clock GMC ENVOY XUV 2004 User Guide

[x] Cancel search | Manufacturer: GMC, Model Year: 2004, Model line: ENVOY XUV, Model: GMC ENVOY XUV 2004Pages: 460, PDF Size: 2.99 MB

Page 301 of 460

Electronically Controlled Air

Suspension System

Your vehicle may be equipped with an electronically

controlled air suspension system that automatically

keeps your vehicle level as you load and unload. The

system includes a compressor, two height sensors

and two air springs supporting the rear axle.

The system also has an internal clock to prevent

overheating. If the system overheats, all leveling function

stops until the system cools down. During this time,

the indicator light on the air in¯ator system will be

¯ashing.

The ignition has to be on for the system to in¯ate, in

order to raise the vehicle to the standard ride height after

loading. The system can lower the vehicle to the

standard ride height after unloading with the ignition on

and also for up to 30 minutes after the ignition has

been turned off.

You may hear the compressor operating when you load

your vehicle, and periodically as the system adjusts

the vehicle to the standard ride height.Load leveling will not function normally with the in¯ator

hose attached to the in¯ator outlet. Remove the

in¯ator hose from the outlet during loading and

unloading.

If the vehicle is parked for an extended period of time,

some bleed down of the suspension is normal. Upon

starting the vehicle, proper height will be achieved.

Overload Protection

The air suspension system is equipped with overload

protection. Overload protection is designed to protect the

air suspension system, and it is an indicator to the

driver that the vehicle is overloaded. When the overload

protection mode is on, it will not allow damage to the

air compressor. However, do not overload the vehicle.

See

Loading Your Vehicle on page 4-49.

If the suspension remains at a low height, the rear axle

load has exceeded GAWR (Gross Axle Weight

Rating). When the overload protection mode is activated,

the compressor operates for about 30 seconds to one

minute without raising the vehicle depending on the

amount of overload. This will continue each time

the ignition is turned on until the rear axle load is

reduced below GAWR.

4-55

Page 320 of 460

While refueling, hang the fuel cap by the tether using

the hook located on the inside of the ®ller door.

To remove the fuel cap, turn it slowly to the left

(counterclockwise).

5-8

Page 321 of 460

{CAUTION:

If you spill fuel and then something ignites it,

you could be badly burned. Fuel can spray out

on you if you open the fuel cap too quickly.

This spray can happen if your tank is nearly

full, and is more likely in hot weather. Open

the fuel cap slowly and wait for any ªhissº

noise to stop. Then unscrew the cap all

the way.

Be careful not to spill fuel. Don't top off or over®ll your

tank, and wait a few seconds after you've ®nished

pumping before you remove the nozzle. Clean fuel from

painted surfaces as soon as possible. See

Cleaning

the Outside of Your Vehicle on page 5-87.

When you put the fuel cap back on, turn it to the right

(clockwise) until you hear a clicking sound. Make

sure you fully install the cap. The diagnostic system can

determine if the fuel cap has been left off or improperly

installed. This would allow fuel to evaporate into the

atmosphere. See

Malfunction Indicator Lamp on

page 3-38.

{CAUTION:

If a ®re starts while you are refueling, do not

remove the nozzle. Shut off the ¯ow of fuel by

shutting off the pump or by notifying the

station attendant. Leave the area immediately.

Notice:If you need a new fuel cap, be sure to get

the right type. Your dealer can get one for you.

If you get the wrong type, it may not ®t properly.

This may cause your malfunction indicator lamp to

light and may damage your fuel tank and emissions

system. See

Malfunction Indicator Lamp on

page 3-38.

5-9

Page 344 of 460

How to Add Coolant to the Radiator

1. You can remove the radiator pressure cap when

the cooling system, including the radiator pressure

cap and upper radiator hose, is no longer hot.

Turn the pressure cap slowly counterclockwise

about one full turn.

If you hear a hiss, wait for that to stop. A hiss

means there is still some pressure left.2. Then keep turning the pressure cap. Remove the

pressure cap.

5-32

Page 360 of 460

When the differential is cold, add enough lubricant to

raise the level to 1/2 inch (12 mm) below the ®ller

plug hole.

When the differential is at operating temperature

(warm), add enough lubricant to raise the level to the

bottom of the ®ller plug hole.

What to Use

To determine what kind of lubricant to use, seeRecommended Fluids and Lubricants on page 6-13.

Bulb Replacement

For the type of bulbs, seeReplacement Bulbs on

page 5-50.

For any bulb changing procedure not listed in this

section, contact your dealer.

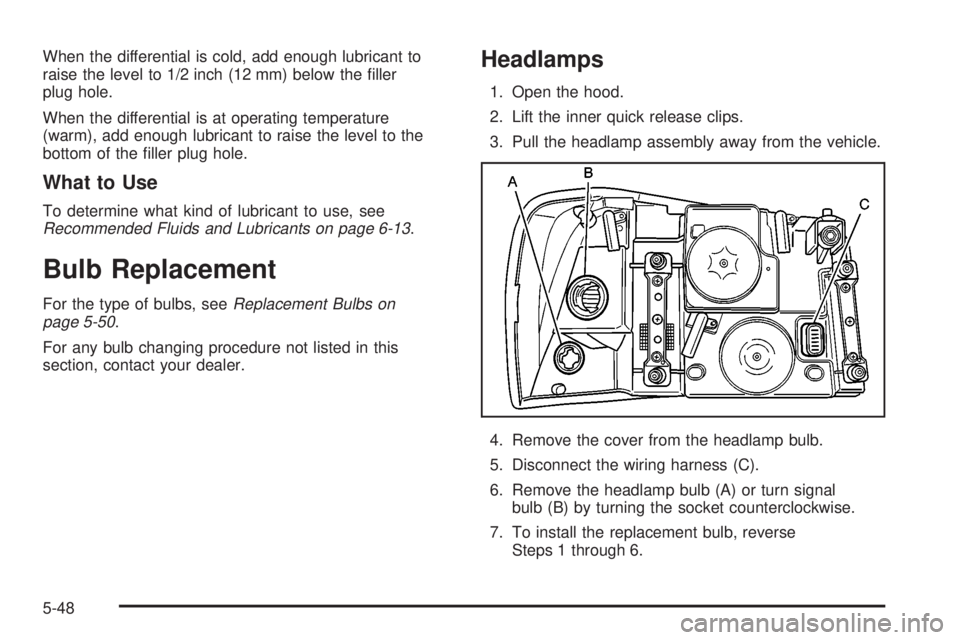

Headlamps

1. Open the hood.

2. Lift the inner quick release clips.

3. Pull the headlamp assembly away from the vehicle.

4. Remove the cover from the headlamp bulb.

5. Disconnect the wiring harness (C).

6. Remove the headlamp bulb (A) or turn signal

bulb (B) by turning the socket counterclockwise.

7. To install the replacement bulb, reverse

Steps 1 through 6.

5-48

Page 361 of 460

Taillamps and Turn Signal Lamps

1. Drop the tailgate.

2. Remove the two

screws from the lamp

assembly.

3. Pull the assembly away from the vehicle.4. Unclip the wiring

harness (B).

5. Remove the socket (Turn Signal Lamp (A) or Brake

Lamp (C)) by rotating it counterclockwise.

6. Holding the socket, pull the bulb to release it from

the socket.

7. Push the new bulb into the socket until it clicks.

8. Reverse steps 1 through 5 to reinstall the lamp

assembly.

5-49

Page 381 of 460

To use the air in¯ator, attach the appropriate nozzle

adapter to the end of the hose if required. Then attach

that end of the hose to the object you wish to in¯ate.

Attach the other end of the hose to the outlet.

Press and release the switch to turn the air in¯ator on.

The indicator light will remain on when the in¯ator is

running.

The system has an internal clock to prevent overheating.

The system will allow about ®ve minutes of running

time, then the compressor will stop. The indicator light

will then begin to ¯ash. When the indicator is off,

the in¯ator can be started again by pressing the switch.

If the compressor is still hot, it may only run for a

short time before shutting off again.

Press and release the switch to turn the in¯ator off.

Place the in¯ator kit tools in the pouch and store

it properly. Remove the in¯ator hose from the outlet

during loading and unloading. Load leveling will

not function with the in¯ator hose attached to the

in¯ator outlet.To reinstall the cover, line up the tabs at the back of the

cover, put it in place and latch the tabs.

A continuous ¯ashing indicator light may also indicate a

malfunction in the air suspension system.

{CAUTION:

In¯ating something too much can make it

explode, and you or others could be injured.

Be sure to read the in¯ator instructions, and

in¯ate any object only to its recommended

pressure.

5-69

Page 384 of 460

Removing the Spare Tire and Tools

A. Wing Nut

B. Jack Bracket

C. Jack and Wheel

BlocksD. Retainer

E. Thumbwheel

F. Tool Kit Wing Nut

G. Tool Kit

The jacking equipment you will need is stored under the

rear seat on the passenger's side of the vehicle. See

Rear Seat Operation on page 1-7for more information

on accessing the jacking equipment. To remove the

tool kit, turn the tool kit wing nut (F) counterclockwise

and remove the jack bracket. To release the jackfrom the bracket, remove wing nut (A). Turn the

thumbwheel counterclockwise to lower the jack head.

Remove the retainer and wheel blocks.

The tools you'll be using include the wheel wrench (A),

wheel blocks (B), extensions (socket end) (C), handle

(jack end) (D), and jack (E).

The following instructions explain how to remove the

spare tire mounted underneath your vehicle.

Notice:If you remove or restow a tire from/to the

storage position under the vehicle when it is

supported by a jack, you could damage the tire

and/or your vehicle. Always remove or restow a tire

when the vehicle is on the ground.

5-72

Page 385 of 460

1. To remove the underbody-mounted spare, insert

the socket end of the extension on a 45 degree

angle downward into the hoist drive shaft hole. It is

exposed when the rear gate is open and is just

above the rear bumper. Be sure the socket end of

the extension connects to the hoist shaft.

2. Turn the wheel wrench counterclockwise to lower

the spare tire. Keep turning the wheel wrench until

the spare tire can be pulled out from under the

vehicle.

If the spare tire does not lower to the ground, the

secondary latch is engaged causing the tire

not to lower. See ªSecondary Latch Systemº later in

this section.When the tire has been completely lowered, tilt the

retainer at the end of the cable and pull it through

the wheel opening. Pull the tire out from under

the vehicle.

Notice:If you drive away before the spare tire or

secondary latch system cable has been reinstalled,

you could damage your vehicle. Always reinstall

this cable before driving your vehicle.

3. Put the spare tire near the ¯at tire.

4. Position the chisel end of the wheel wrench in the

notch of the center cap and pry off the center cap.

See ªRemoving the Flat Tire and Installing the

Spare Tireº later in this section to continue changing

the ¯at tire.

5-73

Page 387 of 460

2. If it is not visible, proceed to Step 6.

If visible, ®rst try to tighten the cable by turning the

wheel wrench clockwise until you hear two clicks

or feel it skip twice. You cannot overtighten

the cable.

3. Loosen the cable by turning the wheel wrench

counterclockwise three or four turns.

4. Repeat this procedure at least two times.

If the spare tire lowers to the ground, continue with

Step 2 of ªRemoving the Spare Tire and Toolsº

earlier in this section.

5. Turn the wrench counterclockwise until about

6 inches (15 cm) of cable is exposed.

6. Attach the jack handle, extensions and the wheel

wrench to the jack and place it under the vehicle

towards the front of the rear bumper. Position

the center lift point of the jack under the center of

the spare tire.

7. Turn the wrench clockwise to raise the jack until it

lifts the end ®tting.

8. Continue raising the jack until the spare tire stops

moving upward and is held ®rmly in place. The

secondary latch has released and the spare tire is

balancing on the jack.

5-75