lock GMC ENVOY XL 2004 Owners Manual

[x] Cancel search | Manufacturer: GMC, Model Year: 2004, Model line: ENVOY XL, Model: GMC ENVOY XL 2004Pages: 466, PDF Size: 3 MB

Page 408 of 466

Fuses Usage

29 Oxygen Sensor

30 Air Conditioning

31 Truck Body Controller

32 Trailer

33 Anti-Lock Brakes (ABS)

34 Ignition A

35 Blower Motor

36 Ignition B

50 Passenger’s Side Trailer Turn

51 Driver’s Side Trailer Turn

52 Hazard Flashers

53 Electric Adjustable Pedal

54 A.I.R. Solenoid

56 A.I.R. PumpRelays Usage

37 Headlamp Washer

38 Rear Window Washer

39 Fog Lamps

40 Horn

41 Fuel Pump

42 Windshield Washer

43 High-Beam Headlamp

44 Air Conditioning

45 Cooling Fan

46 Headlamp Driver Module

47 Starter

49 Electric Adjustable Pedal

55 A.I.R. Solenoid

Miscellaneous Usage

48 Instrument Panel Battery

49 Blank

5-100

Page 410 of 466

Fuses Usage

1Electrically-Controlled Air

Suspension

2Passenger’s Side High-Beam

Headlamp

3Passenger’s Side Low-Beam

Headlamp

4 Back-Up-Trailer Lamps

5Driver’s Side High-Beam

Headlamp

6Driver’s Side Low-Beam

Headlamp

7Rear Window Washer,

Headlamp Washer

8 Active Transfer Case

9 Windshield Washer

10 Powertrain Control Module B

11 Fog Lamps

12 Stop Lamp

13 Cigarette LighterFuses Usage

14 Ignition Coils

15 Canister Vent

16 TBC-Ignition 1

17 Crank

18 Air Bag

19 Trailer Electric Brake

20 Cooling Fan

21 Horn

22 Ignition E

23 Electronic Throttle Control

24Instrument Panel Cluster,

Driver Information Center

25Automatic Shift Lock Control

System

26 Backup

27 Engine 1

28 Powertrain Control Module 1

5-102

Page 411 of 466

Fuses Usage

30 Air Conditioning

31 Truck Body Controller 1

32 Trailer

33 Anti-Lock Brakes (ABS)

34 Ignition A

35 Blower Motor

36 Ignition B

50 Passenger’s Side Trailer Turn

51 Driver’s Side Trailer Turn

52 Hazard Flashers

53 Oxygen Sensor Bank B

54 Oxygen Sensor Bank A

55 Injector Bank A

56 Injector Bank B

57 Electric Adjustable PedalRelays Usage

37 Headlamp Washer

38 Rear Window Washer

39 Fog Lamps

40 Horn

41 Fuel Pump

42 Windshield Washer

43 High-Beam Headlamp

44 Air Conditioning

45 Cooling Fan

46 Headlamp Driver Module

47 Starter

49 Electric Adjustable Pedal

58 Ignition 1

Miscellaneous Usage

48 Instrument Panel Battery

5-103

Page 412 of 466

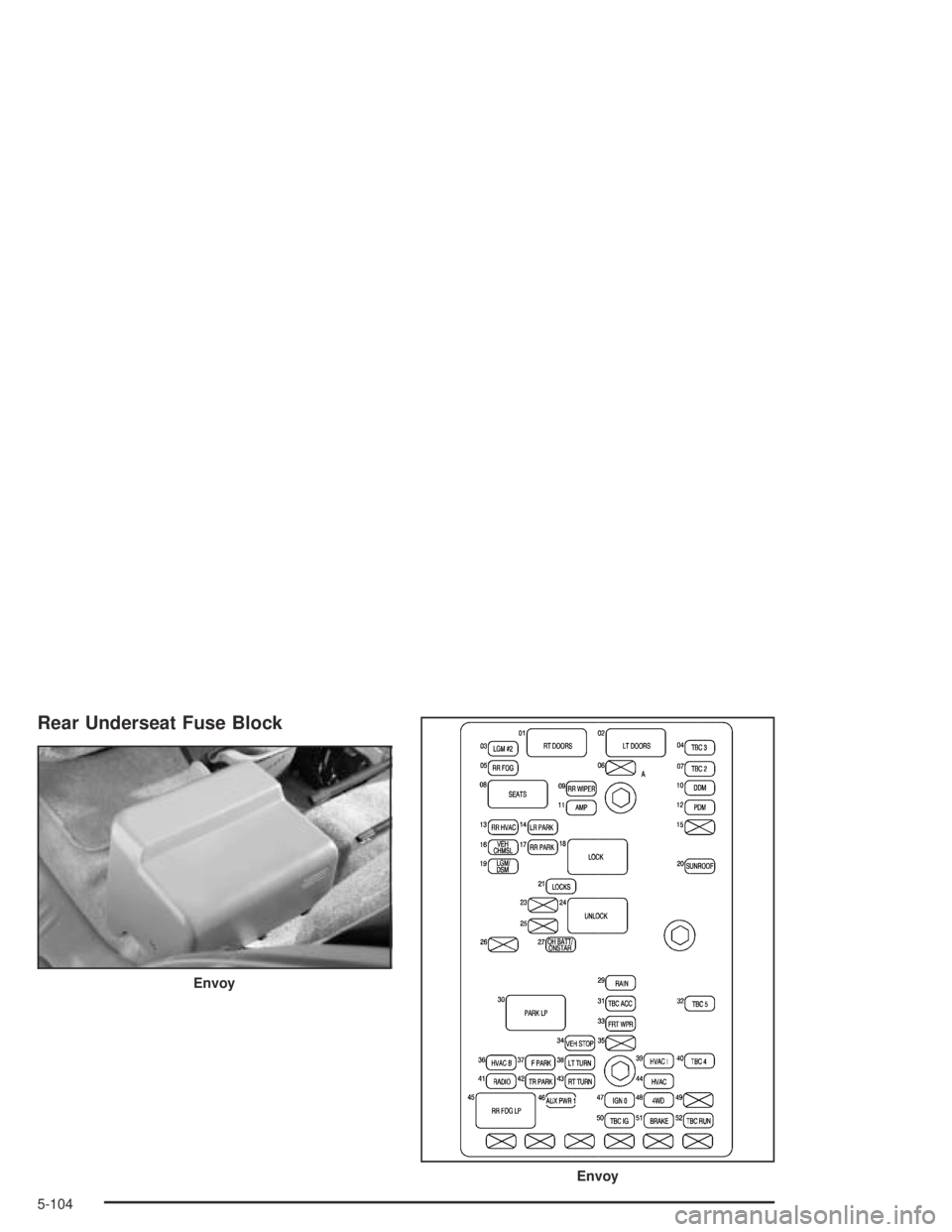

Rear Underseat Fuse Block

Envoy

Envoy

5-104

Page 413 of 466

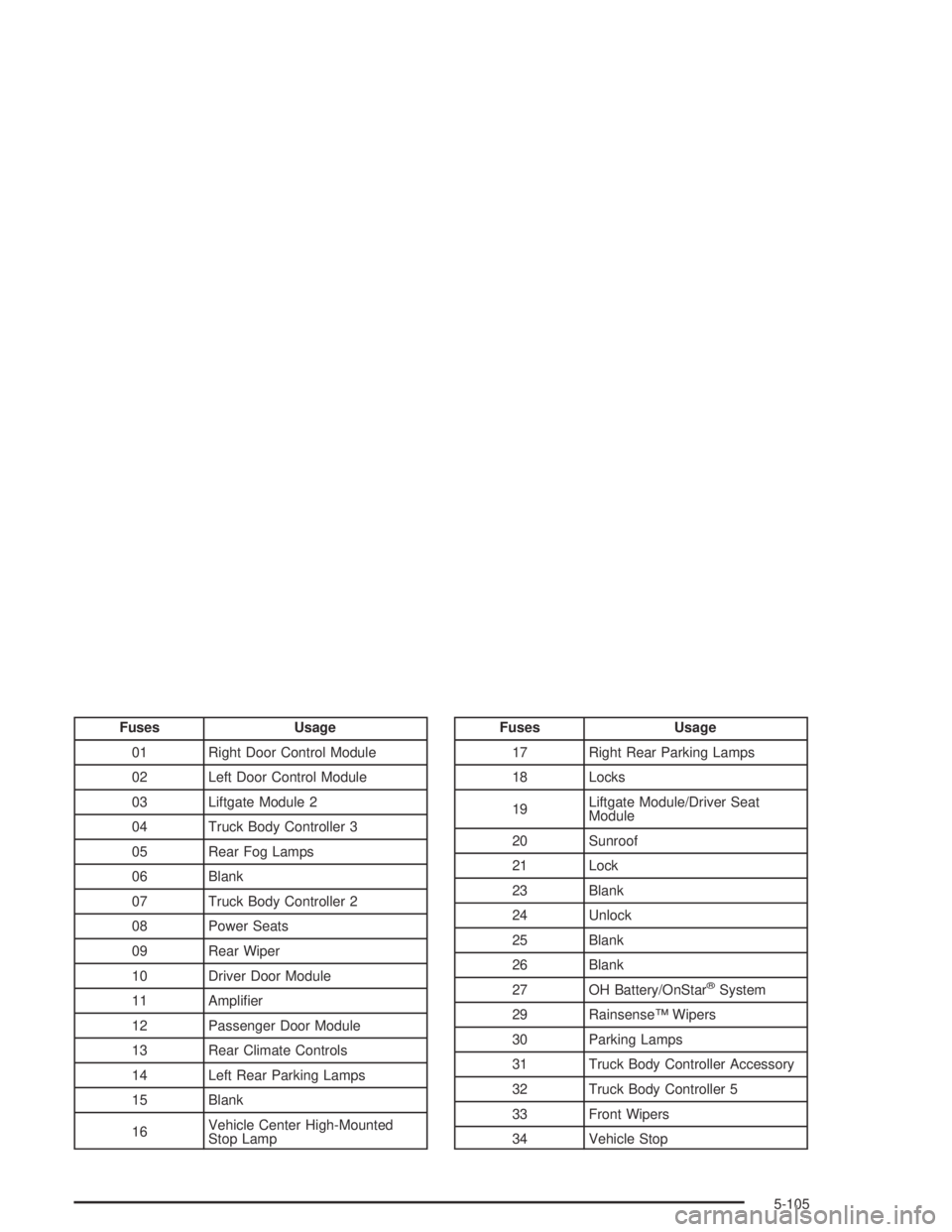

Fuses Usage

01 Right Door Control Module

02 Left Door Control Module

03 Liftgate Module 2

04 Truck Body Controller 3

05 Rear Fog Lamps

06 Blank

07 Truck Body Controller 2

08 Power Seats

09 Rear Wiper

10 Driver Door Module

11 Ampli�er

12 Passenger Door Module

13 Rear Climate Controls

14 Left Rear Parking Lamps

15 Blank

16Vehicle Center High-Mounted

Stop LampFuses Usage

17 Right Rear Parking Lamps

18 Locks

19Liftgate Module/Driver Seat

Module

20 Sunroof

21 Lock

23 Blank

24 Unlock

25 Blank

26 Blank

27 OH Battery/OnStar

®System

29 Rainsenseâ„¢ Wipers

30 Parking Lamps

31 Truck Body Controller Accessory

32 Truck Body Controller 5

33 Front Wipers

34 Vehicle Stop

5-105

Page 416 of 466

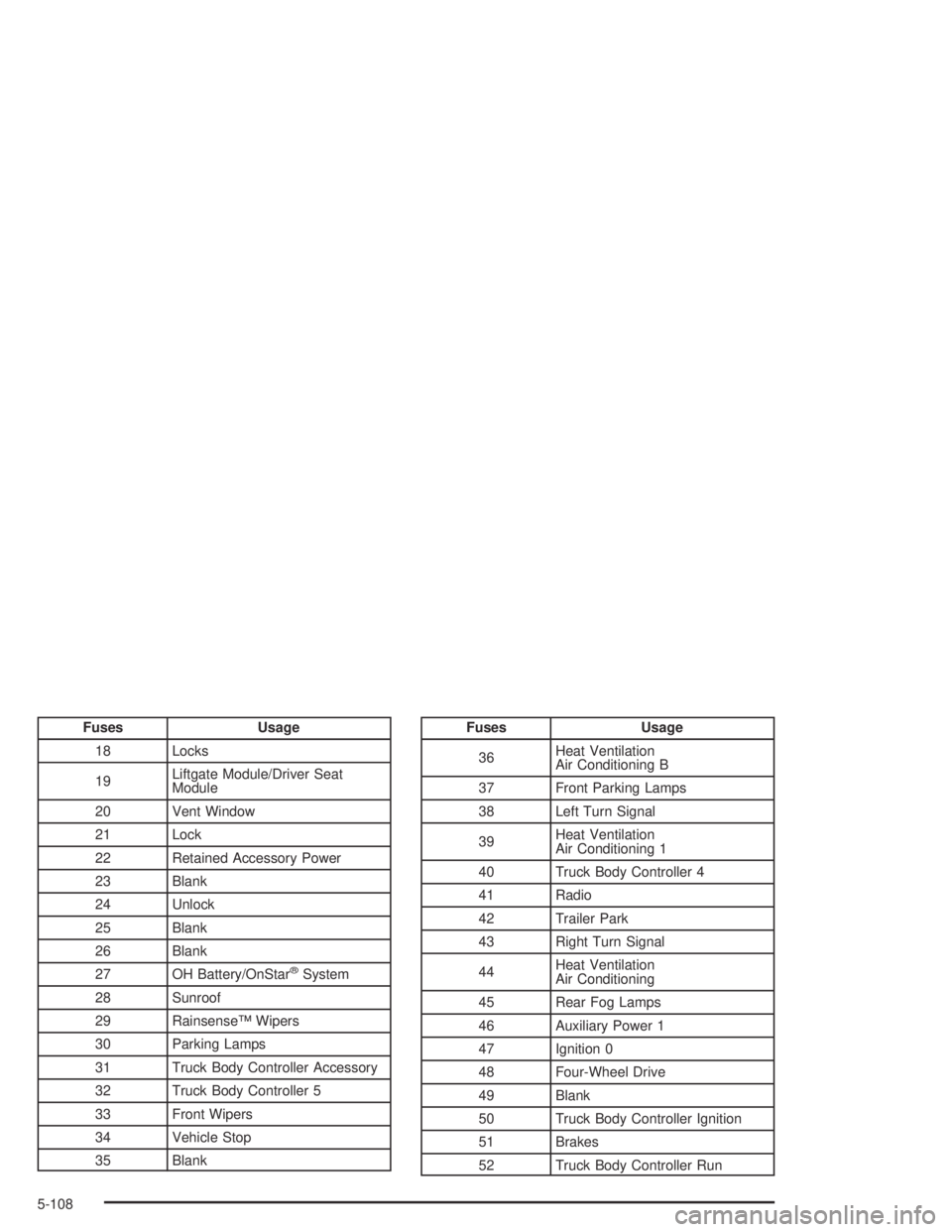

Fuses Usage

18 Locks

19Liftgate Module/Driver Seat

Module

20 Vent Window

21 Lock

22 Retained Accessory Power

23 Blank

24 Unlock

25 Blank

26 Blank

27 OH Battery/OnStar

®System

28 Sunroof

29 Rainsenseâ„¢ Wipers

30 Parking Lamps

31 Truck Body Controller Accessory

32 Truck Body Controller 5

33 Front Wipers

34 Vehicle Stop

35 Blank

Fuses Usage

36Heat Ventilation

Air Conditioning B

37 Front Parking Lamps

38 Left Turn Signal

39Heat Ventilation

Air Conditioning 1

40 Truck Body Controller 4

41 Radio

42 Trailer Park

43 Right Turn Signal

44Heat Ventilation

Air Conditioning

45 Rear Fog Lamps

46 Auxiliary Power 1

47 Ignition 0

48 Four-Wheel Drive

49 Blank

50 Truck Body Controller Ignition

51 Brakes

52 Truck Body Controller Run

5-108

Page 426 of 466

Maintenance Footnotes

†The U.S. Environmental Protection Agency or the

California Air Resources Board has determined that the

failure to perform this maintenance item will not nullify

the emission warranty or limit recall liability prior to

the completion of the vehicle’s useful life. We, however,

urge that all recommended maintenance services be

performed at the indicated intervals and the

maintenance be recorded.

(a)Visually inspect brake lines and hoses for proper

hook-up, binding, leaks, cracks, cha�ng, etc. Inspect

disc brake pads for wear and rotors for surface

condition. Inspect other brake parts, including calipers,

parking brake, etc.

(b)Visually inspect front and rear suspension and

steering system for damaged, loose or missing parts

or signs of wear. Inspect power steering lines and hoses

for proper hook-up, binding, leaks, cracks, cha�ng,

etc.

(c)Visually inspect hoses and have them replaced if they

are cracked, swollen or deteriorated. Inspect all pipes,

�ttings and clamps; replace with genuine GM parts as

needed. To help ensure proper operation, a pressure test

of the cooling system and pressure cap and cleaning the

outside of the radiator and air conditioning condenser is

recommended at least once a year.(d)Visually inspect wiper blades for wear or cracking.

Replace blade inserts that appear worn or damaged

or that streak or miss areas of the windshield.

(e)Make sure the safety belt reminder light and all your

belts, buckles, latch plates, retractors and anchorages

are working properly. Look for any other loose or

damaged safety belt system parts. If you see anything

that might keep a safety belt system from doing its

job, have it repaired. Have any torn or frayed safety belts

replaced. Also look for any opened or broken air bag

coverings, and have them repaired or replaced. (The air

bag system does not need regular maintenance.)

(f)Lubricate all key lock cylinders, hood latch assembly,

secondary latch, pivots, spring anchor, release pawl,

rear compartment hinges, outer liftgate handle pivot

points, rear door detent link, roller mechanism, liftgate

handle pivot points, latch bolt, fuel door hinge, cargo

door hinge, locks and folding seat hardware. More

frequent lubrication may be required when exposed to

a corrosive environment. Applying silicone grease

on weatherstrips with a clean cloth will make them last

longer, seal better and not stick or squeak.

(g)Add �uid as needed. A �uid loss could indicate a

problem; repair as needed. Check vent hose at transfer

case for kinks and proper installation.

6-8

Page 429 of 466

At Least Once a Year

Starter Switch Check

{CAUTION:

When you are doing this inspection, the

vehicle could move suddenly. If the vehicle

moves, you or others could be injured.

1. Before you start, be sure you have enough room

around the vehicle.

2. Firmly apply both the parking brake and the regular

brake. SeeParking Brake on page 2-29if necessary.

Do not use the accelerator pedal, and be ready to

turn off the engine immediately if it starts.

3. Try to start the engine in each gear. The starter

should work only in PARK (P) or NEUTRAL (N).

If the starter works in any other position, contact

your GM Goodwrench dealer for service.

Automatic Transmission Shift Lock

Control System Check

{CAUTION:

When you are doing this inspection, the

vehicle could move suddenly. If the vehicle

moves, you or others could be injured.

1. Before you start, be sure you have enough room

around the vehicle. It should be parked on a level

surface.

2. Firmly apply the parking brake. SeeParking Brake

on page 2-29if necessary.

Be ready to apply the regular brake immediately if

the vehicle begins to move.

3. With the engine off, turn the key to the RUN

position, but do not start the engine. Without

applying the regular brake, try to move the shift

lever out of PARK (P) with normal effort. If the shift

lever moves out of PARK (P), contact your GM

Goodwrench dealer for service.

6-11

Page 430 of 466

Ignition Transmission Lock Check

While parked, and with the parking brake set, try to turn

the ignition key to LOCK in each shift lever position.

The key should turn to LOCK only when the

shift lever is in PARK (P).

The key should come out only in LOCK.

Contact your GM Goodwrench dealer if service is

required.

Parking Brake and Automatic

Transmission Park (P) Mechanism Check

{CAUTION:

When you are doing this check, your vehicle

could begin to move. You or others could

be injured and property could be damaged.

Make sure there is room in front of your

vehicle in case it begins to roll. Be ready to

apply the regular brake at once should the

vehicle begin to move.Park on a fairly steep hill, with the vehicle facing downhill.

Keeping your foot on the regular brake, set the parking

brake.

To check the parking brake’s holding ability: With the

engine running and transmission in NEUTRAL (N),

slowly remove foot pressure from the regular brake

pedal. Do this until the vehicle is held by the parking

brake only.

To check the PARK (P) mechanism’s holding ability:

With the engine running, shift to PARK (P). Then

release the parking brake followed by the regular

brake.

Contact your GM Goodwrench dealer if service is

required.

Underbody Flushing Service

At least every spring, use plain water to �ush any

corrosive materials from the underbody. Take care to

clean thoroughly any areas where mud and other

debris can collect.

6-12

Page 431 of 466

Recommended Fluids and

Lubricants

Fluids and lubricants identi�ed below by name, part

number or speci�cation may be obtained from your

dealer.

Usage Fluid/Lubricant

Engine OilEngine oil which meets GM Standard

GM6094M and displays the

American Petroleum Institute

Certi�ed for Gasoline Engines

starburst symbol. GM Goodwrench

oil meets all the requirements for your

vehicle. To determine the proper

viscosity for your vehicle’s engine,

seeEngine Oil on page 5-16.

Engine Coolant50/50 mixture of clean, drinkable

water and use only DEX-COOL

®

Coolant. SeeEngine Coolant on

page 5-24.

Hydraulic Brake

SystemDelco Supreme 11 Brake Fluid or

equivalent DOT-3 brake �uid.

Windshield

Washer SolventGM Optikleen

®Washer Solvent.

Usage Fluid/Lubricant

Parking Brake

Cable GuidesChassis Lubricant (GM Part No.

U.S. 12377985, in Canada

88901242) or lubricant meeting

requirements of NLGI #2,

Category LB or GC-LB.

Power Steering

SystemGM Power Steering Fluid

(GM Part No. U.S. 89021184,

in Canada 89021186).

Automatic

TransmissionDEXRON

®-III Automatic

Transmission Fluid.

Key Lock

CylindersMulti-Purpose Lubricant, Superlube

(GM Part No. U.S. 12346241,

in Canada 10953474).

Chassis

LubricationChassis Lubricant (GM Part No.

U.S. 12377985, in Canada

88901242) or lubricant meeting

requirements of NLGI #2, Category

LB or GC-LB.

Front and

Rear AxleSAE 75W-90 Synthetic Axle

Lubricant (GM Part No. U.S.

12378261, in Canada 10953455)

meeting GM Speci�cation 9986115.

6-13