clock GMC SIERRA 2010 Owner's Guide

[x] Cancel search | Manufacturer: GMC, Model Year: 2010, Model line: SIERRA, Model: GMC SIERRA 2010Pages: 630, PDF Size: 4.65 MB

Page 458 of 630

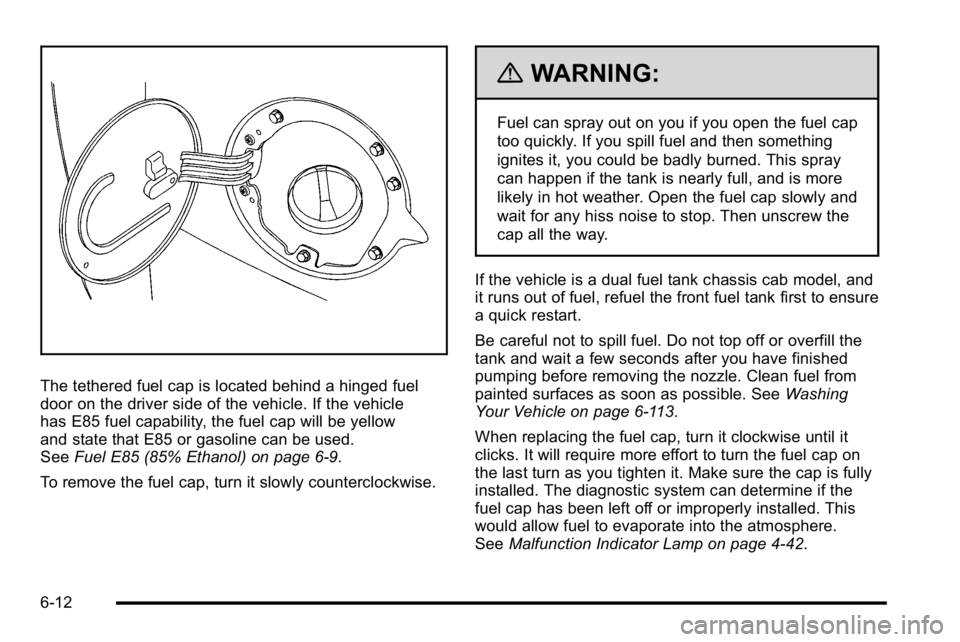

The tethered fuel cap is located behind a hinged fuel

door on the driver side of the vehicle. If the vehicle

has E85 fuel capability, the fuel cap will be yellow

and state that E85 or gasoline can be used.

SeeFuel E85 (85% Ethanol) on page 6‑9.

To remove the fuel cap, turn it slowly counterclockwise.

{WARNING:

Fuel can spray out on you if you open the fuel cap

too quickly. If you spill fuel and then something

ignites it, you could be badly burned. This spray

can happen if the tank is nearly full, and is more

likely in hot weather. Open the fuel cap slowly and

wait for any hiss noise to stop. Then unscrew the

cap all the way.

If the vehicle is a dual fuel tank chassis cab model, and

it runs out of fuel, refuel the front fuel tank first to ensure

a quick restart.

Be careful not to spill fuel. Do not top off or overfill the

tank and wait a few seconds after you have finished

pumping before removing the nozzle. Clean fuel from

painted surfaces as soon as possible. See Washing

Your Vehicle on page 6‑113.

When replacing the fuel cap, turn it clockwise until it

clicks. It will require more effort to turn the fuel cap on

the last turn as you tighten it. Make sure the cap is fully

installed. The diagnostic system can determine if the

fuel cap has been left off or improperly installed. This

would allow fuel to evaporate into the atmosphere.

See Malfunction Indicator Lamp on page 4‑42.

6-12

Page 480 of 630

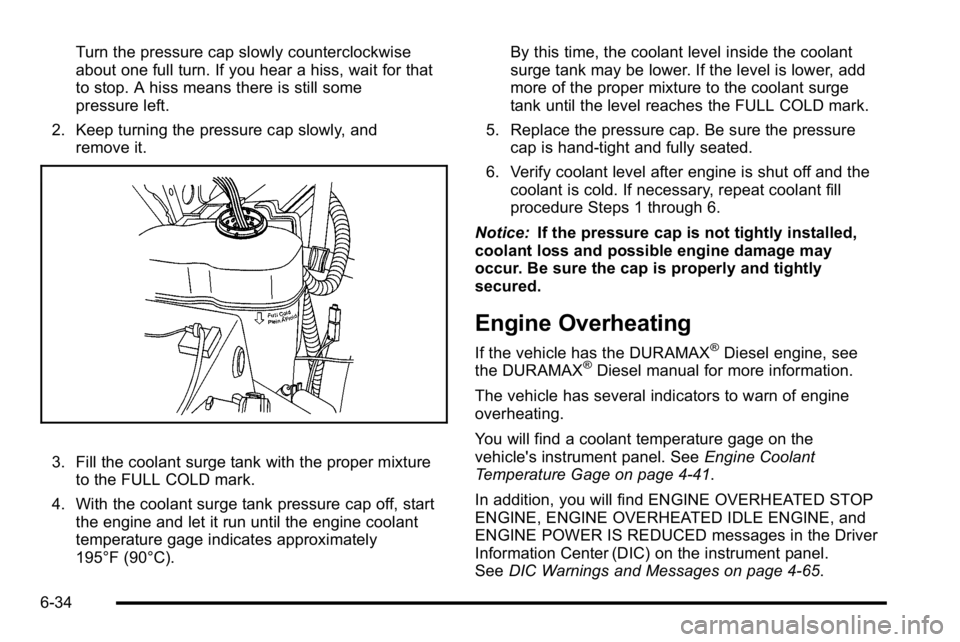

Turn the pressure cap slowly counterclockwise

about one full turn. If you hear a hiss, wait for that

to stop. A hiss means there is still some

pressure left.

2. Keep turning the pressure cap slowly, and remove it.

3. Fill the coolant surge tank with the proper mixtureto the FULL COLD mark.

4. With the coolant surge tank pressure cap off, start the engine and let it run until the engine coolant

temperature gage indicates approximately

195°F (90°C). By this time, the coolant level inside the coolant

surge tank may be lower. If the level is lower, add

more of the proper mixture to the coolant surge

tank until the level reaches the FULL COLD mark.

5. Replace the pressure cap. Be sure the pressure cap is hand-tight and fully seated.

6. Verify coolant level after engine is shut off and the coolant is cold. If necessary, repeat coolant fill

procedure Steps 1 through 6.

Notice: If the pressure cap is not tightly installed,

coolant loss and possible engine damage may

occur. Be sure the cap is properly and tightly

secured.

Engine Overheating

If the vehicle has the DURAMAX®Diesel engine, see

the DURAMAX®Diesel manual for more information.

The vehicle has several indicators to warn of engine

overheating.

You will find a coolant temperature gage on the

vehicle's instrument panel. See Engine Coolant

Temperature Gage on page 4‑41.

In addition, you will find ENGINE OVERHEATED STOP

ENGINE, ENGINE OVERHEATED IDLE ENGINE, and

ENGINE POWER IS REDUCED messages in the Driver

Information Center (DIC) on the instrument panel.

See DIC Warnings and Messages on page 4‑65.

6-34

Page 502 of 630

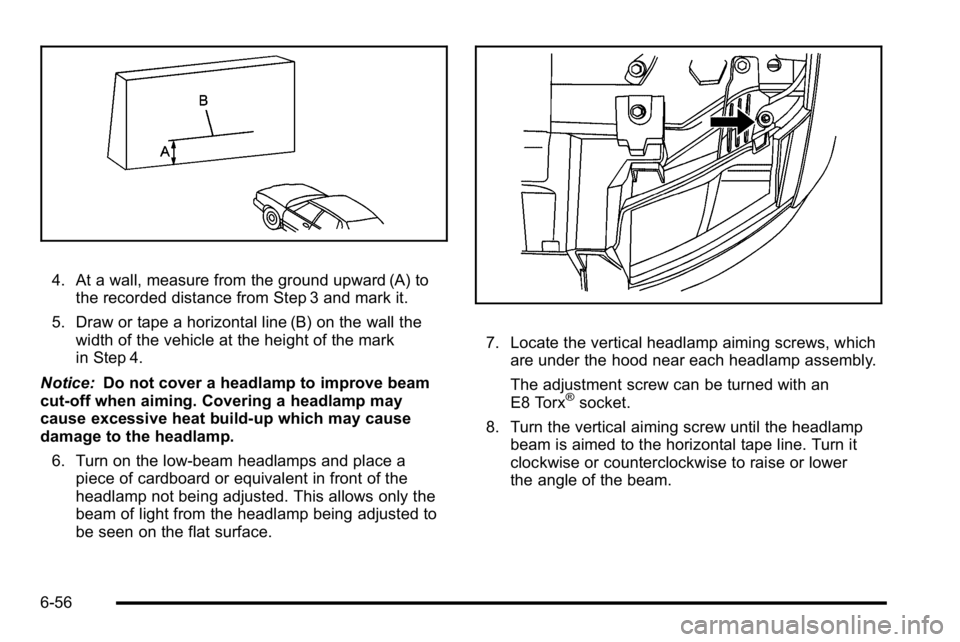

4. At a wall, measure from the ground upward (A) tothe recorded distance from Step 3 and mark it.

5. Draw or tape a horizontal line (B) on the wall the width of the vehicle at the height of the mark

in Step 4.

Notice: Do not cover a headlamp to improve beam

cut-off when aiming. Covering a headlamp may

cause excessive heat build-up which may cause

damage to the headlamp.

6. Turn on the low-beam headlamps and place a piece of cardboard or equivalent in front of the

headlamp not being adjusted. This allows only the

beam of light from the headlamp being adjusted to

be seen on the flat surface.

7. Locate the vertical headlamp aiming screws, whichare under the hood near each headlamp assembly.

The adjustment screw can be turned with an

E8 Torx

®socket.

8. Turn the vertical aiming screw until the headlamp beam is aimed to the horizontal tape line. Turn it

clockwise or counterclockwise to raise or lower

the angle of the beam.

6-56

Page 504 of 630

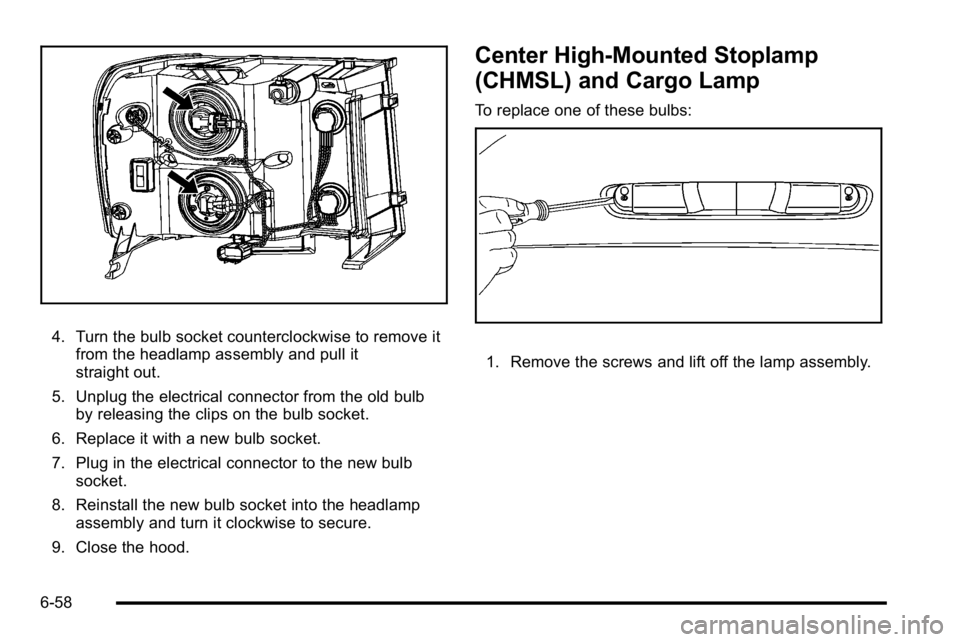

4. Turn the bulb socket counterclockwise to remove itfrom the headlamp assembly and pull it

straight out.

5. Unplug the electrical connector from the old bulb by releasing the clips on the bulb socket.

6. Replace it with a new bulb socket.

7. Plug in the electrical connector to the new bulb socket.

8. Reinstall the new bulb socket into the headlamp assembly and turn it clockwise to secure.

9. Close the hood.

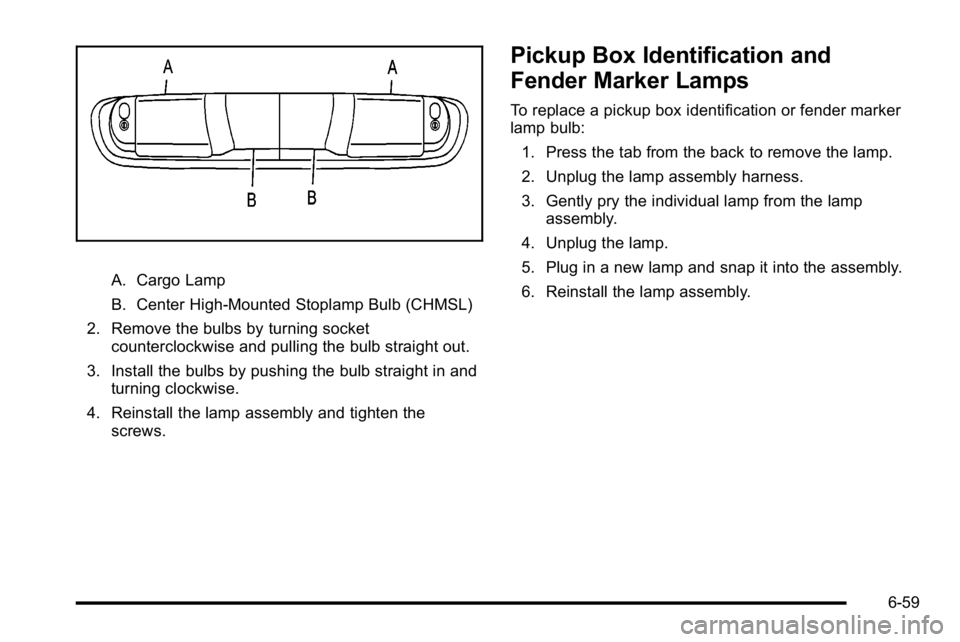

Center High-Mounted Stoplamp

(CHMSL) and Cargo Lamp

To replace one of these bulbs:

1. Remove the screws and lift off the lamp assembly.

6-58

Page 505 of 630

A. Cargo Lamp

B. Center High-Mounted Stoplamp Bulb (CHMSL)

2. Remove the bulbs by turning socket counterclockwise and pulling the bulb straight out.

3. Install the bulbs by pushing the bulb straight in and turning clockwise.

4. Reinstall the lamp assembly and tighten the screws.

Pickup Box Identification and

Fender Marker Lamps

To replace a pickup box identification or fender marker

lamp bulb:

1. Press the tab from the back to remove the lamp.

2. Unplug the lamp assembly harness.

3. Gently pry the individual lamp from the lamp assembly.

4. Unplug the lamp.

5. Plug in a new lamp and snap it into the assembly.

6. Reinstall the lamp assembly.

6-59

Page 506 of 630

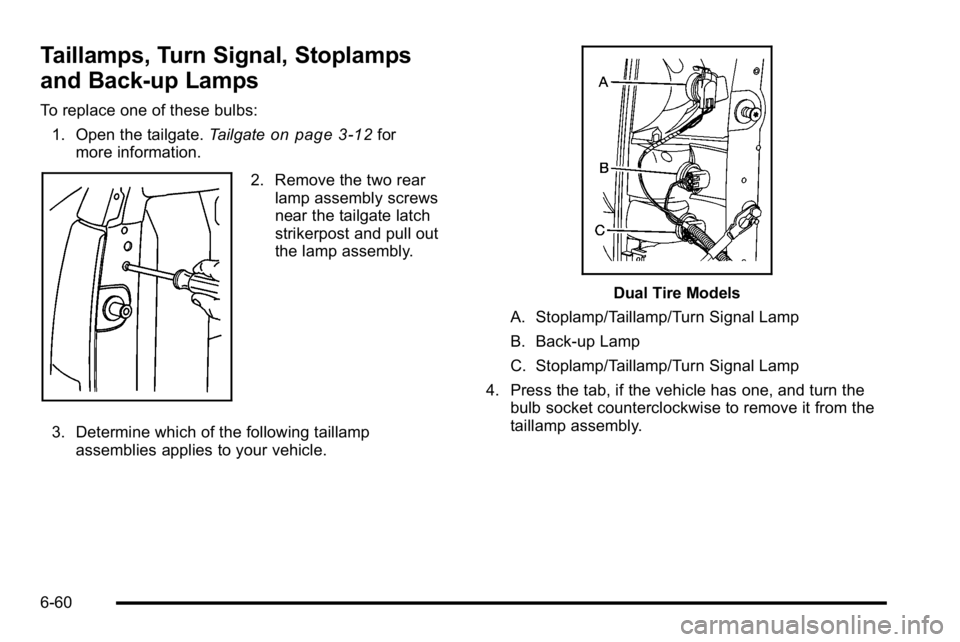

Taillamps, Turn Signal, Stoplamps

and Back-up Lamps

To replace one of these bulbs:1. Open the tailgate. Tailgate

on page 3‑12for

more information.

2. Remove the two rear lamp assembly screws

near the tailgate latch

strikerpost and pull out

the lamp assembly.

3. Determine which of the following taillamp assemblies applies to your vehicle.

Dual Tire Models

A. Stoplamp/Taillamp/Turn Signal Lamp

B. Back-up Lamp

C. Stoplamp/Taillamp/Turn Signal Lamp

4. Press the tab, if the vehicle has one, and turn the bulb socket counterclockwise to remove it from the

taillamp assembly.

6-60

Page 507 of 630

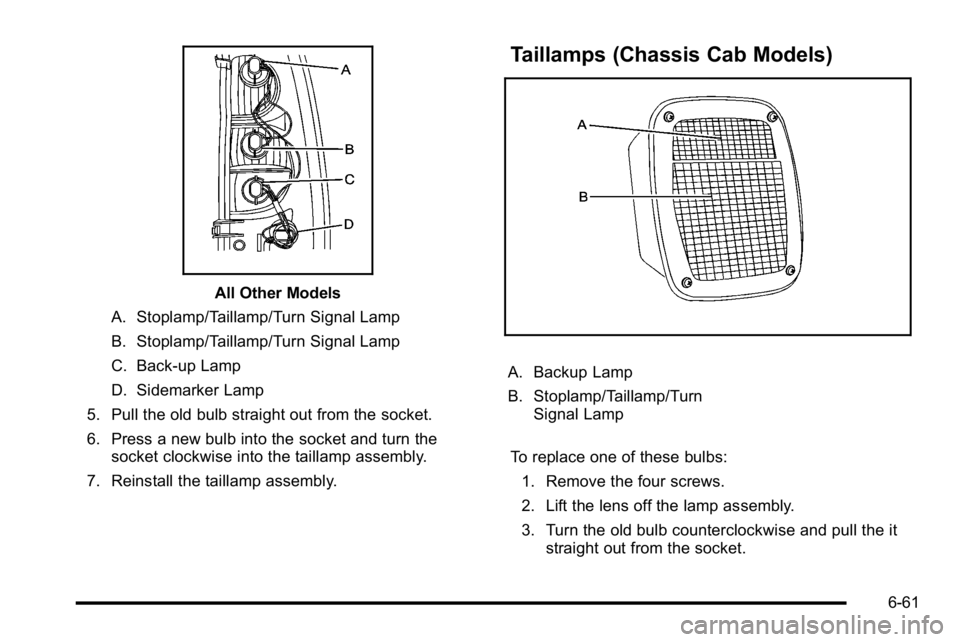

All Other Models

A. Stoplamp/Taillamp/Turn Signal Lamp

B. Stoplamp/Taillamp/Turn Signal Lamp

C. Back-up Lamp

D. Sidemarker Lamp

5. Pull the old bulb straight out from the socket.

6. Press a new bulb into the socket and turn the socket clockwise into the taillamp assembly.

7. Reinstall the taillamp assembly.

Taillamps (Chassis Cab Models)

A. Backup Lamp

B. Stoplamp/Taillamp/Turn Signal Lamp

To replace one of these bulbs: 1. Remove the four screws.

2. Lift the lens off the lamp assembly.

3. Turn the old bulb counterclockwise and pull the it straight out from the socket.

6-61

Page 508 of 630

4. Install a new bulb into the socket, turn it clockwise,and press it in until it is tight.

5. Reinstall the lens and the four screws.

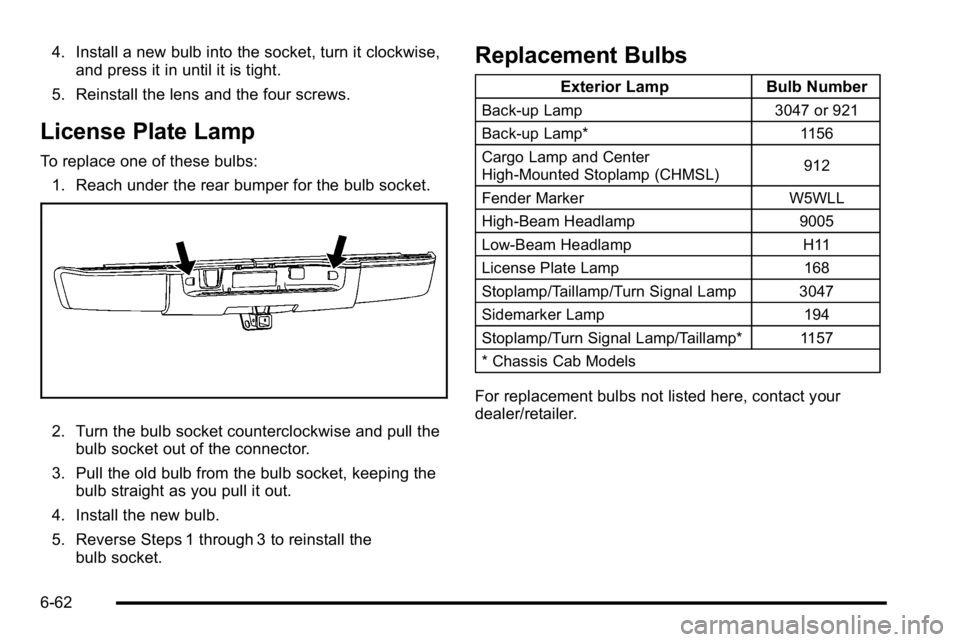

License Plate Lamp

To replace one of these bulbs: 1. Reach under the rear bumper for the bulb socket.

2. Turn the bulb socket counterclockwise and pull the bulb socket out of the connector.

3. Pull the old bulb from the bulb socket, keeping the bulb straight as you pull it out.

4. Install the new bulb.

5. Reverse Steps 1 through 3 to reinstall the bulb socket.

Replacement Bulbs

Exterior Lamp Bulb Number

Back-up Lamp 3047 or 921

Back-up Lamp* 1156

Cargo Lamp and Center

High-Mounted Stoplamp (CHMSL) 912

Fender Marker W5WLL

High-Beam Headlamp 9005

Low-Beam Headlamp H11

License Plate Lamp 168

Stoplamp/Taillamp/Turn Signal Lamp 3047

Sidemarker Lamp 194

Stoplamp/Turn Signal Lamp/Taillamp* 1157

* Chassis Cab Models

For replacement bulbs not listed here, contact your

dealer/retailer.

6-62

Page 539 of 630

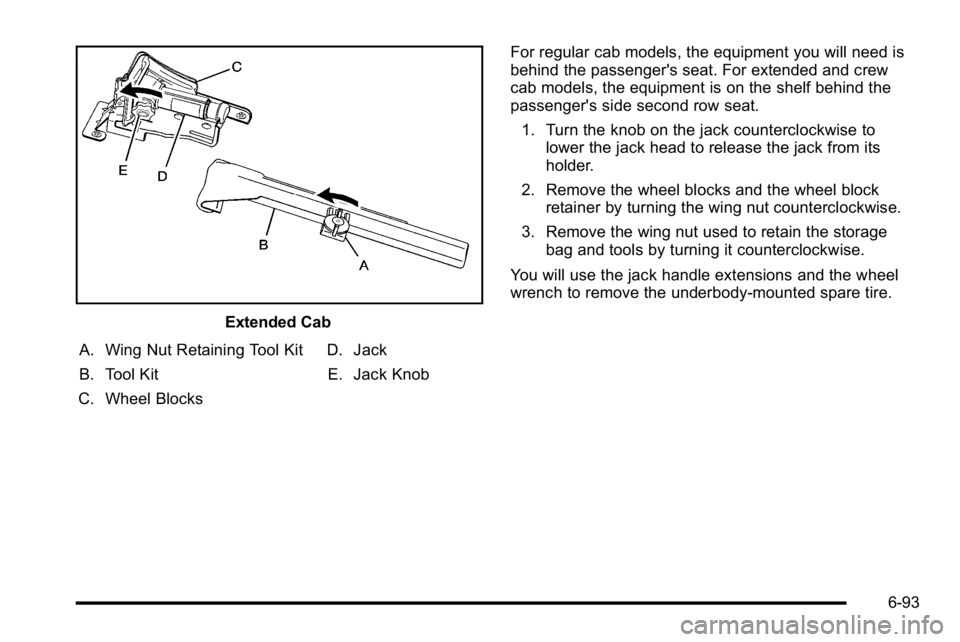

Extended Cab

A. Wing Nut Retaining Tool Kit

B. Tool Kit

C. Wheel Blocks D. Jack

E. Jack Knob For regular cab models, the equipment you will need is

behind the passenger's seat. For extended and crew

cab models, the equipment is on the shelf behind the

passenger's side second row seat.

1. Turn the knob on the jack counterclockwise to lower the jack head to release the jack from its

holder.

2. Remove the wheel blocks and the wheel block retainer by turning the wing nut counterclockwise.

3. Remove the wing nut used to retain the storage bag and tools by turning it counterclockwise.

You will use the jack handle extensions and the wheel

wrench to remove the underbody-mounted spare tire.

6-93

Page 541 of 630

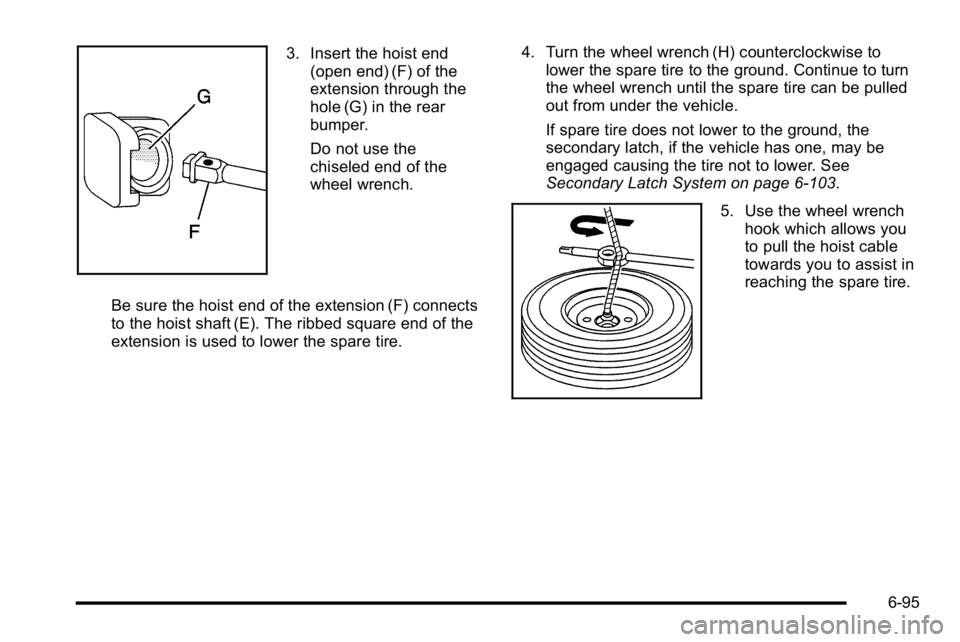

3. Insert the hoist end(open end) (F) of the

extension through the

hole (G) in the rear

bumper.

Do not use the

chiseled end of the

wheel wrench.

Be sure the hoist end of the extension (F) connects

to the hoist shaft (E). The ribbed square end of the

extension is used to lower the spare tire. 4. Turn the wheel wrench (H) counterclockwise to

lower the spare tire to the ground. Continue to turn

the wheel wrench until the spare tire can be pulled

out from under the vehicle.

If spare tire does not lower to the ground, the

secondary latch, if the vehicle has one, may be

engaged causing the tire not to lower. See

Secondary Latch System on page 6‑103.

5. Use the wheel wrench

hook which allows you

to pull the hoist cable

towards you to assist in

reaching the spare tire.

6-95