air condition GMC SIERRA 1993 Owner's Manual

[x] Cancel search | Manufacturer: GMC, Model Year: 1993, Model line: SIERRA, Model: GMC SIERRA 1993Pages: 436, PDF Size: 23.88 MB

Page 394 of 436

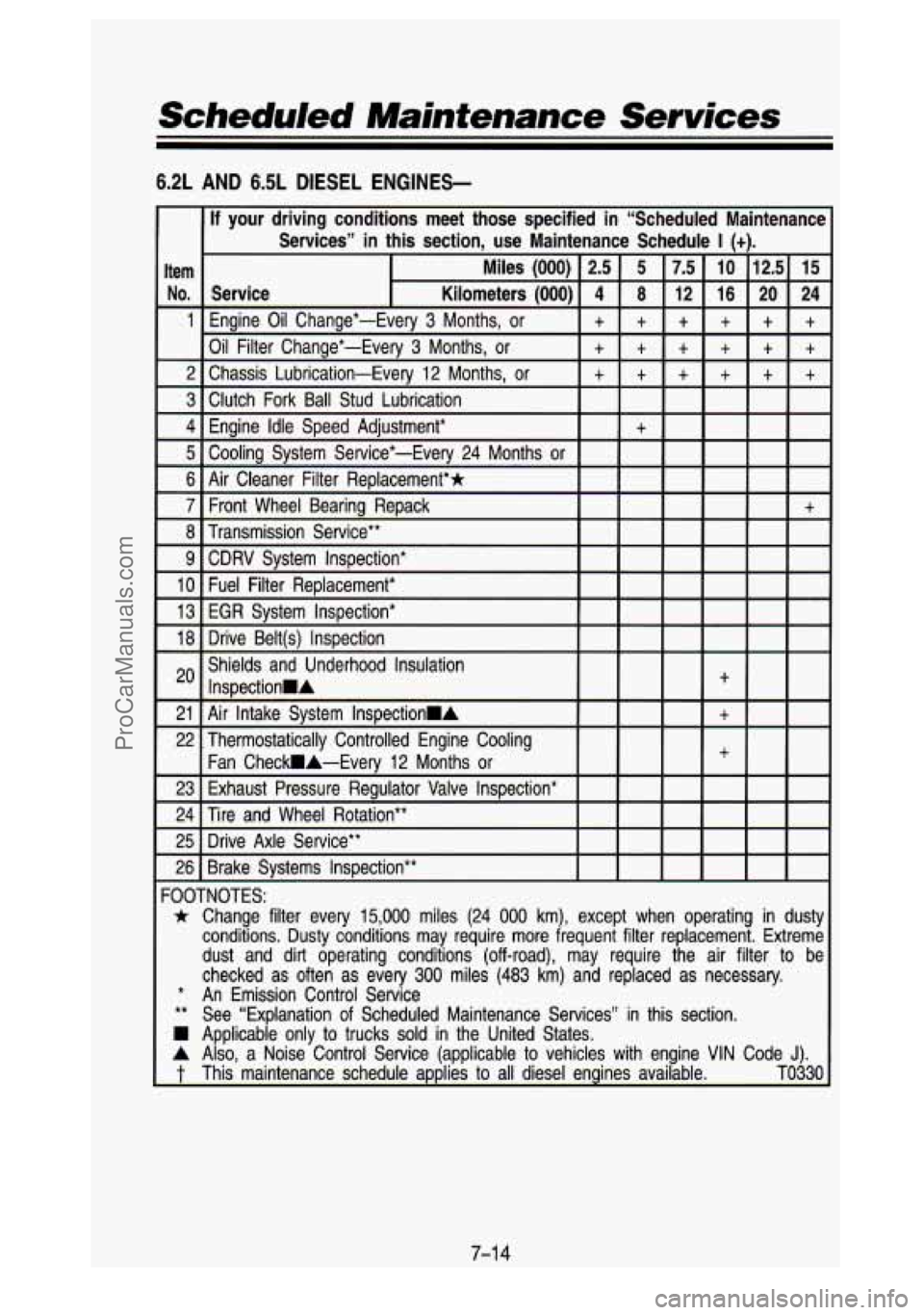

6.2L AND 6.5L DIESEL ENGINES-

-0OTNOTES:

rt Change filter every 15,000 miles (24 000 km), except when operating in dusty

conditions. Dusty conditions may require more frequent filter re\

placement. Extreme

dust and dirt operating conditions (off-road), may require the air filter

to be

checked as often as every 300 miles (483 km) and replaced as necessary.

* An Emission Control Service

** See “Explanation of Scheduled Maintenance Services” in this section.

1 Applicable only to trucks sold in the United States.

A Also, a Noise Control Service (applicable to vehicles with engine VIN Code J).

t This maintenance schedule applies to all diesel engines available. TO330

7-1 4

ProCarManuals.com

Page 398 of 436

Scheduled Maintenance Services

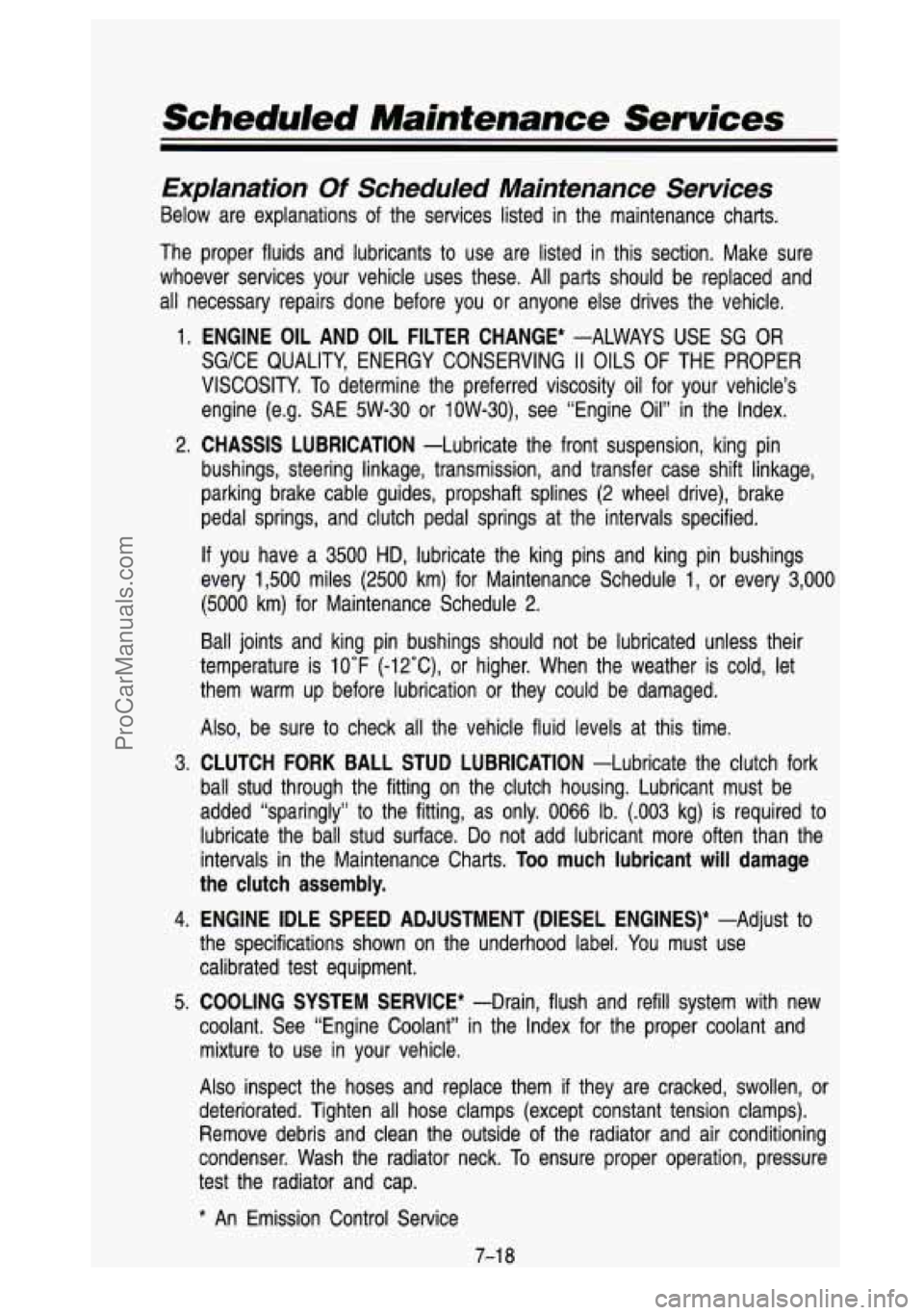

Explanation Of Scheduled Maintenance Services

Below are explanations of the services listed in the maintenance charts.

The proper fluids and lubricants to use are listed in this section. Make sure

whoever services your vehicle uses these. All parts should be \

replaced and

all necessary repairs done before you or anyone else drives the ve\

hicle.

1.

ENGINE OIL AND OIL FILTER CHANGE* -ALWAYS USE SG OR

SGKE QUALITY, ENERGY CONSERVING II OILS OF THE PROPER

VISCOSITY. To determine the preferred viscosity oil for your vehicle’s

engine (e.g. SAE 5W-30 or 10W-30), see “Engine Oil” in the Index.

2. CHASSIS LUBRICATION -Lubricate the front suspension, king pin

bushings, steering linkage, transmission, and transfer case shift\

linkage,

parking brake cable guides, propshaft splines (2 wheel drive), brake

pedal springs, and clutch pedal springs at the intervals specified.

If you have a 3500 HD, lubricate the king pins and king pin bushings

every 1,500 miles

(2500 km) for Maintenance Schedule 1, or every 3,000

(5000 km) for Maintenance Schedule 2.

Ball joints and king pin bushings should not be lubricated unless their

temperature is

10°F (-12”C), or higher. When the weather is cold, let

them warm up before lubrication or they could be damaged.

Also, be sure to check

all the vehicle fluid levels at this time.

3.

CLUTCH FORK BALL STUD LUBRICATION -Lubricate the clutch fork

ball stud through the fitting on the clutch housing. Lubricant must be

added “sparingly” to the fitting, as only.

0066 Ib. (.003 kg) is required to

lubricate the ball stud surface.

Do not add lubricant more often than the

intervals in the Maintenance Charts.

Too much lubricant will damage

the clutch assembly.

4. ENGINE IDLE SPEED ADJUSTMENT (DIESEL ENGINES)* -Adjust to

the specifications shown on the underhood label. You must use

calibrated test equipment.

5. COOLING SYSTEM SERVICE* -Drain, flush and refill system with new

coolant. See “Engine Coolant’’ in the Index for the proper coolant and

mixture to use in your vehicle.

Also inspect the hoses and replace them

if they are cracked, swollen, or

deteriorated. Tighten all hose clamps (except constant tension \

clamps).

Remove debris and clean the outside

of the radiator and air conditioning

condenser. Wash the radiator neck.

To ensure proper operation, pressure

test the radiator and cap.

* An Emission Control Service

7-1

8

ProCarManuals.com

Page 399 of 436

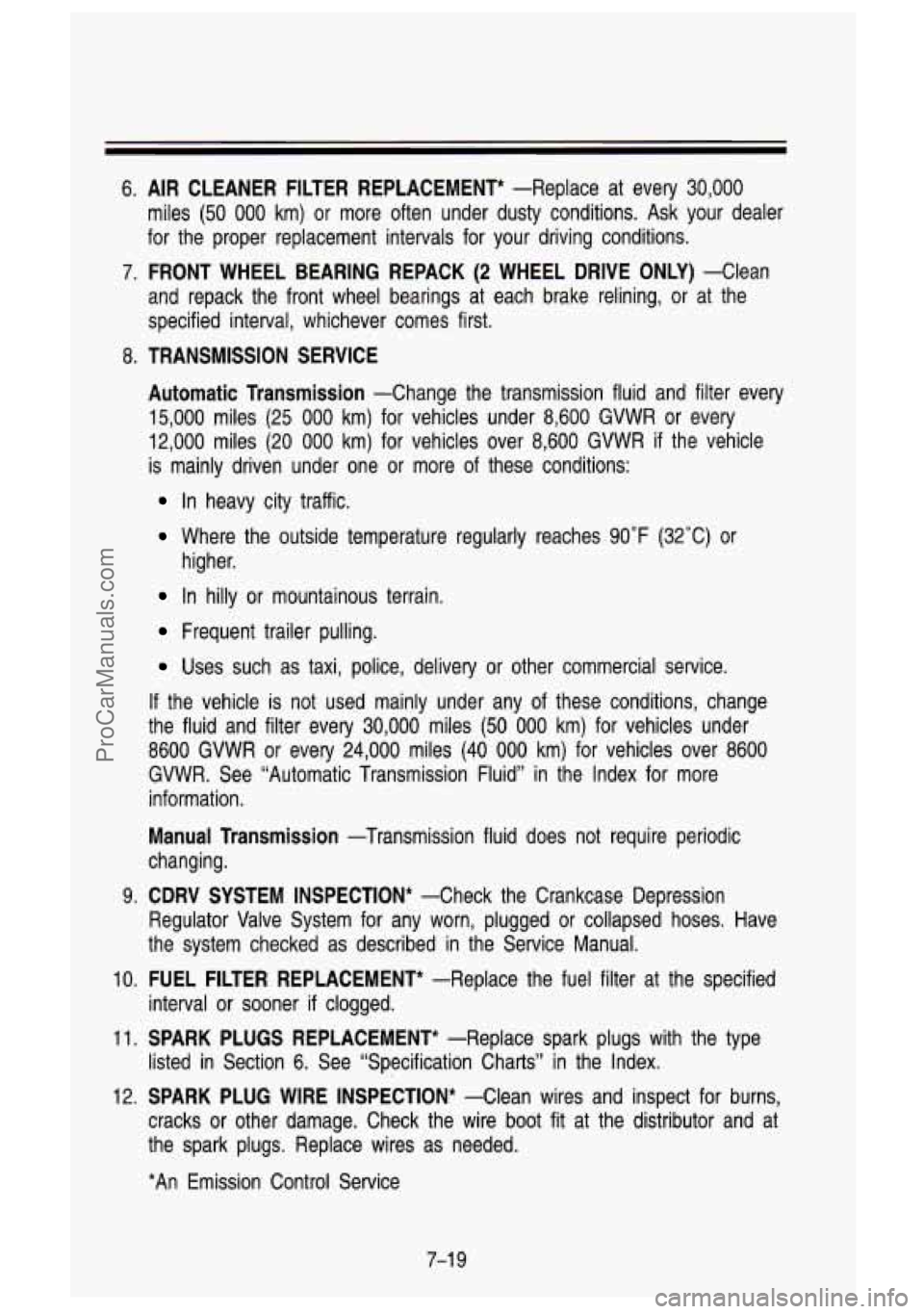

6. AIR CLEANER FILTER REPLACEMENT* -Replace at every 30,000

miles (50 000 km) or more often under dusty conditions. Ask your dealer

for the proper replacement intervals for your driving conditions\

.

7. FRONT WHEEL BEARING REPACK (2 WHEEL DRIVE ONLY) -Clean

and repack the front wheel bearings at each brake relining, or\

at the specified interval, whichever comes first.

8.

TRANSMISSION SERVICE

Automatic Transmission

-Change the transmission fluid and filter every

15,000 miles (25 000 km) for vehicles under 8,600 GVWR or every

12,000 miles (20 000 km) for vehicles over 8,600 GVWR if the vehicle

is mainly driven under one or more of these conditions:

In heavy city traffic.

Where the outside temperature regularly reaches 90°F (32°C\

) or

higher.

In hilly or mountainous terrain.

Frequent trailer pulling.

Uses such as taxi, police, delivery or other commercial service\

.

If the vehicle is not used mainly under any of these conditions, change

the fluid and filter every 30,000 miles

(50 000 km) for vehicles under

8600 GVWR or every

24,000 miles (40 000 km) for vehicles over 8600

GVWR. See “Automatic Transmission Fluid” in the Index for more

information.

Manual Transmission -Transmission fluid does not require periodic

changing.

Regulator Valve System for any worn, plugged or collapsed hoses. Have

the system checked as described in the Service Manual.

9.

CDRV SYSTEM INSPECTION* -Check

the Crankcase Depression

10. FUEL FILTER REPLACEMENT* -Replace the fuel filter at the specified

interval

or sooner if clogged.

11. SPARK PLUGS REPLACEMENT* -Replace spark plugs with the type

listed in Section

6. See “Specification Charts” in the Index.

12.

SPARK PLUG WIRE INSPECTION* -Clean wires and inspect for burns,

cracks or other damage. Check the wire boot fit at the distributor and at

the spark plugs. Replace wires as needed.

*An Emission Control Service

7-1 9

ProCarManuals.com

Page 400 of 436

Scheduled Maintenance Services

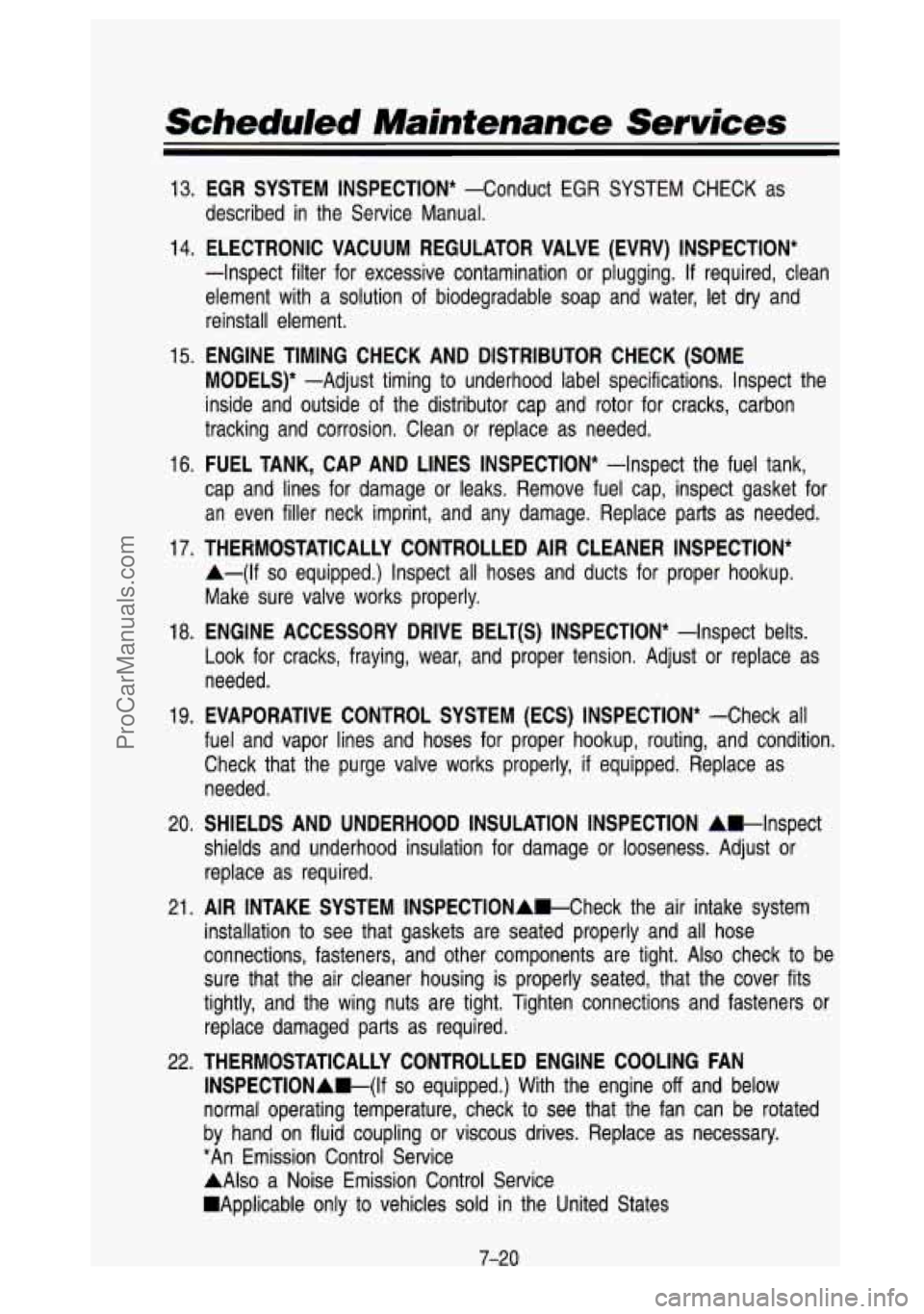

13. EGR SYSTEM INSPECTION* -Conduct EGR SYSTEM CHECK as

described in the Service Manual.

14. ELECTRONIC VACUUM REGULATOR VALVE (EVRV) INSPECTION*

-Inspect filter for excessive contamination or plugging. If required, clean

element with a solution of biodegradable soap and water, let

dry and

reinstall element.

15. ENGINE TIMING CHECK AND DISTRIBUTOR CHECK (SOME

MODELS)”

-Adjust timing to underhood label specifications. Inspect the

inside and outside of the distributor cap and rotor for cracks, carbon

tracking and corrosion. Clean or replace as needed.

cap and lines for damage or leaks. Remove fuel cap, inspect g\

asket for

an even filler neck imprint, and any damage. Replace parts as \

needed.

16. FUEL TANK, CAP AND LINES INSPECTION* -Inspect the fuel tank,

17. THERMOSTATICALLY CONTROLLED AIR CLEANER INSPECTION*

A-(If so equipped.) Inspect all hoses and ducts for proper hookup.

Make sure valve works properly.

Look for cracks, fraying, wear, and proper tension. Adjust or replace as

needed.

19. EVAPORATIVE CONTROL SYSTEM (ECS) INSPECTION* -Check all

fuel and vapor lines and hoses for proper hookup, routing, and\

condition.

Check that the purge valve works properly,

if equipped. Replace as

needed.

18. ENGINE ACCESSORY DRIVE BELT(S) INSPECTION* --Inspect belts.

20. SHIELDS AND UNDERHOOD INSULATION INSPECTION Am-Inspect

shields and underhood insulation for damage or looseness. Adjust\

or

replace as required.

21. AIR INTAKE SYSTEM INSPECTlONAWCheck the air intake system

installation to see that gaskets are seated properly and all hose

connections, fasteners, and other components are tight. Also check to be

sure that the air cleaner housing is properly seated, that the\

cover fits

tightly, and the wing nuts are tight. Tighten connections and \

fasteners or

replace damaged parts as required.

22. THERMOSTATICALLY CONTROLLED ENGINE COOLING FAN INSPECTI0NA.-(If

so equipped.) With the engine off and below

normal operating temperature, check to see that the fan can be rotated

by hand on fluid coupling or viscous drives. Replace as necessary.

*An Emission Control Service

AAlso a Noise Emission Control Service

.Applicable only to vehicles

sold in the United States

7-20

ProCarManuals.com

Page 402 of 436

Scheduled Maintenance Sewices

When the wheels are removed for rotation, inspect disc brake pads f\

or wear

and rotors for surface condition.

Also inspect drum brake linings for wear and

cracks. Inspect other brake parts, including drums, wheel cylind\

ers, parking

brake, etc., at the same time. Remove any rust

or dirt from the wheel and

mounting surfaces before mounting the wheel.

Inspect brakes more often if driving habits or conditions resull In

frequent braking.

Owner Checks and Services

Listed below are owner checks and services which should be mad\

e at the

time period specified

to help ensure proper safety, emission performance, and

dependability of your vehicle.

Be sure any necessary repairs are completed at once. Whenever \

any fluids

or lubricants are added to your vehicle, make sure they are the proper ones,

as shown

in this Section.

At Least Once a Month

Tire inflation pressure check -Check the tires for proper inflation. If they

are low, inflate them

to the level specified on the certification label or on the

tire inflation charts. See “Loading Your Vehicle’’ or “Inflation-Tire Pressure” in

the Index.

At Least Once a Year

Key lock cylinder lubrication -Lubricate key lock cylinders with engine oil.

See the “Recommended Fluid and Lubricants’’ chart in this section.

Transmission neutral or clutch start switch operation

CAUTION

~

1. Before you start, be sure you have enough room around the veh\

icle.

2. Firmly apply both the manual parking brake and the regular brake. See

“Brakes” and “Parking Brake” in the Index.

Do not use the accelerator

pedal.

3. Be ready to turn off the engine immediately if it starts.

4. On automatic transmission vehicles, try to start the engine in each gear.

The starter should work only in

P (Park) or N (Neutral).

7-22

ProCarManuals.com

Page 403 of 436

On manual transmission vehicles, put the shift lever in N (Neutral), push the

clutch down halfway, and try to start the engine. The starter should work only

when the clutch is pushed down all the way to the floor.

Steering column lock operation -While parked, try to turn the key to Lock

in each gear shift position.

With an automatic transmission, the key should turn to

Lock only when the

gear shift is in

P (Park).

On vehicles with a key release lever, try to turn the key to

Lock without

pressing the lever. The key should turn to

Lock only with the key lever

depressed.

On all vehicles, the key should come out only in

Lock.

Parking brake and transmission

P (PARK) mechanism operation -

CAUTION I

4 When you are doing this check, your vehicle could begin to move.

You

or others could be injured and property could be damaged.

Make sure there is

room in front of your vehicle in case you begin

to

roll. Be ready to apply the regular brake at once should the

vehicle begin to move.

IW

Park on a fairly steep hill, with the vehicle facing downhill.\

Keeping your foot

on the regular brake, set the manual parking brake.

To check the parking brake: With the engine running and the

transmission in

N (Neutral), slowly remove foot pressure from the regular

brake pedal.

Do this until the vehicle is held by the parking brake only.

To check the “Park” mechanism’s holding ability: Apply the \

regular brake

and shift to

P (Park). Release the manual parking brake, then slowly

release the regular brake.

Lap and shoulder belts condition and operation -Inspect belt system,

including: webbing, buckles, latch plates, retractors, guide loop\

s and anchors.

Have a belt assembly replaced

if the webbing has been cut or otherwise

damaged.

Body

Lubrication Service -Lubricate all body door hinges with engine oil.

Also lubricate the tailgate, tailgate handle pivot points, and tailga\

te mounted

spare tire carrier

(if equipped). Lubricate the body hood, fuel door and rear

compartment hinges, latches and locks including interior glove

box and

console

doors, and any folding seat hardware. Lubricate the hood safety lever

pivot and prop

rod pivot. More frequent lubrication may be required when

exposed to a corrosive environment.

7-23

ProCarManuals.com

Page 404 of 436

Scheduled Maintenance Services

Periodic Maintenance Inspections

Listed below are inspections and services which should be perfo\

rmed at least

twice a year (for instance each spring or fall).

You should let your GM

dealer’s service department or other qualified service center \

do these jobs.

Make sure any necessary repairs are completed at once.

Steering and Suspension lnspectiont -Inspect front and rear suspension

and steering system for damaged, loose or missing parts, signs \

of wear or

lack of lubrication. Inspect power steering lines and hoses for proper \

hook-up,

binding, leaks, cracks, chafing, etc. (On vehicles equipped wit\

h manual

steering gear, check for seal leakage.) Lubricate the steering linkage.

Accelerator Control System -Lubricate all pivot points with engine oil,

except the

TBI throttle shaft. Remove all external deposits from the injector

pump face cam on 6.2L and 6.5L engines.

Do this when the engine is cold

and not running.

Do not oil any accelerator or cruise control cables. Replace

any cables that have high effort or excessive wear.

Exhaust System Inspection -Inspect the complete system including the

three-way catalytic converter. Inspect the body near the exhaust\

system. Look

for broken, damaged, missing or out-of-position parts, as well \

as, open

seams, holes, loose connections or other conditions which could \

cause a heat buildup in the floor pan or could let exhaust fumes seep into the passenger

compartments.

Drive Axle Service -Check readfront axle fluid level and add as needed.

Check constant velocity joints and axle seals for leaking.

Transfer Case (four-wheel drive) lnspectiont -Every 12 months or at oil

change intervals, check front axle and transfer case and add l\

ubricant when necessary. Oil the control lever pivot point and all exposed c\

ontrol linkage.

Check vent hose at transfer case for kinks and proper installa\

tion. More

frequent lubrication may be required on heavy-duty or off-road use.

tA fluid loss in these systems may indicate a problem. Have them inspected

and repaired at once.

7-24

ProCarManuals.com

Page 416 of 436

Customer Assistance Information

Service Publications

Information on how to obtain Product Service Publications, Subsc\

riptions and

Indexes as described below is applicable only in the fifty

US. states (and the

District of Columbia) and only for light trucks with GVWR less than

10,000

pounds (4536 kg).

In Canada, information pertaining to Product Service Bulletins a\

nd Indexes

can be obtained by writing to: General Motors of Canada Limited, Service

Publications Department, 1908 Colonel Sam Dr., Oshawa, Ontario

L1 H 8P7.

GMC Truck regularly sends its dealers useful service bulletins \

about GMC

Truck products. GMC Truck monitors product performance in the f\

ield. We

then prepare bulletins for servicing our products better. Now, \

you can get

these bulletins too.

Bulletins cover various subjects. Some pertain to the proper us\

e and care

of

your vehicle. Some describe costly repairs. Others describe inex\

pensive repairs which,

if done on time with the latest parts, may avoid future costly

repairs. Some bulletins tell a technician how to repair a new \

or unexpected

condition. Others describe a quicker way to

fix your vehicle. They can help a

technician service your vehicle better.

Most bulletins apply

to conditions affecting a small number of trucks. Your

GMC Truck dealer or a qualified technician may have

to determine if a

specific bulletin applies to your vehicle.

You can subscribe to all GMC Truck bulletins. This way you’ll g\

et them as

they come out. You can wait a while and get an index to the bulletins. You

can also get individual bulletins. However, you’ll need the \

index to identify

them.

Subscriptions

You can subscribe to all GMC Truck Product Service Publications (P\

SP’s).

This

will include bulletins for all light trucks (less than 10,000 Ibs. [4536 kg]

GVWR)

sold by GMC Truck and will not be limited to PSP’s applicable to any

particular model. When you buy a subscription, you

will receive the PSP’s in

periodic mailings, shortly after they come out.

A subscription costs US.

$75,00 ($85.00 including a special binder) and it entitles you to all PSP’s

published by GMC Truck during the model year. You can purchase a

subscription by sending a check or money order to GMC Truck Service

Publications, Post Office Box 436006, Pontiac, Michigan 48343 al\

ong with the

order form located at the end of this section. You may get additional

subscription ordering forms by calling the toll-free number show\

n in this

section, or you can find them at participating dealerships.

8-6

ProCarManuals.com

Page 427 of 436

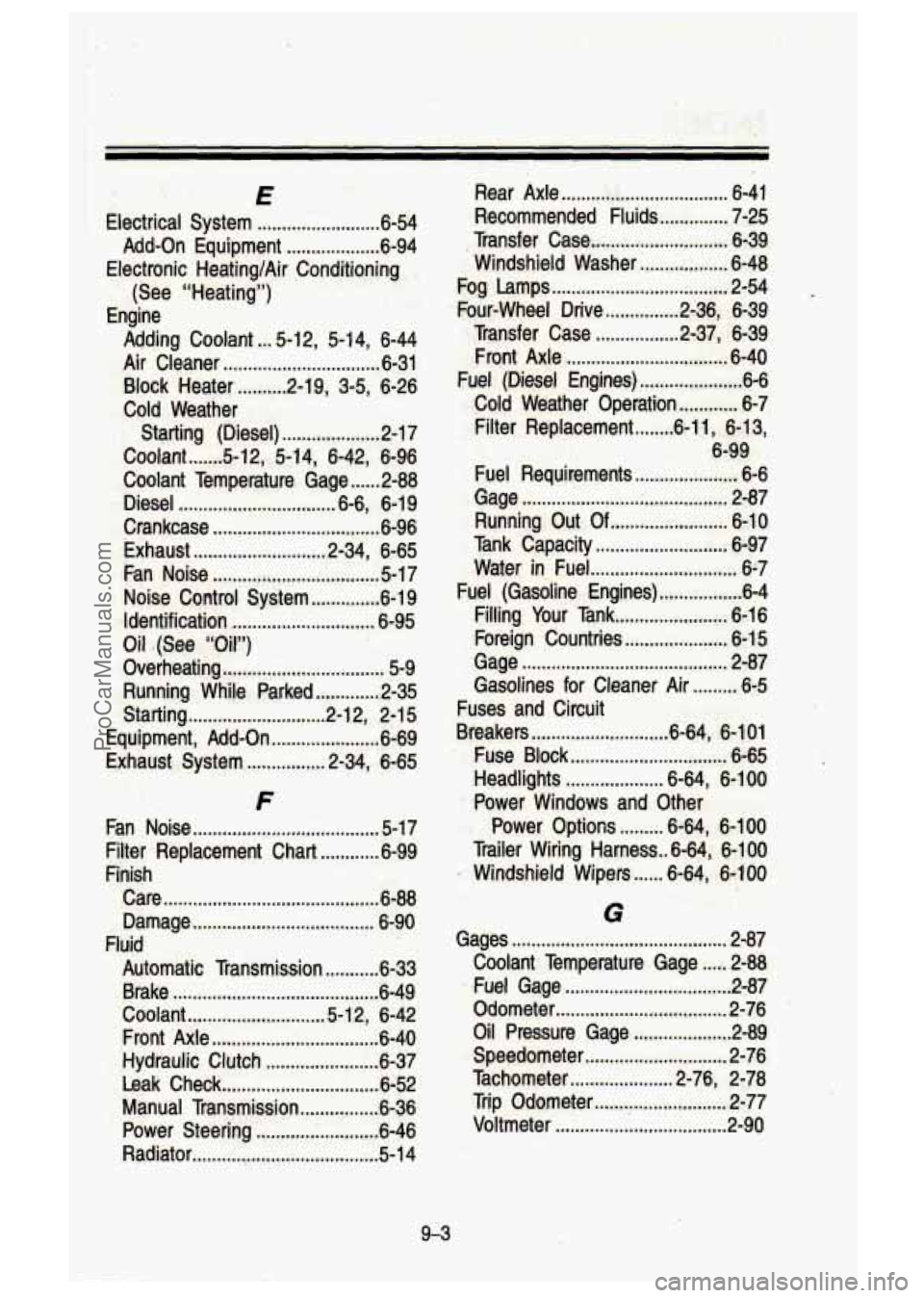

1 Add-on Equipment ................... 6-94

I- Electronic Heatinghir Conditioning

(See "Heating")

Adding Coolant

... 5.12, 5.14. 6-44

... Engine I

Air Cleaner ................................ 6-31

Block Heater

.......... 2.19. 3.5. 6-26

Cold Weather Starting (Diesel)

.................... 2-1 7

Coolant

....... 5.12. 5-1 4. 6.42. 6-96

Coolant Temperature Gage

...... 2-88

Diesel

................................ 6.6. 6-1 9

Crankcase

.................................. 6-96

Fan Noise

.................................. 5-1 7

Noise Control System

.............. 6-1 9

.-Identification,

............................ 6-95

Oil .(See "Oil")

Overheating

................................. 5-9

Running While Parked

............. 2-35

Equipment, Add-on

...................... 6-69

Exhaust System

................ 2.34, 6-65

Exhaust

........................... 2.34,

6-65

Starting

............................ 2.12, 2-1 5

F

Fan Noise ...................................... 5-1 7

Filter

. Replacement Chart ............ 6-99

Finish Care

............................................ 6-88

Damage

..................................... 6-90

Automatic Transmission

........... 6-33

Brake

.......................................... 6-49

Coolant

............................ 5-1 2. 6-42

Front Axle

.................................. 6- 40

Hydraulic Clutch

....................... 6-37

Leak Check

................................ 6-52

Manual Transmission

................ 6-36

Power Steering

............ 1 ............ 6-46

Radiator

....................................... 5-1 4

Fluid

9-3

Rear Axle .................................. 6-41

Recommended Fluids

.............. 7-25

. Transfer Case ............................ 6-39

Windshield Washer.

................. 6-48

Fog Lamps

.................................... 2-54 .

Four-wheel Drive ............... 2.36, 6-39

Transfer Case

................ .2-37, 6-39

Front Axle

................................. 6-40

Fuel (Diesel Engines)

..................... 6.6

Cold Weather Operation

............ 6-7

Filter Replacement

........ 6-1 1, 6.13,

6-99

Fuel Requirements

..................... 6-6

Gage

........................ ; ................. 2-87

Running Out Of

........................ 6-10

Tank Capacity

........................... 6-97

Water in Fuel

.............................. 627

Fuel (Gasoline Engines)

................. 6-4

Filling Your Ta'nk

....................... 6-16

Foreign

. Countries ..................... 6-15

Gage

.......................................... 2-87

Gasolines for Cleaner Air

......... 6-5 A-

Fuses and Circuit

Breakers

............................ 6-64, 6-1 01 * .

Fuse Block ................................ 6-65 . . f

Headlights .................... 6.64, 6-100

Power Windows and Other

Trailer Wiring Harness

.. 6.64, 6-1 00

. Windshield Wipers ...... 6-64, 6-100

G

Gages ............................................ 2.87

Coolant Temperature Gage

..... 2-88

Fuel Gage

.................................. 2-87

Odometer

................................... 2-76

Oil Pressure Gage

..................... 2-89

Speedometer.

............................ 2-76

Tachometer

..................... 2.76, 2-78

Trip Odameter 2-77

Voltmeter

................................... 2-90

-

-.

I

Power Options ......... 6.64, 6-100 :

. ...........................

...

ProCarManuals.com