height adjustment GMC SIERRA 2008 Owner's Manual

[x] Cancel search | Manufacturer: GMC, Model Year: 2008, Model line: SIERRA, Model: GMC SIERRA 2008Pages: 578, PDF Size: 6.47 MB

Page 32 of 578

Lap-Shoulder Belt

All seating positions in your vehicle have a lap-shoulder

belt except for the center front passenger position (if

equipped) if your vehicle is a crew or extended

cab, which has a lap belt. SeeLap Belt (Crew and

Extended Cab) on page 1-34for more information.

Here is how to wear a lap-shoulder belt properly.

1. Adjust the seat, if the seat is adjustable, so you can

sit up straight. To see how, see “Seats” in the Index.

2. Pick up the latch plate and pull the belt across you.

Do not let it get twisted.

The lap-shoulder belt may lock if you pull the belt

across you very quickly. If this happens, let the belt

go back slightly to unlock it. Then pull the belt

across you more slowly.

If you ever pull the shoulder portion of a passenger

belt out all the way, you may engage the child

restraint locking feature. If this happens, just let the

belt go back all the way and start again.

Engaging the child restraint locking feature may

affect the passenger sensing system. See

Passenger Sensing System on page 1-80.3. Push the latch plate into the buckle until it clicks.

Pull up on the latch plate to make sure it is secure.

If the belt is not long enough, seeSafety Belt

Extender on page 1-35.

Make sure the release button on the buckle is

positioned so you would be able to unbuckle the

safety belt quickly if necessary.

4. If equipped with a shoulder belt height adjuster,

move it to the height that is right for you. Improper

shoulder belt height adjustment could reduce

the effectiveness of the safety belt in a crash. See

“Shoulder Belt Height Adjustment” later in this

section.

1-28

Page 34 of 578

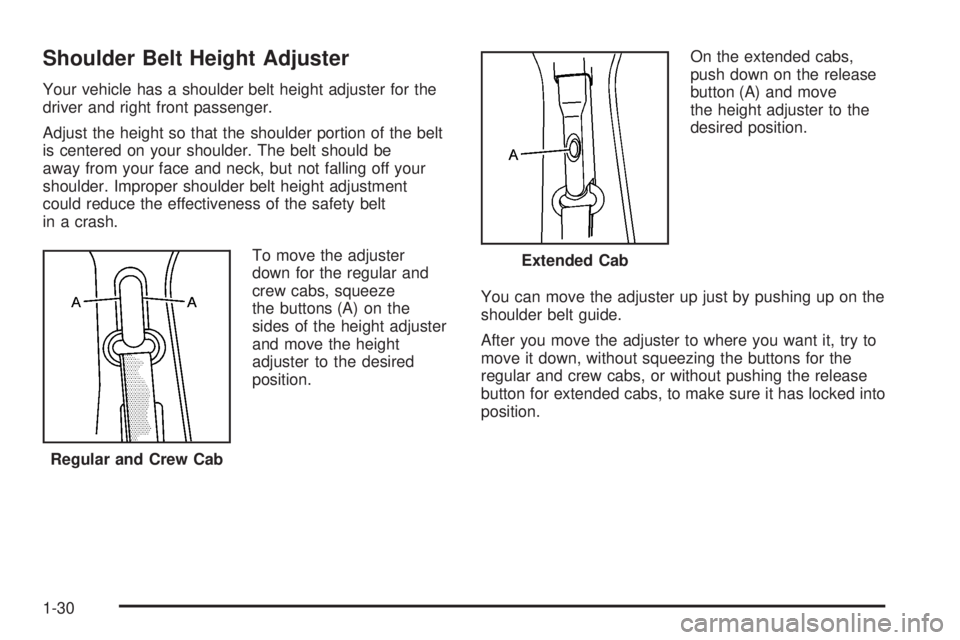

Shoulder Belt Height Adjuster

Your vehicle has a shoulder belt height adjuster for the

driver and right front passenger.

Adjust the height so that the shoulder portion of the belt

is centered on your shoulder. The belt should be

away from your face and neck, but not falling off your

shoulder. Improper shoulder belt height adjustment

could reduce the effectiveness of the safety belt

in a crash.

To move the adjuster

down for the regular and

crew cabs, squeeze

the buttons (A) on the

sides of the height adjuster

and move the height

adjuster to the desired

position.On the extended cabs,

push down on the release

button (A) and move

the height adjuster to the

desired position.

You can move the adjuster up just by pushing up on the

shoulder belt guide.

After you move the adjuster to where you want it, try to

move it down, without squeezing the buttons for the

regular and crew cabs, or without pushing the release

button for extended cabs, to make sure it has locked into

position.

Regular and Crew Cab

Extended Cab

1-30

Page 436 of 578

Brake Wear

Your vehicle has front disc brakes and could have rear

drum brakes or rear disc brakes.

Disc brake pads have built-in wear indicators that make

a high-pitched warning sound when the brake pads

are worn and new pads are needed. The sound can

come and go or be heard all the time your vehicle is

moving, except when you are pushing on the brake

pedal �rmly.

{CAUTION:

The brake wear warning sound means that

soon the brakes will not work well. That could

lead to an accident. When you hear the brake

wear warning sound, have your vehicle

serviced.

Notice:Continuing to drive with worn-out brake

pads could result in costly brake repair.

Some driving conditions or climates can cause a brake

squeal when the brakes are �rst applied or lightly

applied. This does not mean something is wrong with

the brakes.Properly torqued wheel nuts are necessary to help

prevent brake pulsation. When tires are rotated, inspect

brake pads for wear and evenly tighten wheel nuts in

the proper sequence to torque speci�cations in

Capacities and Specifications on page 5-130.

If you have rear drum brakes, they do not have wear

indicators, but if you ever hear a rear brake rubbing

noise, have the rear brake linings inspected immediately.

Rear brake drums should be removed and inspected

each time the tires are removed for rotation or changing.

Drum brakes have an inspection hole to inspect lining

wear during scheduled maintenance. When you have

the front brake pads replaced, have the rear brakes

inspected, too.

Brake linings should always be replaced as complete

axle sets.

Brake Pedal Travel

See your dealer/retailer if the brake pedal does not

return to normal height, or if there is a rapid increase in

pedal travel. This could be a sign that brake service

might be required.

Brake Adjustment

Every time you make a brake stop, the brakes adjust

for wear.

5-44

Page 450 of 578

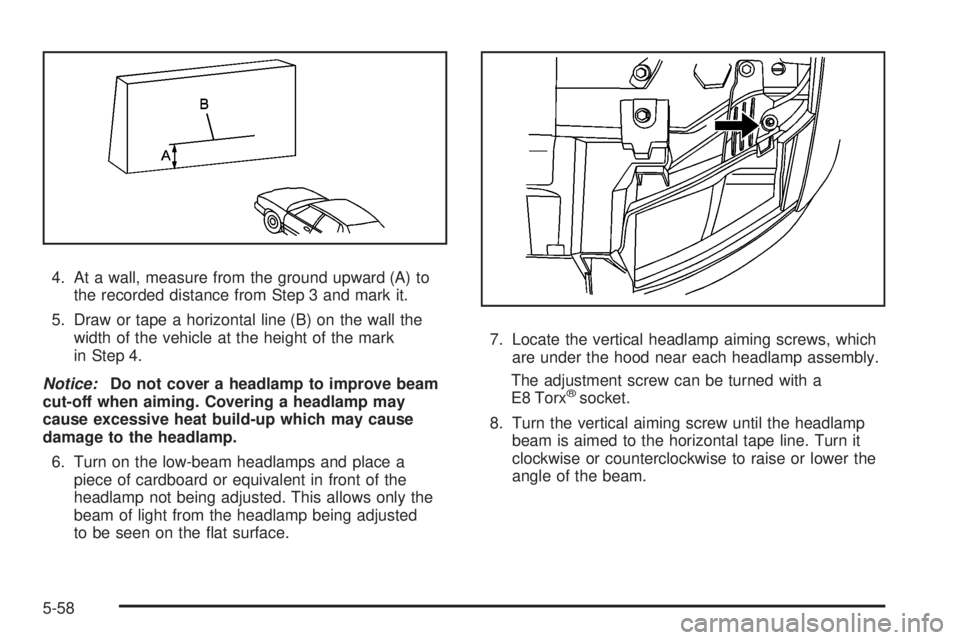

4. At a wall, measure from the ground upward (A) to

the recorded distance from Step 3 and mark it.

5. Draw or tape a horizontal line (B) on the wall the

width of the vehicle at the height of the mark

in Step 4.

Notice:Do not cover a headlamp to improve beam

cut-off when aiming. Covering a headlamp may

cause excessive heat build-up which may cause

damage to the headlamp.

6. Turn on the low-beam headlamps and place a

piece of cardboard or equivalent in front of the

headlamp not being adjusted. This allows only the

beam of light from the headlamp being adjusted

to be seen on the �at surface.7. Locate the vertical headlamp aiming screws, which

are under the hood near each headlamp assembly.

The adjustment screw can be turned with a

E8 Torx

®socket.

8. Turn the vertical aiming screw until the headlamp

beam is aimed to the horizontal tape line. Turn it

clockwise or counterclockwise to raise or lower the

angle of the beam.

5-58