remove front engine mounting assembly and rear en-

gine mounting assembly from engine assembly.

(b) Remove sub frame assembly.36. Remove starter mounting components

[4G18-3708100].

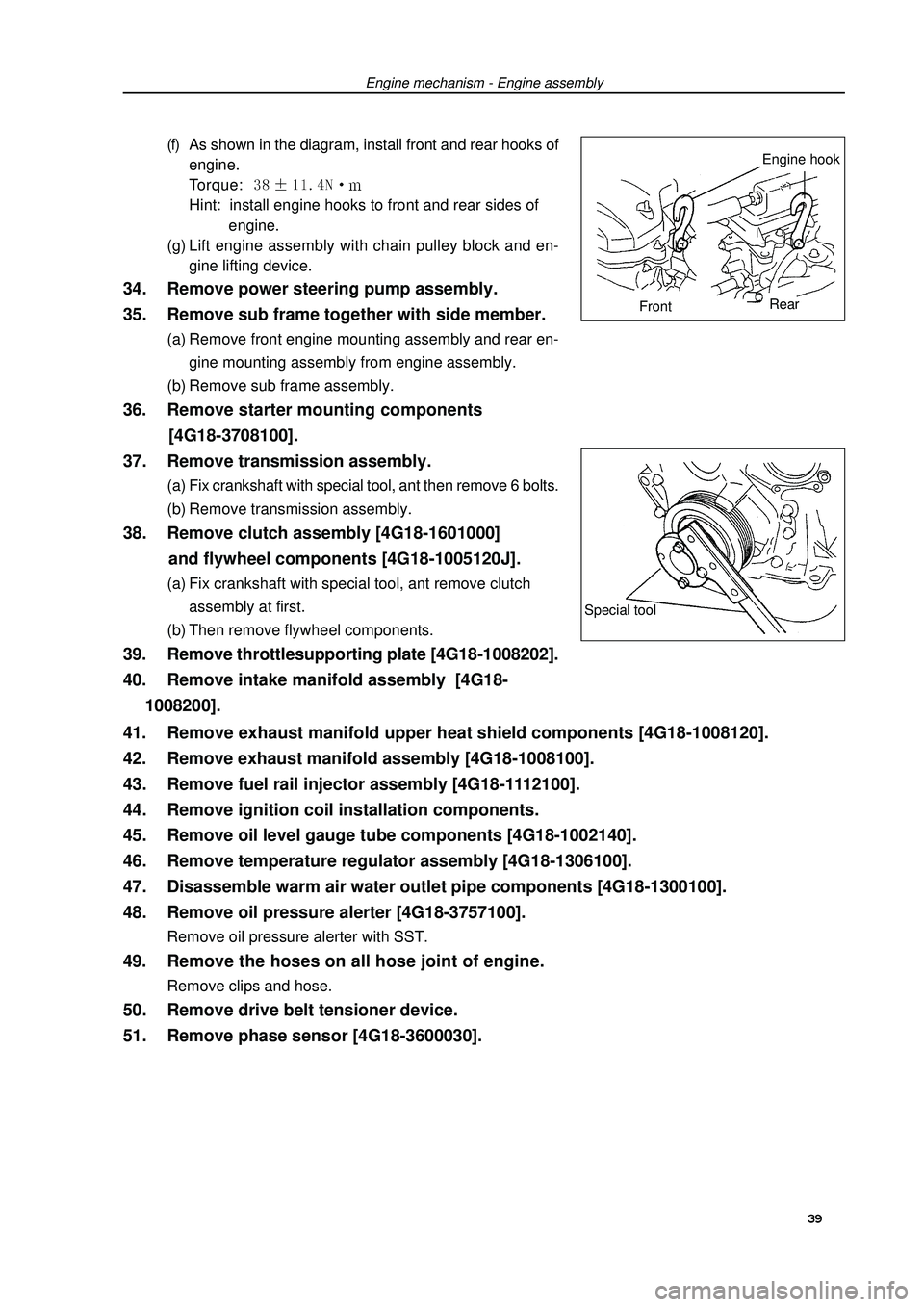

37. Remove transmission assembly.(a) Fix crankshaft with special tool, ant then remove 6 bolts.

(b) Remove transmission assembly.38. Remove clutch assembly [4G18-1601000]

and flywheel components [4G18-1005120J].(a) Fix crankshaft with special tool, ant remove clutch

assembly at first.

(b) Then remove flywheel components.39. Remove throttlesupporting plate [4G18-1008202].

40. Remove intake manifold assembly [4G18-

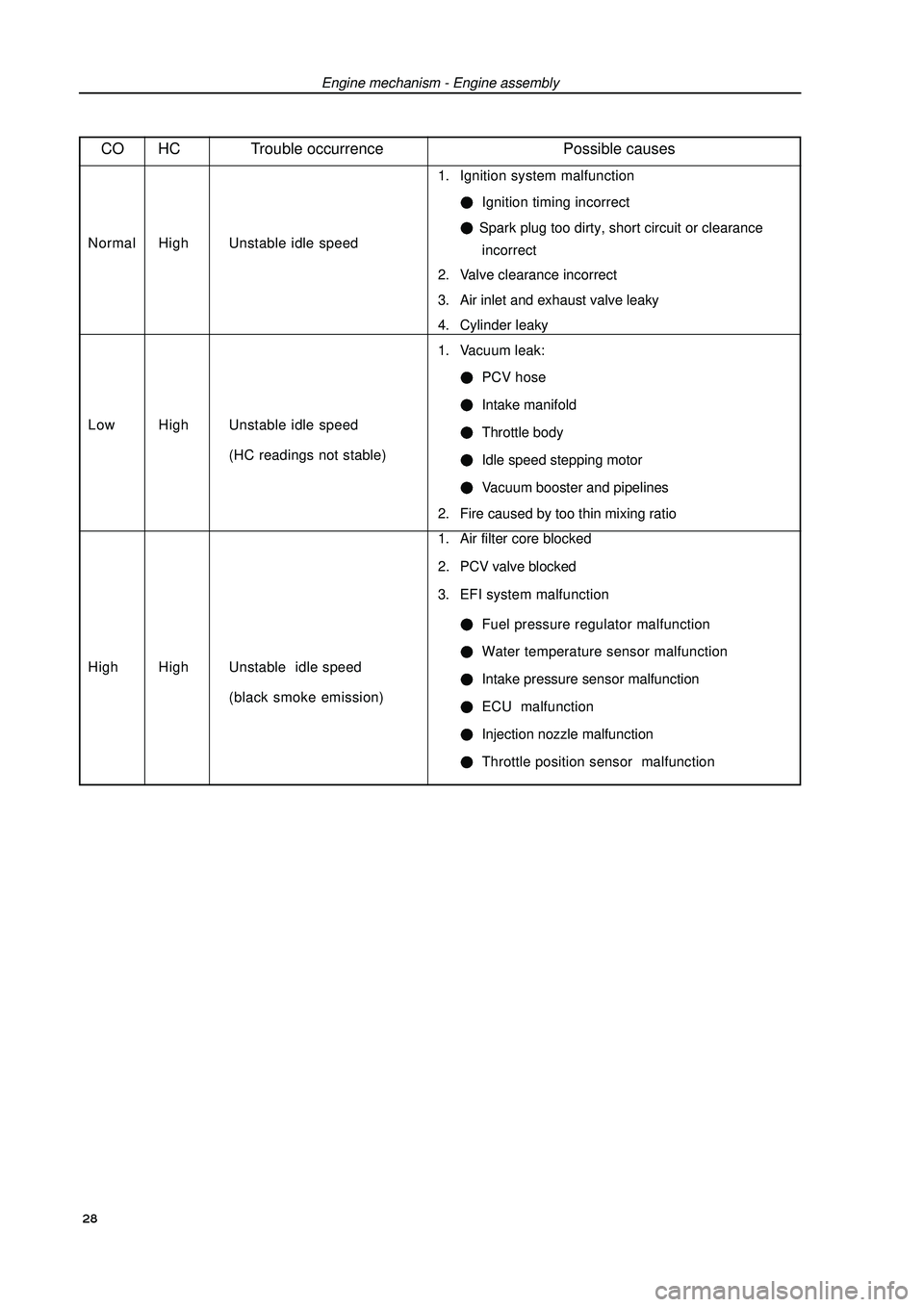

1008200].(f) As shown in the diagram, install front and rear hooks of

engine.

Torque: Hint: install engine hooks to front and rear sides of

engine.

(g) Lift engine assembly with chain pulley block and en-

gine lifting device.Engine mechanism - Engine assemblySpecial tool39 41. Remove exhaust manifold upper heat shield components [4G18-1008120].

42. Remove exhaust manifold assembly [4G18-1008100].

43. Remove fuel rail injector assembly [4G18-1112100].

44. Remove ignition coil installation components.

45. Remove oil level gauge tube components [4G18-1002140].

46. Remove temperature regulator assembly [4G18-1306100].

47. Disassemble warm air water outlet pipe components [4G18-1300100].

48. Remove oil pressure alerter [4G18-3757100].Remove oil pressure alerter with SST.49. Remove the hoses on all hose joint of engine.Remove clips and hose.50. Remove drive belt tensioner device.

51. Remove phase sensor [4G18-3600030].Engine hook

FrontRear

Page 52 of 419

Engine mechanism - Engine assembly64. Install temperature regulator assembly.(a) Check temperature regulator assembly o-ring.

(b) Install temperature regulator assembly as shown in the

diagram.

(c) Install engine water inlet pipe joint components.

Torque: 65. Install oil level gauge tube components.

66. Install ignition coil mounting components.Torque: m67. Install fuel rail injector assembly.(a) Install isolator on cylinder head.

(b) Install fuel rail injector assembly.

Torque: (c) Install fuel pipe retaining clip.68. Install exhaust manifold gasket and exhaust

manifold assembly.Torque: 69. Install exhaust manifold upper heat shield

components.Torque: 70. Install intake manifold assembly.Install new gasket and intake manifold assembly.

Torque: m71. Install throttle supporting plate.Torque: 72. Install flywheel components and clutch assembly.(a) Fix crankshaft with special tool.

(b) Clean bolts and bolt holes.

(c) Coat bolts with adhesive.

Adhesive: thread locking sealant 1234 (Kesaixin 1234).

(d) Install flywheel components.

As sequences shown in the diagram, tighten bolts at

several times.

Torque: 885Nm

(e) Install clutch assembly.Special

tool 41

Page 55 of 419

Engine mechanism - Engine assembly85. Install alternator mounting components.Torque: 12mm bolt head A: 14mm bolt head B: 86. Install drive belt.

87. Install engine wire harness and all hoses

not connected.(a) Check and connect all joints of engine wire harness.

(b) Check and connect all hoses.88. Install transmission control pull cable assembly

and valve control pull cable.

89. Install air filter assembly and its hose.

90. Install steering middle shaft assembly.(a) Align alignment mark on steering middle shaft.

(b) Install 2 bolts.

Torque: m

(c) Install steering column cover.91. Install front exhaust pipe assembly.

92. Install front chassis bracket.Torque: 93. Install battery and connect wire.

94. Install engine plastic hood components.

95. Install front wheel and engine bottom shield.

96. Refill transmission lubricant.

97. Refill engine oil.

98. Refill coolant.

99. Check there is oil leakage.

100. Check there is coolant leakage.

101. Check idle speed and ignition timing.

102. Check CO/HC.Alignment

mark

Sliding in

Pulling 44

Page 56 of 419

Engine mechanism - Timing chain assemblyTiming chain assemblyReplacement1. Remove engine left bottom shield.

2. Remove engine right bottom shield.

3. Discharge coolant.

4. Remove engine plastic hood components.

5. Remove drive belt.

6. Remove power steering pump assembly.

7. Remove alternator assembly.

8. Uncouple engine wire harness.(a) Remove ignition coil joint, PS fuel pressure switch joint,

fuel line control joint and speed sensor joint.

(b) Remove bolts and nuts of fixed earth wire and put aside

engine wire harness.9. Remove ignition coil assembly.

10. Remove cylinder head cover components.(a) Remove fuel pipe retaining clip and 2 PCV hoses from

cylinder head cover.

(b) Remove 9 bolts, 2 seal washers, cylinder head cover

components and gasket.11. Remove right engine mounting assembly.(a) Remove PS oil pump reservoir and put it aside.

(b) Place wooden block between jack and engine, prop-

erly place the jack, and then remove right engine mount-

ing assembly.12. Turn crankshaft to cylinder 1 compression top

dead center position.

13. Remove damping pulley components

[4G18-1005110].Remove pulley bolts with special tool.

Remove damping pulley components with special tool.Special

tool

Special

tool45

Page 61 of 419

![GEELY FC 2008 User Guide Engine mechanism - Timing chain assembly34. Install speed sensor.Torque: 35. Install engine fixing bracketTorque: 36. Install water pump mounting components

[4G18-1307100].(a) Install new o-ring GEELY FC 2008 User Guide Engine mechanism - Timing chain assembly34. Install speed sensor.Torque: 35. Install engine fixing bracketTorque: 36. Install water pump mounting components

[4G18-1307100].(a) Install new o-ring](/img/58/57161/w960_57161-60.png)

Engine mechanism - Timing chain assembly34. Install speed sensor.Torque: 35. Install engine fixing bracketTorque: 36. Install water pump mounting components

[4G18-1307100].(a) Install new o-ring on water pump.

(b) Install water pump with 6 bolts.

Torque: bolt A: m37. Install drive belt tensioner device.Torque: nut: Bolt: m38. Install right engine mounting assembly.Torque: 39. Install cylinder head cover components.(a) Install gasket to cylinder head cover.

(b) Eliminate all old seal materials.

(c) Coat sealant on 2 positions shown in the diagram.

Sealant: silicon rubber flange sealant 1596

(Kesaixin 1596).

Notes:Eliminate all grease on contact surface.After coating sealant, finish installation of cylinder

head cover within 3 minutes.After installing, do not refill engine oil within 2

minutes.

(d) Install cylinder head cover and cable bracket with 9 bolts,

2 seal washers and 2 nuts.

Torque: nut: Bolt: m40. Install ignition coil mounting components.Torque: 50

Page 63 of 419

Engine mechanism - CamshaftCamshaftReplacement1. Remove engine hood.

2. Remove ignition coil assembly.

3. Remove cylinder head cover assembly.

4. Remove engine right bottom shield.

5. Turn crankshaft to cylinder 1 compression top dead

center position.(a) Turn damping pulley to align its groove with “o” mark on

timing chain hood.

(b) Check dot marks on camshaft timing sprocket and VVT

timing sprocket, and they should be in a line on timing chain

hood surface as shown in the diagram.

Hint: if not, turn crankshaft for one circle (360) again

and align the above marks.6. Remove drive belt.Slowly turn drive belt tensioner clockwise to loosen it.Then

remove drive belt and put back drive belt tensioner slowly and

gently.7. Remove right engine mounting assembly.(a) Remove PS oil pump reservoir and put it aside.

(b) Place wooden block between jack and engine, properly

place the jack, and then remove engine fixing bracket shock

absorber.8. Remove drive belt tensioner assembly.Hint: operate the jack up and down to remove bolts. 52Mark

Mark

Mark

Timing chain

hood surface

Groove

Page 75 of 419

Engine mechanism - Cylinder cover gasket components(c) Tighten each cylinder head bolt in turn again.

Torque: m

(d) Install heating air water outlet pipe components.

Torque: 8. Install camshaft.(a) Coat engine oil on camshaft journal.

(b) Put 2 camshafts on cylinder head and with cylinder 1 cam-

shaft end toward the direction shown in the diagram.

(c) Check forward remarks and figures of all bearing cover, and

tighten the bolts as sequences shown in the diagram.

Torque:

Camshaft front bearing cover: Camshaft bearing cover: 9. Check idle speed and ignition timing.

10. Check compression pressure.

11. Check CO/HC.64

Page 79 of 419

Cooling - Cooling fan systemCooling fan systemOn-vehicle inspection1. Check cooling fan function at low temperature (below 95).(a) Turn ignition switch to ON.

(b) Check cooling fan is stopped.

Hint: if it is not stopped, check cooling fan relay and water temperature sensor, or check the

joint or wire harness between them.

(c) Uncouple water temperature sensor joint.

(d) Check cooling fan runs.

If it does not run, check fuse, cooling fan relay, engine ECU and cooling fan, or check there is short

circuit between them.

(e) Connect back water temperature sensor joint.2. Check cooling fan function at high temperature (above 95).(a) Start engine and increase coolant temperature up to above Hint: water temperature is the value measured by water temperature sensor on water outlet.

(d) Check cooling fan runs.

Hint: if it does not run, please replace water temperature sensor.3. Check cooling fan.(a) Uncouple cooling fan joint.

(b) Connect battery and ampere meter to cooling fan joint.

(c) Check cooling fan runs normally and check ampere meter reading.Standard current: 712A

(d) Connect back cooling fan joint.Inspection1. Electronic fan relay [67000064]

2. Electronic fan relay II [67000072]

3. Cooling fan speed adjusting resistance assembly

[67000001]Measure resistance between terminals with ohmmeter.

Resistance: at normal temperature: 1.368 Specified

conditions

Normal stateConductionConductionTerminal connected

by three-use meter Conditions

Supply battery voltage

to No. 1 and No. 2

terminals

Specified

conditions

Normal stateConductionConductionTerminal connected

by three-use meter Conditions

Supply battery voltage

to No. 1 and No. 2

terminals