GMC SIERRA 1995 Owners Manual

Manufacturer: GMC, Model Year: 1995, Model line: SIERRA, Model: GMC SIERRA 1995Pages: 488, PDF Size: 26.01 MB

Page 451 of 488

Brake-Transmission Shift Interlock - BTSI

1.

2.

3.

Before you start, be sure you have enough room around the vehicle. It

should be parked on a level surface.

Firrnly apply the parking brake (see “Parking Brake” in the Index

if

necessary).

NOTE: Be ready to apply the regular brake immediately if the vehicle

begins to move.

With the engine

off, turn the key to the RUN position, but don’t start

the engine. Without applying the regular brake,

try to move the shift

lever out of PARK (P) with normal effort. if the shift lever moves out

of PARK (P), your vehicle’s BTSI needs service.

Steering Column Lock

While parked, and with the parking brake set, try to turn the key to LOCK

in each shift lever position.

With an automatic transmission, the key should turn to LOCK only

With a manual transmission, the key should turn to LOCK only when

On vehicles with

a key release button, try to turn the key to LOCK without

pressing the button. The key should turn to LOCK only with the key button

depressed. when

the shift lever

is in PARK (P).

the shift lever is

in REVERSE (R).

On all vehicles, the key should come out only in LOCK.

7-95

ProCarManuals.com

Page 452 of 488

Parking Brake and Automatic Transmission PARK (P)

Mechanism Check

Park on a fairly steep hill, with the vehicle facing downhill. Keeping your

foot on the regular brake, set the parking brake.

0

0 To check the parking brake: With the engine running and transmission

in NEUTRAL

(N), slowly remove foot pressure from the regular brake

pedal.

Do this until the vehicle is held by the parking brake only.

To check the PARK (P) mechanism’s holding ability: Shift to PARK

(P). Then release all brakes.

Lap and Shoulder Belts Condition and Operation

Inspect belt system, including: webbing, buckles, latch plates, retractors,

guide loops and anchors. Have a belt assembly replaced

if the webbing has

been cut or otherwise damaged.

7-96

ProCarManuals.com

Page 453 of 488

Part C: Periodic Maintenance lnspections

Listed below are inspections and services which should be performed at

least twice a year (for instance, each spring and

fall). You should let your

GM dealer’s service department or other qualified service center do these

jobs. Make sure any necessary repairs are completed at once.

Steering and Suspension Inspection

Inspect the front and rear suspension and steering system for damaged.

loose or missing parts, signs of wear,

or lack of lubrication. Inspect power

steering lines and hoses for proper hookup, binding, leaks, cracks, chafing,

etc. (On vehicles equipped with manual steering gear, check for seal

leakage.)

Exhaust System Inspection

Inspect the complete exhaust system. Inspect the body near the exhaust

system.

Look for broken. damaged, missing or out-of-position parts as well

as open seams, holes, loose connections,

or other conditions which could

cause a heat build-up

in the floor pan or could let exhaust fumes into the

vehicle. See “Engine Exhaust”

in the Index.

Accelerator Control System

On gasoline engines. lubricate the pivot at the TBI throttle lever stud with

engine

oil. Do not oil any accelerator or cruise control cables. Replace any

cables that have high effort or excessive wear.

Drive Axle Service

Check readfront axle fluid level and add as needed. Check constant velocity

Joints and axle seals for leaking.

Transfer Case (Four- Wheel Drive) Inspection

Every 12 months or at oil change intervals, check front axle and transfer

case and add lubricant when necessary. Oil the control lever pivot point and

all exposed control linkage. Check vent hose at transfer case for kinks and

proper installation. More frequent lubrication may be required on off-road

use.

7-97

ProCarManuals.com

Page 454 of 488

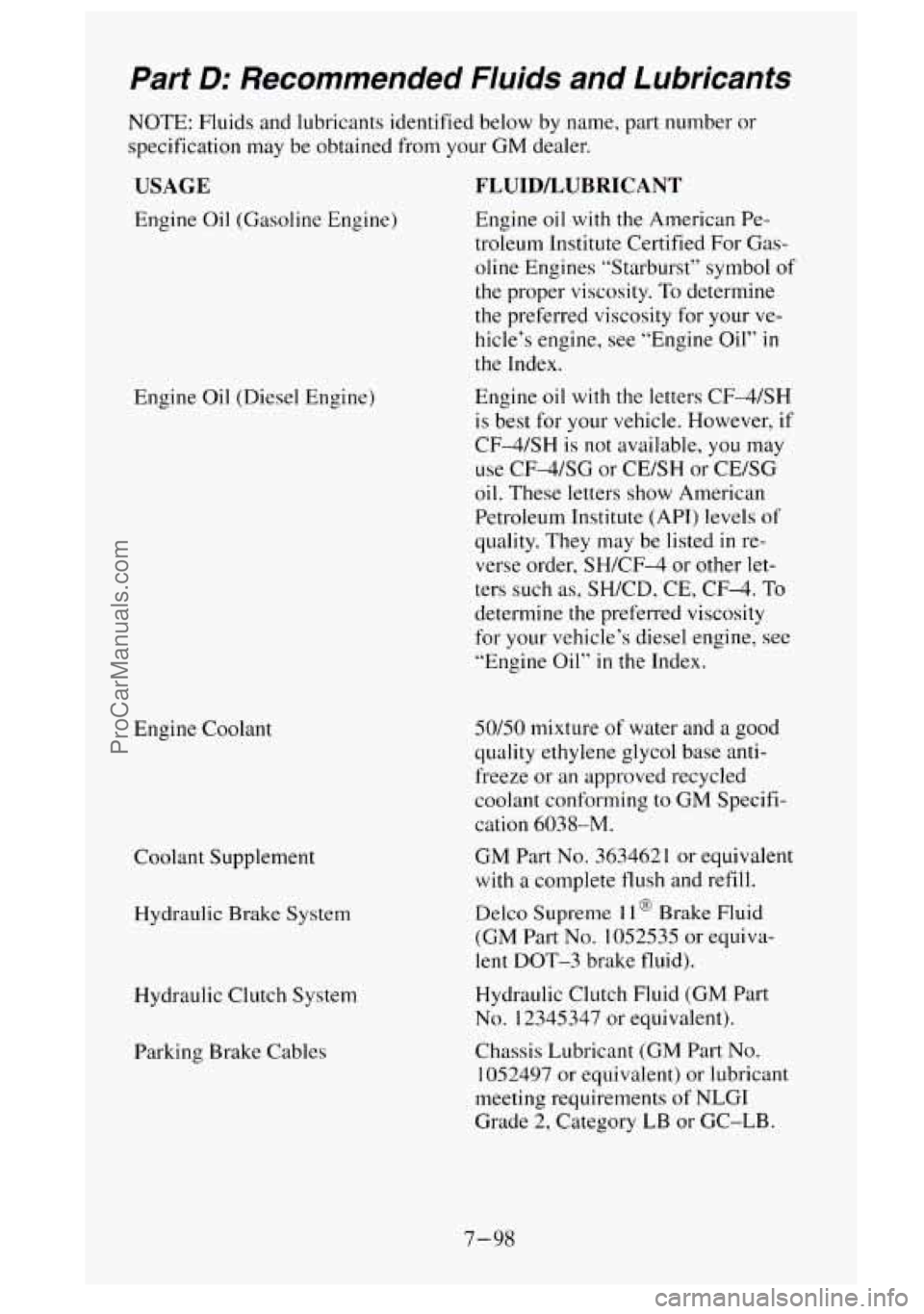

Part D: necommended Fluids and Lubricants

NOTE: Fluids and lubricants identified below by name, part number or

specification may be obtained from your

GM dealer.

USAGE

Engine Oil (Gasoline Engine)

Engine Oil (Diesel Engine)

Engine Coolant

Coolant Supplement

Hydraulic Brake System

Hydraulic Clutch System

Parking Brake Cables

FLUIDLUBRICANT

Engine oil with the American Pe-

troleum Institute Certified For Gas-

oline Engines “Starburst” symbol of

the proper viscosity.

To determine

the preferred viscosity for your ve-

hicle’s engine, see “Engine Oil”

in

the Index.

Engine oil with the letters

CF-4/SH

is best for your vehicle. However, if

CF-4/SH is not available,

you may

use CF-4/SG or CE/SH or CE/SG

oil. These letters show American

Petroleum Institute (APT) levels

of

quality. They may be listed in re-

verse order, SHKF-4 or other let-

ters such

as, SHKD, CE, CF-4. To

determine the preferred viscosity

for your vehicle’s diesel engine, see

“Engine Oil” in the Index.

50/50 mixture of water and a good

quality ethylene glycol base anti-

freeze

or an approved recycled

coolant conforming

to GM Specifi-

cation 6038-M.

GM Part No. 3634621 or equivalent

with a complete flush and refill.

Delco Supreme

11 @ Brake Fluid

(GM Part

No. 1052535 or equiva-

lent DOT-3 brake fluid).

Hydraulic Clutch Fluid (GM Part

No. 12345347 or equivalent).

Chassis Lubricant

(GM Part No.

1052497 or equivalent) or lubricant

meeting requirements of NLGI

Grade

2, Category LB or GC-LB.

7-98

ProCarManuals.com

Page 455 of 488

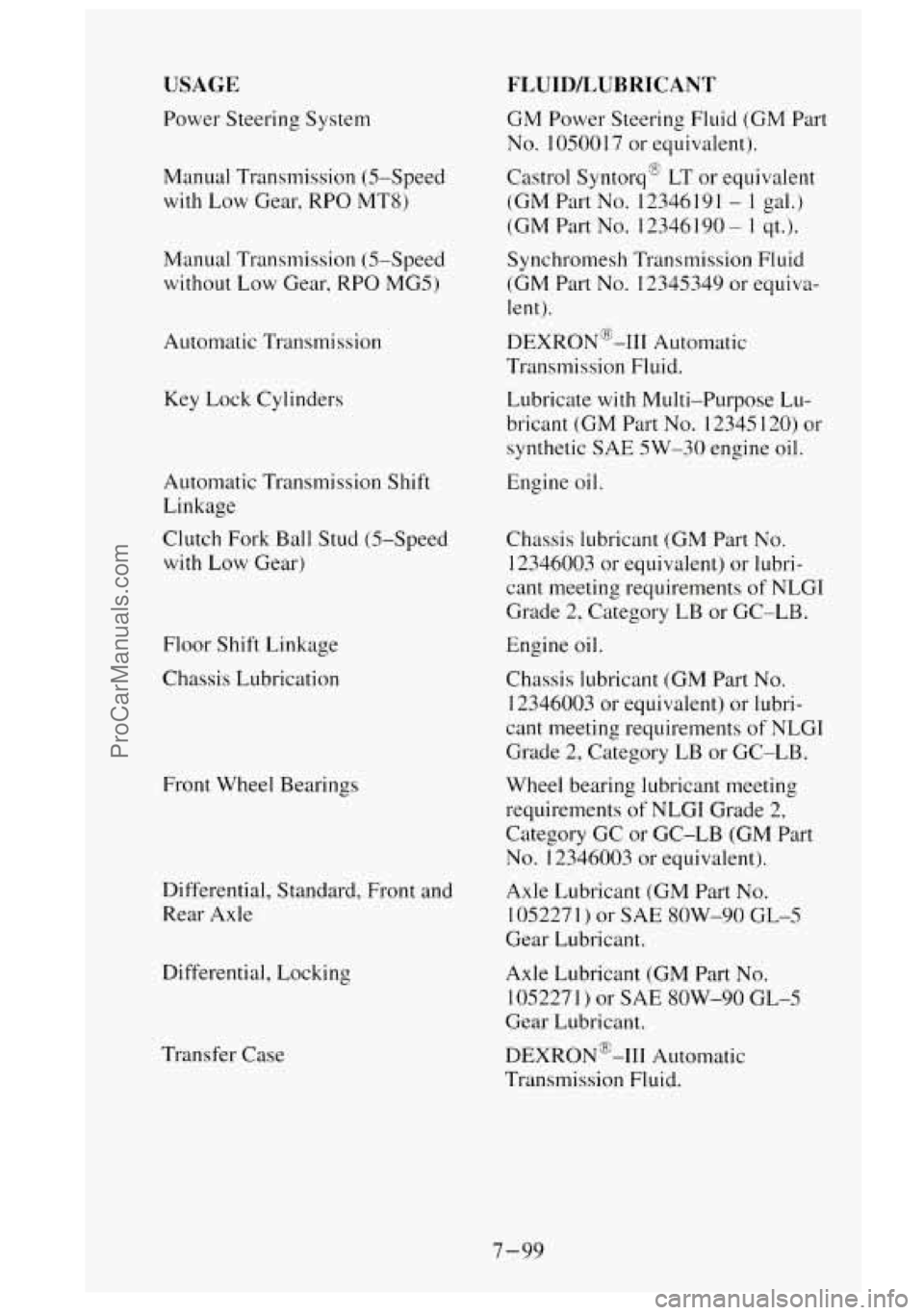

USAGE

Power Steering System Manual Transmission (5-Speed

with Low Gear, RPO MT8)

Manual Transmission (5-Speed

without Low Gear, RPO MG5)

Automatic Transmission Key Lock Cylinders

FLUIDLUBRICANT

GM Power Steering Fluid (GM Part

No. 10500 I7 or equivalent).

Castrol Syntorq'

LT or equivalent

(GM Part No. 12346191

- 1 gal.)

(GM Part

No. I23461 90 - 1 qt.).

Synchromesh Transmission Fluid

(GM Part

No. 12345349 or equiva-

lent).

DEXR0N'-I11 Automauc

Transmission Fluid.

Lubricate

with Multi-Purpose Lu-

bricant (GM Part No. I2345 120) or

synthetic SAE SW-30 engine oil.

Automatic Transmission Shift

Linkage

Clutch Fork Ball Stud (5-Speed

with Low Gear)

Floor Shift Linkage

Chassis Lubrication

Front Wheel Bearings

Differential, Standard, Front and

Rear Axle

Differential, Locking

Transfer Case Engine

oil.

Chassis lubricant (GM Part

No.

12346003 or equivalent) or lubri-

cant meeting requirements of NLGI

Grade 2, Category LB or GC-LB.

Engine

oil.

Chassis lubricant (GM Part No.

I2346003 or equivalent) or lubri-

cant meeting requirements of NLGI

Grade

2, Category LB or GC-LB.

Wheel bearing lubricant meeting

requirements

of NLGI Grade 2,

Category GC or GC-LB (GM Part

No. I2346003 or equivalent).

Axle Lubricant (GM Part No.

105227

1 ) or SAE 8OW-90 GL-5

Gear Lubricant.

Axle Lubricant (GM Part

No.

105227 1) or SAE 80W-90 GL-5

Gear Lubricant.

DEXR0N"-111 Automatic

Transmission Fluid.

7-99

ProCarManuals.com

Page 456 of 488

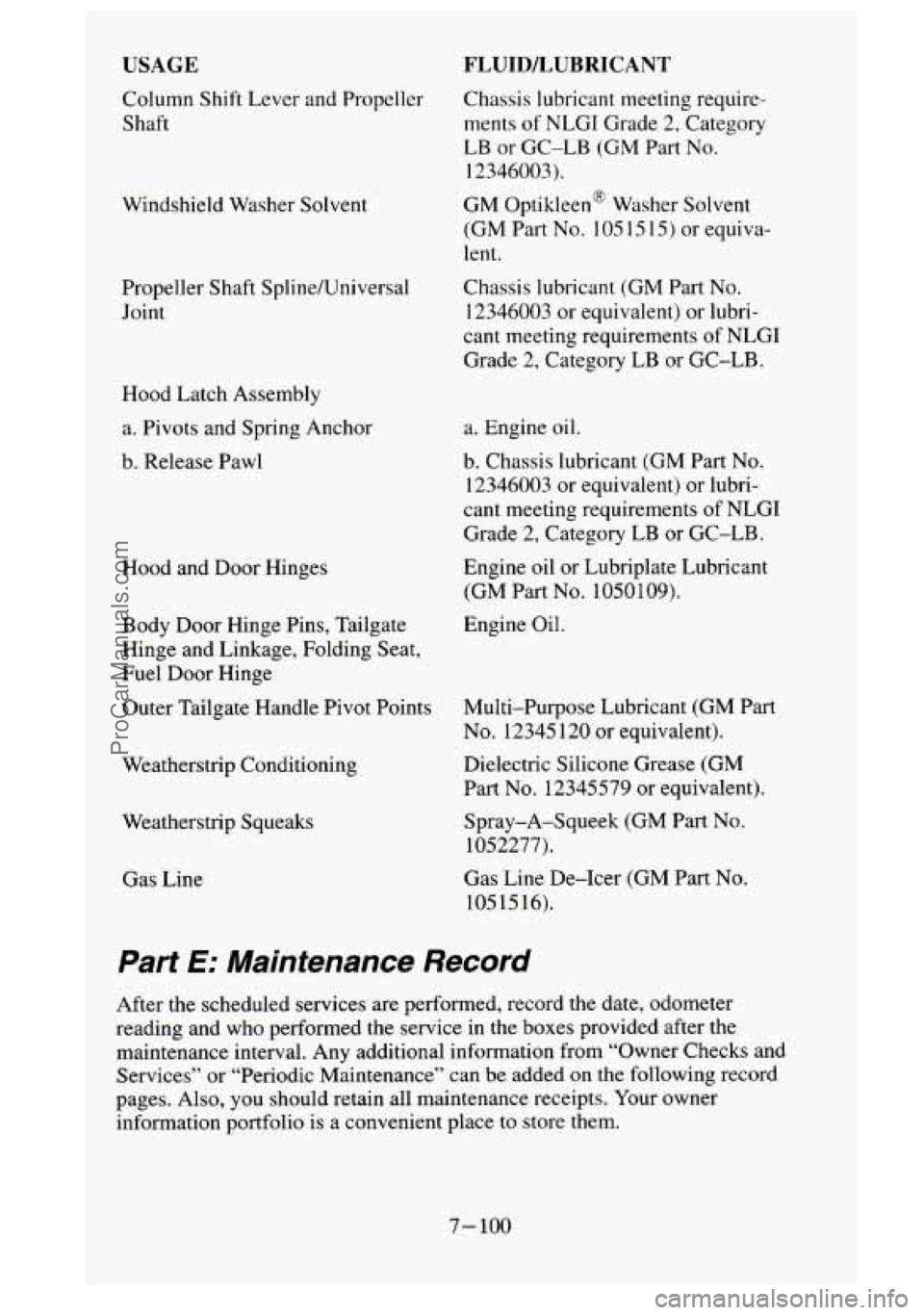

USAGE

Column Shift Lever and Propeller

Shaft

Windshield Washer Solvent

Propeller Shaft Spline/Universal

Joint

Hood Latch Assembly

a. Pivots and Spring Anchor

b. Release Pawl

Hood and Door Hinges

Body Door Hinge Pins, Tailgate

Hinge and Linkage, Folding Seat,

Fuel

Door Hinge

Outer Tailgate Handle Pivot Points

Weatherstrip Conditioning

Weatherstrip Squeaks

Gas Line

FLUIDLUBRICANT

Chassis lubricant meeting require-

ments

of NLGI Grade 2, Category

LB

or GC-LB (GM Part No.

12346003).

GM Optikleen’ Washer Solvent

(GM Part

No. 105 1 5 1 5) or equiva-

lent.

Chassis lubricant (GM Part

No.

12346003 or equivalent) or lubri-

cant meeting requirements

of NLGI

Grade 2, Category LB or GC-LB.

a. Engine oil.

b. Chassis lubricant (GM Part No.

12346003 or equivalent) or lubri-

cant meeting requirements

of NLGI

Grade 2, Category LB or GC-LB.

Engine oil or Lubriplate Lubricant

(GM Part

No. 1050109).

Engine Oil.

Multi-Purpose Lubricant (GM Part

No. 12345 120 or equivalent).

Dielectric Silicone Grease (GM

Part

No. 12345579 or equivalent).

Spray-A-Squeek (GM

Part No.

1 05 2277).

Gas Line De-Icer (GM Part No.

105 15 16).

Part E: Maintenance Record

After the scheduled services are performed, record the date, odometer

reading and who performed the service

in the boxes provided after the

maintenance interval. Any additional information from “Owner Checks and

Services” or “Periodic Maintenance” can be added on the following record

pages. Also, you should retain all maintenance receipts. Your owner

information portfolio

is a convenient place to store them.

7-100

ProCarManuals.com

Page 457 of 488

I Maintenance Record

7- 101

ProCarManuals.com

Page 458 of 488

TO001

7- 102

ProCarManuals.com

Page 459 of 488

Notes

7- 103

ProCarManuals.com

Page 460 of 488

Notes

7-104

ProCarManuals.com