air conditioning GEELY MK 2008 Workshop Manual

[x] Cancel search | Manufacturer: GEELY, Model Year: 2008, Model line: MK, Model: GEELY MK 2008Pages: 416, PDF Size: 25.19 MB

Page 3 of 416

Geely “MK” series sedans (JL7132U,JL7132HU,JL7152U,JL7152HU,JL7162U) are brand

new superior models developed by Geely Group who has fully proprietary intellectual property

rights. As a result of the three years of involvements and efforts of the experts from Geely Automo-

bile Research Institute, these sedans reach international leading level in model design, power,

sense of comfort, safety and manufacturing technology while featured in beautiful appearance,

economy, environment protection and safety. The meaning of MK implied that Geely Automobile

has a great development from caterpillar to butterfly. With respect to the power, Geely “MK” series

sedans are equipped with 1.3L, 1.5L, and 1.6L EFI engines developed and manufactured by Geely

itself, and has reached “Chinese III” (Euro III) emission standard.

This manual contains a detailed description of the structures and principles, servicing and adjustment,

removal, assembling technology and matching clearance of the parts of the Geely “MK” sedans

with torque information of the bolts and nuts as well as schematic diagram for special tool operation.

This manual also introduces the transmission control system of the automatic transmission models,

vehicle electric circuits and elaborates ABS system, SRS, BOSCH M7.9.7 electronic control fuel

injection and ignition system, rear parking radar, sound, air conditioning and onboard hands-free

phone system. You can refer to this manual for the information about the regular maintenance,

servicing, adjustment, troubleshooting, removal and installation procedure, specific operations of

the “MK” sedans.

This manual covers the matching relation among the engine assembly, transmission assembly and

the vehicle, but does not have the further description of the structures and principles of the engine

and transmission assemblies and their servicing process. You can refer to the service manuals

solely prepared for engine assembly and transmission assembly for these information.

All information in this manual is based on the latest products released at the time of publication of

this manual. However, the specifications and procedures may need to be modified, and the subse-

quent change will be revealed in later versions.

This manual is prepared by Geely Automobile Research Institute under the assistance of technical

staff from Zhejiang Geely Automobile Co., Ltd and Geely International Corporation. Readers

discovering during the use of this manual the errors and careless omissions due to limited skills of

the preparers and tight schedule are encouraged and pled to contact Geely International in time for

our timely correction of the mistakes.ForewordGeely International Corporation

Nov . 2007

Page 8 of 416

Table of ContentsV Section 1 SRS General Information ............................................................................... 5-54

Chapter 7 Air Conditioning System................................................................................... 5-72

Section 1 General Information ........................................................................................ 5-72

Section 2 Refrigerant ...................................................................................................... 5-77

Section 3 A/C Operating Mechanism ............................................................................. 5-83

Section 4 Heater, Ventilation and Air Conditioning ........................................................ 5-86

Section 5 Layont of Air Conditioning Hose ..................................................................... 5-92

Section 6 Multi-wedge belt (Connecting Compressor and Crankshaft Pulley) .............. 5-93

Section 7 Compressor Assembly .................................................................................... 5-94

Section 8 Condenser Fan and Condenser Assembly .................................................... 5-96

Chapter 8 MK-60 ABS System........................................................................................... 5-99

Section 1 ABS Diagnosis ................................................................................................ 5-99

Section 2 ABS System Check ...................................................................................... 5-103

Section 3 Removal and Installation .............................................................................. 5-138

Section 2 Power Door Lock Control System ................................................................5-142Part 6 Interior & Exterior Trim and AccessoryChapter 1 Front Seat Assembly......................................................................................... 6-1

Chapter 2 Rear Row Seat Assembly................................................................................. 6-3

Chapter 3 Front Seat Belt................................................................................................... 6-5

Chapter 4 Rear Seat Belt.................................................................................................... 6-9

Chapter 5 Dashboard, Middle Console and Instrument Panel....................................... 6-11

Chapter 6 Windshield......................................................................................................... 6-16

Chapter 7 Rear Window Glass (with Defrosting Heater Wire)........................................ 6-20

Chapter 8 Side Inner Panel Trim........................................................................................ 6-22

Chapter 9 Roof Trim............................................................................................................ 6-25

Chapter 10 Front Door Interior Trim.................................................................................. 6-27

Chapter 11 Rear Door Interior Trim................................................................................... 6-30

Chapter 12 Front Bumper................................................................................................... 6-33

Chapter 13 Rear Bumper.................................................................................................... 6-35

Page 30 of 416

2-9 c. Check levels of braking fluid, engine coolant, engine oil, transmission oil, power steering fluid, and

washing fluid to see if there is any leaking.

d. Inspect if brake pedal, clutch pedal, accelerator pedal, transmission shifter, steering wheel, choke are

loose or stuck. The free travel of clutch pedal is 5~15mm, the free travel of brake pedal is 1~6mm and

the free play of steering wheel is less than 30mm(measurement point at margin of steering wheel). if it

is out of this normal range, the clutch needs to be tuned.

e. Inspect if the connection of battery, lamps and signal lights are normal, and if the wire routing and

position are correct and not loose.

f. Inspect if the tire pressure is correct.

(2) On-road inspection If the inspection result of the above items is good, start the engine and test the car on

road, and perform the following inspections.

a. Acceleration pedal, see if the operation is smooth and if it is loose.

b. Clutch, see if there is any stuck or abnormal noise, and slip when driving.

c. Transmission,check if shifting is smooth,or rough and wrong shifting.Inspect if the display of A/T

shift lever is normal.

d. Steering, check if steering is light and smooth, and if the steering wheel turns back after steering.

e. Brake pedal, apply brake pedal to check if the braking functions well when vehicle speed is at

40km/h and if the vehicle runs off track.

f. Park brake, when parking brake handler is pulled, there should be 6~9 clicking sounds. Pull park brake

when vehicle is running at the speed of 20km/h and transmission is at neutral gear to see if it brakes.

g. Vehicle speed meter, observe the vehicle speed meter while driving. When speed changes, check if the

indicator is moving steadily or shakes.

h. Heating and air-conditioning.Try every control button to see if both heating and cooling system work

well.

i. Abnormal noise, listen carefully to see if there is any abnormal noise from engine, drive line system or

any other parts of the vehicle at a steady speed and during accelerating, and decelerating.

(3) Inspection after test ride check if there is anything abnormal in the vehicle while driving and conduct the

following inspections after the vehicle is parked.

a. Check electrical fan When engine coolant temperature is beyond 92.5°C, the radiator fan should be

running; When A/C is on and the pressure of refrigerant is more than 1.5 cooling ton, air conditioning

cooling fan should be running.

b. Check headlamp, method: park the car 5m away from the inspection surface (inspection board, curtain,

or wall) to the front bumper, and check if the beam from headlamp is good. The upper level if headlamp

should be 540mm above the ground, and the distance between headlamps on the two sides is 900mm.

c. Inspect engine idle speed,idle speed of hot engine is 800r/min±50r/min,when A/C compressor works,

the idle speed should be 900r/min±50r/min. If idle speed is abnormal, adjust the idle speed adjust

ment screw to adjust it.

(4) Usage of new cars in breaking-in period Follow the instructions below in the first 1500~2500km breaking

mileage to avoid wear and abnormal damage in breaking-in period, and to improve vehicle performance, fuel

economy and to extend vehicle useful life.

a. Drive steadily during breaking-in; do not accelerate harshly to avoid running engine at high speed.

Engine should not exceed 4500r/min in any gears. Especially at the early stage of breaking-in, vehicleUsage and Maintenance of MK Series - Usage of MK Series

Page 259 of 416

Item

Temperature regulation method

CompressorNominal refrigerating capacity / w

Displacement / (ml /r)

Model

Power consumed by magnetic clutch /W

Lubricating oil / ml

BlowerMaximum air quantity / (m3/h)

Air regulation

Motor power / W

Dimension /mm

Heat exchange quantity / W

Fan motor current / A

Fan motor revolution / (r/min)

Dimension /mm

Refrigerating capacity /W

Thermostatic expansion valve Condenser

Evaporator

Driving belt

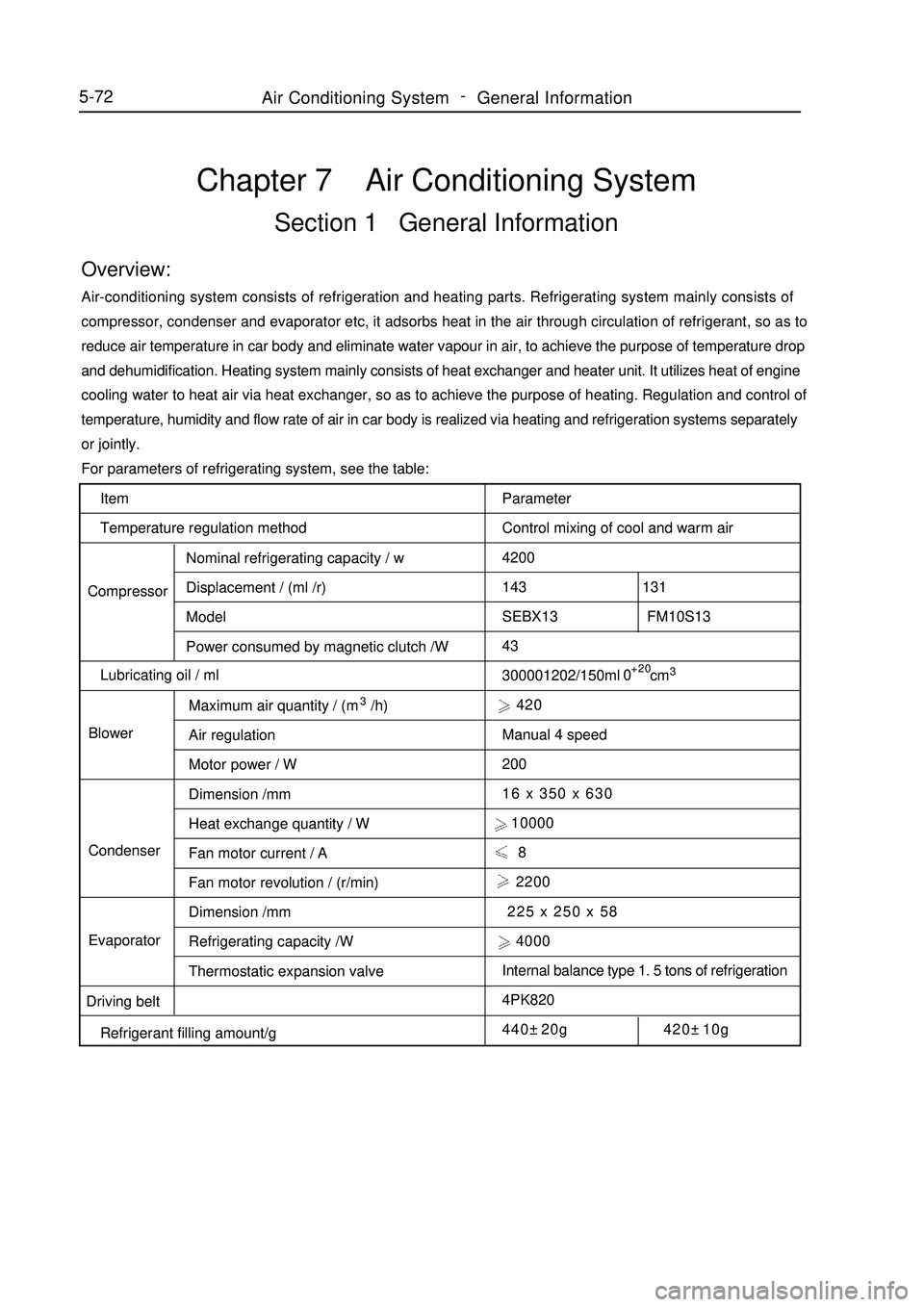

Refrigerant filling amount/gChapter 7 Air Conditioning SystemSection 1 General InformationOverview:Air-conditioning system consists of refrigeration and heating parts. Refrigerating system mainly consists of

compressor, condenser and evaporator etc, it adsorbs heat in the air through circulation of refrigerant, so as to

reduce air temperature in car body and eliminate water vapour in air, to achieve the purpose of temperature drop

and dehumidification. Heating system mainly consists of heat exchanger and heater unit. It utilizes heat of engine

cooling water to heat air via heat exchanger, so as to achieve the purpose of heating. Regulation and control of

temperature, humidity and flow rate of air in car body is realized via heating and refrigeration systems separately

or jointly.

For parameters of refrigerating system, see the table:

Parameter

Control mixing of cool and warm air

4200

143 131

SEBX13 FM10S13

43

300001202/150ml cm3 420

Manual 4 speed

200

16 x 350 x 630

10000

8

2200

225 x 250 x 58

4000

Internal balance type 1. 5 tons of refrigeration

4PK820

440±20g 420±10g+20

05-72Air Conditioning System -

General Information

Page 260 of 416

5-73Precautions:1. Don't operate refrigerant in confined space or near open fire.

2. Always wear eyeglass.

3. Be careful don't let liquid refrigerant contact your eyes and skin,

if liquid refrigerant contacts your eye or skin.

(a) Please wash with fresh water.

Warning:

Don't knead your eyes or scrub your skin

(b) Apply soft petroleum ointment on your skin.

(c) See doctor or go to hospital immediately for specialized

treatment.

4. Don't heat container or put it near open fire.

5. Be careful not to fall off, object should not touch container.

6. If there is no sufficient refrigerant in refrigerating system, don't

operate the compressor.

If there is no sufficient refrigerant in the system, insufficient oil

lubrication might cause burning out of compressor. Be careful to

avoid occurrence of such things.

7. When compressor runs, don't turn on pressure gauge high-pressure

valve.

If high-pressure valve is turned on, refrigerant will flow in reverse

direction, and cause bursting of refrigerant tank, so only low

pressure valve may be turned on or off.

8. Be careful to avoid excess refrigerant

Excess refrigerant will result in poor refrigerating capacity, worse

fuel economical efficiency, engine overheat etc problems.Symptom

Blower does not workSymptom table Use the following table to find out the cause of fault, number indicates probable priority of problem, check each

part according to priority, replace components if required.

Suspected Area

1.Blower fuse

2.Centralized controller fuse

3. Blower relay

4. Integrated control panel assembly (blower switch)

5. Blower adjustment resistor

6. Blower

7. Wiring harness.Air Conditioning System -General Information

Page 261 of 416

Air Conditioning System -General Information5-74Symptom

No air temperature control

Compressor does not work

Insufficient refrigeration

No engine idle speed when air conditioning

switch is ON (switch on)

No air input control

No mode control

Condenser fan does not workSuspected Area

1. Engine coolant quantity

2. Air conditioning control mechanism assembly.

1. Refrigerant quantity

2. Compressor fuse

3. Centralized controller fuse

4. Magnetic clutch relay

5. Pressure switch

6. Magnetic clutch assembly

7. Air conditioning compressor assembly

8. Integrated control panel assembly (air conditioner switch)

9. Air conditioner thermistor

10. Engine ECU

11. Wiring harness

1. Refrigerant quantity

2. Refrigerant pressure

3. Driving belt

4. Air conditioner thermistor

5. Integrated control panel assembly (air conditioner switch)

6. Magnetic clutch assembly

7. Air conditioning compressor assembly

8. Condenser

9. Accumulator-drier

10. Expansion valve

11. Evaporator

12. Refrigerant line

13. Pressure switch

14. Air conditioner control mechanism assembly

15. Wiring harness

1. Idle speed control system

2. Wiring harness

3. ECM

1.Air conditioner control mechanism assembly

1.Air conditioner control mechanism assembly

1. MAIN fuse

2. Condenser fan fuse

3. Condenser fan relay

4. Condenser fan motor

5. Wiring harness

Page 262 of 416

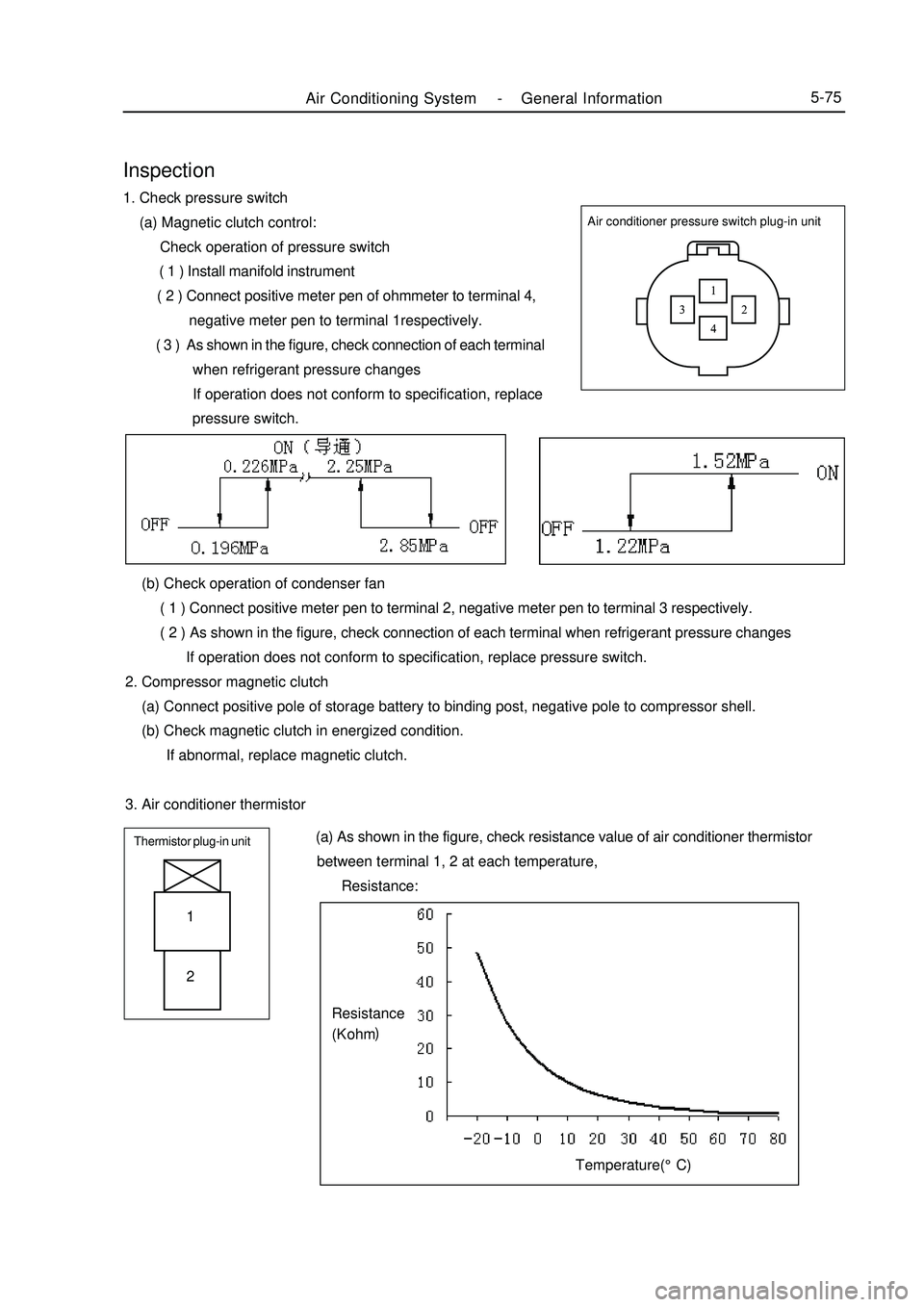

Air Conditioning System -General Information5-75Air conditioner pressure switch plug-in unitInspection1. Check pressure switch

(a) Magnetic clutch control:

Check operation of pressure switch

( 1 ) Install manifold instrument

( 2 ) Connect positive meter pen of ohmmeter to terminal 4,

negative meter pen to terminal 1respectively.

( 3 ) As shown in the figure, check connection of each terminal

when refrigerant pressure changes

If operation does not conform to specification, replace

pressure switch.

(b) Check operation of condenser fan

( 1 ) Connect positive meter pen to terminal 2, negative meter pen to terminal 3 respectively.

( 2 ) As shown in the figure, check connection of each terminal when refrigerant pressure changes

If operation does not conform to specification, replace pressure switch.

2. Compressor magnetic clutch

(a) Connect positive pole of storage battery to binding post, negative pole to compressor shell.

(b) Check magnetic clutch in energized condition.

If abnormal, replace magnetic clutch.

3. Air conditioner thermistorThermistor plug-in unit (a) As shown in the figure, check resistance value of air conditioner thermistor

between terminal 1, 2 at each temperature,

Resistance:1

2Temperature(°C)Resistance

(K ohm)

Page 263 of 416

Condition/ circuit Tester connection Specification

OFF OFF

LO E D1 ON

ML E D1 D2 ON

MH E D1 D4 ON

HI E D1 D5 ONBlower switch connector unitD2 D4 D5

D1 D6 E4. Integrated control panel assembly

(a) Check connection of blower switch. If connection does not conform to specification, replace integrated control panel assembly.

(b) Check lighting operation

Connect positive wire of storage battery to terminal D6, negative wire to terminal E, then check whether

illuminating lamp illuminates. If bulb does not illuminate, replace the bulb.

(c) Check connection of air conditioning switch

As shown in the table, check connection of terminal when switch is pressedA/C switch connectorTester connection Specification

2 5 ON If connection does not conform to specification, replace air

conditioning switch.

(d) Check indicator work

Connect positive wire of storage battery to terminal 1, negative

wire to terminal 3, then check whether illuminating lamp

illuminates.

If connection does not conform to specification, replace

integrated control panel assembly.

4. Blower adjustment resistor

(a) Measure resistance between terminals, as shown in the table

Tester connection Specification

1-2 About 0. 38 Ohm

2-3 About 1. 47 Ohm

1-4 About 2. 71 OhmSpeed regulating resistance connector unit If resistance does not conform to specification, replace blower

resistance.

5. Blower assembly

(a) Connect positive wire of storage battery to terminal 2, negative

wire to terminal 1, check work smoothness of motor.

If work does not conform to specification, replace blower

assembly5-76Air Conditioning System -General Information

Page 264 of 416

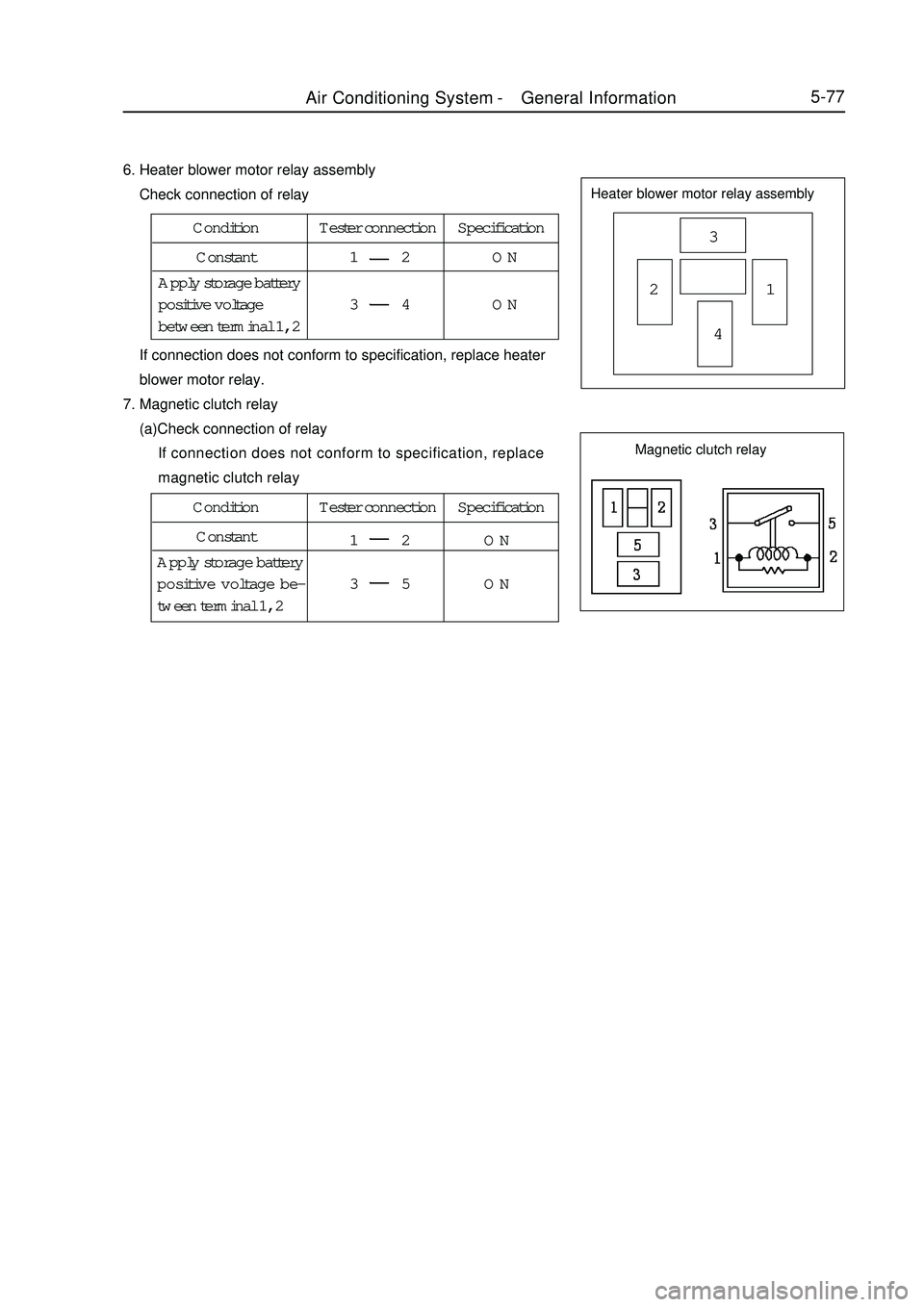

5-776. Heater blower motor relay assembly

Check connection of relayHeater blower motor relay assembly3

21

4 If connection does not conform to specification, replace heater

blower motor relay.

7. Magnetic clutch relay

(a)Check connection of relay

If connection does not conform to specification, replace

magnetic clutch relayCondition Tester connection Specification

Constant1 2 ON

3 4 ON Apply storage battery

positive voltage

between terminal 1, 2Condition Tester connection Specification

Constant

1 2 ON

3 5 ON Apply storage battery

positive voltage be-

tween terminal 1, 2Magnetic clutch relayAir Conditioning System -General Information

Page 265 of 416

Section 2 RefrigerantRefrigerant inspection1. Check refrigerant quantity

(a) Observe sight glass on refrigerating liquid pipe.

Test condition:

Engine speed: 1500 rpm

Blower speed control switch: HI "high "

Air conditioning switch: switch on

Temperature setting: maximum refrigeration

Refrigeration runs for 5 minutes

Open door

*: If refrigerating capacity is sufficient, environmental temperature is higher than normal condition, bubble

in sight glass may be deemed as normal.Symptom Refrigerant quantity Correct treatment2. Use manifold meter to check refrigerant pressure

( a ) This method is to utilize installed instrument to determine

where the fault is. Use manifold pressure meter reading to evaluate

fault condition.

Test condition:

Switch sets temperature of cyclical air inlet: 30-35°C

Engine speed: 1500 rpm

Blower speed control switch: high

Temperature control panel: refrigeration5-78With foam

Without foam

No temperature difference be-

tween input and output of

compressor

There is considerable tem-

perature difference between

compressor input and output

After air conditioner is turned

off, refrigerant should be

cleared immediately

After air conditioner is turned

off, refrigerant foams

immediately, then clears 1

2

3

4

5

6Insufficient *

Empty, insufficient or beyond

Empty or nearly full

Proper or beyond

Excess

Appropriate quantity1. Check gas leakage, repair if necessary

2. Add refrigerant until foam disappears

Refer to 3 and 4

1. Use detector to check gas leakage,

repair if necessary

2. Add refrigerant until foam disappears.

Refer to 5 and 6

1. Discharge refrigerant

2. Eliminate air, add appropriate quantity

of pure refrigerantSight glassAir Conditioning System -

Refrigerant