GMC SIERRA 1993 Owners Manual

Manufacturer: GMC, Model Year: 1993, Model line: SIERRA, Model: GMC SIERRA 1993Pages: 436, PDF Size: 23.88 MB

Page 391 of 436

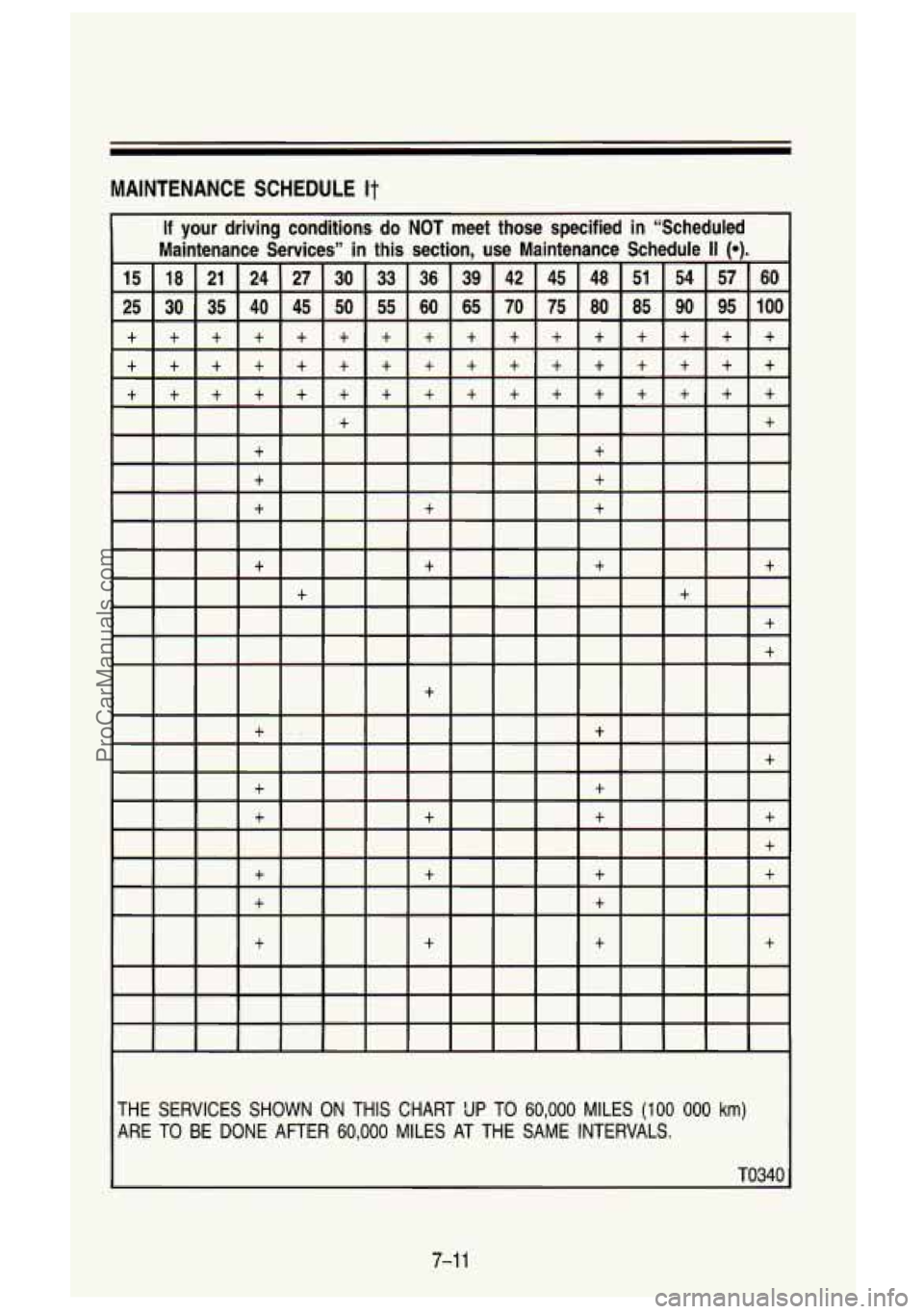

MAINTENANCE SCHEDULE It

If your driving conditions do NOT meet those specified in “Scheduled

Maintenance Services” in this section, use Maintenance Schedule

II (4.

THE SERVICES SHOWN ON THIS CHART UP TO 60,000 MILES (100 000 km)

ARE TO BE DONE AFTER 60,000 MILES AT THE SAME INTERVALS.

TO340

7-1 1

ProCarManuals.com

Page 392 of 436

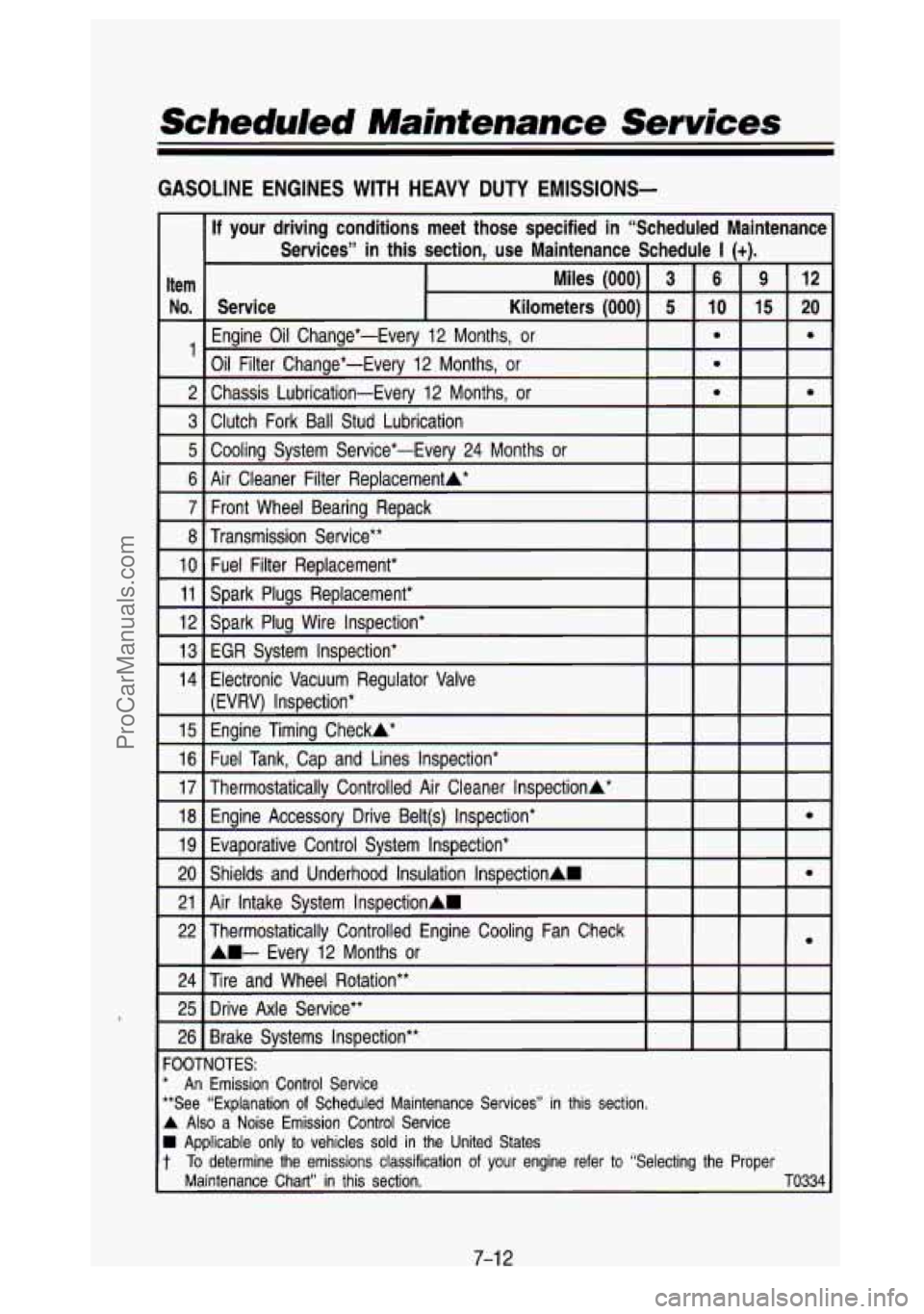

Scheduled Maintenance Services

GASOLINE ENGINES WITH HEAVY DUTY EMISSIONS-

7-1 2

ProCarManuals.com

Page 393 of 436

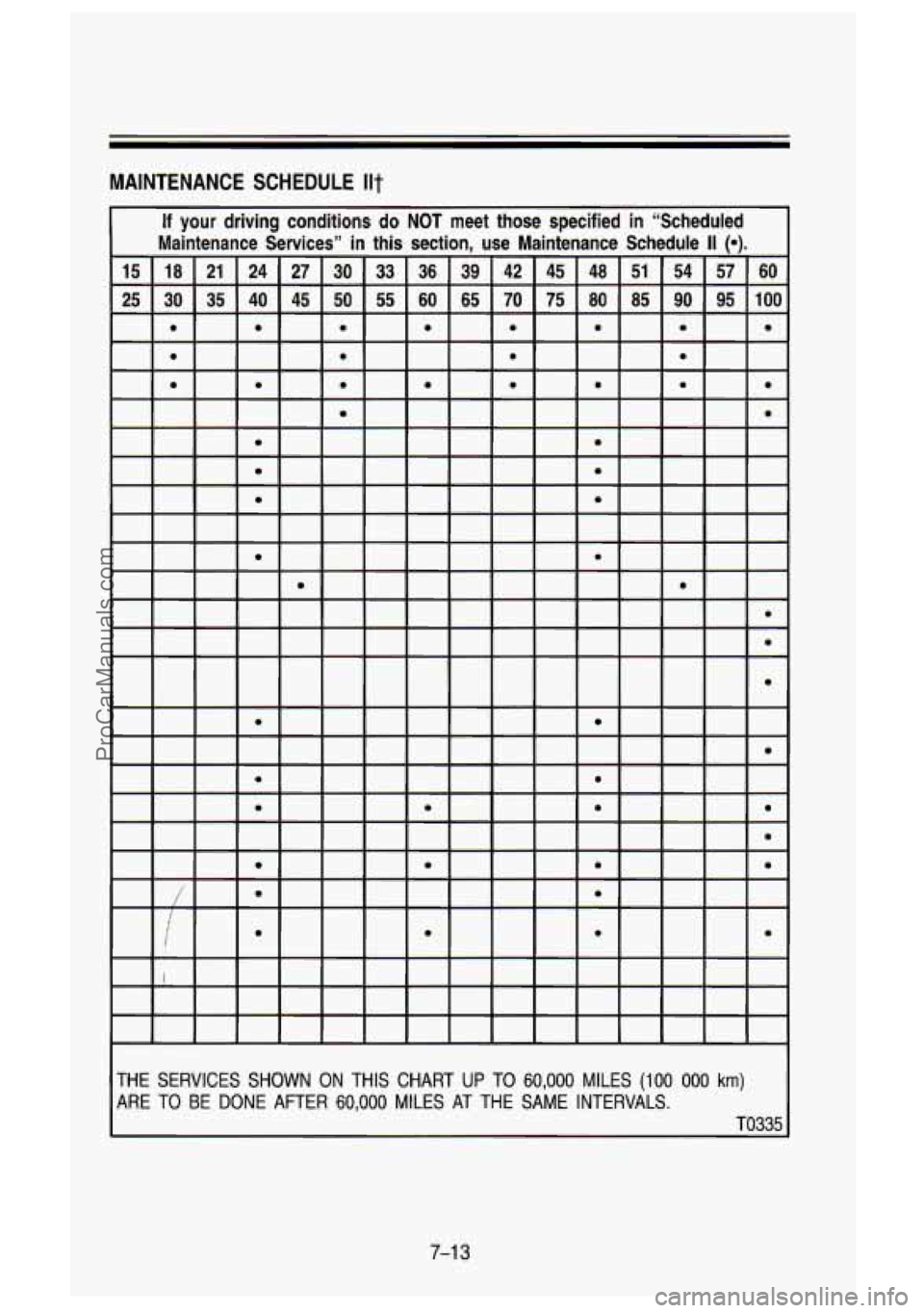

MAINTENANCE SCHEDULE Ilt

If your driving conditions do NOT meet those specified in “Scheduled

Maintenance Services” in this section, use Maintenance Schedul\

e

II h),

54 57 60

90 95 100

.e

e e

e

e

e

e

THE SERVICES SHOWN ON THIS CHART UP TO 60,000 MILES (100 000 km)

ARE TO BE DONE AFTER 60,000 MILES AT THE SAME INTERVALS.

TO335

7-1 3

ProCarManuals.com

Page 394 of 436

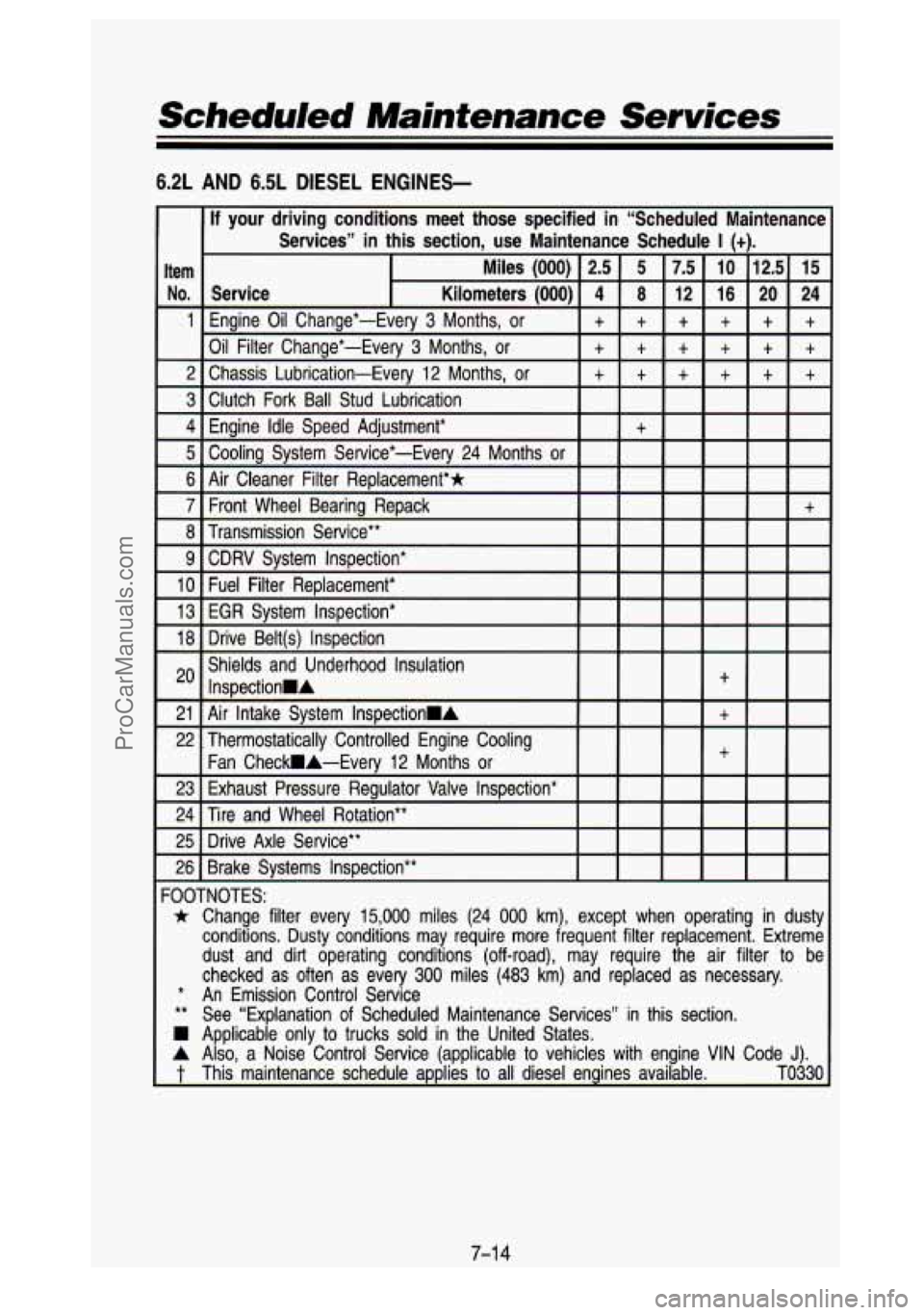

6.2L AND 6.5L DIESEL ENGINES-

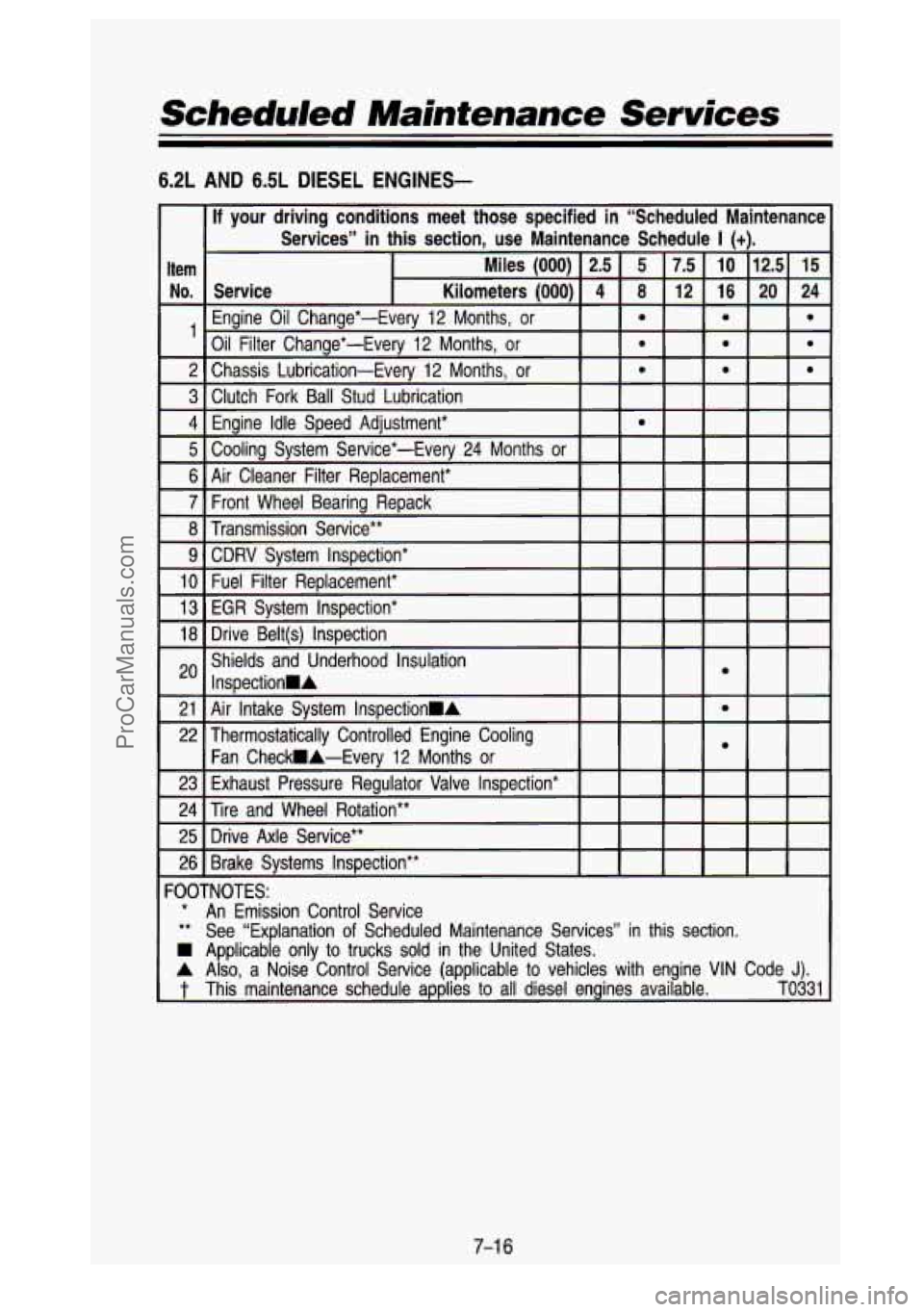

-0OTNOTES:

rt Change filter every 15,000 miles (24 000 km), except when operating in dusty

conditions. Dusty conditions may require more frequent filter re\

placement. Extreme

dust and dirt operating conditions (off-road), may require the air filter

to be

checked as often as every 300 miles (483 km) and replaced as necessary.

* An Emission Control Service

** See “Explanation of Scheduled Maintenance Services” in this section.

1 Applicable only to trucks sold in the United States.

A Also, a Noise Control Service (applicable to vehicles with engine VIN Code J).

t This maintenance schedule applies to all diesel engines available. TO330

7-1 4

ProCarManuals.com

Page 395 of 436

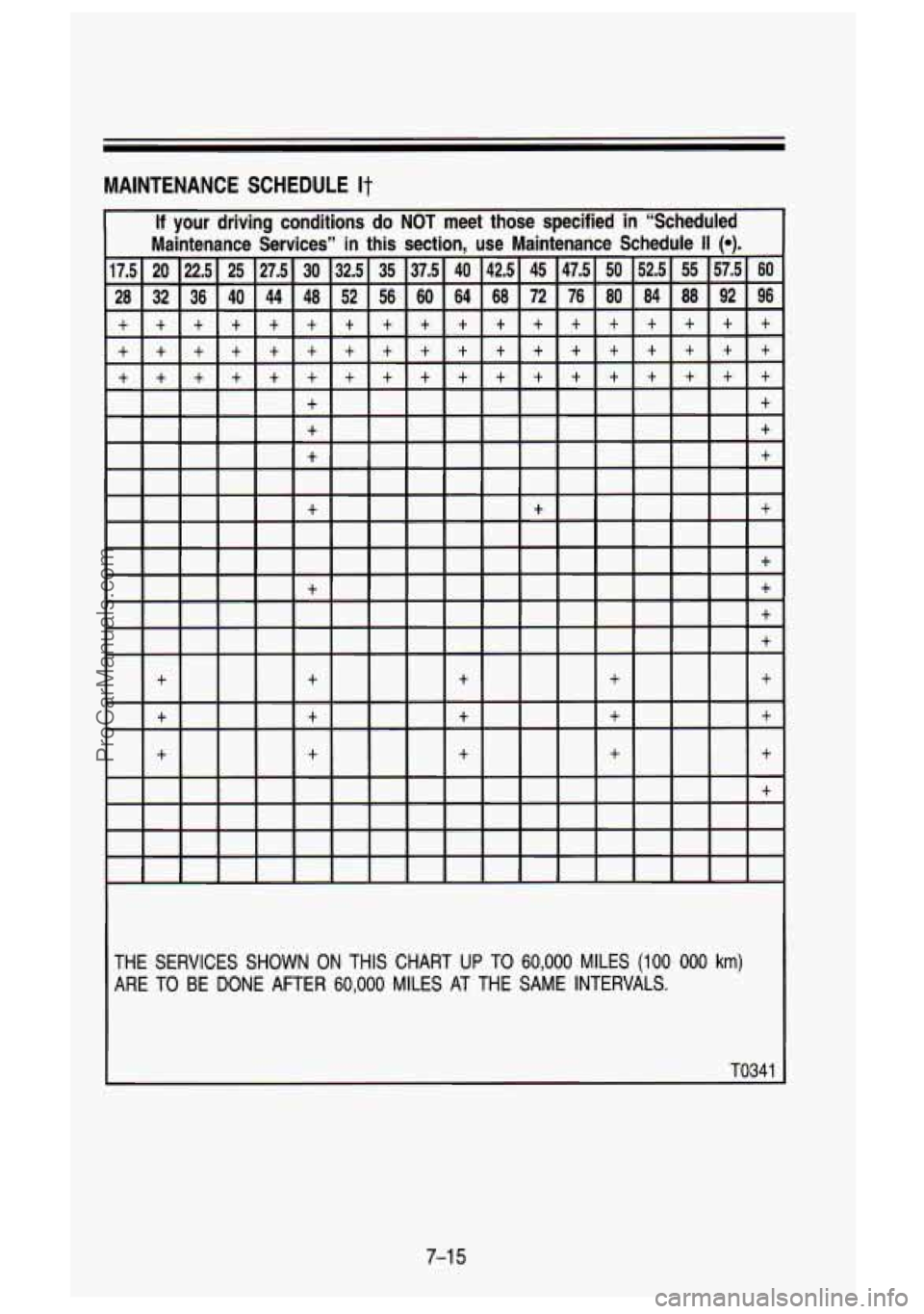

MAINTENANCE SCHEDULE It

If your driving conditions do NOT meet those specified in “Scheduled

THE SERVICES SHOWN ON THIS CHART UP TO 60,000 MILES (100 000 km)

ARE TO BE DONE AFTER 60,000 MILES AT THE SAME INTERVALS.

TO341

7-1 5

ProCarManuals.com

Page 396 of 436

Scheduled Maintenance Services

6.2L AND 6.5L DIESEL ENGINES-

If your driving conditions meet those specified in “Scheduled Ma\

intenance Services” in this section, use Maintenance Schedule

I (4.

7-1 6

ProCarManuals.com

Page 397 of 436

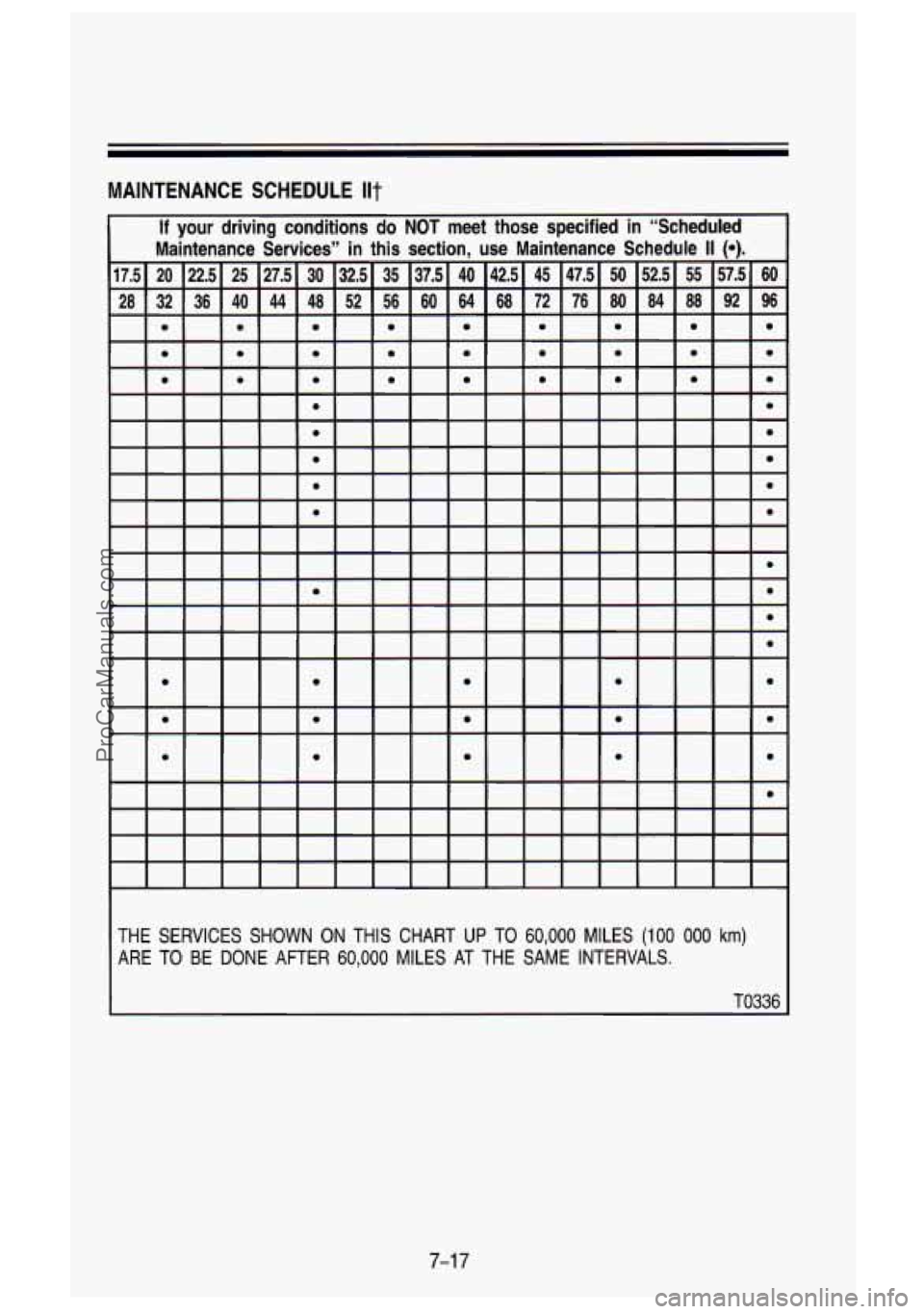

MAINTENANCE SCHEDULE Ilt

THE SERVICES SHOWN ON THIS CHART UP TO 60,000 MILES (100 000 km)

ARE TO BE DONE AFTER 60,000 MILES AT THE SAME INTERVALS.

TO336

7-1 7

ProCarManuals.com

Page 398 of 436

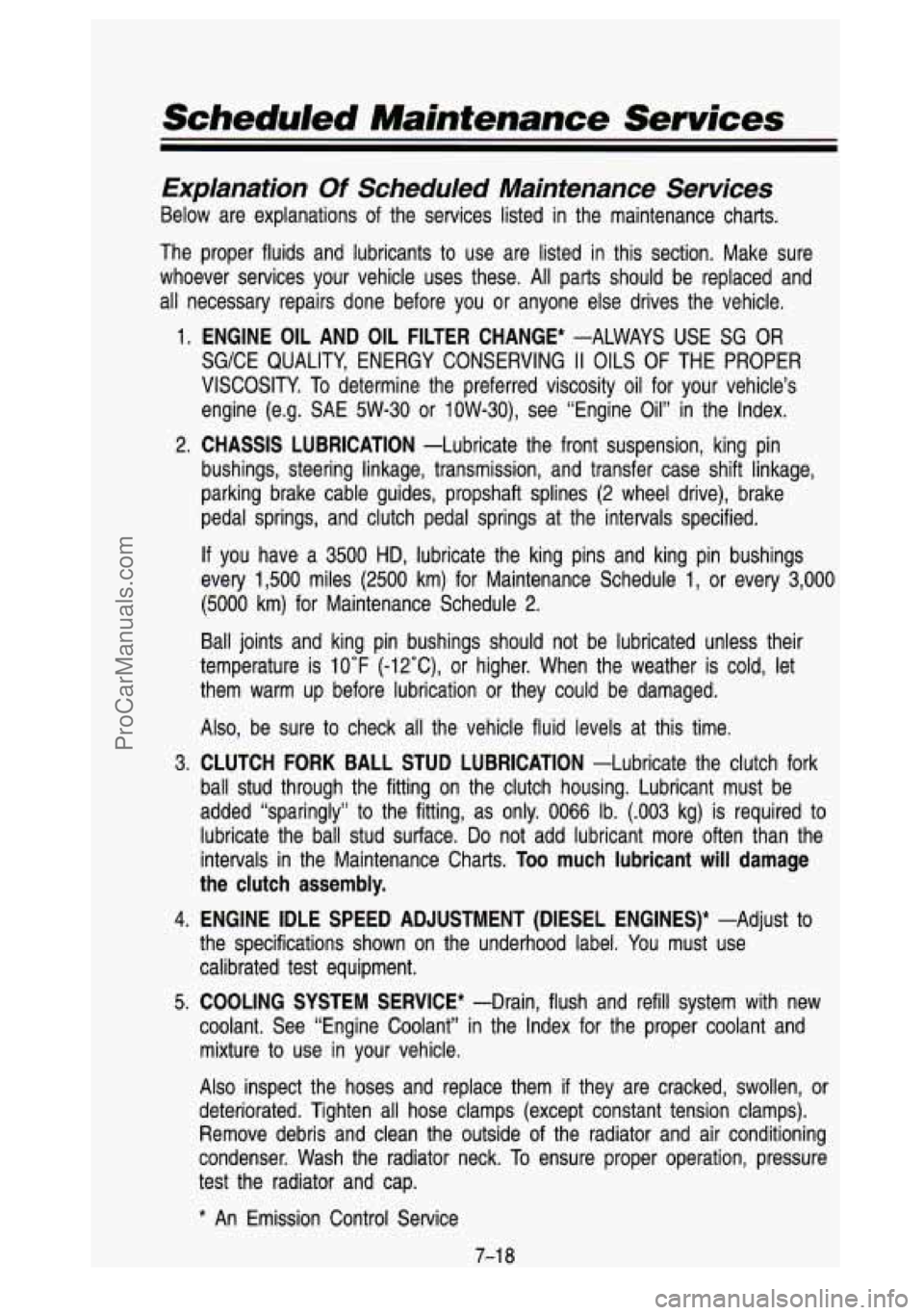

Scheduled Maintenance Services

Explanation Of Scheduled Maintenance Services

Below are explanations of the services listed in the maintenance charts.

The proper fluids and lubricants to use are listed in this section. Make sure

whoever services your vehicle uses these. All parts should be \

replaced and

all necessary repairs done before you or anyone else drives the ve\

hicle.

1.

ENGINE OIL AND OIL FILTER CHANGE* -ALWAYS USE SG OR

SGKE QUALITY, ENERGY CONSERVING II OILS OF THE PROPER

VISCOSITY. To determine the preferred viscosity oil for your vehicle’s

engine (e.g. SAE 5W-30 or 10W-30), see “Engine Oil” in the Index.

2. CHASSIS LUBRICATION -Lubricate the front suspension, king pin

bushings, steering linkage, transmission, and transfer case shift\

linkage,

parking brake cable guides, propshaft splines (2 wheel drive), brake

pedal springs, and clutch pedal springs at the intervals specified.

If you have a 3500 HD, lubricate the king pins and king pin bushings

every 1,500 miles

(2500 km) for Maintenance Schedule 1, or every 3,000

(5000 km) for Maintenance Schedule 2.

Ball joints and king pin bushings should not be lubricated unless their

temperature is

10°F (-12”C), or higher. When the weather is cold, let

them warm up before lubrication or they could be damaged.

Also, be sure to check

all the vehicle fluid levels at this time.

3.

CLUTCH FORK BALL STUD LUBRICATION -Lubricate the clutch fork

ball stud through the fitting on the clutch housing. Lubricant must be

added “sparingly” to the fitting, as only.

0066 Ib. (.003 kg) is required to

lubricate the ball stud surface.

Do not add lubricant more often than the

intervals in the Maintenance Charts.

Too much lubricant will damage

the clutch assembly.

4. ENGINE IDLE SPEED ADJUSTMENT (DIESEL ENGINES)* -Adjust to

the specifications shown on the underhood label. You must use

calibrated test equipment.

5. COOLING SYSTEM SERVICE* -Drain, flush and refill system with new

coolant. See “Engine Coolant’’ in the Index for the proper coolant and

mixture to use in your vehicle.

Also inspect the hoses and replace them

if they are cracked, swollen, or

deteriorated. Tighten all hose clamps (except constant tension \

clamps).

Remove debris and clean the outside

of the radiator and air conditioning

condenser. Wash the radiator neck.

To ensure proper operation, pressure

test the radiator and cap.

* An Emission Control Service

7-1

8

ProCarManuals.com

Page 399 of 436

6. AIR CLEANER FILTER REPLACEMENT* -Replace at every 30,000

miles (50 000 km) or more often under dusty conditions. Ask your dealer

for the proper replacement intervals for your driving conditions\

.

7. FRONT WHEEL BEARING REPACK (2 WHEEL DRIVE ONLY) -Clean

and repack the front wheel bearings at each brake relining, or\

at the specified interval, whichever comes first.

8.

TRANSMISSION SERVICE

Automatic Transmission

-Change the transmission fluid and filter every

15,000 miles (25 000 km) for vehicles under 8,600 GVWR or every

12,000 miles (20 000 km) for vehicles over 8,600 GVWR if the vehicle

is mainly driven under one or more of these conditions:

In heavy city traffic.

Where the outside temperature regularly reaches 90°F (32°C\

) or

higher.

In hilly or mountainous terrain.

Frequent trailer pulling.

Uses such as taxi, police, delivery or other commercial service\

.

If the vehicle is not used mainly under any of these conditions, change

the fluid and filter every 30,000 miles

(50 000 km) for vehicles under

8600 GVWR or every

24,000 miles (40 000 km) for vehicles over 8600

GVWR. See “Automatic Transmission Fluid” in the Index for more

information.

Manual Transmission -Transmission fluid does not require periodic

changing.

Regulator Valve System for any worn, plugged or collapsed hoses. Have

the system checked as described in the Service Manual.

9.

CDRV SYSTEM INSPECTION* -Check

the Crankcase Depression

10. FUEL FILTER REPLACEMENT* -Replace the fuel filter at the specified

interval

or sooner if clogged.

11. SPARK PLUGS REPLACEMENT* -Replace spark plugs with the type

listed in Section

6. See “Specification Charts” in the Index.

12.

SPARK PLUG WIRE INSPECTION* -Clean wires and inspect for burns,

cracks or other damage. Check the wire boot fit at the distributor and at

the spark plugs. Replace wires as needed.

*An Emission Control Service

7-1 9

ProCarManuals.com

Page 400 of 436

Scheduled Maintenance Services

13. EGR SYSTEM INSPECTION* -Conduct EGR SYSTEM CHECK as

described in the Service Manual.

14. ELECTRONIC VACUUM REGULATOR VALVE (EVRV) INSPECTION*

-Inspect filter for excessive contamination or plugging. If required, clean

element with a solution of biodegradable soap and water, let

dry and

reinstall element.

15. ENGINE TIMING CHECK AND DISTRIBUTOR CHECK (SOME

MODELS)”

-Adjust timing to underhood label specifications. Inspect the

inside and outside of the distributor cap and rotor for cracks, carbon

tracking and corrosion. Clean or replace as needed.

cap and lines for damage or leaks. Remove fuel cap, inspect g\

asket for

an even filler neck imprint, and any damage. Replace parts as \

needed.

16. FUEL TANK, CAP AND LINES INSPECTION* -Inspect the fuel tank,

17. THERMOSTATICALLY CONTROLLED AIR CLEANER INSPECTION*

A-(If so equipped.) Inspect all hoses and ducts for proper hookup.

Make sure valve works properly.

Look for cracks, fraying, wear, and proper tension. Adjust or replace as

needed.

19. EVAPORATIVE CONTROL SYSTEM (ECS) INSPECTION* -Check all

fuel and vapor lines and hoses for proper hookup, routing, and\

condition.

Check that the purge valve works properly,

if equipped. Replace as

needed.

18. ENGINE ACCESSORY DRIVE BELT(S) INSPECTION* --Inspect belts.

20. SHIELDS AND UNDERHOOD INSULATION INSPECTION Am-Inspect

shields and underhood insulation for damage or looseness. Adjust\

or

replace as required.

21. AIR INTAKE SYSTEM INSPECTlONAWCheck the air intake system

installation to see that gaskets are seated properly and all hose

connections, fasteners, and other components are tight. Also check to be

sure that the air cleaner housing is properly seated, that the\

cover fits

tightly, and the wing nuts are tight. Tighten connections and \

fasteners or

replace damaged parts as required.

22. THERMOSTATICALLY CONTROLLED ENGINE COOLING FAN INSPECTI0NA.-(If

so equipped.) With the engine off and below

normal operating temperature, check to see that the fan can be rotated

by hand on fluid coupling or viscous drives. Replace as necessary.

*An Emission Control Service

AAlso a Noise Emission Control Service

.Applicable only to vehicles

sold in the United States

7-20

ProCarManuals.com