warning GEELY MK 2008 Owner's Guide

[x] Cancel search | Manufacturer: GEELY, Model Year: 2008, Model line: MK, Model: GEELY MK 2008Pages: 416, PDF Size: 25.19 MB

Page 296 of 416

Check ABS warning lamp

safety wire in fuse boxCheck

ABS warning lamp safety wire

in fuse boxReplace AbnormalRemove ECU joint, when igni-

tion switch is in ON, does warn-

ing lamp illuminate ?NoNormalCheck whether ABS warn-

ing lamp is burnt outYes

ReplaceCheck whether warning

lamp power supply circuit

and ground loop in wiring

harness is disconnectedAbnormalRepair wiring

harnessCheck warning lamp power

supply circuit and ground

loop socket connector in

wiring harnessAbnormalRepair socket

connectorDoes fault reoccurNoRepair wiring harnessYe s NormalNormal NoRefer to key point

for repair of occa-

sional faultII. Check list of fault without malfunction codeMK-60 ABS system -ABS System Check5-109When ignition switch is in ON position (engine stall), ABS warning

lamp does not illuminate 1

[Description ] ABS warning lamp does not illuminate, warning lamp power

supply circuit might be disconnected, bulb is burnt out or

warning lamp driving module is damaged.Possible cause

Safety wire is burnt out

ABS warning lamp bulb

is burnt out

Power circuit is discon-

nected

ABS warning lamp driv-

ing module is damaged

YesCheck whether the wire in ABS

wiring harness connecting ABS

warning lamp driving module

and ECU is shorted to ground

Page 297 of 416

Note: this fault mode is only limited to the condition in which system may communicate with fault diagnosis

instrument (ABS ECU ABS ECU power supply is normal), and there is no fault code.MK-60 ABS system -ABS System Check5-110 After engine starts up, ABS warning lamp illuminates normally 2

[Description] Probably because ABS warning lamp driving module is

damaged or ABS warning lamp circuit is disconnected.Possible cause

ABS warning lamp driving

module is damaged

ABS warning lamp driving

module circuit is disconnected

ABS ECU is damagedCheck whether wire between

ECU and ABS warning lamp

driving module is disconnectedRepair wire harness Yes

NoCheck ABS warning lamp driv-

ing moduleReplace Abnormal

NormalReplace ABS ECU

Page 301 of 416

Inspection item

V

V

V

V

V

Visual inspection

Visual inspection

Visual inspection

Visual inspection

V

V

ohm

k ohm

MV/Hz

MV/Hz

MV/Hz

MV/Hz Storage battery voltage (motor)

Storage battery voltage

(Solenoid valve)

Power supply insulating property

Earth insulating property

Supply voltage

ABS warning lamp

Brake light switch function pedal

is not stepped down

Brake light switch function pedal

is stepped down

Diagnostic interface

Left front wheel speed sensor

resistance value

Right front wheel speed sensor

resistance value

Left rear wheel speed sensor

resistance value

Right rear wheel speed sensor

resistance value

Left front wheel sensor output

voltage value

Right front wheel sensor output

voltage value

Left rear wheel sensor output

voltage value

Right rear wheel sensor output

voltage value

Speed sensor output voltage ratio10.1 ~ 14.5

10.1 ~ 14.5

0.00 ~ 0.5

0.00 ~ 0.5

10.1 ~ 14.5

Warning lamp goes out

Warning lamp illuminates

Warning lamp goes out

Warning lamp illuminates

for about 1.7s,then goes out

0.0 ~ 0.5

10.0 ~ 14.5

0.0 ~ 0.5

1.2 ~ 1.3

1.2 ~ 1.3

1.0 ~ 1.3

1.0 ~ 1.3

3.4 ~ 14.8

3.4 ~ 14.8

>12.2

>12.2 1-47

32-16

4-16

16-47

4-16

ECU is not

connected

Connect ECU

16-41

16-41

Diagnosis joint

K and 7

45-46

33-34

37-36

42-43

45-46

33-34

37-36

42-43 OFF

OFF

OFF

OFF

ON

OFF

ON

OFF

ON

ON

ON

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

Maximum peak to peak value voltage

Minimum peak to peak value voltage2III. ABS system inspectionMK-60 ABS system -ABS System Check5-114Ignition switchpositionBinding post Standard value

Unitk ohmk ohmk ohm

Page 305 of 416

V. Reinstallation of ABS assemblyNote: plug of hydraulic opening on ABS assembly may be removed only when brake hard tube is to be installed,

so as to avoid foreign body entering brake system

1. Mount ABS assembly to bracket and tighten it, moment is 20~24 N.m.

2. Remove the plug on hydraulic opening, mount brake hard tube, confirm that hard tube connection is correct.

3. Mount brake hard tube to master cylinder.

4. Tightening moment for assembly of brake hard tube is 12~16N.m (M10 x 1) and 15~18 N.m (M12 x 1).

5. Fill new brake fluid into tank until liquid level reaches MAX place, use specified method to exhaust.

6. Turn ignition switch to ON, ABS warning lamp must illuminate for 1. 7s, then go out.

7. Eliminate fault code memory, reread to see whether there is any fault code.

8. Finally, run the vehicle in actual situation to confirm function of ABS (you should feel rebound of pedal).VI. ECU codeNote: when replacing HECU or ECU, encode new ECU, otherwise ABS warning lamp blinks, system can not work

normally.

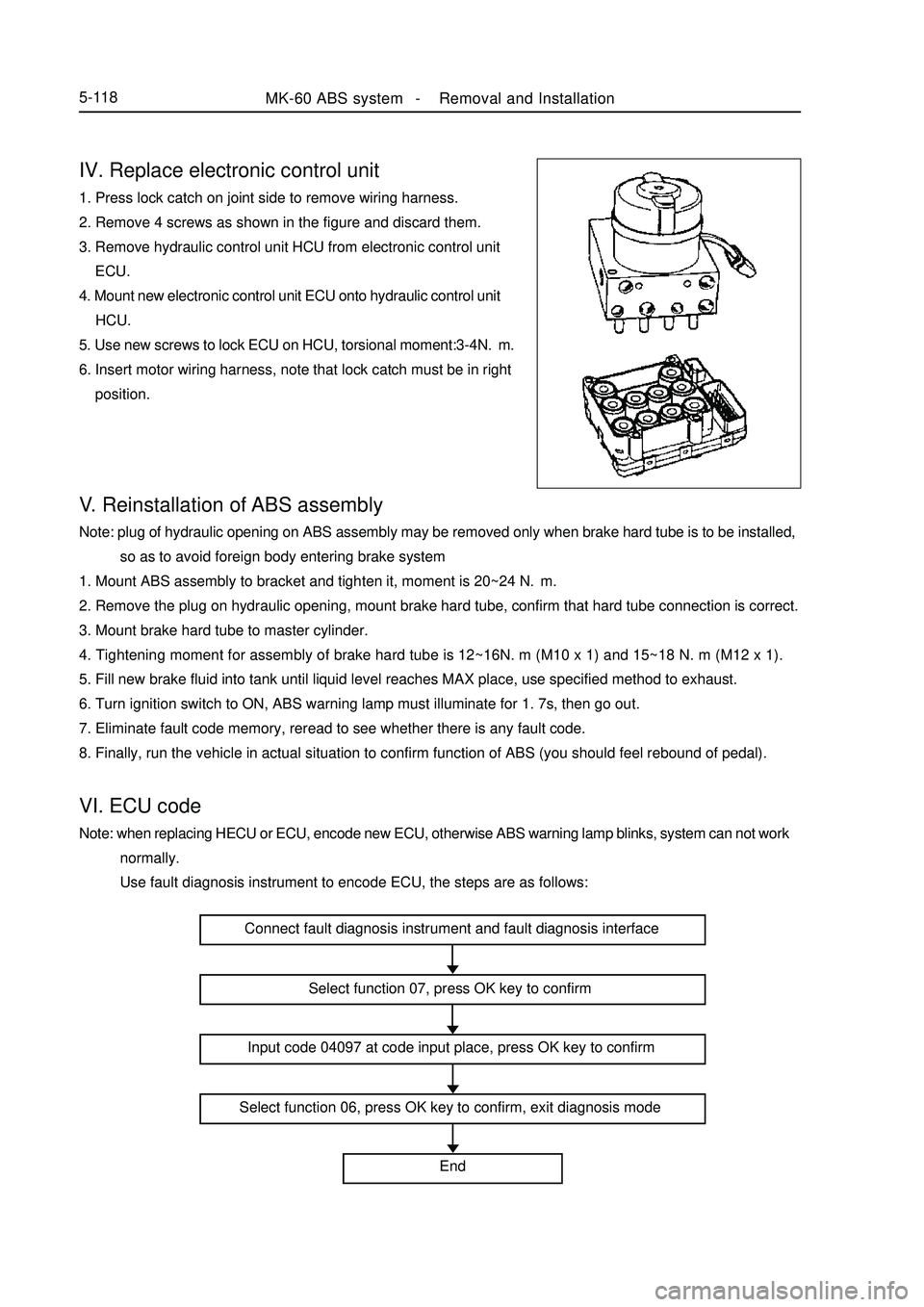

Use fault diagnosis instrument to encode ECU, the steps are as follows:IV. Replace electronic control unit1. Press lock catch on joint side to remove wiring harness.

2. Remove 4 screws as shown in the figure and discard them.

3. Remove hydraulic control unit HCU from electronic control unit

ECU.

4. Mount new electronic control unit ECU onto hydraulic control unit

HCU.

5. Use new screws to lock ECU on HCU, torsional moment:3-4N.m.

6. Insert motor wiring harness, note that lock catch must be in right

position.MK-60 ABS system -Removal and Installation5-118Connect fault diagnosis instrument and fault diagnosis interface

Select function 07, press OK key to confirm

Input code 04097 at code input place, press OK key to confirm

Select function 06, press OK key to confirm, exit diagnosis mode

End

Page 313 of 416

Engine ECU5-126as to avoid damaging electronic control unit.

(1) Simple measuring method:

(Remove joint) turn digital multimeter to ohm position, connect two meter pens with primary winding pinsrespectively, rated resistance at 2 0°C is 0. 4-0. 6 ohm for 2X2 type; on secondary winding, 11-15k ohm for 2x2 type.13. Electronic control unit ECU

Possible cause

Electric overload of externally connected

device leads to burnout of components inside

ECU and results in malfunction Symptom

Unsteady idle speed, poor speedup, failure to start, too high

idle, tail gas overproof, difficult to start, malfunction of air

conditioner, malfunction of fuel injector control, flameout

Repair precautions:

1. Don't remove ECU at discretion during repair;

2. ECU may be removed more than 1 minute after removing storage battery head;

3. Store removed ECU properly;

4. It is prohibited to attach any circuit onto connecting wire of ECU.

Simple measuring method:

1. (Connect joint) use engine data K-line to read engine trouble record;

2. (Remove joint) check whether ECU connecting wire is in good condition or not, mainly check whether ECU

power supply grounded circuit is normal or not;

3. Check whether external sensor works normally, whether output signal is credible, whether circuit is in good

condition;

4. Check whether actuator works normally, whether its circuit is in good condition;

5. Finally replace ECU to conduct test.

Judgment principle: "two interchange principle" ---interchange ECU, interchange fault symptom.III. Diagnostic system Description:

When engine ECU detects a trouble, engine trouble warning lamp on instrument will illuminate. In addition,

relevant diagnostic code will be recorded in ECU memory. Connect handheld tester with diagnostic interface on

automobile, read various data from automobile ECU. Connect handheld tester with diagnostic interface. Technical

personnel may also read fault code via blinking of instrument fault warning lamp.Engine EFI System-

Engine EFI System

Page 314 of 416

Flashing way of malfuntion code 17 for O2 sensor (3) Each fault code will blink for three times, interval time is 3s, after blinking for the third times, after an

interval of 3s, next fault code will blink. After blinking of all fault codes is finished, they will blink from begining

again. The following diagram shows engine fault warning lamp blinking mode for oxygen sensor fault code 17.5-127Terminal No. Terminal definition

4 Power supply (-)

7 Bus (signal)

16 Power supply (+)Diagnosis connector Notes: use tester cable to connect handheld tester with diagnostic interface, turn ignition switch to ON position,

operate tester, if tester displays that communication is not possible, the vehicle or tester fails.

Inspection diagnosis

1. Check engine fault warning lamp

(1) When ignition switch is turned to ON position and engine does not run, engine warning lamp on

instrument should illuminate.

(2) When engine runs, engine fault warning lamp should go out. If it still illuminates, diagnostic system

detects system fault or abnormity.

2. Use handheld tester to check diagnostic code

(1) Connect handheld tester according to corresponding pin.

(2) Turn ignition switch to ON position, turn on main switch of handheld tester.

(3) Use handheld tester to detect and check diagnostic code, refer to fault diagnostic code table. (For

operation of handheld tester, see instruction manual of handheld tester)

3. Engine fault warning lamp displays fault code through blinking code, so professional may make fault

judgment in case of emergency.

(1)Turn ignition switch to ON position.

(2) Short signal pin (9#) and negative pole (4#) for more than 2. 5s,then disconnect them,detection fault lamp

on dashboard will blink the faults in fault code according to their occurrence sequence.See from terminal outlet

endConnect in jump way over 2.5s and

disconnect

Diagnosis connectorDiagnosis connectorEngine EFI System-

Engine EFI System

Page 321 of 416

IV. Post-defrost: 1. When engine speed exceeds 700rpm (ignition switch is turned on), defrost work is permitted.

2. Turn on defrost switch, perform defrost work for 12 minutes, if defrost switch is pressed down again during

defrost work, defrost work will stop.

3. During defrost, turn off ignition switch, cancel this defrost.V. Light control: 1. Headlight:

(1) After press remote lock key to close four doors, if remote lock key is pressed down again twice in

succession within in 2s, dipped headlight will extend lighting for 1 minute; if remote unlock key is

pressed down within 60s, dipped headlight control output will be turned off.

(2) During output of 60s low level, if ignition switch is turned on, low level output will stop.

2. Ceiling lamp:

(1) When any of the doors is opened, ceiling lamp illuminates; if door is not closed, ceiling lamp will be

turned off after 10 minutes of delay.

(2) For closing of all doors, ceiling lamp will go out after time delay of 30s;

(3) In case all doors are closed,and ceiling lamp illuminates,ignition switch is turned on,ceiling lamp goes

out.

(4) For remote unlock, ceiling lamp illuminates; in case all doors are closed and ceiling lamp illuminates,

remote lock ceiling lamp goes out.VI. Remote anti-theft 1. Protected state: press lock key on remote controller, while closing four doors, anti-theft indicator lamp will

flashes slowly, indicating that the system enters protected state, when the system is triggered, turn light of the

vehicle will flash, warning horn gives out alarm.

2. Cancel protection: press unlock key on remote controller, while opening left front door, anti-theft indicator

lamp flashes rapidly, if at least one of ignition switch, door is opened within 30 s, anti-theft indicator lamp will

go out; otherwise it will enter secondary anti-theft state.

3. Two stage type protection cancellation: while the system is in triggered state, press any key on the remote

controller, alarm sound will stop, however, the system is still in protected state, and car door is still locked; if the

system continues to receive invasion signal, alarm will ring again after brief stop. To cancel protection completely,

cancel alarm for the first time, then press unlock key once immediately;

4. Secondary anti-theft: after protection is cancelled, if any of ignition switch, door is not opened within 30s,

the system will restore alert status automatically, and lock the car door.

Distribution of centralized controller connector terminals:

Connector on wiring harness, as shown in the figure below (view from outgoing terminal):Centralized Controller System-

Function Inspectior5-134Centralized

controller

Page 336 of 416

Interior & Exterior Trim and Accessory -Front Seat Belt6-7Pulley coverUnlock

Lock Notes:

Wrap the sharp end of screwdriver up with adhesive tape before

operation.

4. Use screwdriver to pry open the seat belt pulley cover;

5. Unscrew the bolt and detach the seat belt ring from the car;

6. Disconnect the pre-load insertion of seat belt on the bottom edge

of the middle pillar;

7. Detach the front seat belt from the car;

8. Unfix the clip using the screwdriver and detach the trim from the

right middle pillar;

9.Unscrew two bolts using the spanner and detach the remote adjuster

assembly.

Notice:Only the ignition switch turns to "OFF" position and the battery negative should be disconncted more than

90s, the seat belt with pretensioner can be removed.

III. Seat belt with ELR and pre-tensioner

Seat belt with ELR and pre-tensioner is provided with pre-tensioner which works together with the airbag.

The pre-tensioner is part of airbag assembly. The pre-tensioner is mounted in the retractor and controlled by SDM.

When the front bumping force of the car exceeds a specific value, the pre-tensioner and airbag can be triggered

at the same time. To maintain the pre-tension type of seat belt (retractor), observe all the "Alarm" and

"Operation Instruction".

Warning:

Do not try to remove or repair seat belt pre-tensioner. If any abnormal situations take place, replace the whole

assembly with a new one.

Before working, be sure to read through "Attention for Maintenance", and observe them during working. Any

ignorance can cause injury or the failure of seat belt pre-tensioner.

IV. Inspect Operations of Seat Belt Alarm Lamp (on Driver's side)

1. Turn on the ignition switch and check if the seat belt alarm lamp flashes;

2. Fasten the belt buckle and check if the belt alarm lamp goes out;

3. Turn off the ignition switch;

4. Disconnect the seat belt buckle;

5. Turn on the ignition switch;

6. Connect wiring terminal and make earth connection, and inspect the lamp status of the seat belt. Seat belt lamp:

flashing.

V. Inspect Seat Belt

1. Confirm whether the seat belt is properly mounted.

2. Inspect whether the metal part of seat belt is damaged.

3. If the car vibrates in accidents, pull out the seat belt from the retractor and determine whether the seat belt is

scratched (load limit retractor does not work) by visual inspection and touching.

4.Inspection contents before outer seat belt instalation:When ELR

lock,check the gradient of ELR. Check and make sure the seat belt

can not be locked from any aspect within 15°.When you move the

belt ring device beyond 45° slowly,the seat belt should be locked.

5.After installation check the seat belt lock in this way that draw the

seat belt from belt ring quiekly and the seat belf can be locked

normally.

Attention:

Should the seat belt not comply with the technical specification,

you should replace it.

Page 337 of 416

Interior & Exterior Trim and Accessory -Front Seat Belt6-8VI. Attentions:

1. Before mounting, you must check if the product is damaged, cracked or rusted.

2. Place the retractor on the vertical position before pulling out the strap. Check if the strap can be easily pulled

out and rotated and the retractor can be locked.

3. When installing a pretensioning seat belt, check if the emitter head pin deflects and is rusted, etc. The emitter

in the pre-tensioning seat belt can work for 15 years.

4. Check if the buckle lock and connection piece comply with the connection of the car. And check if the buckle

can be opened easily.

5. When fitting the bolts, check if the threads on the nut of coating are clear. Those with welding slag must be

cleaned before fitting the bolts.

6. After pulling out the strap of retractor, no barrier (such as wiring harness, etc.) around the strap is allowed. If

there is, it is necessary to get rid of the barrier to ensure the force of retractor and that the strap is not scratched.

VII. How to handle with scraped seat belt

Tips:

Scrap seat belt provided with pre-tensioner, you have to trigger the pre-tensioner taking the following steps.

1. Check if the storage battery is above 12 V on its positive and negative poles;

2. Check the energizing tool;

Warning:

When energizing the pre-tensioner of seat belt, be sure to use dedicated energizing tool for the pre-tensioner

of seat belt.

3. Connect the special tool with the storage battery and also connect

the red clip on the special tool with the positive terminal of the battery

and connect the black clip with the negative terminal of the battery;

4. If the front seat belt is on the car body and is not taken off,

disconnect the joint of the pre-tensioner of seat belt;

5. Connect the yellow joint of the special tool with the joint of the

pre-tensioner of seat belt;

6. At 10 meter away from seat belt, use a special tool to trigger theAbove 10 meterpre-tensioner of seat belt.

Warning:

a. Ensure that there be no people within 10 meters from the seat

belt;

b. If the seat belt has already been taken down from the car, it is

necessary to cover it using the car wheel with tire to avoid injury.

c. When triggering, explosion will emit loud sound. So it shall be

done outdoors without disturbing local community.

d. When you hold the triggered seat belt, be sure to wear gloves

and goggles.

e. After you have finished the operation, you must wash your hands.

f. Do not pour water, etc. to the energized seat belt pre-tensioner.

7. Place the already triggered seat belt into the ethylene bag and tighten it as you do with other articles.

Warning:

a. Do not dispose untriggered seat belt at will.

b. When the pre-tensioner of seat belt is triggered, the seat belt assembly would be very hot. Therefore, you

cannot touch it until at least 30 minutes after it is triggered.