warning GEELY MK 2008 Owner's Manual

[x] Cancel search | Manufacturer: GEELY, Model Year: 2008, Model line: MK, Model: GEELY MK 2008Pages: 416, PDF Size: 25.19 MB

Page 246 of 416

(9) The passenger side airbag module resistance is too low

When using the scan tool to test the airbag ECU, the DTC is 93C9, indicating that the passenger side airbag

module resistance is too low, the resistance is lower than 1.2 ohm.5-59Step Operation Yes No

1 When using the scan tool to test the airbag ECU, is the DTC 93C7? Go to step 2 other

2 Go to step 3 Go to step 5

3 Go to step 4 Go to step 5

4 Whether the clock spring is ok? Go to step 5

5 Go to step 6 Go to step 1

6 The fault has been removed, use the scan tool to eliminate the DTC.Shut off the power supply, check whether the connector wire harness of

the airbag ECU is in good condition?

Disconnect the battery negative cable for 30 seconds, check whether the

connector wire harness of driver side airbag module is in good condition?After the troubleshooting, switch on the power supply, observe the status of the warning

light. The warning light shall goes off after lighting up for 4 seconds (self-check). (8) The passenger side airbag module resistance is too high (DTC 93C8)

When using the scan tool to test the airbag ECU, the DTC is 93C8, indicating that the passenger side airbag

module resistance is too high, the resistance is higher than 4.5 ohm.

Step Operation Yes No

1 When using the scan tool to test the airbag ECU, is the DTC 93C8? Go to step 2 other

2 Go to step 3 Go to step 5

3 Go to step 4 Go to step 5

4 Whether the passenger side airbag module resistance is ok? Go to step 5

5 Go to step 6 Go to step 1

6 The fault has been removed, use the scan tool to eliminate the DTC.Shut off the power supply, check whether the connector of the airbag ECU

is well plugged (whether the wire harness connector is in good condition)?

Disconnect the battery negative cable for 30 seconds, check whether the

passenger side airbag module is well connected? (whether the wire

harness connector is in good condition)After the troubleshooting, switch on the power supply, observe the status of the warning

light. The warning light shall goes off after lighting up for 4 seconds (self-check).Step Operation Yes No

1 When using the scan tool to test the airbag ECU, is the DTC 93C9? Go to step 2 other

2 Go to step 3 Go to step 5

3 Go to step 4 Go to step 5

4 Whether the passenger side airbag module resistance is ok? Go to step 5

5 Go to step 6 Go to step 1

6 The fault has been removed, use the scan tool to eliminate the DTC.Shut off the power supply, check whether the connector of the airbag ECU

is well plugged (whether the wire harness connector is in good condition)?

Disconnect the battery negative cable for 30 seconds, check whether the

passenger side airbag module is well connected? (whether the wire

harness connector is in good condition)After the troubleshooting, switch on the power supply, observe the status of the warning

light. The warning light shall goes off after lighting up for 4 seconds (self-check).SRS (Supplemental Restraint System)-

SRS-General Information

Page 247 of 416

(11) The passenger side airbag module is short to power supply (DTC 93CB)

When using the scan tool to test the airbag ECU, the DTC is 93CB, indicating that the passenger side airbag

module is short to power supply, the resistance is lower than 21K ohm.

(12) The driver side pretensioner seat belt resistance is too high (DTC 93CC)

When using the scan tool to test the airbag ECU, the DTC is 93CC, indicating that the driver side pretensioner

seat belt resistance is too high, the resistance is higher than 4.5 ohm.

(13) The driver side pretensioner seat belt resistance is too low (DTC 93CD)

When using the scan tool to test the airbag ECU, the DTC is 93CD, indicating that the driver side pretensioner

seat belt resistance is too low, the resistance is lower than 1.2 ohm.

(14) The driver side pretensioner seat belt resistance is short to ground (DTC 93CE)

When using the scan tool to test the airbag ECU, the DTC is 93CE, indicating that the driver side pretensioner

seat belt is short to ground, the resistance is lower than 6.5K ohm.

(15) The driver side pretensioner seat belt resistance is short to power supply (DTC 93CF)

When using the scan tool to test the airbag ECU, the DTC is 93CF, indicating that the driver side pretensioner

seat belt is short to power supply, the resistance is lower than 21K ohm.5-60 (10) The passenger side airbag module is short to ground

When using the scan tool to test the airbag ECU, the DTC is 93CA, indicating that the passenger side airbag

module is short to ground, the resistance is lower than 6.5K ohm.

Step Operation Yes No

1 When using the scan tool to test the airbag ECU, is the DTC 93CA? Go to step 2 other

2 Go to step 3 Go to step 5

3 Go to step 4 Go to step 5

4 Whether the passenger side airbag module resistance is ok? Go to step 5

5 Go to step 6 Go to step 1

6 The fault has been removed, use the scan tool to eliminate the DTC.Shut off the power supply, check whether the connector wire harness of

the airbag ECU is in good condition?Disconnect the battery negative cable for 30 seconds, check whether the

connector wire harness of passenger side airbag module is in good condition?After the troubleshooting, switch on the power supply, observe the status

of the warning light. The warning light shall goes off after lighting up for

4 seconds (self-check).Step Operation Yes No

1 When using the scan tool to test the airbag ECU, is the DTC 93CB? Go to step 2 other

2 Go to step 3 Go to step 4

3Go to step 4

4 Go to step 5 Go to step 1

5 The fault has been removed, use the scan tool to eliminate the DTC.Shut off the power supply, check whether the connector wire harness of

the airbag ECU is in good condition?Disconnect the battery negative cable for 30 seconds, check whether the

connector wire harness of passenger side airbag module is in good condition?After the troubleshooting, switch on the power supply, observe the status

of the warning light. The warning light shall goes off after lighting up for

4 seconds (self-check).SRS (Supplemental Restraint System)-SRS-General Information

Page 248 of 416

(21) Airbag ECU warning light is short to power supply (DTC 93D5)

When using the scan tool to test the airbag ECU, the DTC is 93D5, indicating that the airbag ECU warning

light is short to power supply.5-61 (16) The passenger side pretensioner seat belt resistance is too high (DTC 93D0)

When using the scan tool to test the airbag ECU, the DTC is 93D0, indicating that the passenger side

pretensioner seat belt resistance is too high, the resistance is higher than 4.5 ohm.

(17) The passenger side pretensioner seat belt resistance is too low (DTC 93D1)

When using the scan tool to test the airbag ECU, the DTC is 93D1, indicating that the passenger side

pretensioner seat belt resistance is too low, the resistance is lower than 1.2 ohm.

(18) The passenger side pretensioner seat belt resistance is short to ground (DTC 93D2)

When using the scan tool to test the airbag ECU, the DTC is 93D2, indicating that the passenger side

pretensioner seat belt is short to ground, the resistance is lower than 6.5K ohm.

(19) The passenger side pretensioner seat belt resistance is short to power supply (DTC 93D3)

When using the scan tool to test the airbag ECU, the DTC is 93D3, indicating that the passenger side

pretensioner seat belt is short to power supply, the resistance is lower than 21K ohm.

(20) Airbag ECU warning light is short to ground or warning light wire harness is disconnected (DTC 93D4)

When using the scan tool to test the airbag ECU, the DTC is 93D4, indicating that the airbag ECU warning light

is short to ground or the warning light wire harness is disconnected.

Step Operation Yes No

1 When using the scan tool to test the airbag ECU, is the DTC 93D5? Go to step 2 other

2 Go to step 3 Go to step 5

3 Go to step 4 Go to step 5

4 Check the LED and wire harness for connection. Go to step 5

5 Go to step 6 Go to step 1

6 The fault has been removed, use the scan tool to eliminate the DTC.Shut off the power supply, check whether the airbag ECU wire harness

connection is ok? (is there any short)

Check the connector of the warning light on airbag ECU wire harness (is

there any short)?

After the troubleshooting, switch on the power supply, observe the status

of the warning light. The warning light shall goes off after lighting up for

4 seconds (self-check).Step Operation Yes No

1 When using the scan tool to test the airbag ECU, is the DTC 93D4? Go to step 2 other

2 Go to step 3 Go to step 5

3 Go to step 4 Go to step 5

4 Check the LED and wire harness for connection. Go to step 5

5 Go to step 6 Go to step 1

6 The fault has been removed, use the scan tool to eliminate the DTC.Shut off the power supply, check whether the airbag ECU wire harness

connection is ok? (is there any short)Check the connector of the warning light on airbag ECU wire harness (is there any short)?After the troubleshooting, switch on the power supply, observe the status

of the warning light. The warning light shall goes off after lighting up for

4 seconds (self-check).SRS (Supplemental Restraint System)-SRS-General Information

Page 249 of 416

5-62 (22) There are problems in the configuration of the airbag ECU (DTC 93D6)

When using the scan tool to test the airbag ECU, the DTC is 93D6, indicating that there are problems in the

configuration of the airbag ECU.

Step Operation Yes No

1 When using the scan tool to test the airbag ECU, is the DTC 93D6? Go to step 2 other

2Go to step 3

3 Go to step 4 Go to step 1

4 The fault has been removed, use the scan tool to eliminate the DTC.Check whether the configuration of the airbag ECU is consistent with the

actual on-board configuration?

After the troubleshooting, switch on the power supply, observe the status

of the warning light. The warning light shall goes off after lighting up for

4 seconds (self-check). (23) The impact signal output interface of the airbag ECU is short to ground or the impact output circuit is

disconnected. (DTC 93D7)

When using the scan tool to test the airbag ECU, the DTC is 93D7, indicating that the impact signal output

interface of the airbag ECU is short to ground or the impact output circuit is disconnected.IV. Diagnosis of collided vehicle No matter airbag is unfolded or folded, inspection and maintenance of collided vehicle should be performed

according to the following sequence.

1. Check ECU diagnosis signal.

(1) Connect scanner diagnosis joint

(2) Use scanner to read out diagnosis result.

2. Repair sequence

(1) when airbag is unfolded.

The following components should be replaced with new parts

a. Airbag assembly on passenger side

b. ECU

c. Airbag assembly on driver side

d. Seat belt with pretensionerNote:

due to impact, when battery power is insufficient, scanner can not communicate with ECU, now check and

service instrument board wire harness or use external power supply.SRS (Supplemental Restraint System)-SRS-General Information (2 ) Check the following components, if there is any abnormity, replace with new parts

a. Clock spring.

b. Steering wheel, steering column, lower steering shaft assembly

(3 ) The installation status of driver airbag assembly in relation to steering wheel

a. Check and see if there is abnormal noise in the steering wheel, the action of the same is good, or the

clearance is normal.

b. Check the connecter of the wire harness for damage and the terminal for distortion.

Page 251 of 416

6. Steering wheel, steering column and steering lower shaft component.

(1) Check the installation status of driver airbag assembly.

(2) Check the steering wheel for any abnormal noise and see if the clearance is normal.

7. Check the wire harness connector (instrument panel wire harness).

Check and see if the wire harness is securely installed, if the joint is damaged and if the terminal is distorted.V. Warning marks When using or maintaining an airbag, the warnings shall be indicated. When maintaining, proceed in

accordance with the description of mark. In addition, if the mark is damaged or stained, it shall be replaced.

(1) Steering wheel, see Fig. 1.

(2) Driver airbag assembly, see Fig. 2.

(3) Clock spring, see Fig. 3.

Fig. 1.Fig. 2.Warning markFig. 3.Warning

mark (4) ECU, see Fig. 4.

(5) Sunshade, see Fig. 5.VI. SRS electronic control unit (ECU)Removal and Installation

1. Operations prior to Removal

(1) Turn the ignition switch OFF.

(2) Remove negative (-) terminal cable of the battery. Put it in a proper position or wrap it up with insulating

tape.Fig. 4.Fig. 5.5-64SunshadeSRS (Supplemental Restraint System)-SRS-General Information

Page 252 of 416

Notice

1. Work must be started 60s after the negative (-) terminal cable is detached from battery. The detached

negative (-) terminal cable shall be protected with insulating tape for insulation.

2. Never attempt to dismantle or repair an ECU. If there is any trouble, replace the ECU with a new one.

3. Prevent the ECU from shock or vibration. If pitting, crack or distortion is found, replace the ECU with a

new one.

4. Every time an airbag is deployed, the ECU shall be replaced with a new one.

5. When disassembling or maintaining the parts around ECU, attention must be given to avoid contacting the

ECU. 2. Removal procedures:

(1) Remove the miscellaneous box in the middle consoce.

(2) Remove the connectors to SRS ECU.

(3) Remove ECU.

3. Installation procedures:

(1) Install ECU.

(2) Install the connectors to SRS ECU.

(3) Install the miscellaneous box in the middle consoce.

(4) Connect negative (-) terminal cable of the battery.

4. Key points for Installation:

(1) Install ECU.Notice

If the ECU cannot be installed correctly, the airbag will not act normally.

5. Check

a. ECU case for pitting, crack and distortion

b. The connector for damage and distortion.Notice

If pitting, crack or distortion is found on an ECU, replace it with a new one.VII. Airbag assembly & clock spring1.Removal and Installation of driver airbag and clock spring

Operations prior to removal

(1)Take out the ignition key after the steering wheel and front

wheel are adjusted to straightforward direction.

(2)Remove negative (-) terminal cable from the battery.

Removal procedures of the driver airbag assembly:

(1) Unscrew the screws of the two sides, see fig.15-65SRS (Supplemental Restraint System)-SRS-General Information (2) Check after installation.

a. Turn the ignition switch ON.

b. The warning light goes on within 4s, and then goes out.

(3) If the light doesn't go out, check the trouble and eliminate it.

For other ECU inspections, see Troubleshooting.

fig.1

Page 254 of 416

5-67Notice

When connecting or disconnecting the turn the ignition switch OFF first.

d. Turn the ignition switch ON.

e. Read the diagnostic circuit and see if the other locations than the troubled area of the airbag are normal.

f. Turn the ignition switch OFF.

g. Remove the negative (-) terminal cable from the battery, and protect it with insulating tape for insulation.Notice

Work must be started 60s after the negative (-) terminal cable is disconnected from battery.

(2) Installation of clock spring

Screw up the clock spring clockwise to the end, rotate it counter-

clockwise by 2.5 turns, and align it with the mark (see the figure 3).Notice

If the center of the clock spring cannot be aligned, the steering

wheel will not turn midway, or cause bad performance to the clock

spring circuit, consequently hamper the normal action of the airbag.

(3) Installation of the components of the steering wheel and airbag assembly

a. When the center of the clock spring is aligned, install the components of the steering wheel and airbag

assembly.

b. After being installed, rotate the left and right sides of the steering wheel to position, and make sure there

is no abnormality.

(4) Check after installation

a. Slightly rotate the steering wheel left and right, make sure that there is no abnormality or noise. (Driver

airbag module, clock spring)

b. Turn the ignition switch ON.

c. The warning light goes on within 4s, and then goes out.figure 3SRS (Supplemental Restraint System)-

SRS-General Information b. Connect negative (-) terminal cable of the battery.

c. Connect the diagnostic connector (16 pins).Notice

In case of scrapping an airbag, it shall be noted that the airbag shall be deployed according to the specified

procedures before being scrapped.SRS Air Bag

Warning LightNotice

When installing the components of the steering wheel and

airbag assembly, attention should be given to protect the wire

harness of the clock spring from seizure.

d. The trouble shall be eliminated if the warning light remains on when the ignition switch is turned on or

after it goes out after 4s.

Page 260 of 416

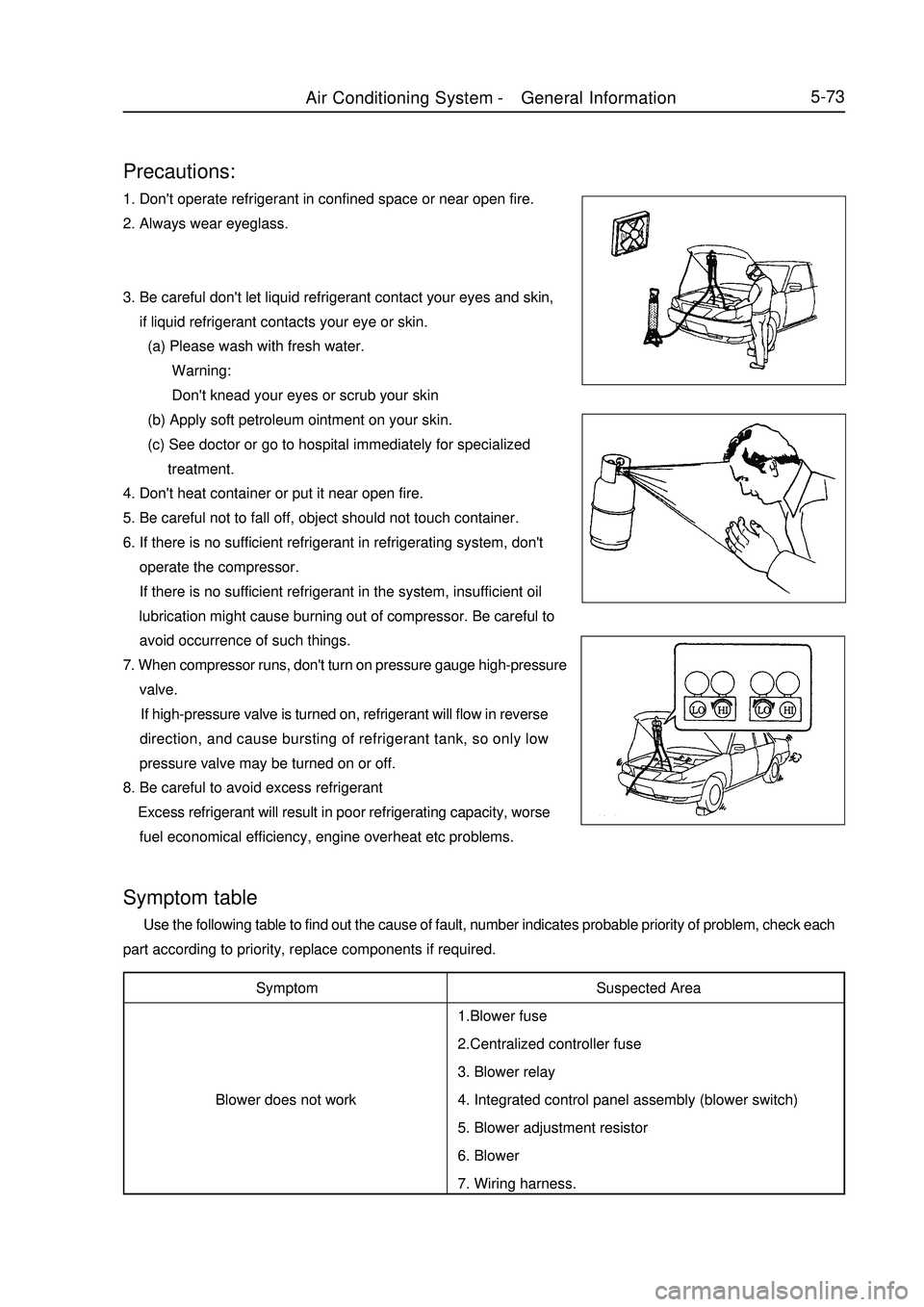

5-73Precautions:1. Don't operate refrigerant in confined space or near open fire.

2. Always wear eyeglass.

3. Be careful don't let liquid refrigerant contact your eyes and skin,

if liquid refrigerant contacts your eye or skin.

(a) Please wash with fresh water.

Warning:

Don't knead your eyes or scrub your skin

(b) Apply soft petroleum ointment on your skin.

(c) See doctor or go to hospital immediately for specialized

treatment.

4. Don't heat container or put it near open fire.

5. Be careful not to fall off, object should not touch container.

6. If there is no sufficient refrigerant in refrigerating system, don't

operate the compressor.

If there is no sufficient refrigerant in the system, insufficient oil

lubrication might cause burning out of compressor. Be careful to

avoid occurrence of such things.

7. When compressor runs, don't turn on pressure gauge high-pressure

valve.

If high-pressure valve is turned on, refrigerant will flow in reverse

direction, and cause bursting of refrigerant tank, so only low

pressure valve may be turned on or off.

8. Be careful to avoid excess refrigerant

Excess refrigerant will result in poor refrigerating capacity, worse

fuel economical efficiency, engine overheat etc problems.Symptom

Blower does not workSymptom table Use the following table to find out the cause of fault, number indicates probable priority of problem, check each

part according to priority, replace components if required.

Suspected Area

1.Blower fuse

2.Centralized controller fuse

3. Blower relay

4. Integrated control panel assembly (blower switch)

5. Blower adjustment resistor

6. Blower

7. Wiring harness.Air Conditioning System -General Information

Page 286 of 416

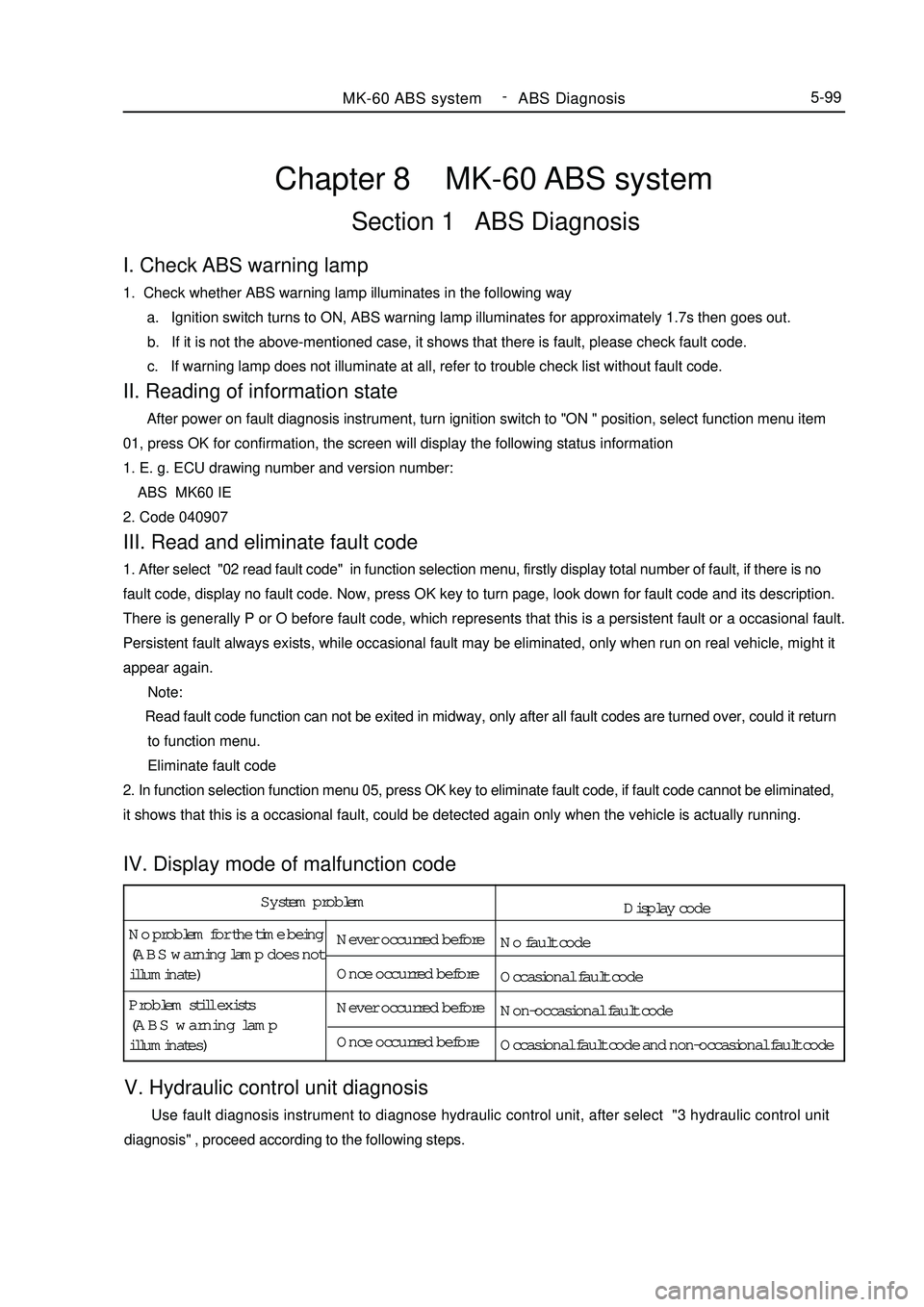

System problem

No problem for the time being

(ABS warning lamp does not

illuminate)Never occurred before

Once occurred before

Never occurred before

Once occurred before Problem still exists

(ABS warning lamp

illuminates)Chapter 8 MK-60 ABS systemSection 1 ABS DiagnosisV. Hydraulic control unit diagnosis Use fault diagnosis instrument to diagnose hydraulic control unit, after select "3 hydraulic control unit

diagnosis" , proceed according to the following steps.MK-60 ABS system -

ABS Diagnosis5-99I. Check ABS warning lamp1. Check whether ABS warning lamp illuminates in the following way

a. Ignition switch turns to ON, ABS warning lamp illuminates for approximately 1.7s then goes out.

b. If it is not the above-mentioned case, it shows that there is fault, please check fault code.

c. If warning lamp does not illuminate at all, refer to trouble check list without fault code.II. Reading of information state After power on fault diagnosis instrument, turn ignition switch to "ON " position, select function menu item

01, press OK for confirmation, the screen will display the following status information

1. E. g. ECU drawing number and version number:

ABS MK60 IE

2. Code 040907III. Read and eliminate fault code1. After select "02 read fault code" in function selection menu, firstly display total number of fault, if there is no

fault code, display no fault code. Now, press OK key to turn page, look down for fault code and its description.

There is generally P or O before fault code, which represents that this is a persistent fault or a occasional fault.

Persistent fault always exists, while occasional fault may be eliminated, only when run on real vehicle, might it

appear again.

Note:

Read fault code function can not be exited in midway, only after all fault codes are turned over, could it return

to function menu.

Eliminate fault code

2. In function selection function menu 05, press OK key to eliminate fault code, if fault code cannot be eliminated,

it shows that this is a occasional fault, could be detected again only when the vehicle is actually running.IV. Display mode of malfunction codeDisplay code

No fault code

Occasional fault code

Non-occasional fault code

Occasional fault code and non-occasional fault code

Page 288 of 416

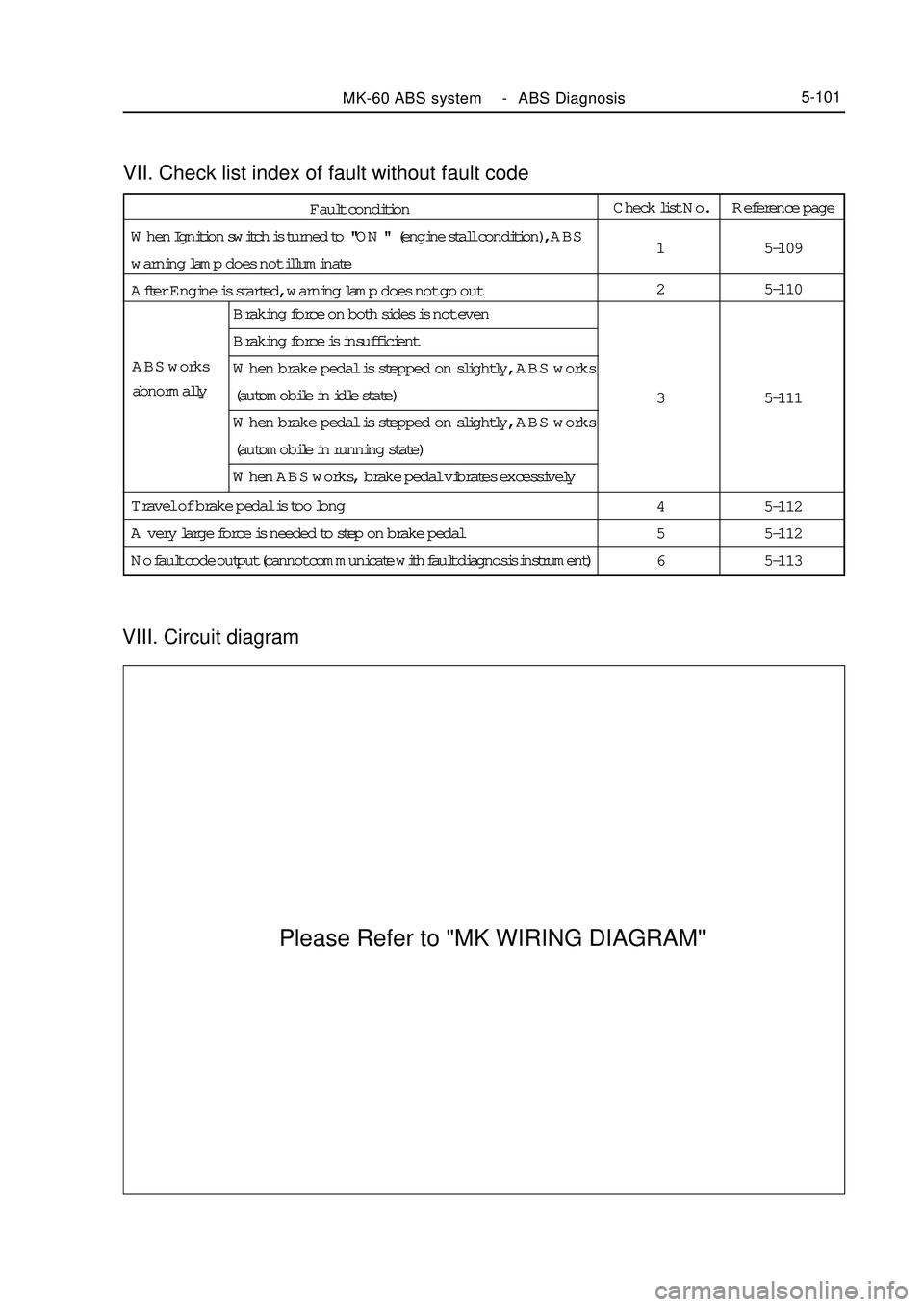

VIII. Circuit diagramVII. Check list index of fault without fault codeMK-60 ABS system -ABS Diagnosis5-101Fault condition

When Ignition switch is turned to "ON " (engine stall condition), ABS

warning lamp does not illuminate

After Engine is started, warning lamp does not go outCheck list No.

1

2

3

4

5

6Reference page

5-109

5-110

5-111

5-112

5-112

5-113 ABS works

abnormallyBraking force on both sides is not even

Braking force is insufficient

When brake pedal is stepped on slightly, ABS works

(automobile in idle state)

When brake pedal is stepped on slightly, ABS works

(automobile in running state)

When ABS works, brake pedal vibrates excessively

Travel of brake pedal is too long

A very large force is needed to step on brake pedal

No fault code output (cannot communicate with fault diagnosis instrument)Please Refer to "MK WIRING DIAGRAM"