torque GEELY MK 2008 Owners Manual

[x] Cancel search | Manufacturer: GEELY, Model Year: 2008, Model line: MK, Model: GEELY MK 2008Pages: 416, PDF Size: 25.19 MB

Page 309 of 416

4. Knocking sensor

(1) Knocking sensor is a vibration acceleration sensor. Mounted on engine cylinder body. Sensing element of

the sensor is a piezocrystal. Vibration of engine cylinder body is transferred to piezocrystal via mass block in the

sensor. Since pressure generated by vibration of mass block is applied to piezocrystal, it generates voltage on two

polar planes and turns vibration signal into voltage signal for output.5-122Symptom

Poor accelerationPossible cause

Various liquids, such as engine oil, cooling fluid, brake fluid, water etc

contact the sensor for a long time, which cause corrosion to the sensor. Mounting torque: 20 ± 5 N.M

Repair precautions: sensor must be fitted closely to cylinder body with its metal surface, any type of washer

is not permitted for installation. For wiring of sensor signal cables, note that do not let resonance occur to signal

cables, otherwise they might be broken. Energizing of high voltage between sensor 1 # and 2 # pins must be

avoided, otherwise piezoelectric element might be damaged.

(2) Simple measuring method:

(Remove joint) turn digital multimeter to ohm position, connect two meter pens with sensor 1 #, 2 # pin

respectively, its resistance value at room temperature should exceed 1M ohm. Turn digital multimeter to millivolt

position, use a hand hammer to tap near knocking sensor, now voltage signal output should be available.

5. Oxygen sensor

(1) Its sensing element is a ceramic tube, outside is open to exhaust, inside is open to atmosphere. When

temperature of sensing ceramic tube reaches 350°C, it will have the characteristic of solid state electrolyte. Just

utilizing this characteristic, it converts concentration difference of oxygen into electric potential difference, thus

forms electrical signal output. If mixed gas is a bit concentrated, inside and outside oxyanion concentration

difference of ceramic tube is high, electric potential difference is a bit high.

A large number of oxyanions move from inside to outside, output voltage is high (approximate 900mV); if

mixed gas is a bit thin, inside and outside oxyanion concentration difference of ceramic tube is low, electric

potential difference is low, only a small quantity of oxyanions move from inside to outside, output voltage is low

(approximate 100mV).

Possible cause

1. humid water vapor ingresses inside of sensor, temperature

changes rapidly, probe is broken.

2. oxygen sensor "is poisoned". (Pb, S, Br, Si) Symptom

Poor idle speed, poor speedup, tail gas

overproof, too high oil consumption1 2 3 4Oxygen sensor Mounting torque: 40-60 N.m

Repair precautions: it is prohibited to use cleaning fluid, oily liquid or volatile solid on oxygen sensor during

repair.

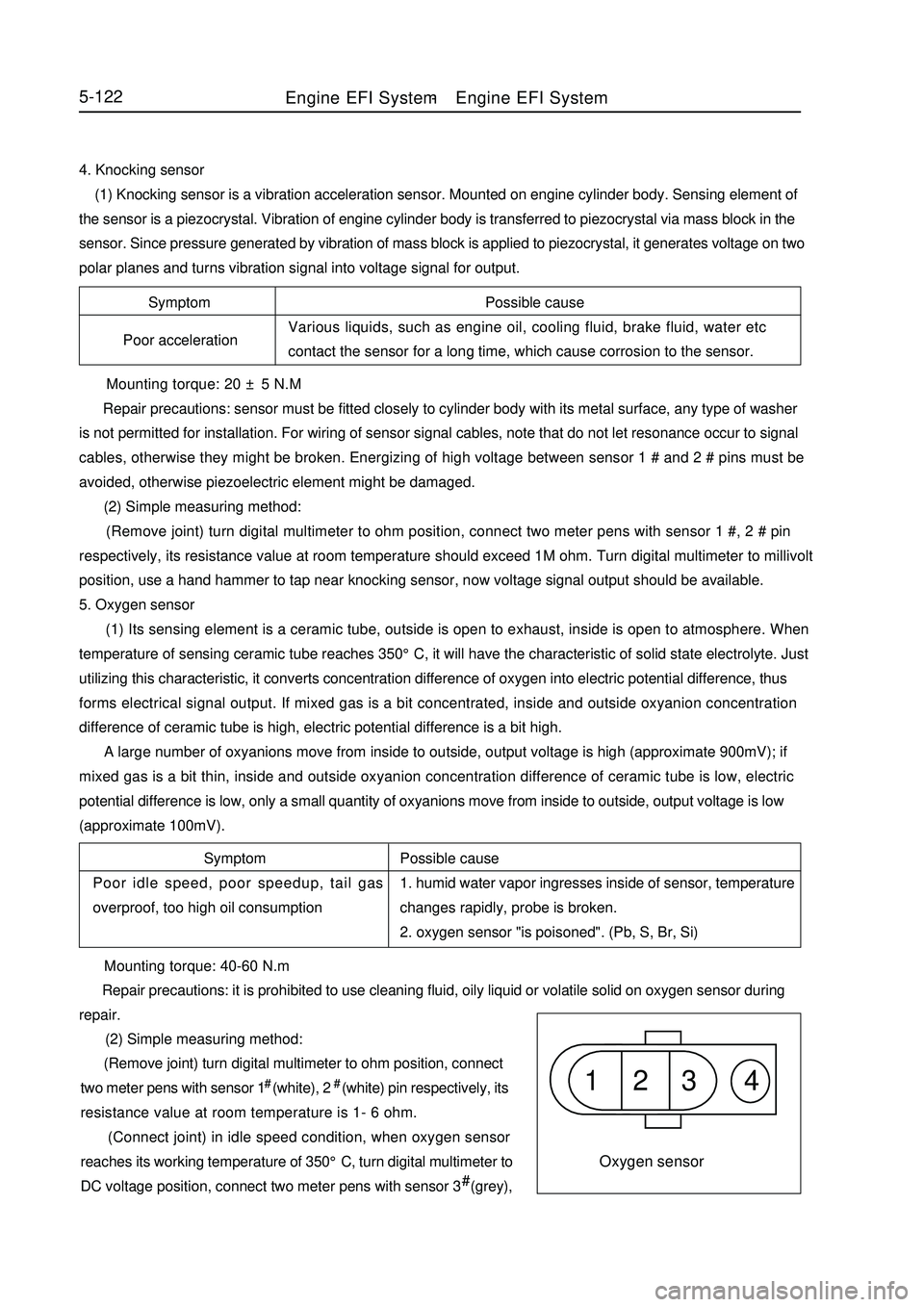

(2) Simple measuring method:

(Remove joint) turn digital multimeter to ohm position, connect

two meter pens with sensor 1# (white), 2# (white) pin respectively, its

resistance value at room temperature is 1- 6 ohm.

(Connect joint) in idle speed condition, when oxygen sensor

reaches its working temperature of 350°C, turn digital multimeter to

DC voltage position, connect two meter pens with sensor 3# (grey),Engine EFI System-Engine EFI System

Page 310 of 416

Symptom Possible cause

Fail to start Man made faultSpeed sensor1 2 3Fault symptom Common cause

Dischrge overproof, increased oil consumption Man made fault5-1234#(black) pin respectively, now voltage should fluctuate quickly between 0. 1-0. 9V.

6. Speed sensor

(1) Use with oscillator. Oscillator is a fluted disc, originally has 60 teeth, but two teeth are absent. Oscillator

is mounted on crankshaft, and rotates with the crankshaft. When tooth tip passes by sensor end closely, the

oscillator which is made of ferromagnetic material cuts magnetic line of permanent magnet in the sensor, and

generates induced voltage in coil, which is output as rotating speed signal. Mounting torque: 8 ± 2 N.m

Repair precautions: use pressing in instead of hammering method for installation during repair.

(2) Simple measuring method:

(Remove joint) turn digital multimeter to ohm position, connect

two meter pens with sensor 2#, 3# pins respectively, rated resistance

at 20°C is 770-950 ohm.

(Connect joint) turn digital multimeter to AC voltage position,

connect two meter pens with sensor 2 #, 3# pins respectively, start up

engine, now voltage output should be available.

Suggestion: use oscillograph for vehicle use to check.

7. Phase sensor

(1) This sensor consists of a hall sensor and a rotor made of steel plate. Fix hall sensor, mount rotor on camshaft.

Rotor is a 180( range cylindrical face steel blade. When the blade covers hall sensor, high Level signal is output;

otherwise low level signal is output. This differentiates two different upper dead points. Repair precautions: avoid removing end cover as far as possible during repair, so as to avoid ingress of foreign

matter, which might result in abnormal damage of magnetic gate.

(2) Simple measuring method:

(Connect joint) turn on ignition switch but not start up engine, turn digital multimeter to DC voltage position,

connect two meter pens with sensor red, black conductors respectively, ensure reference voltage of 5V is available.

Start up engine, voltage output between green and black conductors should be available.

Suggestion: use oscillograph for vehicle use to check.

8. Idle speed regulator

(1) Idle speed regulator consists of a step motor and a sealing plug on its shaft, sealing plug may generate radial

displacement driven by step motor shaft, position of sealing plug determines extent of opening of by-pass airway,

so as to adjust the size of by-pass air quantity. Position of sealing plug is controlled by ECU output.Fault symptom

Too high idle speed, flameout at idle speedPossible cause

Since interior contamination is severe, regulating element

is blocked and leads to malfunction.

Repair precautions: dust and sand grain will result in damage of idle speed regulator. Intake air should be

filtered by dry air cleaner before entering idle speed regulator, filtration efficiency should exceed 99 %. ToEngine EFI System-Engine EFI System

Page 330 of 416

I. Component View3721

Non-reusable partsFront seat-belt buckle assy.Interior & Exterior Trim and Accessory -Front Seat Assembly6-1N.

m :Specified torquePart VI Interior & Exterior Trim and AccessoryChapter 1 Front Seat AssemblyHeadrest

Front seat (L)

Cushion trim

Seat cushion

Seat cushion frame

Seat rail handleInner seat rail cover

Seat backrest cushion

Outer seat rail cover

Seat backrest trim

C-ring

C-ring

Headrest bracket

Front seat adjuster

Angle adjuster inside cover FL seat cushion inside stopper

FL seat cushion stopper

Release lever

Page 333 of 416

Interior & Exterior Trim and Accessory -Rear Row Seat Assembly6-4II. Removal & Installation of Rear Seat Assembly1. Remove the rear seat cushion assembly

a. Pull out the front part of seat cushion upwards.

b. Release the wire harness of seat cushion from the central

protuberance, and remove the seat cushion assembly.

2. Remove the assembly of left-rear seatback

a. Fold the seatback;

b. Remove the clamp, and uncover the seat;

c. Remove the 2 bolts and seatback assembly.

3. Remove the assembly of right-rear seatback

Tip:

Apply the procedures the same as aforesaid for the left side.

4. Remove the assembly of left-rear seatback lockup

Remove the 2 bolts and the seatback lockup device off the

seatback frame.

5. Remove the assembly of right-rear seatback lockup

Tip:

Apply the procedures the same as aforesaid for the left side.

6. Install the assembly of rear seatback

Tip:

Follow the sequence reverse to removal.

All the bolts shall be installed with the torque: 18N.m.

Page 335 of 416

Detach and Mount Front Seat BeltI.Component View40~6040~60

Pulley cover

Lower trim20 Buckle assy.40~60 Front seat assy.Front seat belt

assy. Trim Remote adjuster assy.

for seat beltFront doorsill shieldFront door frame

weather stripRear door frame

weather strip

Rear doorsill shield

N.

m :Specified torque47Interior & Exterior Trim and Accessory

-Front Seat Belt6-6II. Belt replacement

Notes: Installation is basically the reverse of removal and different operation(s) in the process of installation,

if any, will be pointed out specifically.

1. Remove the negative terminal of battery;

2. Detach the front seat assembly;

Loosen the front lock bolt and remove the buckle assembly from inside the front seat;

3. Use the screwdriver to detach the center pillar lower trim; Cut two clips and 4 buckles and remove the trim;

Page 339 of 416

Interior & Exterior Trim and Accessory -Rear Seat Belt6-10II. Rear seat belt removal1. Remove the rear cushion assembly;

2. Remove the rear backrest assembly;

3. Remove left (right) side quarter upper trim;

4. Remove the high mounted stop light;

5. Remove the rear shelf trim;

6. Remove the rear seat belt assembly;

a. Remove bolts under the quarter lower trim connecting the left and right rear side;

b. Remove bolts for the retractor and take down the rear seat belt assembly;

7. Remove bolts on the floor and disassemble the right rear seat belt buckle assembly and the waistband assembly;

8. Remove bolts on the floor and take down the left and rear buckle assembly.III. Installing rear seat belt1. Install the left and rear buckle assembly;

As per the drawing, bolt the left and rear buckle assembly. on the

floor. Torque: 40~60N.m

2. Install the right rear seat belt buckle and the waistband assembly;

Tips: same as way of the left.

3. Install the rear seat belt assembly;

Attention: Do not break down the retractor.

a.Inspection contents before outer seat belt instalation:When ELR

lock,check the gradient of ELR. Check and make sure the seat belt

can not be locked from any aspect within 15°.When you move the

belt ring device beyond 45° slowly,the seat belt should be locked.

b. Install the rear seat belt assembly using bolts (part of

retractor) ;

Torque: 40~60N.m

c. Install the rear seat belt assembly using bolts(part of anchor).

Torque: 40~60N.m

4. Inspect the properties of seat belt assembly;

5. Install the rear seat and trim.Floor projectionFrontFront markLockUnlockIV. Precaution for Usage and Disposal of Used Safty Belt The details are the same as front safty belt.

Page 364 of 416

Chapter 13 Rear BumperI. Component ViewRight trunk trim board

Rear shelf lower trim panel

Spare tire board

Rear bumper support installation nut

Torque nut: 6 N¡¤mRear bumper Left mud guard Left trunk trim boardInterior & Exterior Trim and Accessory -Rear Bumper6-35II. Disassembly and assembly of the rear bumper Notes:

Installation is basically the reverse of removal and different operation(s) in the process of installation, if any,

will be pointed out specifically.

1. Remove the spare tire cover assembly.

2. Remove the lower trim board of the rear separator.

3. Remove the ornamental blanket at the left side of the luggage compartment.

a. Remove six snaps.

Page 365 of 416

Interior & Exterior Trim and Accessory -Rear Bumper6-36 b. Remove the ornamental blanket at the left side of the luggage

compartment.

4. Remove the ornamental blanket at the right side of the luggage

compartment.

a. Remove six snaps.

b. Remove the ornamental blanket at the right side of the luggage

compartment.

5. Remove the rear bumper.

a. Remove four nuts;

b. Remove two screws and four clips;

c. Remove 8 snaps and the bumper.

6. Mount the rear bumper.

Installation is basically the reverse of removal.

(Notes: Mount the rear bumper with two screws, 4 clips and 4

nuts; Torque: 5.5N.m, for the nut)Snap Rear bumper

Snap

Page 366 of 416

Interior & Exterior Trim and Accessory -Outside Rearview Mirror6-37Chapter 14 Outside Rearview MirrorThe outside rearview mirrors are mounted on the left and right doors. With specially designed rubber sheath, the

rearview mirrors are seamlessly and smoothly joined to the body of vehicle. Meanwhile, they block neither upward

nor backward turn of rearview mirrors upon knocking. Such installation also plays an important role in decreasing

the air resistance coefficient of the whole vehicle.

The mirror glasses are fixed to the supporting plates with double-side adhesive tape. The supporting plates are

connected to the shell of rearview mirrors with ball hinge in order to make sure no glass will scatter that causes

secondary injury, as well as replacing the damaged glasses easily. When the glasses are damaged, the supporting

plates can be taken out of the ball-head mount with tools, and then pressed into the mount again after replacing

the glasses. The turning force of rearview mirror is designed as 30N, which enables easy turn and less hurt/damage

in case human or object knocks the mirror. In addition, the rearview mirrors are equipped with electric adjustment

and heat defrosting.

Notes

When turning over the rearview mirror, please don't put your finger between the exterior rearview mirror and

the hinge in order to avoid extrusion injury!Replacement of Rearview MirrorRemoval procedures

1. Remove the cathode lead wire off the storage battery;

2. Remove the corner decoration of door;

3. Disconnect the plug of electric-driven exterior rearview mirror;

4. Remove the 3 screws;

5. Remove the electric-driven exterior rearview mirror

Installation procedures

1. Mount the rearview mirrors onto the doors

2. Fasten the screws from the lower-left side clockwise

Fastening

Fasten the screws of exterior rearview mirrors with the torque

of 8.0N.m

3. Connect the plug of electric-driven exterior rearview mirrors;

4. Install the corner decoration of door

Page 409 of 416

II. Supplemental Specifications on Tightening TorqueFor those fastening pieces either not specified in the "Body" part or not stated in other assemblies, the following

specifications shall apply.

Thread Dia. Thread Pitch Tightening Torque

(mm) (mm)Standard Value (N.m) Max. Value(N.m) Min. Value(N.m)

61 9 12 6

8 1.25 23 26 16

8 1 25 28 17

10 1.5 59 75 37

10 1.25 63 79 45

10 1 64 80 46

12 1.75 95 111 73

12 1.5 97 113 75

12 1.25 99 115 78

14 2 160 185 122

14 1.5 180 205 146

16 2 215 245 182

16 1.5 240 270 199

18 2.5 268 298 229

18 1.5 316 346 287

20 2.5 430 470 389

20 1.5 440 480 396Body Repair -Service Data For for Body7-37Table 5-2

Supplemental Specifications for Vehicle Body and All Assembly Fastening Piece