ABS GEELY MK 2008 Owner's Manual

[x] Cancel search | Manufacturer: GEELY, Model Year: 2008, Model line: MK, Model: GEELY MK 2008Pages: 416, PDF Size: 25.19 MB

Page 100 of 416

15. Install LF steering knuckle assembly

Notice:

The hub bearing could be damaged if it is subjected to the vehicle

weight, such as when moving the vehicle with the drive shaft

bearing removed.

Therefore if it is absolutely necessary to place the vehicle weight

on the hub bearing, first support it with the special service tool for

front hub bearing.

16. Check left constant velocity drive shaft assembly

(1) Check the outboard joint for apparent looseness.

(2) Check that the inboard joint slide smoothly.

(3) Check the inboard joint for radial looseness.

(4) Check the boot for damage.

Notice:

Place the drive shaft assembly on level surface during the

inspection.

17. Remove inboard joint big clamp

Using a screw driver, loosen the inboard joint big clamp.

18. Remove inboard joint small clamp

Using a screw driver, loosen the inboard joint small clamp.

19. Separate inboard joint boot

Separate the outboard joint boot from the outboard Rzeppa joint

assembly.

20. Remove left tripod joint assembly

(1) Wipe off the old grease from the tripod joint assembly.

(2) Place the matchmarks between the tripod joint assembly and

the outboard Rzeppa joint.

Notice:

Do not punch the matchmarks.Propeller Shaft/DriveshaftFront Driveshaft4-23Mark -

Page 105 of 416

Propeller Shaft/DriveshaftFront Driveshaft4-28 Hint:

Please refer to the following table for dimension (A).LH mm

528.3±5.0

527.0±5.0RH mm

859.3±5.0

860.0±5.0 M/T manual transmission

A/T automatic transmission38. Install left constant velocity drive shaft assembly

(1) M/T

Coat the spline of the tripod joint assembly with gear oil.

(2) A/T

Coat the spline of the tripod joint assembly with ATF

(Automatic Transmission Fluid).

(3) Align the spline, use a brass bar and hammer to install the left

drive shaft assembly.

Notice:

Face the retainer open end downward.

Be careful not to damage the boot and oil seal.

Hint:

You can find out whether the tripod joint shaft contact the pinion shaft by rotating the shaft assembly, listening

to the sound and feeling.

39. Install right constant velocity drive shaft assembly

Hint:

The installation of the right side is the same as that of the left side.

Notice:

Install the retainer with its open end facing downward.

Be careful not to damage the boot and oil seal.

40. Install left steering knuckle assembly

Install the left constant velocity drive shaft assembly on the left steering knuckle assembly.

Notice:

Be careful not to damage the outboard joint boot.

With ABS:

Be careful not to damage the vehicle speed sensor rotor.

41. Install left steering gear with tie rod assembly

(1) Install the steering gear with tie rod assembly on the steering knuckle assembly with nuts.

Torque: 33N.m

(2) Install the new cotter pins.

Notice:

If the pin holes are not aligned, further tighten the nut by 60°.

42. Install left lower swing arm assembly

(1) Install the left lower swing arm assembly on the steering knuckle assembly with nuts.

Torque: 98N.m -

Page 106 of 416

Propeller Shaft/DriveshaftFront Driveshaft4-29 (2) Install the new cotter pins.

Notice:

If the pin holes are not aligned, further tighten the nut by 60°.

43. Install front stabilizer bar

(1) As shown in the illustration, install the stabilizer bar with two

No.1 collars and two gaskets and nuts.

Notice:

Make sure the gaskets and collars are correctly installed.

(2) Tighten the nut with a 10mm wrench.

Torque: 18N.m

44. Install left front vehicle speed sensor (with ABS)

(1) Install the left front vehicle speed sensor and brake hose on the

front shock absorber with bolts and clps.

Torque: 29N.m

(2) Install the vehicle speed sensor on the steering knuckle with

bolts.

Torque: 8.0N.m

Notice:

Be careful not to damage the wheel speed sensor.

Keep the vehicle speed sensor clean.

When installing the sensor,do not twist the sensor wire harness.

45. Install left steering knuckle wheel hub nut

(1) Install new left steering knuckle hub nuts

Torque: 216N.m

(2) Using a chisel and hammer, stake the hub locking nut.

46. Install engine bottom left shield

47. Install engine bottom right shield

48. Install engine bottom shield assembly

49. Install front wheel

Torque: 103 N.m

50. Add oil into manual transmission

51. Check and adjust the manual transmission fluid

52. Refill automatic transmission fluid

53. Check and adjust the automatic transmission fluid

54. Check and adjust front wheel alignment

55. Check ABS vehicle speed signal (with ABS) -

Page 107 of 416

Section 3 Front Wheel HubComponent ViewLeft Constant Velocity

Drive Shaft Assembly

Left Brake Caliper Assembly

Retainer

Dual Ball Bearing

Left Steering Knuckle

Front Axle Hub Front Axle Hub NutBrake DiscPropeller Shaft/DriveshaftFront Wheel Hub4-30With ABS

Left Front Vehicle

Speed Sensor

Left Tie Rod End Subassembly

Brake Hose

Left Front Axle Assembly

No. 1 Cushion Collar

Cotter Pin

Cushion

ClipFront Stabilizer

Left No.1 Front Lower

Suspension Arm

SubassemblyLeft Front Axle Hub Nut

Left Front Brake Disc Dust Cover

specified torqueN.

m :No. 1 Cushion Collar - Non-reusable parts -

Page 108 of 416

Propeller Shaft/DriveshaftFront Wheel Hub4-31Replacement1. Remove front wheel

2. Using a drive shaft nut chisel, remove the front axle hub left nut

3. Remove left front vehicle speed sensor (with abs)

4. Remove left front brake caliper assembly

Remove 2 bolts, remove the left front brake caliper assembly

from the steering knuckle.5. Remove front brake disc

6. Remove front stabilizer

7. Remove left no.1 front lower suspension arm subassembly with a ball joint puller

8. Remove left tie rod end subassembly with a ball joint puller

9. Remove left front axle assembly

10. Remove left front shock absorber assembly

Remove 2 sets of bolts and nuts, remove the left front shock

absorber from the left front axle assembly.

11. Remove left front axle hub snap ring

Using a snap ring plier, remove front axle hub left snap ring.

12. Remove left front axle hub subassembly

(1) Remove the left front axle hub subassembly with rear axle

puller. -

Page 110 of 416

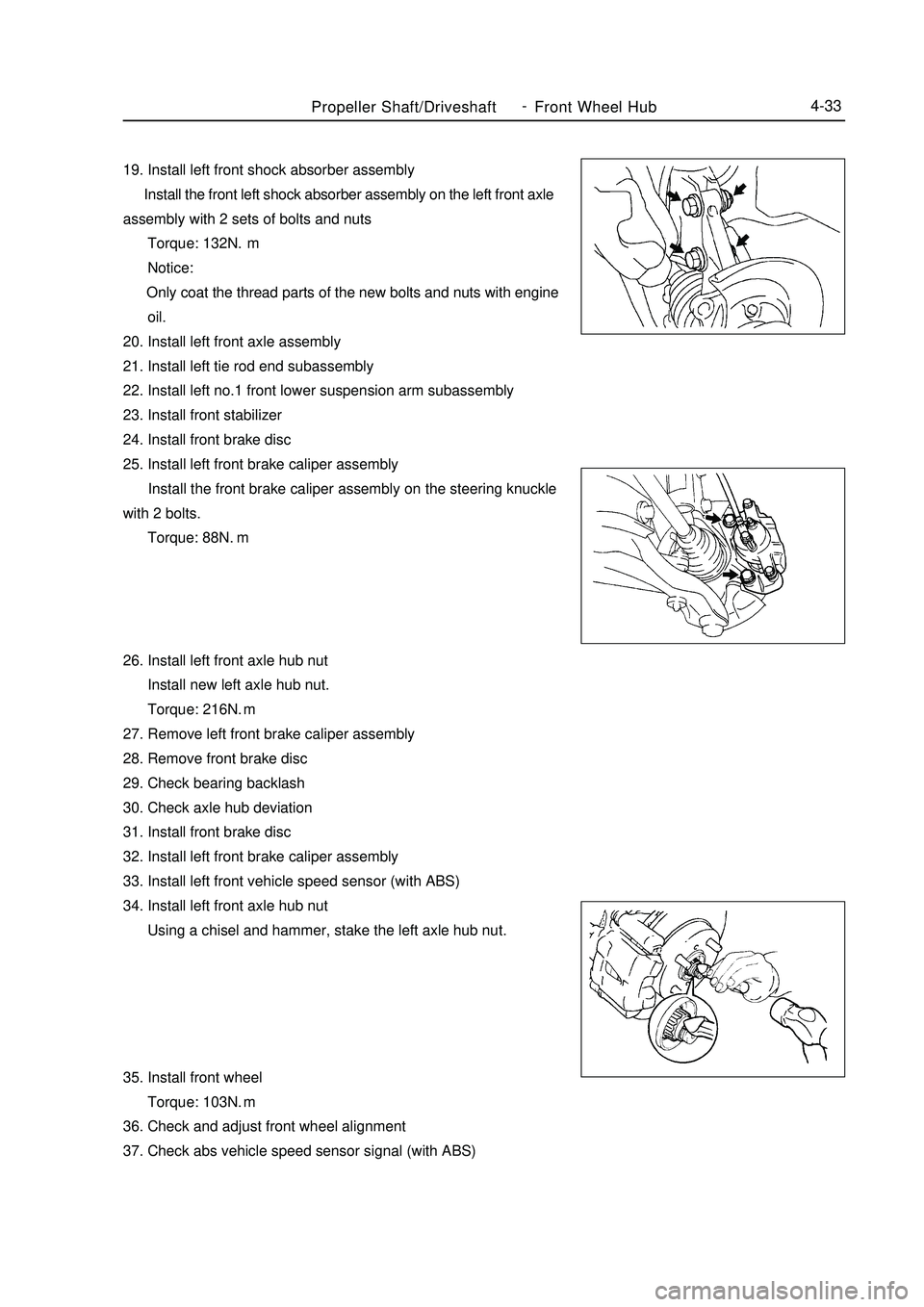

Propeller Shaft/DriveshaftFront Wheel Hub4-3319. Install left front shock absorber assembly

Install the front left shock absorber assembly on the left front axle

assembly with 2 sets of bolts and nuts

Torque: 132N.m

Notice:

Only coat the thread parts of the new bolts and nuts with engine

oil.

20. Install left front axle assembly

21. Install left tie rod end subassembly

22. Install left no.1 front lower suspension arm subassembly

23. Install front stabilizer

24. Install front brake disc

25. Install left front brake caliper assembly

Install the front brake caliper assembly on the steering knuckle

with 2 bolts.

Torque: 88N.

m

26. Install left front axle hub nut

Install new left axle hub nut.

Torque: 216N.m

27. Remove left front brake caliper assembly

28. Remove front brake disc

29. Check bearing backlash

30. Check axle hub deviation

31. Install front brake disc

32. Install left front brake caliper assembly

33. Install left front vehicle speed sensor (with ABS)

34. Install left front axle hub nut

Using a chisel and hammer, stake the left axle hub nut.

35. Install front wheel

Torque: 103N.m

36. Check and adjust front wheel alignment

37. Check abs vehicle speed sensor signal (with ABS) -

Page 112 of 416

Propeller Shaft/DriveshaftRear Wheel Hub and Bearing Assembly4-35Section 4 Rear Wheel Hub and Bearing AssemblyComponent ViewRear Axle Hub UnitBrake Drum Assembly

specified torqueN.

m :Slip Control Sensor Wire Harness

With ABS

Left Rear Axle Hub Bolt - Non-reusable parts

Page 113 of 416

Replacement1. Remove rear wheel

2. Remove rear wheel brake drum subassembly

3. Remove slip control sensor wire harness (with ABS)

4. Remove left rear axle hub and bearing assembly

Remove 4 bolts and left axle hub and bearing assembly.

5. Install left rear axle hub and bearing assembly

Install left axle hub and bearing assembly with 4 bolts

Torque: 63N.m

6. Connect slip control sensor wire harness (with ABS)

Notice:

Do not twist the sensor wire harness during connection.

7. Check bearing backlash

8. Check axle hub deviation

9. Install rear wheel brake drum subassembly

10. Install rear wheel

Torque: 103N.m

11. Check as vehicle speed sensor signal (with ABS)Propeller Shaft/DriveshaftRear Wheel Hub and Bearing Assembly4-36 -

Page 115 of 416

Chapter 5 Front Suspension SystemSection 1 Front Suspension SystemDescription on front suspension structureThis model uses strut swing arm independent suspension with stabilizer bar.

The shock absorber upper end is flexibly connected to the body through the shock absorber mounting seat, the

lower end is rigidly connected to the steering knuckle. The coil spring encloses the shock absorber (coil spring

geometrical axial line does not coincide with that of the shock absorber piston rod), and is supported between the

upper and lower spring seats.

Both ends of the stabilizer bar are connected to the shock absorber through the strut bar ball pin and the intermediate

part is supported on the lower front body by the rubber bushing and support frame.

The front cushion sleeves the shock absorber piston rod head to restrict the wheel jump limit position and plays

the role of buffer.

The thrust ball bearing, installed between the spring upper seat and the shock absorber mount, is used for the

relative rotation upon steering of the shock absorber rigidly connected to the steering knuckle to the shock absorber

mount flexibly connected to the body.

"L" type lower swing arm is secured to the lower engine compartment with the press plate through elastic rubber

bushing and hinge, and its outer end is connected to the steering knuckle through the ball stud pin which is attached

to the lower swing arm by 3 high intension bolts. The ball stud pin can be removed and replaced when it is worn.

The ball seat material is saturated polyester containing oil, featured in comparatively high intensity and wearability

and good self-lubrication performance. Proper amount of grease has been added during the assembly and there is

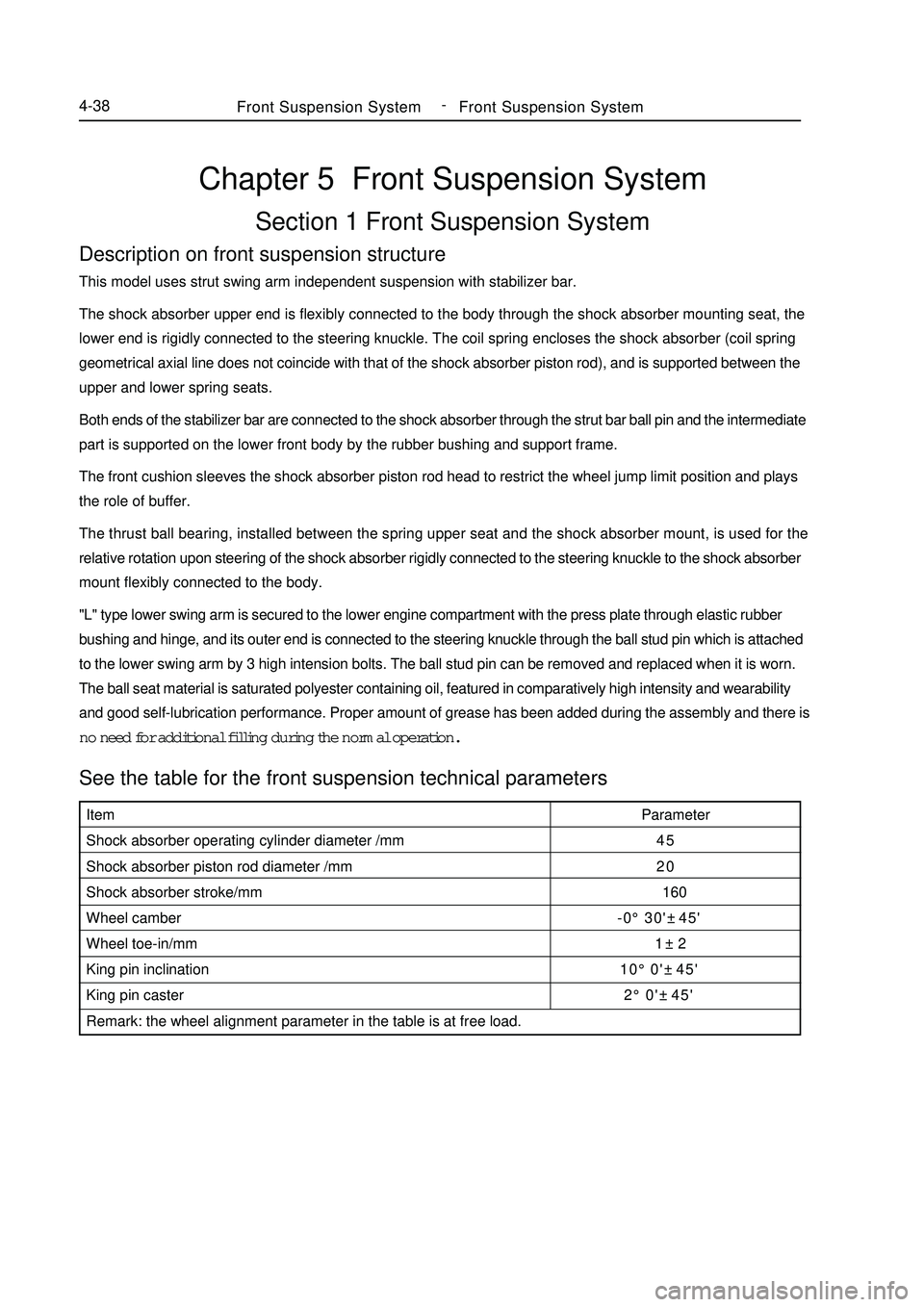

no need for additional filling during the normal operation.See the table for the front suspension technical parametersFront Suspension SystemFront Suspension System4-38Item

Shock absorber operating cylinder diameter /mm

Shock absorber piston rod diameter /mm

Shock absorber stroke/mm

Wheel camber

Wheel toe-in/mm

King pin inclination

King pin caster

Remark: the wheel alignment parameter in the table is at free load.Parameter

45

20

160

-0°30'±45'

1±2

10°0'±45'

2°0'±45' -

Page 116 of 416

Suspected Area

1. Tires (Worn or improperly inflated)

2. Wheel alignment (Incorrect)

3. Steering system joint (Loose or worn)

4. Hub bearing (Worn)

5. Steering gear (Out of adjustment or worn)

6. Suspension parts (Worn or damaged)

1. Vehicle (Overloaded)

2. Spring (stiffness not comply with or damage)

3. Shock absorber (Worn)

1. Tire (Worn or improperly inflated)

2. Steering linkage (Loose or damaged)

3. Stabilizer bar (Bent or broken)

4. Shock absorber (Worn or damaged)

1. Tire (Worn or improperly inflated)

2. Tire (Dynamic balance is not as specified)

3. Shock absorber (Worn or damaged)

4. Wheel alignment (Incorrect)

5. Ball stud pin (Worn or damaged)

6. Hub bearing (Worn or damaged)

7. Steering linkage (Loose or worn)

8. Steering gear (Out of adjustment or worn)

1. Tire (Worn or improperly inflated)

2. Wheel alignment (Incorrect)

3. Shock absorber (Worn or damaged)

4. Suspension parts (Worn or damaged)Symptom Table Use the table below to help you find the cause of the problem. The numbers indicate the priority of the likely

cause of the problem. Check each part in order. If necessary, replace parts.

Symptom

Off track

Body Descent

Sways

Front wheel shimmy

Abnormal tire wearFront Suspension System-Front Suspension System4-39