ESP GEELY MK 2008 User Guide

[x] Cancel search | Manufacturer: GEELY, Model Year: 2008, Model line: MK, Model: GEELY MK 2008Pages: 416, PDF Size: 25.19 MB

Page 171 of 416

Brake System -Front Brake Disc4-94Component ViewSection 6 Front Brake Disc34Front disc brake pistonSet ring Dust shield Piston oil seal Left front disc

brake cylinder accessory3483088Connector bolt

Washer

Discharge screw

plug capTubeDust shield Front disc brake

cylinder sliding pin

#2 muffle pad

#1 muffle pad

Brake pad

Brake pad#1 muffle pad

#2 muffle pad

Support piece

Front brake pad ISupport piece

Front brake pad IIFront disc brake cylinder

sliding pin88Dust shield

Left cylinder support

Non-reusable parts

Lithium soap base glycol lube

Disc brake lubespecified torqueN.

m :

Page 176 of 416

Section 7 Rear Brake DrumComponent ViewDust shield

Piston

Cup

Spring

Rear bake shoe

Locating spring

Rear brake drum Shoe pad positioning spring cover Front brake shoe

Shoe pad positioning spring cover Pin

BaseboardDust

coverPiston

PinCupLeft parking brake shoe pad postCvlinder

Extension springBrake System -Rear Brake Drum4-99Discharge plug

Discharge plug

Hole plug

Pin plug

C-ringExtension rod

Shoe pad positioning spring Adjustment rod springRear brake automatic

adjustment rodParking brake

inhaul cable

Return spring

Non-reusable parts

Lithium soap base glycol lube

Heat-resistant lubespecified torqueN.

m :

Page 183 of 416

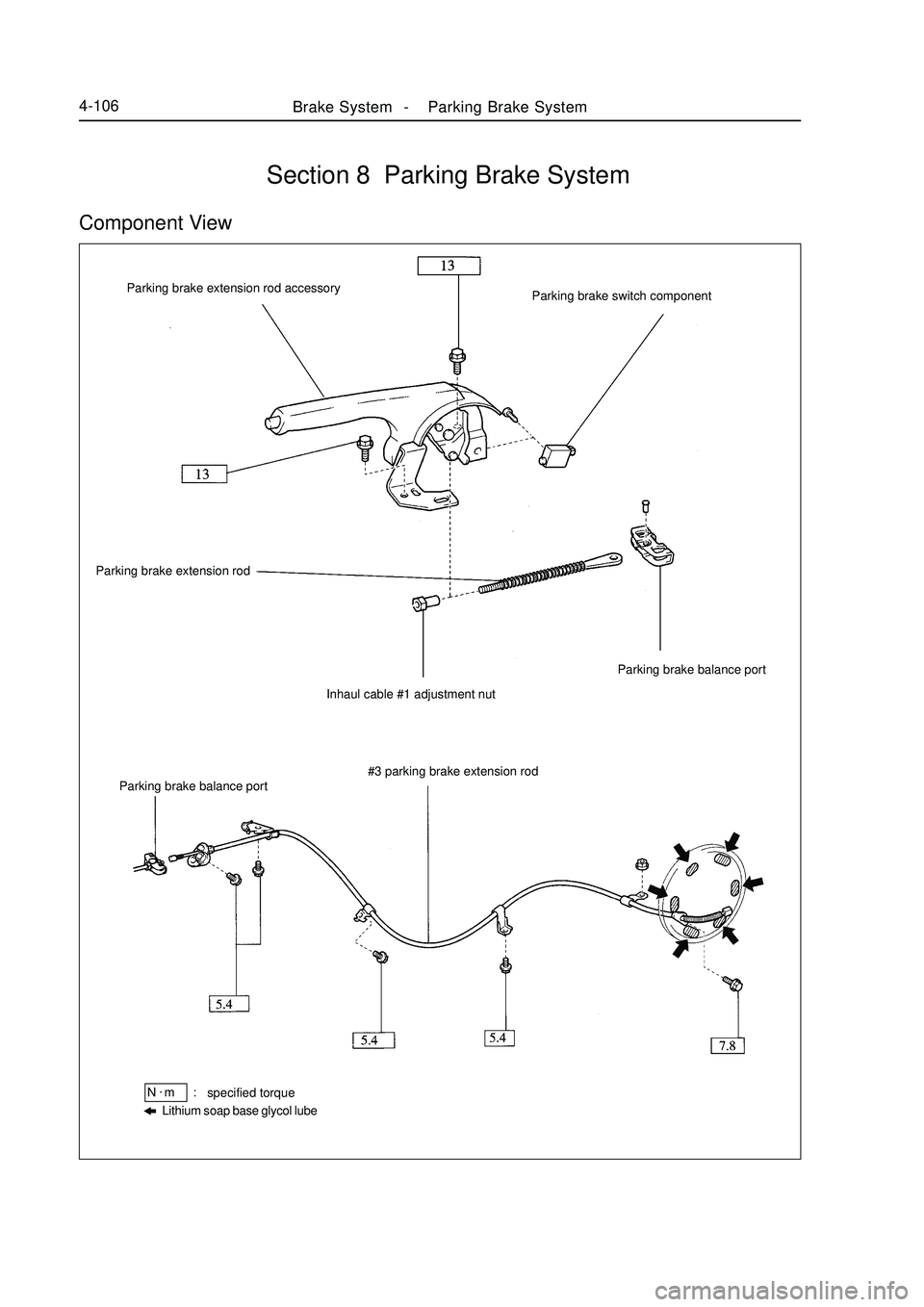

Brake System -Parking Brake System4-106Section 8 Parking Brake SystemComponent View#3 parking brake extension rod

Lithium soap base glycol lubespecified torqueN.

m :Parking brake balance port Parking brake extension rod

Inhaul cable #1 adjustment nutParking brake balance port Parking brake extension rod accessory

Parking brake switch component

Page 184 of 416

Brake System -Parking Brake System4-107Adjustment1. Remove the rear wheel.

2. Adjust the clearance of the brake shoe.

3. Install the rear wheel.

Torque: 103N.m

4. Check the stroke of the parking brake extension rod.

Pull the parking brake extension rod, and count the number of sound.

Parking Brake Extension Rod Stroke: Pull with 196N force till 6-9 clicks.

5. Adjust the stroke of the parking brake extension rod.

(1) Remove the glove box cover.

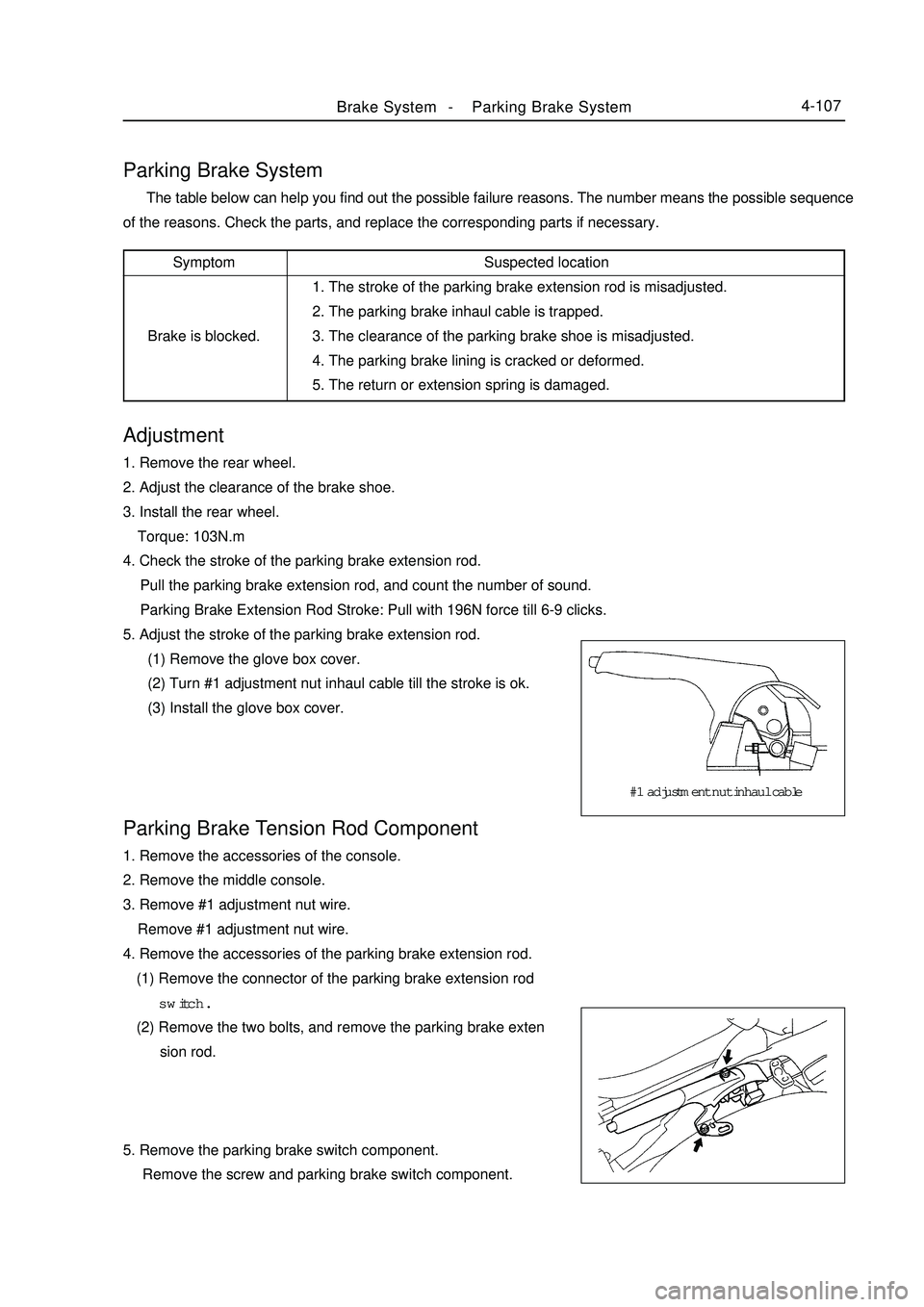

(2) Turn #1 adjustment nut inhaul cable till the stroke is ok.

(3) Install the glove box cover.Parking Brake System The table below can help you find out the possible failure reasons. The number means the possible sequence

of the reasons. Check the parts, and replace the corresponding parts if necessary.Parking Brake Tension Rod Component1. Remove the accessories of the console.

2. Remove the middle console.

3. Remove #1 adjustment nut wire.

Remove #1 adjustment nut wire.

4. Remove the accessories of the parking brake extension rod.

(1) Remove the connector of the parking brake extension rod

switch.

(2) Remove the two bolts, and remove the parking brake exten

sion rod.

5. Remove the parking brake switch component.

Remove the screw and parking brake switch component.Suspected location

1. The stroke of the parking brake extension rod is misadjusted.

2. The parking brake inhaul cable is trapped.

3. The clearance of the parking brake shoe is misadjusted.

4. The parking brake lining is cracked or deformed.

5. The return or extension spring is damaged.Symptom

Brake is blocked.#1 adjustment nut inhaul cable

Page 193 of 416

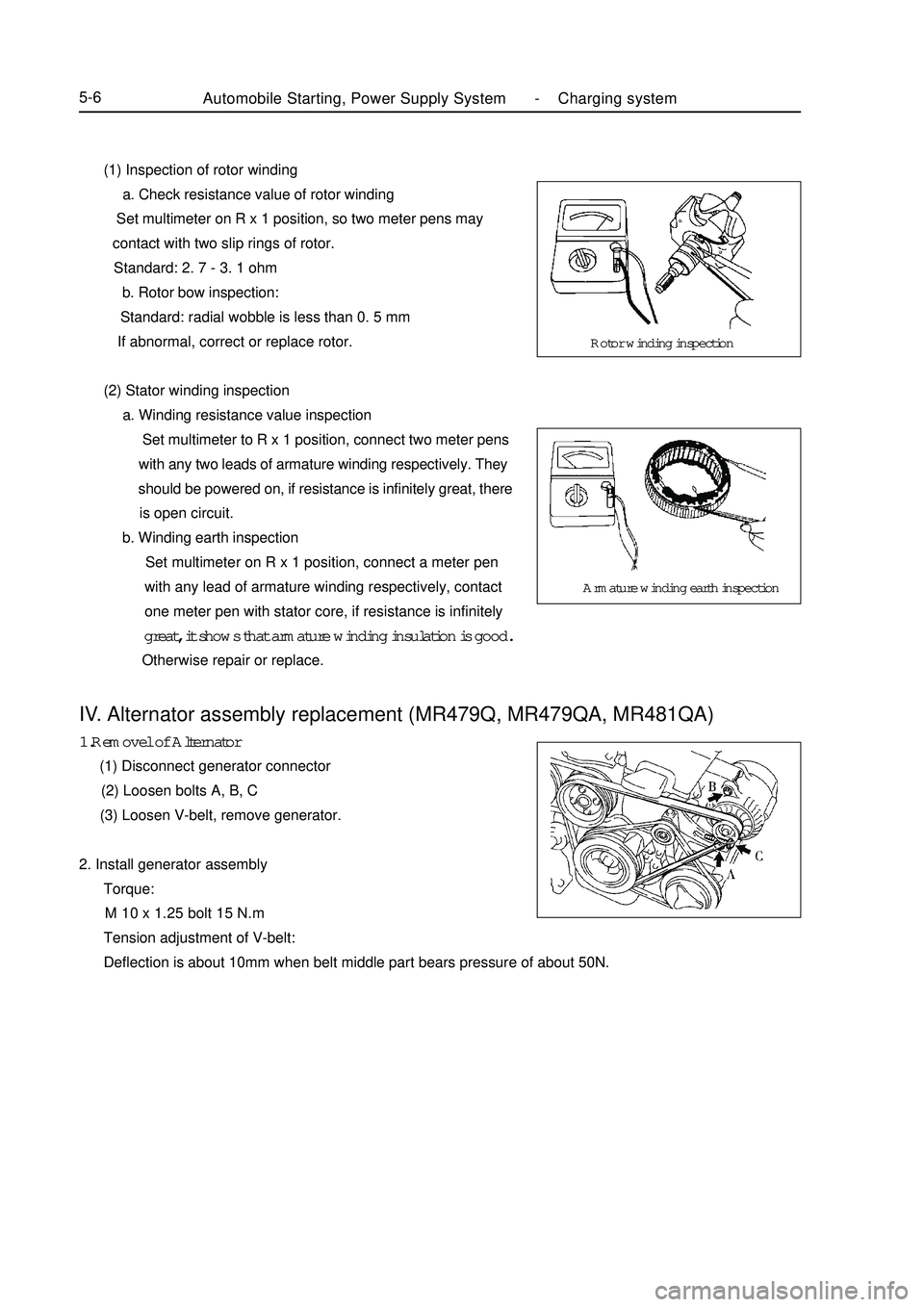

(1) Inspection of rotor winding

a. Check resistance value of rotor winding

Set multimeter on R x 1 position, so two meter pens may

contact with two slip rings of rotor.

Standard: 2. 7 - 3. 1 ohm

b. Rotor bow inspection:

Standard: radial wobble is less than 0. 5 mm

If abnormal, correct or replace rotor.

(2) Stator winding inspection

a. Winding resistance value inspection

Set multimeter to R x 1 position, connect two meter pens

with any two leads of armature winding respectively. They

should be powered on, if resistance is infinitely great, there

is open circuit.

b. Winding earth inspection

Set multimeter on R x 1 position, connect a meter pen

with any lead of armature winding respectively, contact

one meter pen with stator core, if resistance is infinitely

great, it shows that armature winding insulation is good.

Otherwise repair or replace.Automobile Starting, Power Supply System -Charging system5-6IV. Alternator assembly replacement (MR479Q, MR479QA, MR481QA)1.Removel of Alternator

(1) Disconnect generator connector

(2) Loosen bolts A, B, C

(3) Loosen V-belt, remove generator.

2. Install generator assembly

Torque:

M 10 x 1.25 bolt 15 N.m

Tension adjustment of V-belt:

Deflection is about 10mm when belt middle part bears pressure of about 50N.Rotor winding inspection

Armature winding earth inspection

Page 211 of 416

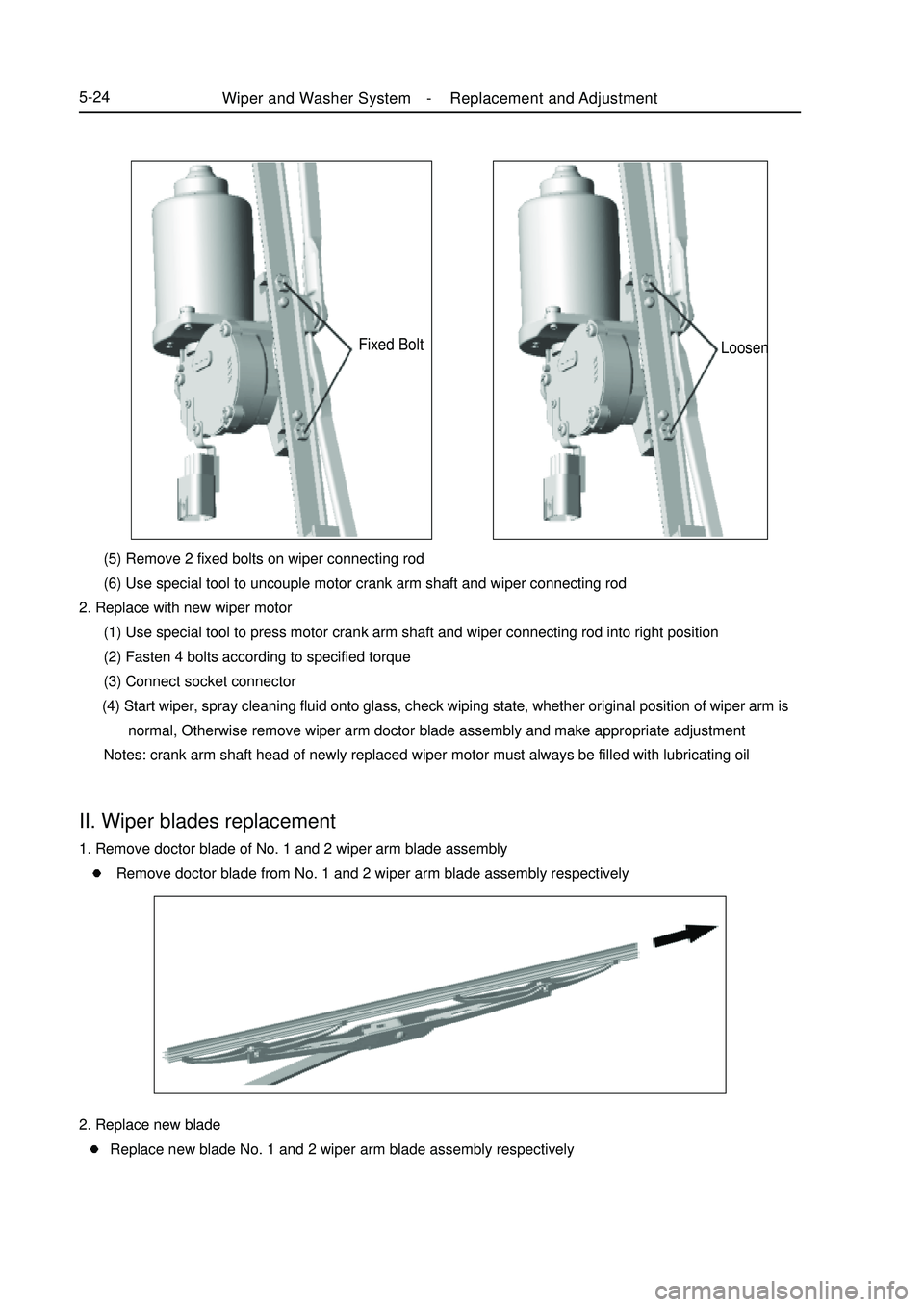

Fixed Bolt (5) Remove 2 fixed bolts on wiper connecting rod

(6) Use special tool to uncouple motor crank arm shaft and wiper connecting rod

2. Replace with new wiper motor

(1) Use special tool to press motor crank arm shaft and wiper connecting rod into right position

(2) Fasten 4 bolts according to specified torque

(3) Connect socket connector

(4) Start wiper, spray cleaning fluid onto glass, check wiping state, whether original position of wiper arm is

normal, Otherwise remove wiper arm doctor blade assembly and make appropriate adjustment

Notes: crank arm shaft head of newly replaced wiper motor must always be filled with lubricating oilII. Wiper blades replacement1. Remove doctor blade of No. 1 and 2 wiper arm blade assembly

Remove doctor blade from No. 1 and 2 wiper arm blade assembly respectivelyLoosenWiper and Washer System -Replacement and Adjustment5-242. Replace new blade

Replace new blade No. 1 and 2 wiper arm blade assembly respectively

Page 225 of 416

Wave band LF MF HF VHF

Radio wave AM FM

Modulation Amplitude modulation Frequency modulationFrequency 30KHZ 300KHZ 3MHZ 30MHZ 300MHZ

2. Area coverage

Scope of AM and FM broadcasting coverage area differs greatly.

Sometimes although AM broadcast may be received clearly, FM

binaural broadcasting cannot be received. Not only listening zone of

FM binaural broadcasting is small, but also static noise or other

cacophony (noise) tends to occur.

3. Receiving problem

Notes:

Besides static noise problem, there is also interference, multiplex

and attenuation. These problems are not caused by electric cacophony,

but the problem of radio wave itself.

(1) Interference

Besides static noise problem, AM broadcast tends to receive

other types of noise, especially at night. This is because ionosphere

reflects AM radio wave at night, these interference electric waves

interfere with signals from the same signal source while entering into

vehicle antenna directly, this kind of noise is called "interference".

(2) Multiplex

Noise caused by radio wave reflected from barrier is called

"multiplex". When radio signal emitted by broadcast antenna is

reflected by high buildings or high mountains, and disturbs directly

received other signals, multiplex phenomenon occurs.

(3) Attenuation

Since its frequency is higher than AM, FM wave is more easily

reflected by high buildings or high mountains. Therefore, FM signal

often disappears gradually, or when vehicle is blocked by barrier, it

cannot receive any signal, such phenomenon is called "attenuation".Audio System -Audio System Description5-38Chapter 5 Audio SystemSection 1 Audio System DescriptionDescription:

1. Radio wave band

Wave bands used in radiobroadcast are as follows:

LF: low frequency MF: medium frequency HF: high frequency VHF: very high frequencyFM (stereo)

FM (non-stereo)

AMInterference

IonosphereMultiplexAttenuation

Page 231 of 416

(1) Check LCD Illumination

a. Turn the ignition switch to ACC

b. Turn on radio assembly

c. Turn on the position light

Standard: The LCD indicator of the radio assembly goes on

Abnormal: go to step (7)

Normal: go to the next step

(2) Control volume and adjust the volume balance

Adjust the volume and its balance of the radio assembly to find out the inaudible speaker.

If all speakers are mute, check and replace the radio assembly

If individual speaker is mute, then respectively check and replace the inaudible speaker.

(3) Tweeter assembly inspection

a. Disconnect the speaker connector

b. Check the resistance

Notice:

Do not remove the speaker during inspection.

Standard Value: 4 ohm

Abnormal: Replace tweeter speaker assembly

Normal: Check wire harness and connector

(4) Check front speaker assembly

a. Disconnect speaker connector

b. Check resistance

Standard Value: 4 ohm

Abnormal: Replace front speaker assembly

Normal: Check wire harness and connector

(5) Check rear speaker assembly

a. Disconnect speaker connector

b. Check resistance

Standard Value: 4 ohm

Abnormal: Replace rear speaker assembly

Normal: Check wire harness and connector

(6) Check wire harness and connector

Abnormal Repair or replace wire harness and connector

Normal Check and replace radio assembly

(7) Check and replace radio assembly (+B, ACC, GND)

a. Check the continuity between terminals under each operating condition as shown in the table below.

Standard:Audio System -Audio System Inspection5-44Tester connection Condition Standard Status

GND Normal ON

Page 262 of 416

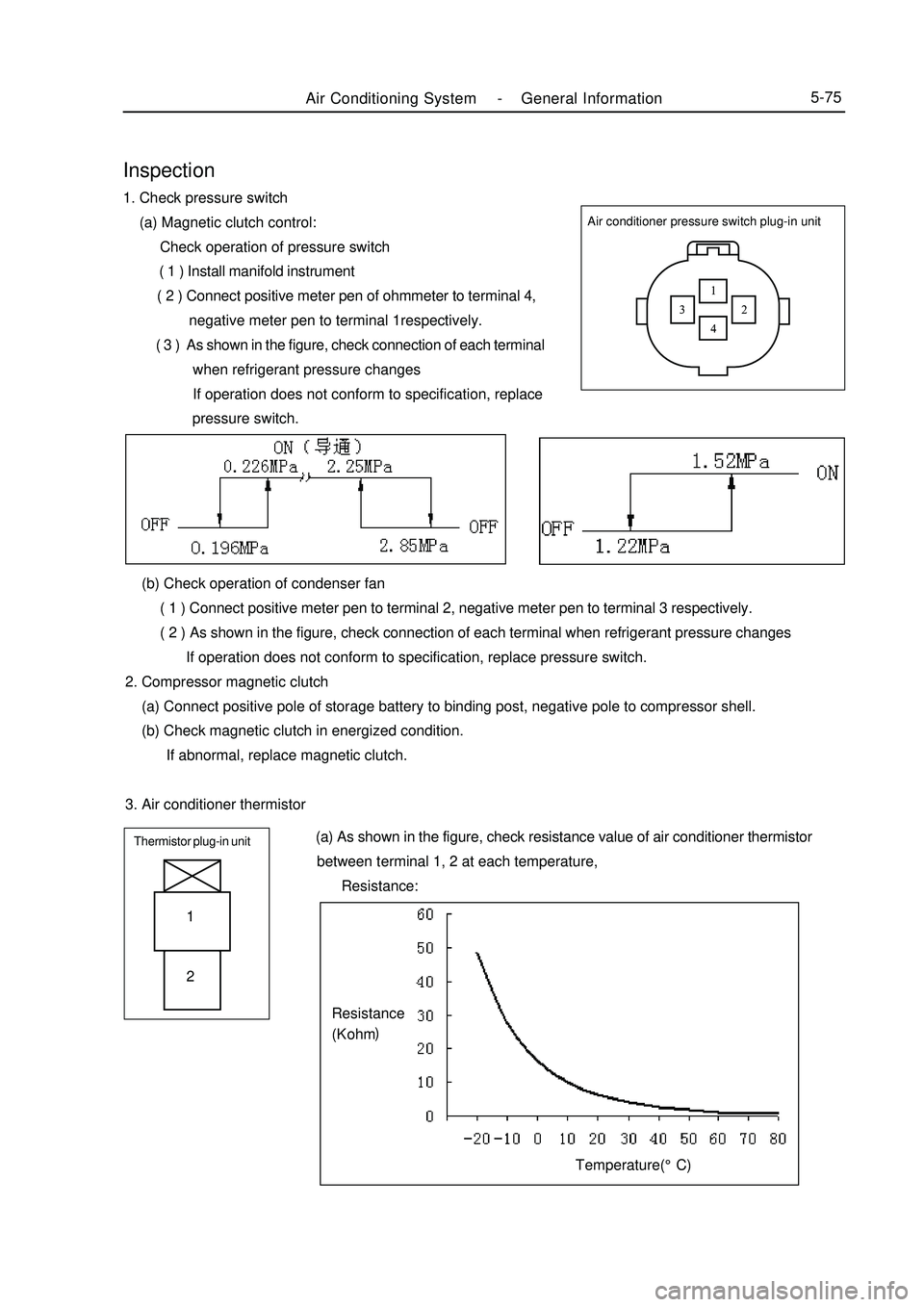

Air Conditioning System -General Information5-75Air conditioner pressure switch plug-in unitInspection1. Check pressure switch

(a) Magnetic clutch control:

Check operation of pressure switch

( 1 ) Install manifold instrument

( 2 ) Connect positive meter pen of ohmmeter to terminal 4,

negative meter pen to terminal 1respectively.

( 3 ) As shown in the figure, check connection of each terminal

when refrigerant pressure changes

If operation does not conform to specification, replace

pressure switch.

(b) Check operation of condenser fan

( 1 ) Connect positive meter pen to terminal 2, negative meter pen to terminal 3 respectively.

( 2 ) As shown in the figure, check connection of each terminal when refrigerant pressure changes

If operation does not conform to specification, replace pressure switch.

2. Compressor magnetic clutch

(a) Connect positive pole of storage battery to binding post, negative pole to compressor shell.

(b) Check magnetic clutch in energized condition.

If abnormal, replace magnetic clutch.

3. Air conditioner thermistorThermistor plug-in unit (a) As shown in the figure, check resistance value of air conditioner thermistor

between terminal 1, 2 at each temperature,

Resistance:1

2Temperature(°C)Resistance

(K ohm)

Page 287 of 416

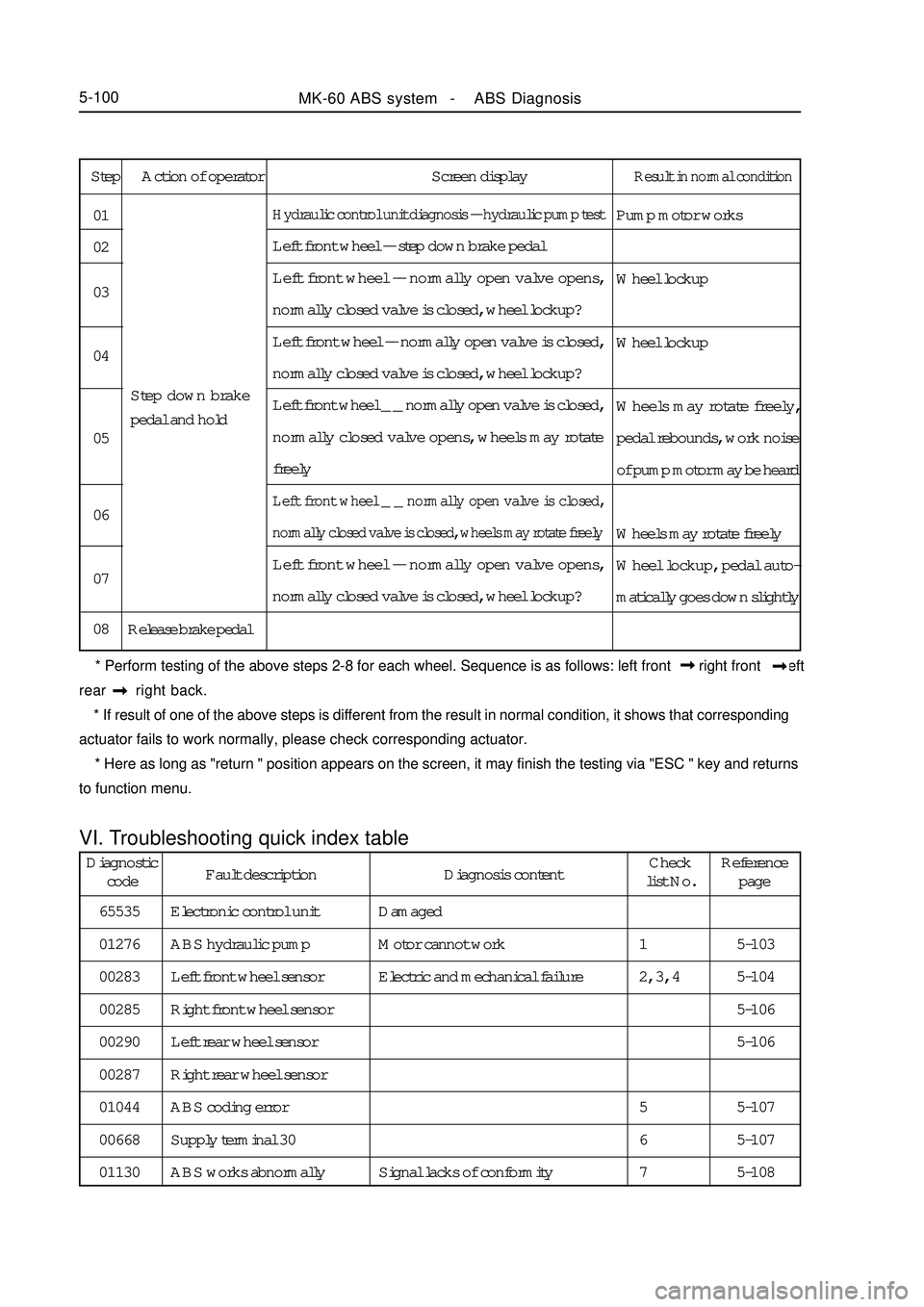

Step Action of operator Screen displayResult in normal conditionPump motor works

Wheel lockup

Wheel lockup

Wheels may rotate freely,

pedal rebounds, work noise

of pump motor may be heard

Wheels may rotate freely

Wheel lockup, pedal auto-

matically goes down slightlyHydraulic control unit diagnosis -- hydraulic pump testLeft front wheel -- step down brake pedal

Left front wheel -- normally open valve opens,

normally closed valve is closed, wheel lockup?

Left front wheel -- normally open valve is closed,

normally closed valve is closed, wheel lockup?

Left front wheel _ _ normally open valve is closed,

normally closed valve opens, wheels may rotate

freelyLeft front wheel _ _ normally open valve is closed,

normally closed valve is closed, wheels may rotate freelyLeft front wheel -- normally open valve opens,

normally closed valve is closed, wheel lockup?

Release brake pedal 01

02

03

04

05

06

07

08Step down brake

pedal and hold

* Perform testing of the above steps 2-8 for each wheel. Sequence is as follows: left front right front left

rear right back.

* If result of one of the above steps is different from the result in normal condition, it shows that corresponding

actuator fails to work normally, please check corresponding actuator.

* Here as long as "return " position appears on the screen, it may finish the testing via "ESC " key and returns

to function menu.VI. Troubleshooting quick index tableMK-60 ABS system - ABS Diagnosis5-100Diagnostic

codeFault description Diagnosis contentCheck

list No.Reference

page

65535

01276

00283

00285

00290

00287

01044

00668

01130Electronic control unit

ABS hydraulic pump

Left front wheel sensor

Right front wheel sensor

Left rear wheel sensor

Right rear wheel sensor

ABS coding error

Supply terminal 30

ABS works abnormallyDamaged

Motor cannot work

Electric and mechanical failure

Signal lacks of conformity5-103

5-104

5-106

5-106

5-107

5-107

5-108 1

2, 3, 4

5

6

7