lock GEELY FC 2008 Owner's Manual

[x] Cancel search | Manufacturer: GEELY, Model Year: 2008, Model line: FC, Model: GEELY FC 2008Pages: 419, PDF Size: 13.87 MB

Page 50 of 419

34. Remove power steering pump assembly.

35. Remove sub frame together with side member.(a) Remove front engine mounting assembly and rear en-

gine mounting assembly from engine assembly.

(b) Remove sub frame assembly.36. Remove starter mounting components

[4G18-3708100].

37. Remove transmission assembly.(a) Fix crankshaft with special tool, ant then remove 6 bolts.

(b) Remove transmission assembly.38. Remove clutch assembly [4G18-1601000]

and flywheel components [4G18-1005120J].(a) Fix crankshaft with special tool, ant remove clutch

assembly at first.

(b) Then remove flywheel components.39. Remove throttlesupporting plate [4G18-1008202].

40. Remove intake manifold assembly [4G18-

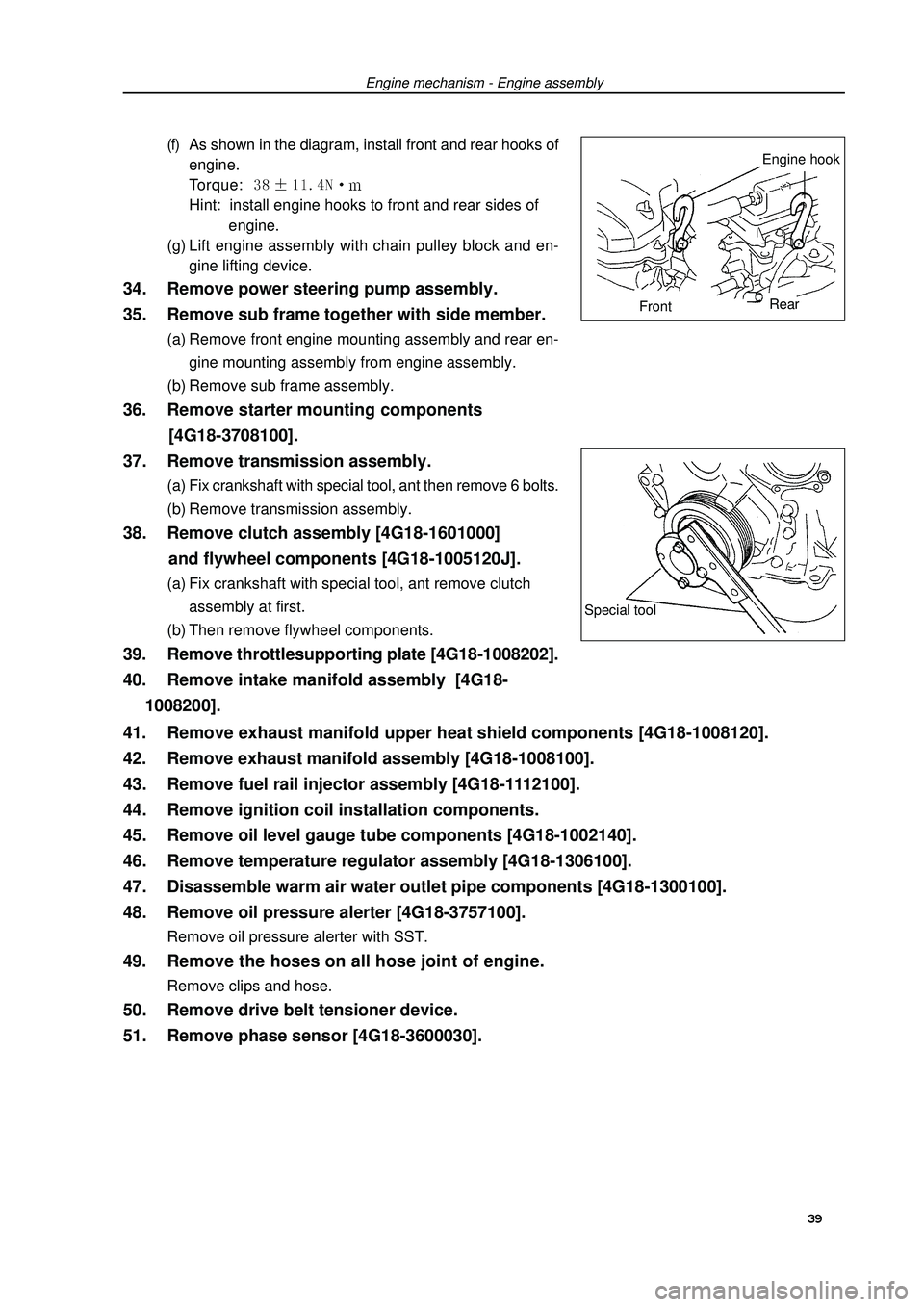

1008200].(f) As shown in the diagram, install front and rear hooks of

engine.

Torque: Hint: install engine hooks to front and rear sides of

engine.

(g) Lift engine assembly with chain pulley block and en-

gine lifting device.Engine mechanism - Engine assemblySpecial tool39 41. Remove exhaust manifold upper heat shield components [4G18-1008120].

42. Remove exhaust manifold assembly [4G18-1008100].

43. Remove fuel rail injector assembly [4G18-1112100].

44. Remove ignition coil installation components.

45. Remove oil level gauge tube components [4G18-1002140].

46. Remove temperature regulator assembly [4G18-1306100].

47. Disassemble warm air water outlet pipe components [4G18-1300100].

48. Remove oil pressure alerter [4G18-3757100].Remove oil pressure alerter with SST.49. Remove the hoses on all hose joint of engine.Remove clips and hose.50. Remove drive belt tensioner device.

51. Remove phase sensor [4G18-3600030].Engine hook

FrontRear

Page 52 of 419

Engine mechanism - Engine assembly64. Install temperature regulator assembly.(a) Check temperature regulator assembly o-ring.

(b) Install temperature regulator assembly as shown in the

diagram.

(c) Install engine water inlet pipe joint components.

Torque: 65. Install oil level gauge tube components.

66. Install ignition coil mounting components.Torque: m67. Install fuel rail injector assembly.(a) Install isolator on cylinder head.

(b) Install fuel rail injector assembly.

Torque: (c) Install fuel pipe retaining clip.68. Install exhaust manifold gasket and exhaust

manifold assembly.Torque: 69. Install exhaust manifold upper heat shield

components.Torque: 70. Install intake manifold assembly.Install new gasket and intake manifold assembly.

Torque: m71. Install throttle supporting plate.Torque: 72. Install flywheel components and clutch assembly.(a) Fix crankshaft with special tool.

(b) Clean bolts and bolt holes.

(c) Coat bolts with adhesive.

Adhesive: thread locking sealant 1234 (Kesaixin 1234).

(d) Install flywheel components.

As sequences shown in the diagram, tighten bolts at

several times.

Torque: 885Nm

(e) Install clutch assembly.Special

tool 41

Page 53 of 419

Engine mechanism - Engine assembly73. Install transmission assembly.(a) Install transmission assembly.

Torque: bolt A: Bolt B: Bolt C: (b) Install 6 bolts.

Torque: 74. nstall starter mounting components.Torque: bolt: Nut: 75. Install sub frame together with side member.Install front mounting assembly and rear mounting

assembly.

Torque: front: Rear: 76. Install power steering pump assembly.Torque: 77. Install engine assembly together with

transmission assembly.(a) Erect engine together with transmission assembly on

engine crane.

(b) Install engine assembly to vehicle.

(c) Temporarily install side member and 6 bolts.

(d) Install left engine mounting assembly.

Torque: (e) Install right engine mounting assembly.

(f) Insert special tool into location hole on right side of sub

frame and vehicle.

(g) Temporarily lock bolt A at first, and then lock bolt B.

(h) Insert special tool into location hole on left side of sub

frame and vehicle.

(i) Temporarily lock bolt A at first, and then lock bolt B.

(j) Insert special tool into location hole on right side of sub

frame and vehicle, and then tighten bolts up to speci-

fied torque.

Torque: bolt A: m

Bolt B: Special

tool

Special tool42

Page 56 of 419

Engine mechanism - Timing chain assemblyTiming chain assemblyReplacement1. Remove engine left bottom shield.

2. Remove engine right bottom shield.

3. Discharge coolant.

4. Remove engine plastic hood components.

5. Remove drive belt.

6. Remove power steering pump assembly.

7. Remove alternator assembly.

8. Uncouple engine wire harness.(a) Remove ignition coil joint, PS fuel pressure switch joint,

fuel line control joint and speed sensor joint.

(b) Remove bolts and nuts of fixed earth wire and put aside

engine wire harness.9. Remove ignition coil assembly.

10. Remove cylinder head cover components.(a) Remove fuel pipe retaining clip and 2 PCV hoses from

cylinder head cover.

(b) Remove 9 bolts, 2 seal washers, cylinder head cover

components and gasket.11. Remove right engine mounting assembly.(a) Remove PS oil pump reservoir and put it aside.

(b) Place wooden block between jack and engine, prop-

erly place the jack, and then remove right engine mount-

ing assembly.12. Turn crankshaft to cylinder 1 compression top

dead center position.

13. Remove damping pulley components

[4G18-1005110].Remove pulley bolts with special tool.

Remove damping pulley components with special tool.Special

tool

Special

tool45

Page 60 of 419

Engine mechanism - Timing chain assembly(b) Coat engine oil on the chain tensioner, and then install

it.

Torque: Note: when installing the chain temsioner, buckle

on the hook again if plunger has ejected.33. Install damping pulley.(a) Align the key groove on the damping pulley with the

key on the crankshaft, and slide damping pulley in.

(b) Install damping pulley bolts with special tool.

Torque: (c) Turn crankshaft counterclockwise to separate the hook

from lock pin on the plunger.

(d) Turn crankshaft clockwise, and check the chain ten-

sion rail is blocked by plunger.

Hint: if the plunger does not eject, press the chain ten-

sion rail toward chain tensioner with screwdriver

or fingers to separate the hook from lock pin and

make the plunger eject.Special

tool 49 Pushing intoSeparationHook

Pin

TurningPlunger

Pushing

intoTurning

Page 63 of 419

Engine mechanism - CamshaftCamshaftReplacement1. Remove engine hood.

2. Remove ignition coil assembly.

3. Remove cylinder head cover assembly.

4. Remove engine right bottom shield.

5. Turn crankshaft to cylinder 1 compression top dead

center position.(a) Turn damping pulley to align its groove with “o” mark on

timing chain hood.

(b) Check dot marks on camshaft timing sprocket and VVT

timing sprocket, and they should be in a line on timing chain

hood surface as shown in the diagram.

Hint: if not, turn crankshaft for one circle (360) again

and align the above marks.6. Remove drive belt.Slowly turn drive belt tensioner clockwise to loosen it.Then

remove drive belt and put back drive belt tensioner slowly and

gently.7. Remove right engine mounting assembly.(a) Remove PS oil pump reservoir and put it aside.

(b) Place wooden block between jack and engine, properly

place the jack, and then remove engine fixing bracket shock

absorber.8. Remove drive belt tensioner assembly.Hint: operate the jack up and down to remove bolts. 52Mark

Mark

Mark

Timing chain

hood surface

Groove

Page 65 of 419

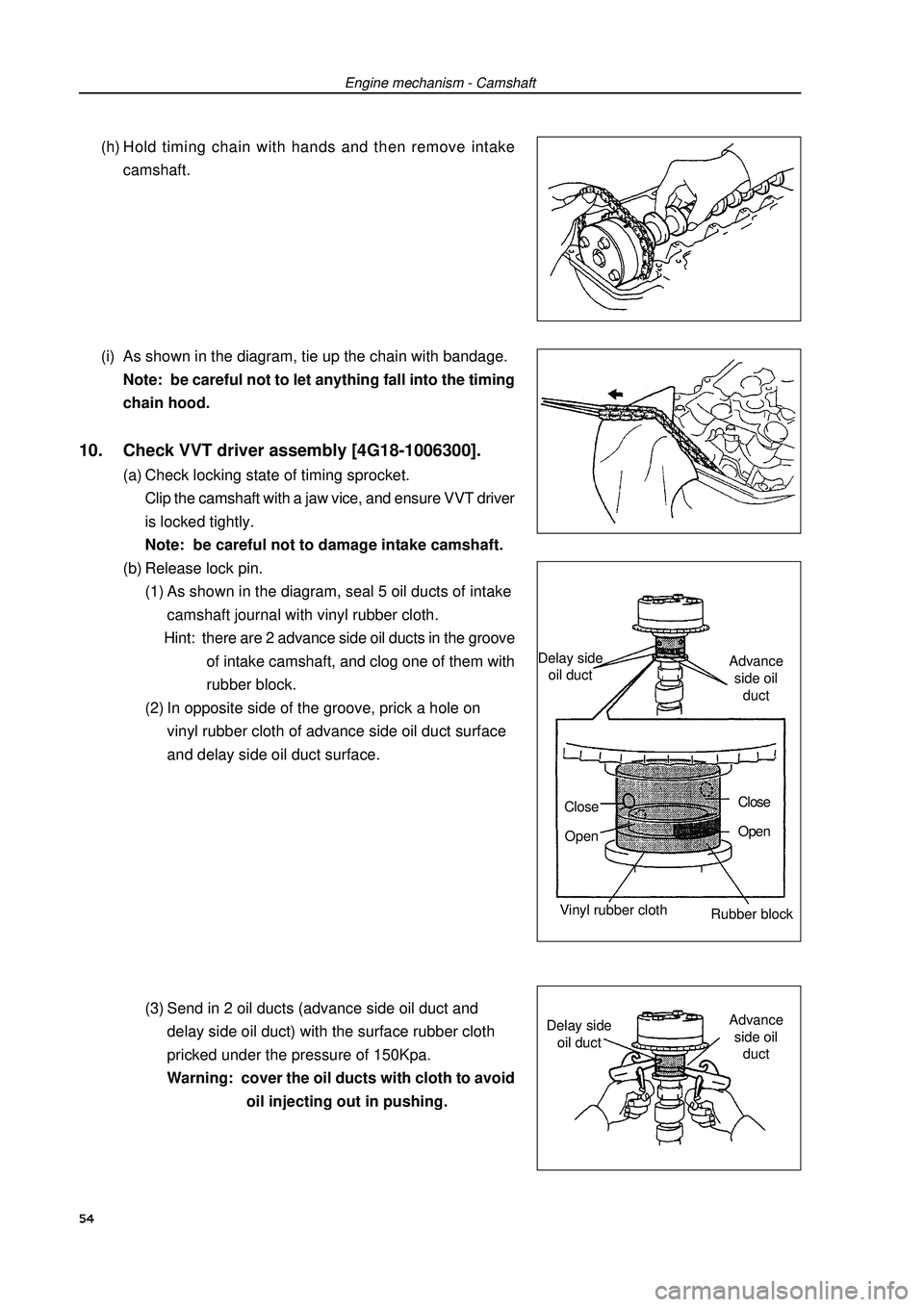

Engine mechanism - Camshaft(h) Hold timing chain with hands and then remove intake

camshaft.

(i) As shown in the diagram, tie up the chain with bandage.

Note: be careful not to let anything fall into the timing

chain hood.10. Check VVT driver assembly [4G18-1006300].(a) Check locking state of timing sprocket.

Clip the camshaft with a jaw vice, and ensure VVT driver

is locked tightly.

Note: be careful not to damage intake camshaft.

(b) Release lock pin.

(1) As shown in the diagram, seal 5 oil ducts of intake

camshaft journal with vinyl rubber cloth.

Hint: there are 2 advance side oil ducts in the groove

of intake camshaft, and clog one of them with

rubber block.

(2) In opposite side of the groove, prick a hole on

vinyl rubber cloth of advance side oil duct surface

and delay side oil duct surface.

(3) Send in 2 oil ducts (advance side oil duct and

delay side oil duct) with the surface rubber cloth

pricked under the pressure of 150Kpa.

Warning: cover the oil ducts with cloth to avoid

oil injecting out in pushing.54Delay side

oil ductAdvance

side oil

duct

Close

OpenClose

Open

Vinyl rubber cloth

Rubber blockDelay side

oil ductAdvance

side oil

duct

Page 66 of 419

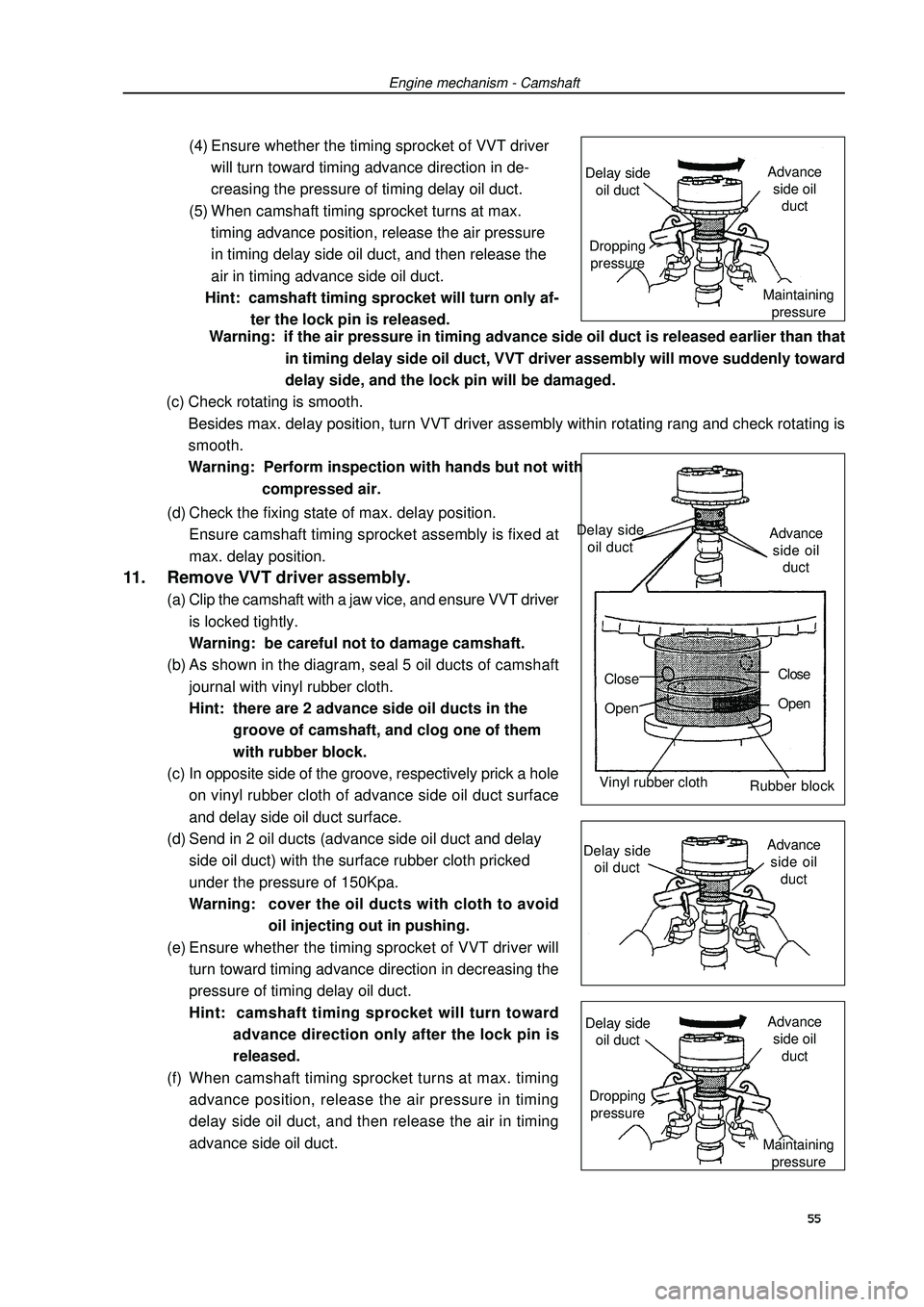

Engine mechanism - Camshaft(4) Ensure whether the timing sprocket of VVT driver

will turn toward timing advance direction in de-

creasing the pressure of timing delay oil duct.

(5) When camshaft timing sprocket turns at max.

timing advance position, release the air pressure

in timing delay side oil duct, and then release the

air in timing advance side oil duct.

Hint: camshaft timing sprocket will turn only af-

ter the lock pin is released.

(d) Check the fixing state of max. delay position.

Ensure camshaft timing sprocket assembly is fixed at

max. delay position.11. Remove VVT driver assembly.(a) Clip the camshaft with a jaw vice, and ensure VVT driver

is locked tightly.

Warning: be careful not to damage camshaft.

(b) As shown in the diagram, seal 5 oil ducts of camshaft

journal with vinyl rubber cloth.

Hint: there are 2 advance side oil ducts in the

groove of camshaft, and clog one of them

with rubber block.

(c) In opposite side of the groove, respectively prick a hole

on vinyl rubber cloth of advance side oil duct surface

and delay side oil duct surface.

(d) Send in 2 oil ducts (advance side oil duct and delay

side oil duct) with the surface rubber cloth pricked

under the pressure of 150Kpa.

Warning:cover the oil ducts with cloth to avoid

oil injecting out in pushing.

(e) Ensure whether the timing sprocket of VVT driver will

turn toward timing advance direction in decreasing the

pressure of timing delay oil duct.

Hint: camshaft timing sprocket will turn toward

advance direction only after the lock pin is

released.

(f) When camshaft timing sprocket turns at max. timing

advance position, release the air pressure in timing

delay side oil duct, and then release the air in timing

advance side oil duct. Warning: if the air pressure in timing advance side oil duct is released earlier than that

in timing delay side oil duct, VVT driver assembly will move suddenly toward

delay side, and the lock pin will be damaged.

(c) Check rotating is smooth.

Besides max. delay position, turn VVT driver assembly within rotating rang and check rotating is

smooth.

Warning: Perform inspection with hands but not with

compressed air.55Delay side

oil ductAdvance

side oil

duct

Close

OpenClose

Open

Vinyl rubber cloth

Rubber block

Delay side

oil ductAdvance

side oil

ductDropping

pressure

Maintaining

pressure Delay side

oil ductAdvance

side oil

duct

Dropping

pressure

Maintaining

pressure Delay side

oil ductAdvance

side oil

duct

Page 67 of 419

Engine mechanism - CamshaftWarning: if the air pressure in timing advance side oil duct is released earlier than that in

timing delay side oil duct, VVT driver assembly will move suddenly toward

delay side.This will cause the damage of lock pin.

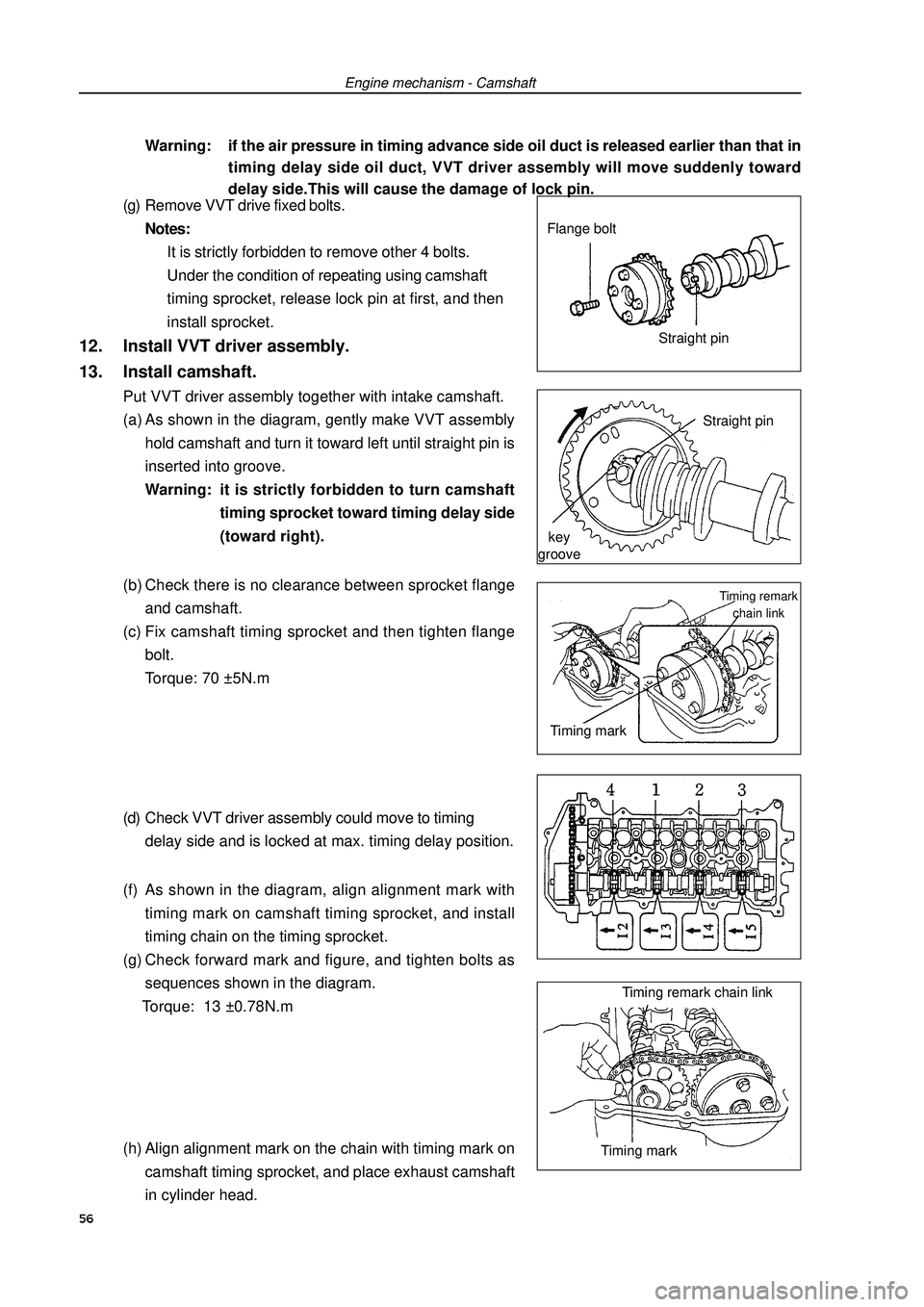

(g) Remove VVT drive fixed bolts.

Notes:

It is strictly forbidden to remove other 4 bolts.

Under the condition of repeating using camshaft

timing sprocket, release lock pin at first, and then

install sprocket.12. Install VVT driver assembly.

13. Install camshaft.Put VVT driver assembly together with intake camshaft.

(a) As shown in the diagram, gently make VVT assembly

hold camshaft and turn it toward left until straight pin is

inserted into groove.

Warning: it is strictly forbidden to turn camshaft

timing sprocket toward timing delay side

(toward right).

(b) Check there is no clearance between sprocket flange

and camshaft.

(c) Fix camshaft timing sprocket and then tighten flange

bolt.

Torque: 70 ±5N.m

(d) Check VVT driver assembly could move to timing

delay side and is locked at max. timing delay position.

(f) As shown in the diagram, align alignment mark with

timing mark on camshaft timing sprocket, and install

timing chain on the timing sprocket.

(g) Check forward mark and figure, and tighten bolts as

sequences shown in the diagram.

Torque: 13 ±0.78N.m

(h) Align alignment mark on the chain with timing mark on

camshaft timing sprocket, and place exhaust camshaft

in cylinder head.Straight pin

key

grooveFlange bolt

Straight pin56Timing remark

chain linkTiming mark

Timing remark chain link

Timing mark

Page 69 of 419

Engine mechanism - Camshaft(n) Install chain tensioner components.

(1) Check o-ring is clean, and buckle on the hook as

shown in the diagram.

(2) Coat engine oil on the chain tensioner, and then

install it.

Torque: 9 ±1.8N.m

Note:when installing the chain temsioner,

buckle on the hook again if plunger has

ejected.

(3) Turn crankshaft counterclockwise to separate the

hook from lock pin on the plunger.

(4) Turn crankshaft clockwise, and check the sliding

parts are blocked by plunger.

Hint: if the plunger does not eject, press the ten-

sion rail toward chain tensioner with

screwdriver or fingers to separate the hook

from lock pin and make the plunger eject.Pushing into

Turning Plunger

Pushing into58Lifting

Hook Pressing

in

Pin

PinHook Sepa-

rate