lock GMC SIERRA 2010 Owner's Manual

[x] Cancel search | Manufacturer: GMC, Model Year: 2010, Model line: SIERRA, Model: GMC SIERRA 2010Pages: 630, PDF Size: 4.65 MB

Page 567 of 630

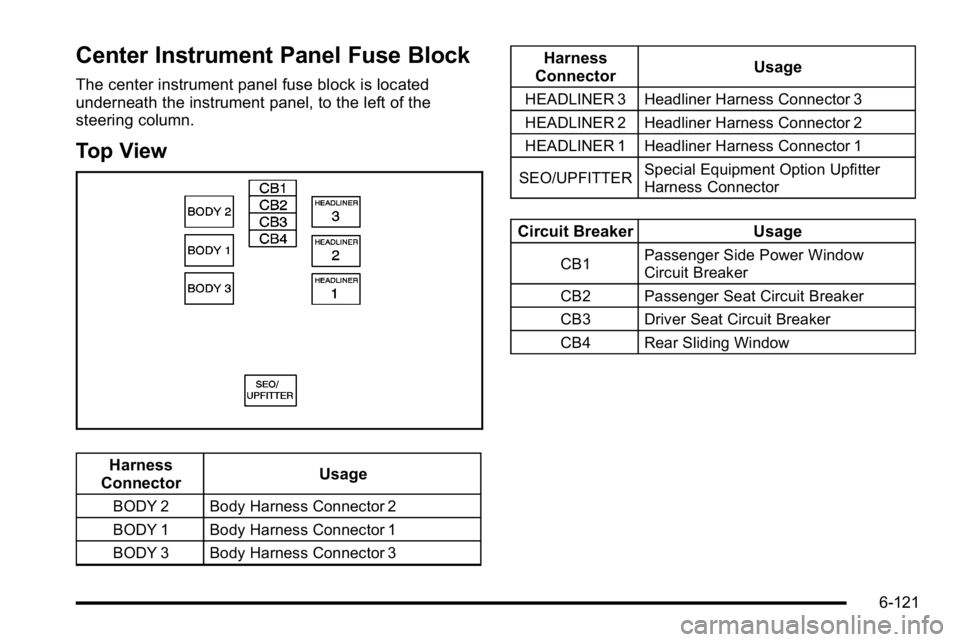

Center Instrument Panel Fuse Block

The center instrument panel fuse block is located

underneath the instrument panel, to the left of the

steering column.

Top View

Harness

Connector Usage

BODY 2 Body Harness Connector 2

BODY 1 Body Harness Connector 1

BODY 3 Body Harness Connector 3

Harness

Connector Usage

HEADLINER 3 Headliner Harness Connector 3

HEADLINER 2 Headliner Harness Connector 2

HEADLINER 1 Headliner Harness Connector 1

SEO/UPFITTER Special Equipment Option Upfitter

Harness Connector

Circuit Breaker

Usage

CB1Passenger Side Power Window

Circuit Breaker

CB2 Passenger Seat Circuit Breaker

CB3 Driver Seat Circuit Breaker

CB4 Rear Sliding Window

6-121

Page 568 of 630

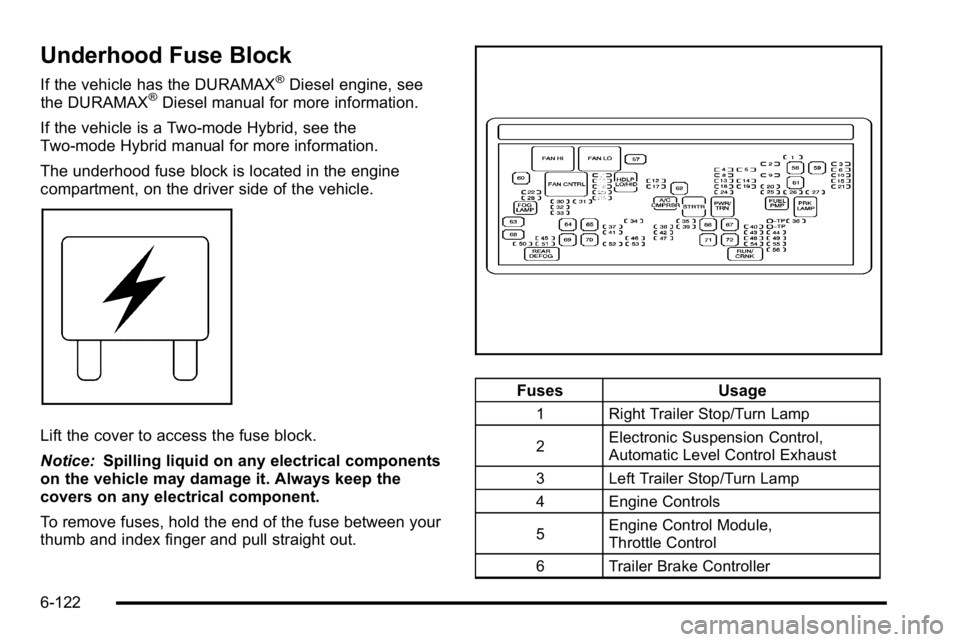

Underhood Fuse Block

If the vehicle has the DURAMAX®Diesel engine, see

the DURAMAX®Diesel manual for more information.

If the vehicle is a Two-mode Hybrid, see the

Two-mode Hybrid manual for more information.

The underhood fuse block is located in the engine

compartment, on the driver side of the vehicle.

Lift the cover to access the fuse block.

Notice: Spilling liquid on any electrical components

on the vehicle may damage it. Always keep the

covers on any electrical component.

To remove fuses, hold the end of the fuse between your

thumb and index finger and pull straight out.

Fuses Usage

1 Right Trailer Stop/Turn Lamp

2Electronic Suspension Control,

Automatic Level Control Exhaust

3 Left Trailer Stop/Turn Lamp

4 Engine Controls

5 Engine Control Module,

Throttle Control

6 Trailer Brake Controller

6-122

Page 569 of 630

FusesUsage

7 Front Washer

8 Oxygen Sensor

9 Antilock Brakes System 2

10 Trailer Back-up Lamps 11 Driver Side Low-Beam Headlamp

12 Engine Control Module (Battery)

13 Fuel Injectors, Ignition

Coils (Right Side)

14 Transmission Control

Module (Battery)

15 Vehicle Back-up Lamps

16 Passenger Side Low-Beam Headlamp

17 Air Conditioning Compressor

18 Oxygen Sensors

19 Transmission Controls (Ignition)

20 Fuel Pump

21 Fuel System Control Module

22 Not Used

Fuses Usage

23 Not Used

24Fuel Injectors, Ignition

Coils (Left Side)

25 Trailer Park Lamps

26 Driver Side Park Lamps

27 Passenger Side Park Lamps

28 Fog Lamps

29 Horn

30 Passenger Side High-Beam

Headlamp

31 Daytime Running Lamps (DRL)

32 Driver Side High-Beam Headlamp

33 Daytime Running Lights 2

34 Sunroof

35 Key Ignition System, Theft

Deterrent System

36 Windshield Wiper

37 SEO B2 Upfitter Usage (Battery)

6-123

Page 570 of 630

FusesUsage

38 Electric Adjustable Pedals

39 Climate Controls (Battery)

40 Airbag System (Ignition)

41 Amplifier

42 Audio System

43Miscellaneous (Ignition), Cruise

Control

44 Not Used

45 Airbag System (Battery)

46 Instrument Panel Cluster

47 Power Take-Off

48 Auxiliary Climate Control (Ignition)

49 Center High-Mounted

Stoplamp (CHMSL)

50 Rear Defogger

Fuses Usage

51 Heated Mirrors

52 SEO B1 Upfitter Usage (Battery)

53Cigarette Lighter, Auxiliary

Power Outlet

54 SEO Upfitter Usage

55 Climate Controls (Ignition)

56 Engine Control Module, Secondary

Fuel Pump (Ignition)

J-Case Fuses

Usage

57 Cooling Fan 1

58 Not Used

59 Heavy Duty Antilock Brake System

60 Cooling Fan 2

61 Antilock Brake System 1

6-124

Page 574 of 630

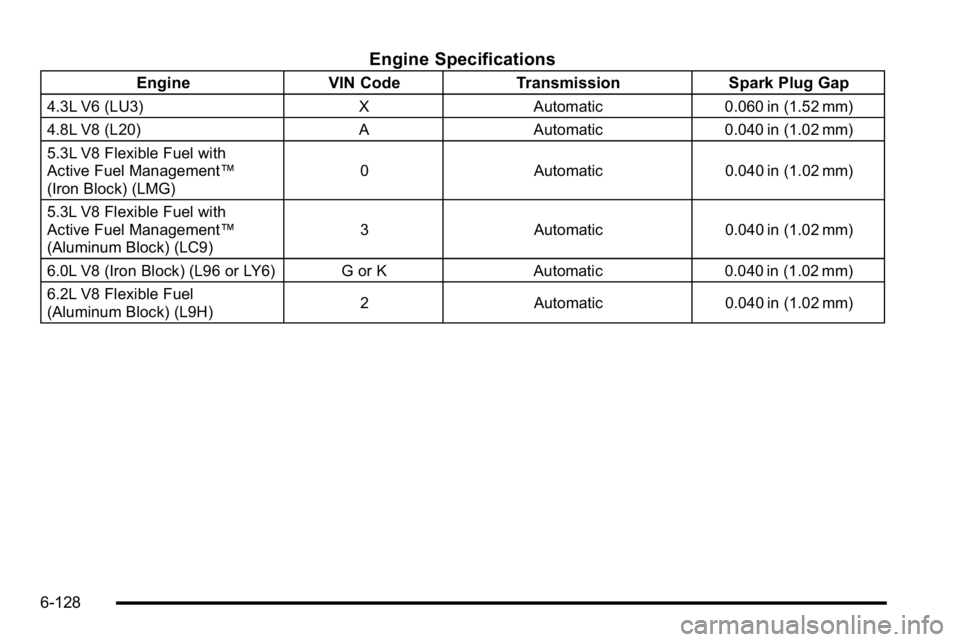

Engine Specifications

EngineVIN CodeTransmission Spark Plug Gap

4.3L V6 (LU3) XAutomatic 0.060 in (1.52 mm)

4.8L V8 (L20) AAutomatic 0.040 in (1.02 mm)

5.3L V8 Flexible Fuel with

Active Fuel Management™

(Iron Block) (LMG) 0

Automatic 0.040 in (1.02 mm)

5.3L V8 Flexible Fuel with

Active Fuel Management™

(Aluminum Block) (LC9) 3

Automatic 0.040 in (1.02 mm)

6.0L V8 (Iron Block) (L96 or LY6) G or K Automatic0.040 in (1.02 mm)

6.2L V8 Flexible Fuel

(Aluminum Block) (L9H) 2

Automatic 0.040 in (1.02 mm)

6-128

Page 579 of 630

.Engine cooling system inspection. Visual

inspection of hoses, pipes, fittings, and clamps and

replacement, if needed.

.Windshield wiper blade inspection for wear,

cracking, or contamination and windshield and

wiper blade cleaning, if contaminated. See

Windshield and Wiper Blades

on page 6‑114.

Worn or damaged wiper blade replacement.

See Windshield Wiper Blade Replacement

on

page 6‑63.

.Body hinges and latches, key lock cylinders,

folding seat hardware, and tailgate hinges,

linkage, and handle pivot points lubrication.

See Recommended Fluids and Lubricants

on

page 7‑12. More frequent lubrication may be

required when vehicle is exposed to a corrosive

environment. Applying silicone grease on

weatherstrips with a clean cloth makes them last

longer, seal better, and not stick or squeak.

.Restraint system component check. See Checking

the Restraint Systems on page 2‑93.

.Automatic transmission fluid level check and

adding fluid, if needed. See Automatic

Transmission Fluid (4-Speed Transmission)

on

page 6‑23or Automatic Transmission Fluid

(6-Speed Transmission) on page 6‑26.

.Four‐wheel drive vehicles: Transfer case fluid level

check and adding fluid, if needed.

.Engine air cleaner filter inspection. See Engine Air

Cleaner/Filter on page 6‑21.

.Vehicles with diesel engine or GVWR above

4 536 kg (10,000 lbs) only: Shields inspection for

damage or looseness. Adjust or replace as

required. This is a Noise Emission Control Service.

Applicable to vehicles sold in the United States

and recommended for vehicles sold in Canada.

Additional Required Services

At the First 160 km/100 Miles, 1 600 km/

1,000 Miles, and 10 000 km/6,000 Miles

.For vehicles with dual wheels: Check dual wheel

nut torque. For proper torque, see Capacities and

Specifications on page 6‑126.

At Each Fuel Stop

.Engine oil level check. See Engine Oilon

page 6‑18.

.Engine coolant level check. See Engine Coolanton page 6‑31.

.Windshield washer fluid level check. See

Windshield Washer Fluid on page 6‑38.

7-5

Page 580 of 630

Once a Month

.Tire inflation check. SeeInflation - Tire Pressureon page 6‑72.

.Tire wear inspection. See Tire Inspection and

Rotation on page 6‑80.

Once a Year

.Starter switch check. See Owner Checks and

Services on page 7‑11.

.Parking brake and automatic transmission P (Park)

mechanism check. See Owner Checks and

Services on page 7‑11.

.Automatic transmission shiftlock control system

check. See Owner Checks and Serviceson

page 7‑11.

.Ignition transmission lock check. See Owner

Checks and Services on page 7‑11.

.Engine cooling system and pressure cap pressure

check. Radiator and air conditioning condenser

outside cleaning. See Cooling System

on

page 6‑30.

.Exhaust system and nearby heat shields

inspection for loose or damaged components.

.Accelerator pedal check for damage, high effort,

or binding. Replace if needed.

First Engine Oil Change After Every

40 000 km/25,000 Miles

.Fuel system inspection for damage or leaks.

.Four‐wheel drive only: Transfer case fluid change

(extreme duty service) for vehicles mainly driven

off‐road in four‐wheel drive. Vehicles used for

farming, mining, forestry, Department of Natural

Resources (DNR), and snow plowing occupations

meet this definition. Check vent hose at transfer

case for kinks and proper installation. Check to be

sure vent hose is unobstructed, clear, and free of

debris. During any maintenance, if a power washer

is used to clean mud and dirt from the underbody,

care should be taken to not directly spray the

transfer case output seals. High pressure water

can overcome the seals and contaminate the

transfer case fluid. Contaminated fluid will

decrease the life of the transfer case and should

be replaced.

7-6

Page 585 of 630

Owner Checks and Services

Starter Switch Check

{WARNING:

When you are doing this inspection, the vehicle

could move suddenly. If the vehicle moves, you or

others could be injured.

1. Before starting this check, be sure there is enough room around the vehicle.

2. Firmly apply both the parking brake and the regular brake. See Parking Brake on page 3‑50.

Do not use the accelerator pedal, and be ready to

turn off the engine immediately if it starts.

3. Try to start the engine in each gear. The vehicle should start only in P (Park) or N (Neutral). If the

vehicle starts in any other position, contact your

dealer/retailer for service.

Automatic Transmission Shift Lock

Control System Check

{WARNING:

When you are doing this inspection, the vehicle

could move suddenly. If the vehicle moves, you or

others could be injured.

1. Before starting this check, be sure there is enough room around the vehicle. It should be parked on a

level surface.

2. Firmly apply the parking brake. See Parking Brake

on page 3‑50.

Be ready to apply the regular brake immediately if

the vehicle begins to move.

3. With the engine off, turn the ignition to ON/RUN, but do not start the engine. Without applying the

regular brake, try to move the shift lever out of

P (Park) with normal effort. If the shift lever moves

out of P (Park), contact your dealer/retailer for

service.

7-11

Page 586 of 630

Ignition Transmission Lock Check

While parked, and with the parking brake set, try to turn

the ignition to LOCK/OFF in each shift lever position.

.The ignition should turn to LOCK/OFF only when

the shift lever is in P (Park).

.The ignition key should come out only in

LOCK/OFF.

Contact your dealer/retailer if service is required.

Parking Brake and Automatic

Transmission P (Park) Mechanism

Check

{WARNING:

When you are doing this check, the vehicle could

begin to move. You or others could be injured and

property could be damaged. Make sure there is

room in front of the vehicle in case it begins to

roll. Be ready to apply the regular brake at once

should the vehicle begin to move. Park on a fairly steep hill, with the vehicle facing

downhill. Keeping your foot on the regular brake,

set the parking brake.

.To check the parking brake's holding ability: With

the engine running and the transmission in

N (Neutral), slowly remove foot pressure from the

regular brake pedal. Do this until the vehicle is held

by the parking brake only.

.To check the P (Park) mechanism's holding ability:

With the engine running, shift to P (Park). Then

release the parking brake followed by the regular

brake.

Contact your dealer/retailer if service is required.

Recommended Fluids and

Lubricants

This maintenance section applies to vehicles with a

gasoline engine. If the vehicle has a diesel engine

and/or an Allison Transmission, see the maintenance

schedule section in the DURAMAX

®Diesel manual.

Fluids and lubricants identified below by name, part

number, or specification can be obtained from your

dealer/retailer.

7-12

Page 587 of 630

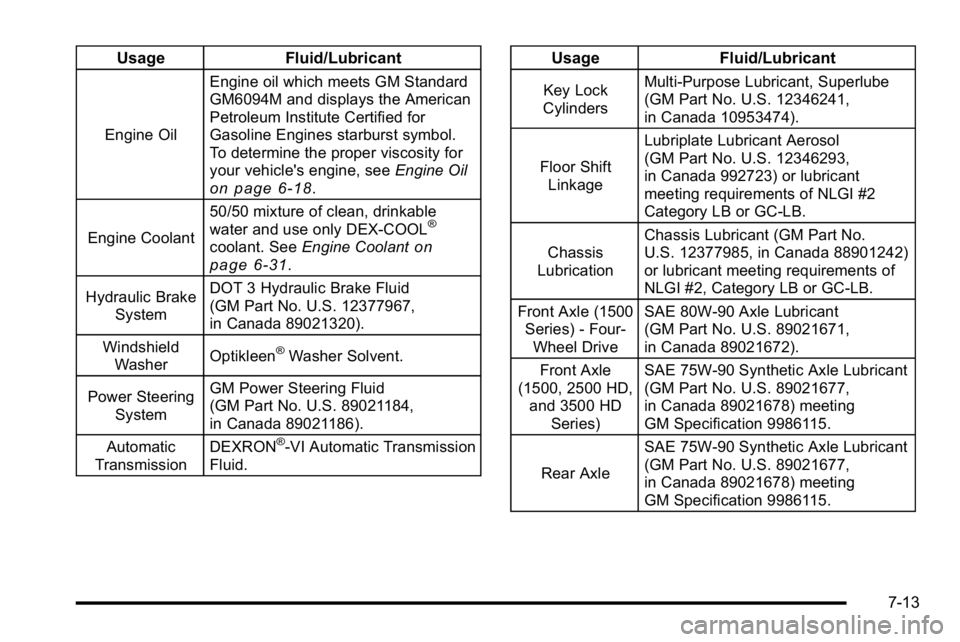

UsageFluid/Lubricant

Engine OilEngine oil which meets GM Standard

GM6094M and displays the American

Petroleum Institute Certified for

Gasoline Engines starburst symbol.

To determine the proper viscosity for

your vehicle's engine, see

Engine Oil

on page 6‑18.

Engine Coolant 50/50 mixture of clean, drinkable

water and use only DEX-COOL

®

coolant. See

Engine Coolanton

page 6‑31.

Hydraulic Brake System DOT 3 Hydraulic Brake Fluid

(GM Part No. U.S. 12377967,

in Canada 89021320).

Windshield Washer Optikleen

®Washer Solvent.

Power Steering System GM Power Steering Fluid

(GM Part No. U.S. 89021184,

in Canada 89021186).

Automatic

Transmission DEXRON

®-VI Automatic Transmission

Fluid.

Usage Fluid/Lubricant

Key Lock

Cylinders Multi-Purpose Lubricant, Superlube

(GM Part No. U.S. 12346241,

in Canada 10953474).

Floor Shift Linkage Lubriplate Lubricant Aerosol

(GM Part No. U.S. 12346293,

in Canada 992723) or lubricant

meeting requirements of NLGI #2

Category LB or GC-LB.

Chassis

Lubrication Chassis Lubricant (GM Part No.

U.S. 12377985, in Canada 88901242)

or lubricant meeting requirements of

NLGI #2, Category LB or GC-LB.

Front Axle (1500 Series) ‐Four‐

Wheel Drive SAE 80W-90 Axle Lubricant

(GM Part No. U.S. 89021671,

in Canada 89021672).

Front Axle

(1500, 2500 HD, and 3500 HD Series) SAE 75W-90 Synthetic Axle Lubricant

(GM Part No. U.S. 89021677,

in Canada 89021678) meeting

GM Specification 9986115.

Rear Axle SAE 75W-90 Synthetic Axle Lubricant

(GM Part No. U.S. 89021677,

in Canada 89021678) meeting

GM Specification 9986115.

7-13