wheel GMC SIERRA 1995 Repair Manual

[x] Cancel search | Manufacturer: GMC, Model Year: 1995, Model line: SIERRA, Model: GMC SIERRA 1995Pages: 488, PDF Size: 26.01 MB

Page 256 of 488

Changing the Tire

.

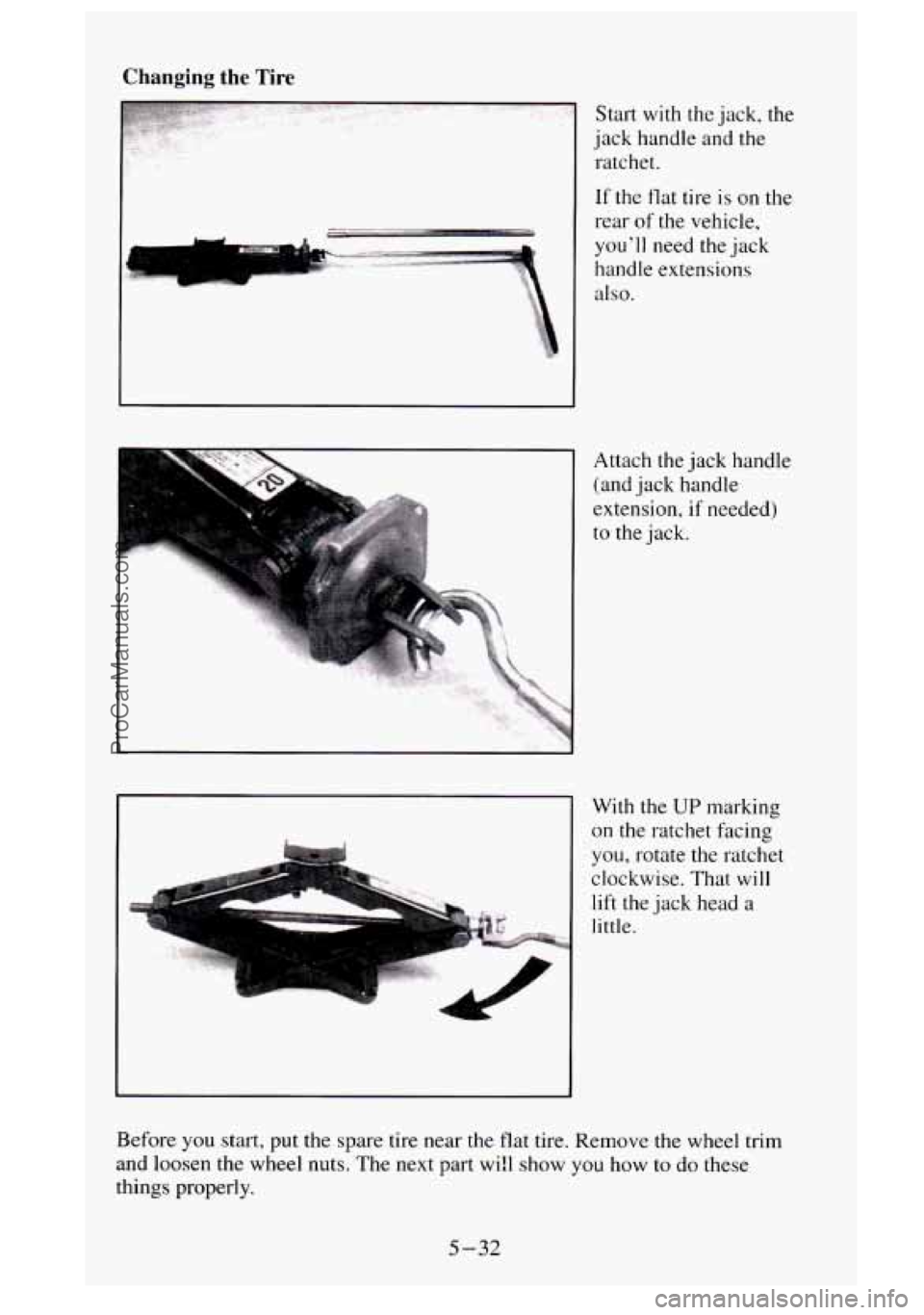

Start with the jack, the

jack handle and the

ratchet.

If

the flat tire is on the

rear of

the vehicle,

you’ll need the jack

handle extensions

also.

Attach the jack handle

(and jack handle

extension, if needed)

to the jack.

With the

Up marking

on the ratchet facing

you, rotate the ratchet

clockwise. That will

lift the jack head a

little.

Before

you start, put the spare tire near the flat tire. Remove the wheel trim

and loosen

the wheel nuts. The next part wi!l show you how to do these

things properly.

5-32

ProCarManuals.com

Page 257 of 488

Kemoving Wheel Trim

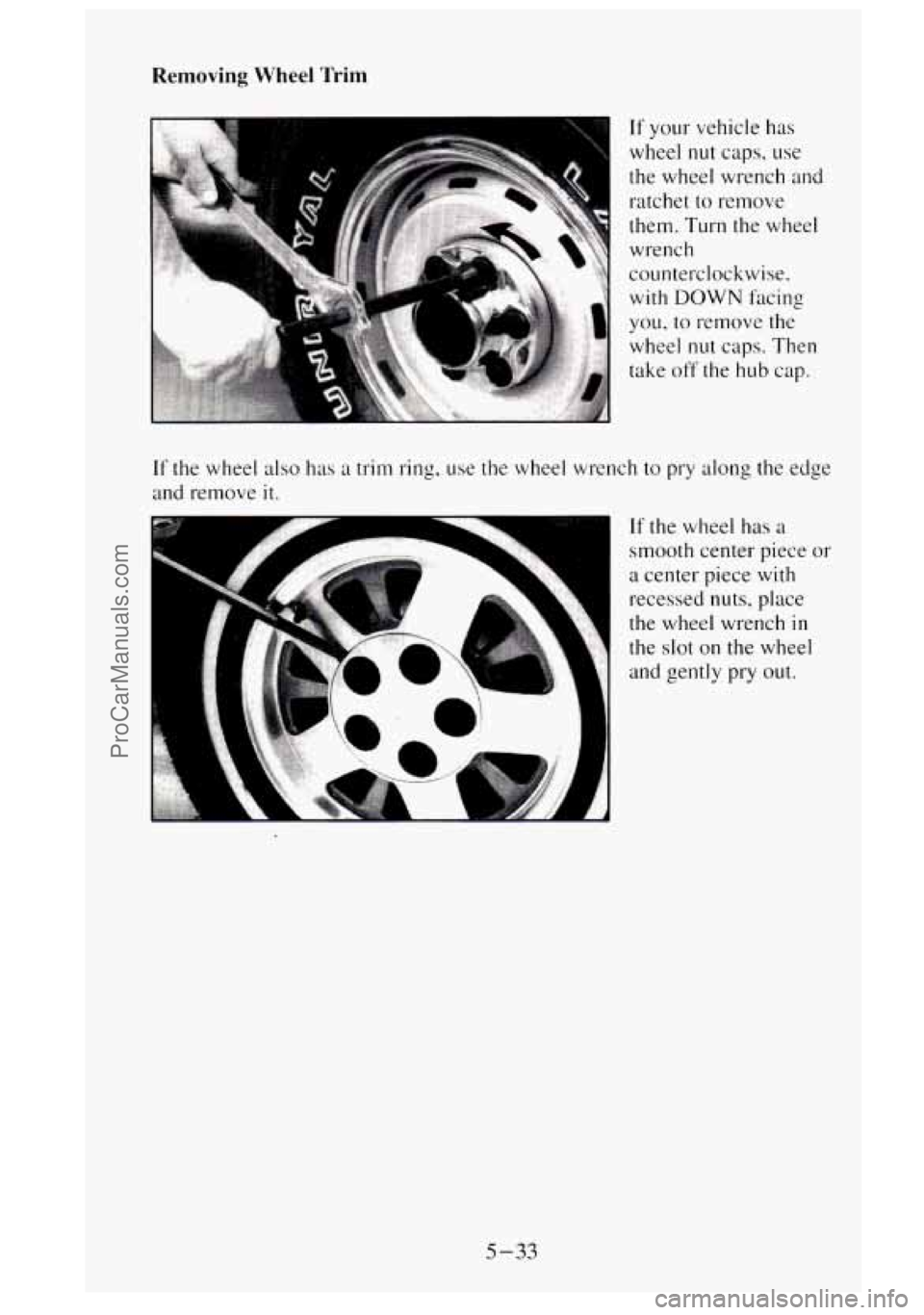

If your vehicle has

wheel

nut caps, use

the wheel wrench and

ratchet

to remove

them. Turn the wheel

wrench

counterclockwise.

with DOWN facing

you, to remove the

wheel

nut caps. Then

take off the hub cap.

If the wheel also has a trim ring. use the wheel wrench to pry along the edge

and remove

it.

If the wheel has a

smooth center piece or

a center piece with

recessed nuts, place

the wheel wrench

in

the slot on the wheel

and gently

pry out.

5-33

ProCarManuals.com

Page 258 of 488

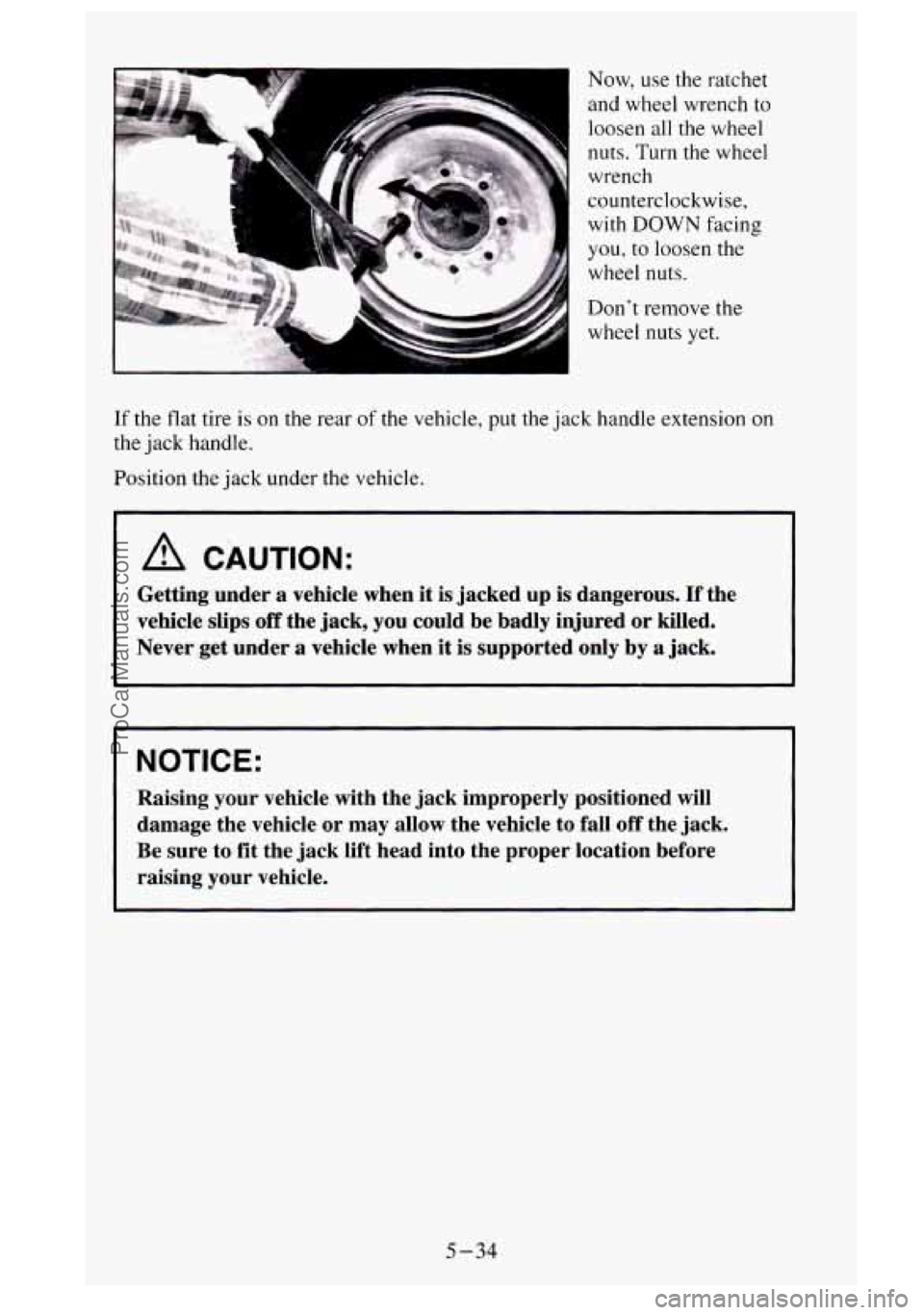

Now, use the ratchet

and wheel wrench to loosen all the wheel

nuts.

Turn the wheel

wrench

counterclockwise,

with DOWN facing

you, to loosen the

wheel nuts.

Don’t remove the

wheel nuts yet.

If the flat tire is on the rear of the vehicle, put the jack handle extension on

the jack handle.

Position the jack under the vehicle.

1 A CAUTION:

Getting under a vehicle when it is jacked up is dangerous. If the

vehicle slips

off the jack, you could be badly injured or killed.

Never get under a vehicle when

it is supported only by a jack.

NOTICE:

Raising your vehicle with the jack improperly positioned will

damage the vehicle or may allow the vehicle to fall

off the jack.

Be sure to

fit the jack lift head into the proper location before

raising your vehicle.

5-34

ProCarManuals.com

Page 259 of 488

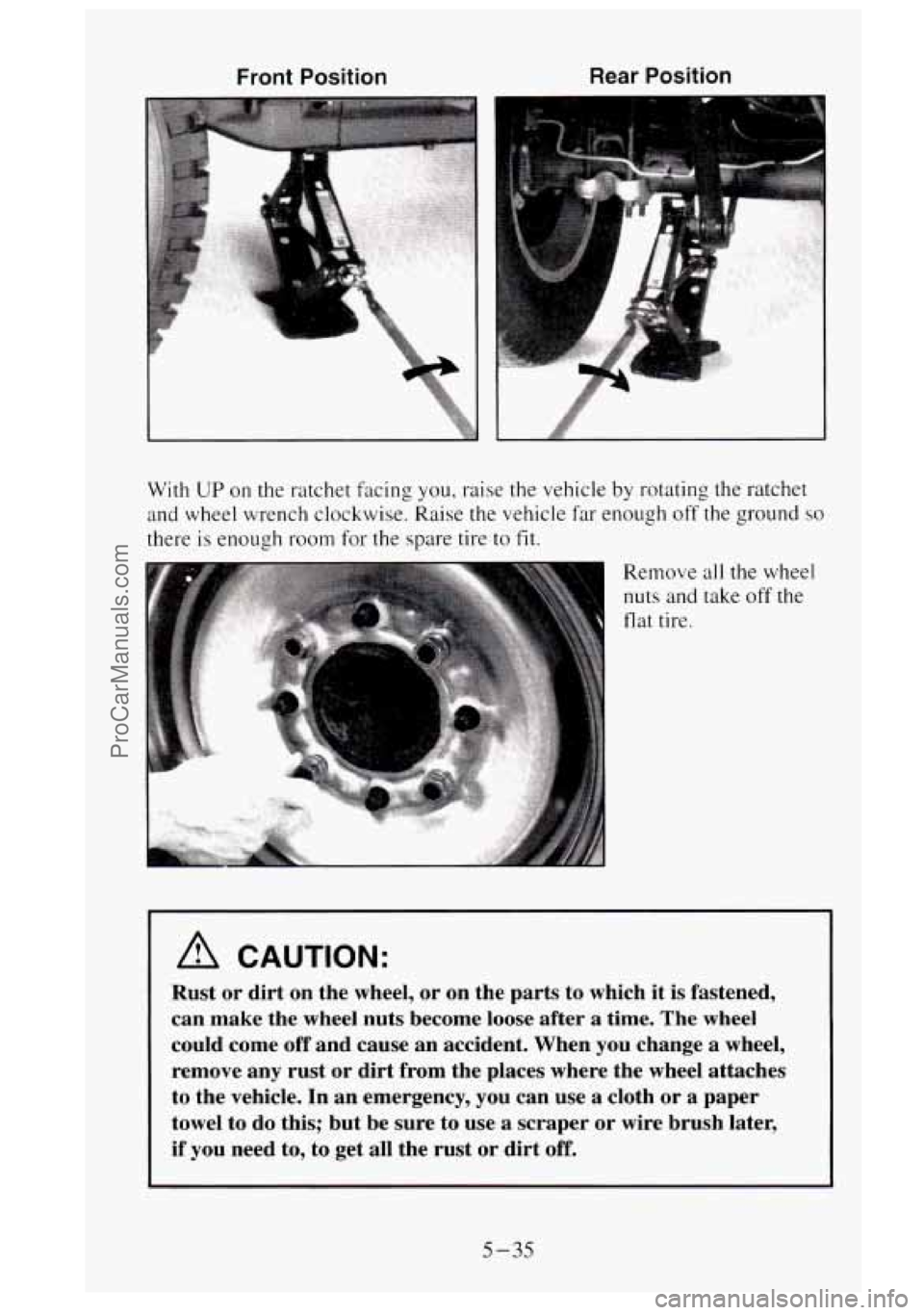

Front rosluon Rear Position

With UP on the ratchet facing you, raise the vehicle by rotating the ratchet

and wheel wrench clockwise. Raise the vehicle

far enough off the ground so

there is enough room for the spare tire to fit.

Remove

all the wheel

nuts and take

off the

flat tire,

A CAUTION:

Rust or dirt on the wheel, or on the parts to which it is fastened,

can make the wheel nuts become loose after a time. The wheel

could come

off and cause an accident. When you change a wheel,

remove any rust or dirt from the places where the wheel attaches

to the vehicle. In an emergency, you can use a cloth or a paper

towel

to do this; but be sure to use a scraper or wire brush later,

if you need to, to get all the rust or dirt off.

5-35

ProCarManuals.com

Page 260 of 488

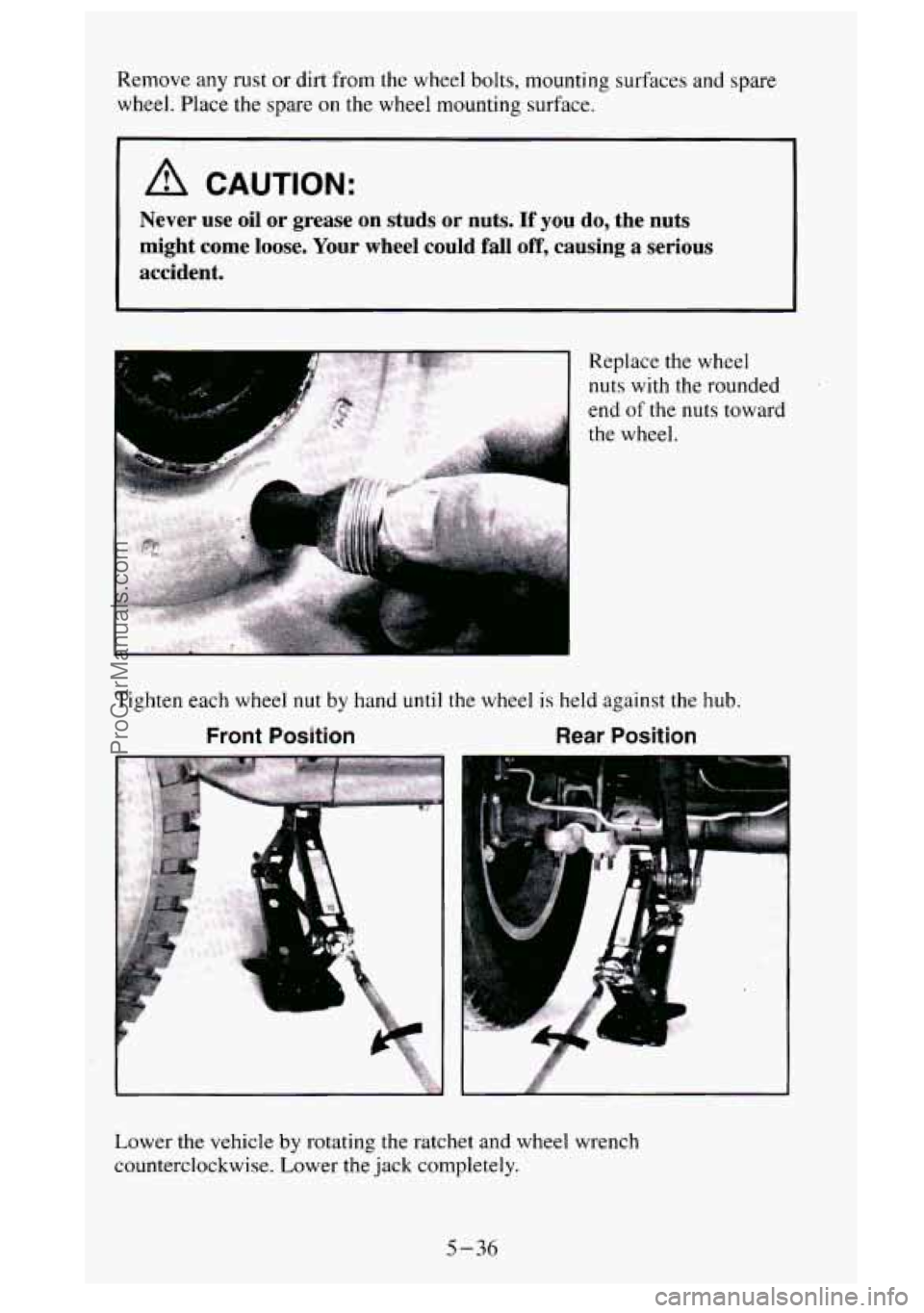

Remove any rust or dirt from the wheel bolts, mounting surfaces and spare

wheel. Place the spare

on the wheel mounting surface.

A CAUTION:

Never use oil or grease on studs or nuts. If you do, the nuts

might come loose. Your wheel could fall

off, causing a serious

accident.

Replace the wheel

nuts with the rounded

end

of the nuts toward

the wheel.

Tighten each wheel

nut by hand until the wheel is held against the hub.

Front Position Rear Position

Lower the vehicle by rotating the ratchet and wheel wrench

counterclockwise. Lower the jack completely.

5-36

ProCarManuals.com

Page 261 of 488

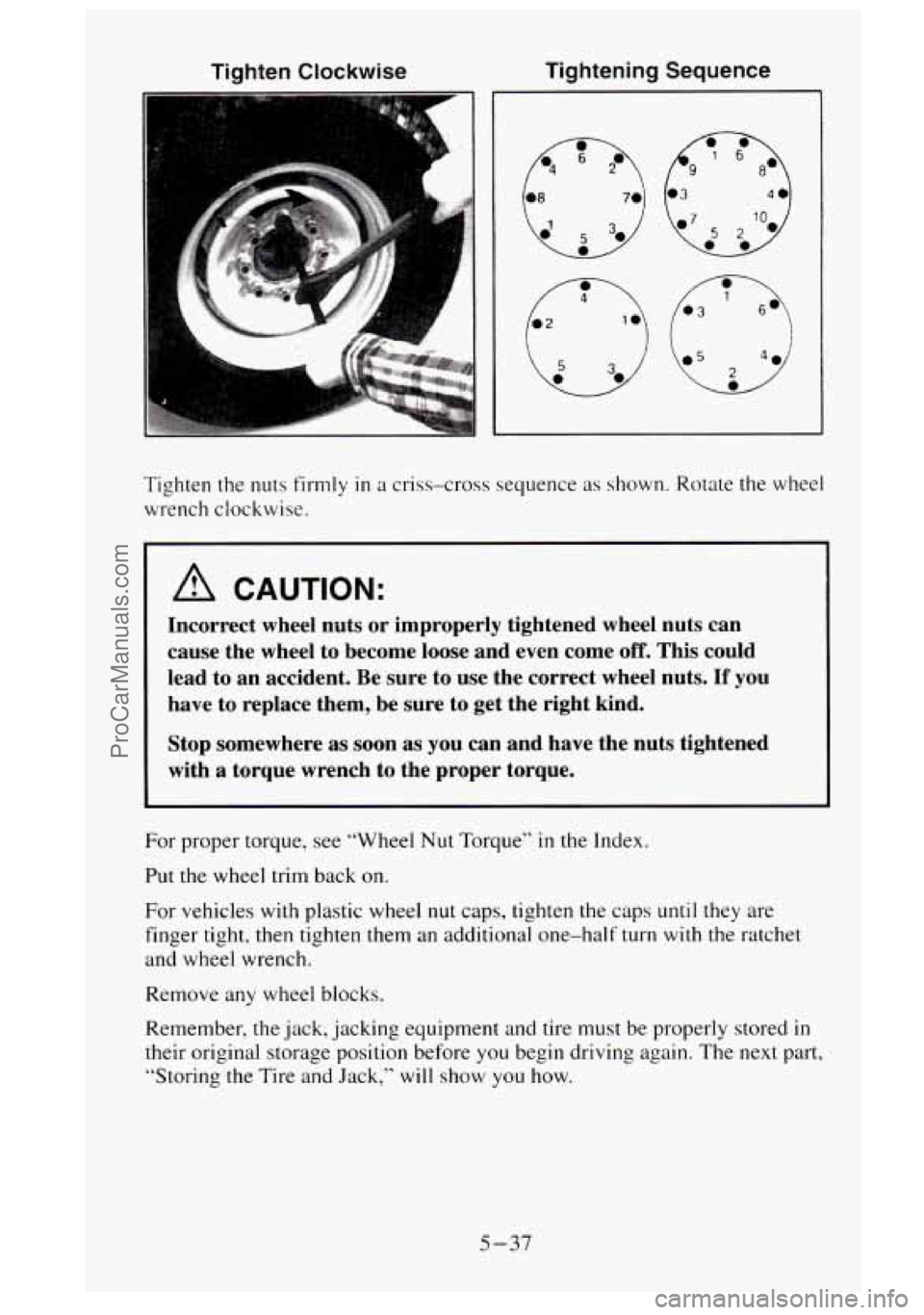

Tighten Clockwise Tightening Sequence

t

40

Tighten the

nuts firmly in a criss-cross sequence as shown. Rotate the wheel

wrench clockwise.

A CAUTION:

Incorrect wheel nuts or improperly tightened wheel nuts can

cause the wheel to become loose and even come

off. This could

lead to an accident. Be sure to use the correct wheel nuts.

If you

have to replace them, be sure to get the right kind.

Stop somewhere

as soon as you can and have the nuts tightened

with

a torque wrench to the proper torque.

For proper torque, see “Wheel Nut Torque” in the Index.

Put the wheel trim back on.

For vehicles with plastic wheel

nut caps, tighten the caps until they are

finger tight, then tighten them an additional one-half turn

with the ratchet

and wheel wrench.

Remove any wheel blocks.

Remember, the jack, jacking equipment and tire must be properly stored

in

their original storage position before you begin driving again. The next part,

“Storing the Tire and Jack,”

will show you how.

5-37

ProCarManuals.com

Page 262 of 488

I

A ,CAUTION:

Storing a jack, a tire or other equipment in the passenger

compartment

of the vehicle could cause injury. In a sudden stop

or collision, loose equipment could strike someone. Store all

these

in the proper place.

Stowing the

Tire - Under-Body Carrier

Stow the flat tire under the rwr of the vehicle in spare tire carrier. To stow

the flat tire:

1.

AI 3

3.

4.

5.

Put the tire on the ground at the rear of the vehicle with the valve stern

pointed down.

Pull the wheel retainer through thc wheel opening.

Attach the ratchet

to the urheel n'rench with the UP marking Facing

you.

Put the other end of the whcel wrench through the rcar bumper access

hole, located at the passenger side edge

of the license plate. Be sure the

wheel wrench connects into the hoist

shaft.

Turn the ratchet clockwise to raise the tire. Keep turning the ratchet

until the tire is all the way up. You will hear two "clicks" when the tire

is secure. Pull on the tire to nuke sure it is tightly secured.

Stowing the Jack and Jacking Tools

Return the jack, ratchet, wheel wrench and jack extensions to their location

behind the passenger's

seat. Stow thc jack and jacking tools as shown in the

illustrations earlier

in this part. Secure the items and replace the jack cover,

if there is one.

5-38

ProCarManuals.com

Page 263 of 488

If You’re Stuck: In Sand, Mud, Ice or Snow

What you don’t want to do when your vehicle is stuck is to spin your wheels

too fast. The method known as ”rocking” can help you get out when you’re

stuck, but you nlust use caution.

A CAUTION:

If you let your tires spin at high speed, they can explode and you

or others could be injured. And, the transmission or other par\

ts

of the vehicle can overheat. That could cause an engine

compartment fire or other damage. When you’re stuck, spin th\

e wheels

as little as possible. Don’t spin the wheels above 35 mph

(55 km/h) as shown on the speedometer.

I NOTICE:

Spinning your wheels can destroy parts of your vehicle as well as

the tires. If you spin the wheels too fast while shifting your

transmission back and forth, you can destroy your transmission.

For information about using tire chains on your vehicle, see “Tire Chains”

in the Index.

Rocking

your vehicle to get it out:

First. turn your steering wheel left and right. That will clear the area around

your front wheels. Then shift back and forth between REVERSE

(R) and a

forward gear (or

with a manual transmission, between FIRST (1 ) or

SECOND (2) gear and REVERSE), spinning the wheels as little as possible.

Release

the accelerator pedal while you shift, and press lightly on the

accelerator pedal when the transmission

is in gear. If that doesn’t get you

out after a few tries, you may need

to be towed out. Or, you can use your

recovery hooks,

if your vehicle has them. If you do need to be towed out.

see “Towing Your Vehicle”

in the Index.

5-39

ProCarManuals.com

Page 299 of 488

What to Use

Refer to the Maintenance Schedule to determine what kind of lubricant to

use. See “Recommended Fluids and Lubricants”

in the Index.

C3 (3500 H.D.) Trucks Equipped with Dana Rear Axle

Additional rear axle scheduled maintenance is required on 3500 H.D.

models equipped with Dana rear axles when they are driven under the

following conditions:

0 Extreme loading (at or near GVWR) or trailer towing, and:

Operation above 45 mph for extended periods of time

Vehicles used

in any of these conditions require the rear axle lubricant (SAE

8OW-90 - GL-5) be changed every 3 months or 3,000 miles, whichever

comes first.

To reduce required maintenance, SAE 75W-140 synthetic gear lubricant

may be used. With the use of synthetic

SAE 75W-140 lubricant, the fluid

change intervals may be increased to 30,000 miles. Before using SAE

75W-140, it is important to drain and flush the axle with clean mineral

based (non-synthetic) axle lubricant. Fluid capacity is 4.12 qts. (3.9L).

Four- Wheel Drive

Most lubricant checks in this section also apply to four-wheel-drive

vehicles. However, they have two additional systems that need lubrication.

Transfer Case

When to Check Lubricant

Refer to the Maintenance Schedule to determine how often to check the

lubricant. See “Periodic Maintenance Inspections”

in the Index.

6-33

ProCarManuals.com

Page 310 of 488

Brake Wear

Your vehicle has front disc brakes and rear drum brakes. If you have a C

3500 HD model, it has four-wheel disc brakes.

Disc brake pads have built-in wear indicators that make

a high-pitched

warning sound when the brake pads are worn and new pads are needed. The

sound may come and

go or be heard all the time your vehicle is moving

(except when you are pushing on the brake pedal firmly).

I A CAUTION:

The brake wear warning sound means that sooner or later your

brakes won’t work well. That could lead to an accident. Whe\

n

you hear the brake wear warning sound, have your vehicle

serviced.

NOTICE:

Continuing to drive with worn-out brake pads could result in

costly brake repair.

Some driving conditions or climates may cause a brake squeal when the

brakes are first applied or lightly applied. This does not mean something is

wrong with your brakes.

If you have rear drum brakes, they don’t have wear indicators, but if you

ever hear

a rear brake rubbing noise, have the rear brake linings inspected.

Also, the rear brake drum should be removed and inspected each time the

tires are removed for rotation

or changing. When you have the front brakes

replaced, have the rear brakes inspected, too.

Brake linings should always be replaced as complete axle sets.

Brake Pedal Travel

See your dealer if the brake pedal does not return to normal height, or if

there is a rapid increase in pedal travel. This could be a sign of brake

trouble.

6-44

ProCarManuals.com