engine coolant GEELY FC 2008 Workshop Manual

[x] Cancel search | Manufacturer: GEELY, Model Year: 2008, Model line: FC, Model: GEELY FC 2008Pages: 419, PDF Size: 13.87 MB

Page 16 of 419

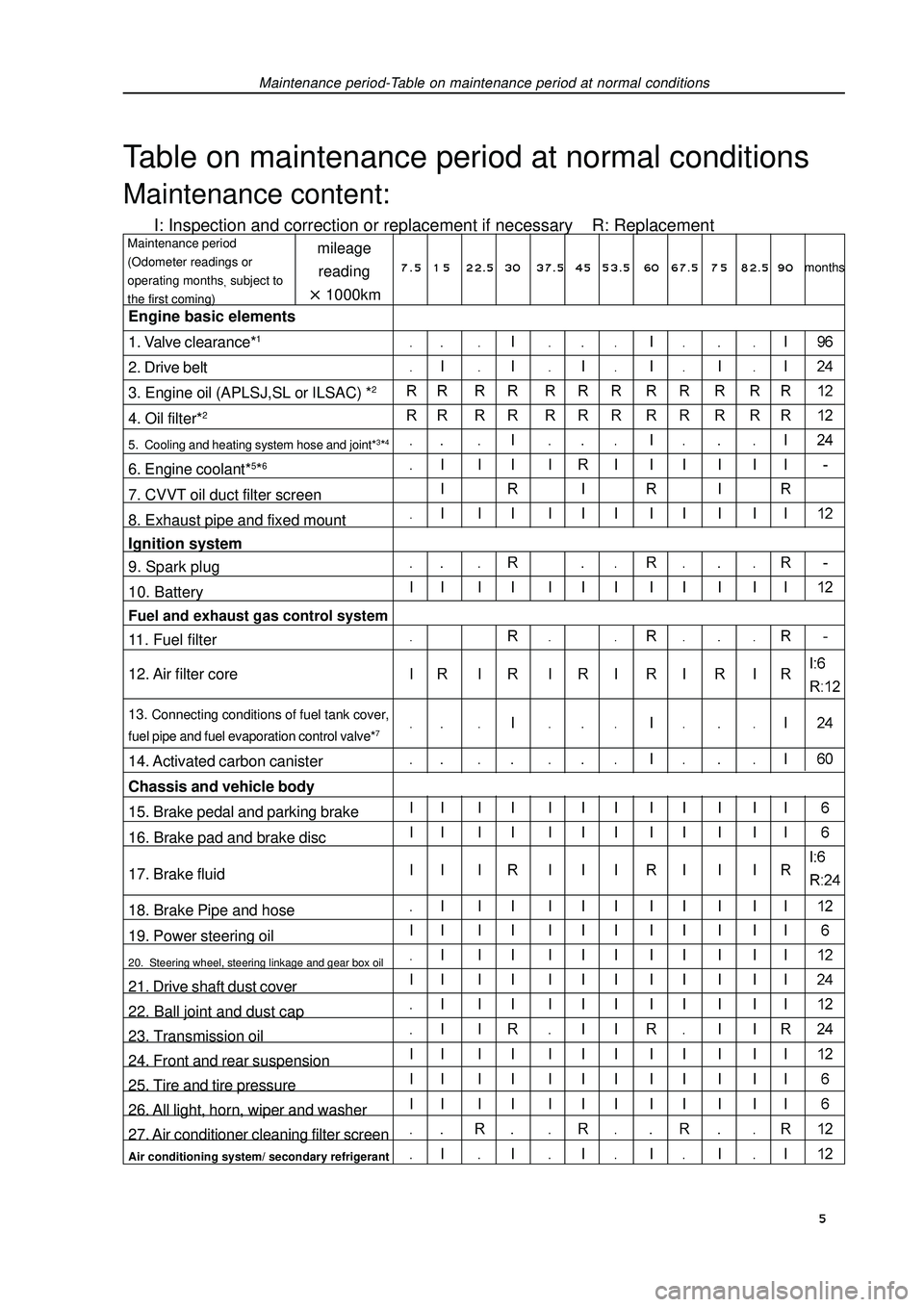

Maintenance period-Table on maintenance period at normal conditionsTable on maintenance period at normal conditionsMaintenance content:I: Inspection and correction or replacement if necessary R: Replacementmileage

reading1000kmMaintenance period

(Odometer readings or

operating monthssubject to

the first coming)Engine basic elements

1. Valve clearance*12. Drive belt

3. Engine oil (APLSJ,SL or ILSAC) *24. Oil filter*25. Cooling and heating system hose and joint*3*46. Engine coolant*5*67. CVVT oil duct filter screen

8. Exhaust pipe and fixed mount

Ignition system

9. Spark plug

10. BatteryFuel and exhaust gas control system11. Fuel filter

12. Air filter core13. Connecting conditions of fuel tank cover,

fuel pipe and fuel evaporation control valve*714. Activated carbon canister

Chassis and vehicle body

15. Brake pedal and parking brake

16. Brake pad and brake disc

17. Brake fluid

18. Brake Pipe and hose

19. Power steering oil20. Steering wheel, steering linkage and gear box oil21. Drive shaft dust cover

22. Ball joint and dust cap

23. Transmission oil

24. Front and rear suspension

25. Tire and tire pressure

26. All light, horn, wiper and washer

27. Air conditioner cleaning filter screenAir conditioning system/ secondary refrigerant7 . 5 1 5 22.5 3037.5 4553.5 60 67.5 7 582.5 90months 5

Page 17 of 419

Note: *1 Indicating that check valve noise and engine vibration condition, and adjust them if necessary.*2 It is suggested that see operating modes on page 116 of operating instruction to perform.*3 Indicating that check once every 20000km or 12 moths after 80000km or 48 months.*4 Indicating that check water tank and condenser are blocked by leaves, dust or insects, and clean

hose connections.*5 Replace at initial 60000km, and replace every 30000km in future.*6 Only “Geely genuine ultra-long engine coolant” or equivalent high-quality ethylene glycol engine

coolant without silicate, amines, nitrite, borate and with long-life compound organic acid technology

are allowed to use, and coolant should be repeated several times until it is filled up.*7 Indicating that check once every 20000km or 12 moths after 80000km or 48 months.Maintenance period-Table on maintenance period at normal conditions 6

Page 24 of 419

Engine control system·- Throttle body assemblyThrottle body assemblyRemoving, installing and disassembling, assembling1. Discharge coolant (see Page 73).

2. Remove air cleaner hose assembly.

3. Remove engine plastic hood components [4G18-1000310].

4. Remove throttle pull cable assembly.

5. remove throttle body assembly [4G18-1008240].(a) Uncouple throttle position sensor joint and stepping motor joint.

(b) Disassemble ventilation hose.

(c) Remove 2 bolts and throttle control pull cable bracket.

(d) Remove 2 preheating water inlet and outlet hoses of throttle.

(e) Remove 2 bolts and 2 nuts, and remove throttle body from intake air manifold.6. Remove stepping motor of throttle body [4G18-3600070].Remove 3 screws and stepping motor.7. Install stepping motor of throttle body.Install stepping motor.8. Install throttle body assembly.(a) Install new seal gasket on intake air manifold.

(b) Install throttle body, 2 bolts and 2 nuts.

Torque: 9. Refill coolant.

10.Check there is leakage with coolant.

13

Page 37 of 419

![GEELY FC 2008 Workshop Manual Engine mechanismEngine assemblyInspection1. Check coolant.

2. Check engine oil.

3. Check battery.

4. Check air filter assembly.

5. Check spark plug [4G18-3705113].

6. Check drive belt [4G18-1307107].H GEELY FC 2008 Workshop Manual Engine mechanismEngine assemblyInspection1. Check coolant.

2. Check engine oil.

3. Check battery.

4. Check air filter assembly.

5. Check spark plug [4G18-3705113].

6. Check drive belt [4G18-1307107].H](/img/58/57161/w960_57161-36.png)

Engine mechanismEngine assemblyInspection1. Check coolant.

2. Check engine oil.

3. Check battery.

4. Check air filter assembly.

5. Check spark plug [4G18-3705113].

6. Check drive belt [4G18-1307107].Hint: do not check belt tension, because automatic tensioner is applied.7. Check ignition timing.(a) Warm up engine.

(b) Connect timing lamp to engine.

(c) Check ignition timing at idle speed.

Ignition timing: before top dead center Note: when checking ignition timing, place

transmission at neutral position.

Hint: After run the engine for 5 seconds with rotating

speed of 1000-1300rpm, check the engine could

recover to idle running.8. Check engine idle speed.(a) Warm up engine and run it at idle speed.

(b) Read engine rotating number in data flow with diagnostic instrument.

(c) Check idle speed.

Idle speed: about 750-850rpm

Notes:When checking idle speed, place cooling fan at OFF position.Turn off all auxiliary devices and air conditioner.Engine mechanism - Engine assemblyK-line 26

Page 47 of 419

Engine mechanism - Engine assemblyEngine assemblyReplacement1. Take measures to prevent gasoline leaking.

2. Remove engine right bottom shield.

3. Remove engine left bottom shield.

4. Discharge coolant.

5. Remove front wheels.

6. Remove engine plastic hood components.

7. Remove battery.

8. Remove air filter assembly.

9. Remove air filter hose.

10. Remove battery tray.

11. Disassemble fuel hose assembly.

12. Remove throttle cable assembly.

13. Disassemble radiator hose inlet end.

14. Disassemble radiator hose outlet end.

15. Disassemble cold air pipe inlet hose.

16. Disassemble cold air pipe outlet hose.

17. Remove transmission control pull cable assembly.

18. Disassemble warm air water inlet hose [4G18-1300102].

19. Disassemble warm air water outlet hose [4G18-1300108].

20. Disassemble the hoses of all joints to connect vehicle body end.

21. Uncouple engine wire harness.(a) Remove glove compartment door.

(b) Remove engine wire harness from engine ECU and junction block.

(c) Pull out engine wire harness.

(b) Remove engine wire harness from junction block of engine room.

(e) Remove vehicle body earth wire. 36

Page 55 of 419

Engine mechanism - Engine assembly85. Install alternator mounting components.Torque: 12mm bolt head A: 14mm bolt head B: 86. Install drive belt.

87. Install engine wire harness and all hoses

not connected.(a) Check and connect all joints of engine wire harness.

(b) Check and connect all hoses.88. Install transmission control pull cable assembly

and valve control pull cable.

89. Install air filter assembly and its hose.

90. Install steering middle shaft assembly.(a) Align alignment mark on steering middle shaft.

(b) Install 2 bolts.

Torque: m

(c) Install steering column cover.91. Install front exhaust pipe assembly.

92. Install front chassis bracket.Torque: 93. Install battery and connect wire.

94. Install engine plastic hood components.

95. Install front wheel and engine bottom shield.

96. Refill transmission lubricant.

97. Refill engine oil.

98. Refill coolant.

99. Check there is oil leakage.

100. Check there is coolant leakage.

101. Check idle speed and ignition timing.

102. Check CO/HC.Alignment

mark

Sliding in

Pulling 44

Page 56 of 419

Engine mechanism - Timing chain assemblyTiming chain assemblyReplacement1. Remove engine left bottom shield.

2. Remove engine right bottom shield.

3. Discharge coolant.

4. Remove engine plastic hood components.

5. Remove drive belt.

6. Remove power steering pump assembly.

7. Remove alternator assembly.

8. Uncouple engine wire harness.(a) Remove ignition coil joint, PS fuel pressure switch joint,

fuel line control joint and speed sensor joint.

(b) Remove bolts and nuts of fixed earth wire and put aside

engine wire harness.9. Remove ignition coil assembly.

10. Remove cylinder head cover components.(a) Remove fuel pipe retaining clip and 2 PCV hoses from

cylinder head cover.

(b) Remove 9 bolts, 2 seal washers, cylinder head cover

components and gasket.11. Remove right engine mounting assembly.(a) Remove PS oil pump reservoir and put it aside.

(b) Place wooden block between jack and engine, prop-

erly place the jack, and then remove right engine mount-

ing assembly.12. Turn crankshaft to cylinder 1 compression top

dead center position.

13. Remove damping pulley components

[4G18-1005110].Remove pulley bolts with special tool.

Remove damping pulley components with special tool.Special

tool

Special

tool45

Page 62 of 419

Engine mechanism - Timing chain assembly41. Install alternator mounting components.Torque: 12mm bolt head: 14mm bolt head: m42. Refill coolant.

43. Check there is coolant leakage.

44. Check there is oil leakage.

51

Page 77 of 419

Cooling - Cooling syste2. Check engine coolant level in reservoir.Engine coolant level should be between “Low” and “Full” mark line.

Hint: if the level is too low, check there is leakage and refill coolant to “Full” mark line.3. Check engine coolant quality.(a) Remove radiator cap.

Warning: when the temperature of engine and radiator is high, do not remove radiator cap to

avoid being scalded, because coolant and steam will spurt under high pressure.

(b) Check there is too much rust deposit around radiator cap or at outlet and check there is flake; there

should not be oil in the coolant.

Hint: if coolant is too dirty, it is required to replace coolant.

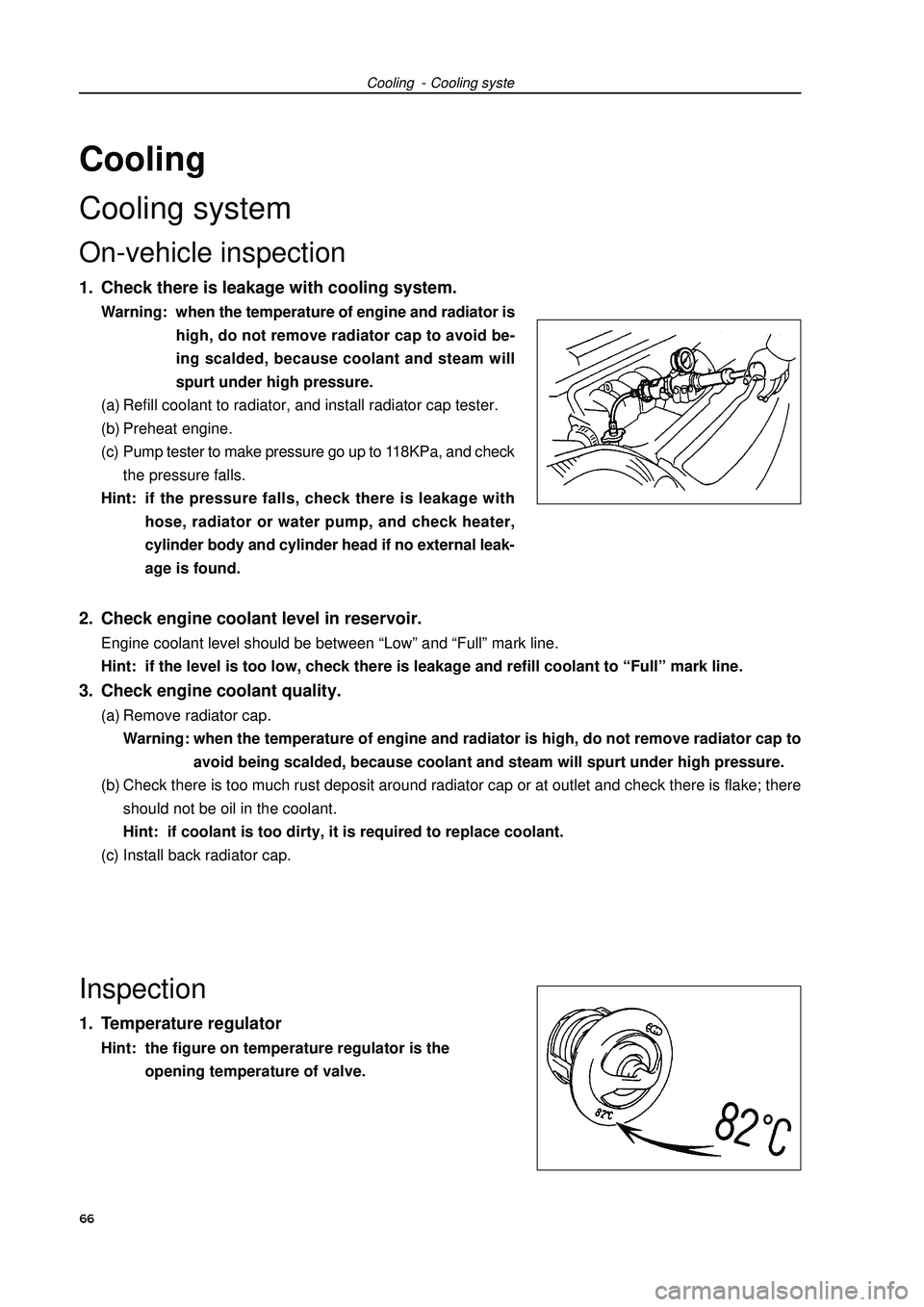

(c) Install back radiator cap.Inspection1. Temperature regulatorHint: the figure on temperature regulator is the

opening temperature of valve.CoolingCooling systemOn-vehicle inspection1. Check there is leakage with cooling system.Warning: when the temperature of engine and radiator is

high, do not remove radiator cap to avoid be-

ing scalded, because coolant and steam will

spurt under high pressure.

(a) Refill coolant to radiator, and install radiator cap tester.

(b) Preheat engine.

(c) Pump tester to make pressure go up to 118KPa, and check

the pressure falls.

Hint: if the pressure falls, check there is leakage with

hose, radiator or water pump, and check heater,

cylinder body and cylinder head if no external leak-

age is found.66

Page 79 of 419

Cooling - Cooling fan systemCooling fan systemOn-vehicle inspection1. Check cooling fan function at low temperature (below 95).(a) Turn ignition switch to ON.

(b) Check cooling fan is stopped.

Hint: if it is not stopped, check cooling fan relay and water temperature sensor, or check the

joint or wire harness between them.

(c) Uncouple water temperature sensor joint.

(d) Check cooling fan runs.

If it does not run, check fuse, cooling fan relay, engine ECU and cooling fan, or check there is short

circuit between them.

(e) Connect back water temperature sensor joint.2. Check cooling fan function at high temperature (above 95).(a) Start engine and increase coolant temperature up to above Hint: water temperature is the value measured by water temperature sensor on water outlet.

(d) Check cooling fan runs.

Hint: if it does not run, please replace water temperature sensor.3. Check cooling fan.(a) Uncouple cooling fan joint.

(b) Connect battery and ampere meter to cooling fan joint.

(c) Check cooling fan runs normally and check ampere meter reading.Standard current: 712A

(d) Connect back cooling fan joint.Inspection1. Electronic fan relay [67000064]

2. Electronic fan relay II [67000072]

3. Cooling fan speed adjusting resistance assembly

[67000001]Measure resistance between terminals with ohmmeter.

Resistance: at normal temperature: 1.368 Specified

conditions

Normal stateConductionConductionTerminal connected

by three-use meter Conditions

Supply battery voltage

to No. 1 and No. 2

terminals

Specified

conditions

Normal stateConductionConductionTerminal connected

by three-use meter Conditions

Supply battery voltage

to No. 1 and No. 2

terminals