engine GMC SIERRA DENALI 2003 Owners Manual

[x] Cancel search | Manufacturer: GMC, Model Year: 2003, Model line: SIERRA DENALI, Model: GMC SIERRA DENALI 2003Pages: 428, PDF Size: 20.35 MB

Page 314 of 428

Using a match near a battery can cause battery

gas to explode. People have been hurt doing

this, and some have been blinded. Use a

flashlight if you need more light.

Be sure the battery has enough water.

You don’t need to add water to the ACDelco@

battery installed in your new vehicle. But

if

a battery has filler caps, be sure the right

amount of fluid is there. If

it is low, add water

to take care of that first. If you don’t, explosive

gas could be present.

Battery fluid contains acid that can burn you.

Don’t get

it on you. If you accidentally get it in

your eyes or on your skin, flush the place with

water and get medical help immediately.

I

Fans or other moving engine parts can injure

you badly. Keep your hands away from moving

parts once the engine is running.

I

5. Check that the jumper cables don’t have loose or

missing insulation. If they do, you could get a

shock. The vehicles could be damaged too.

Before you connect the cables, here are some

basic things you should know. Positive

(+) will go to

positive

(+) or a remote positive (+) terminal if the

vehicle has one. Negative

(-) will go to a heavy,

unpainted metal engine part or a remote

negative

(-) terminal if the vehicle has one.

Don’t connect positive

(+) to negative (-) or you’ll

get a short that would damage the battery and

maybe other parts too. And don’t connect the

negative

(-) cable to the negative (-) terminal on

the dead battery because this can cause sparks.

5-45

Page 316 of 428

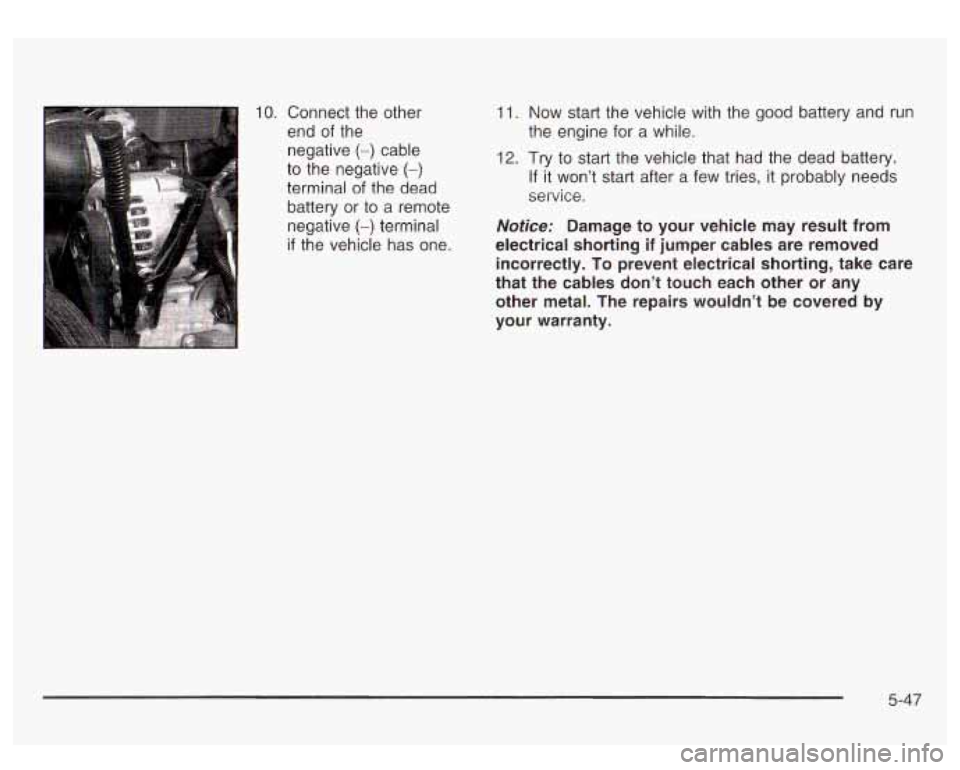

I 10. Connect the other

end of the

negative

(-) cable

to the negative

(-)

terminal of the dead

battery or to a remote

negative

(-) terminal

if the vehicle has one.

11. Now start the vehicle with the good battery and run

the engine for a while.

12. Try to start the vehicle that had the dead battery.

If it won’t start after a few tries, it probably needs

service.

Notice: Damage to your vehicle may result from

electrical shorting if jumper cables are removed

incorrectly.

To prevent electrical shorting, take care

that the cables don’t touch each other or any

other metal. The repairs wouldn’t be covered by

your warranty.

5-47

Page 317 of 428

A 8

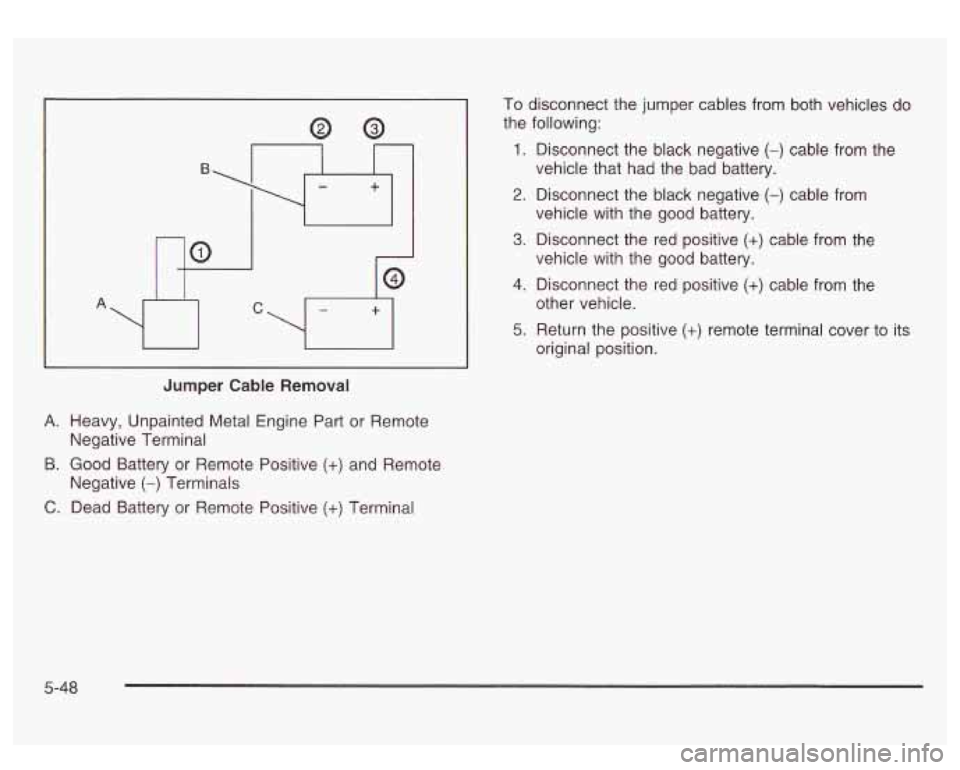

Jumper Cable Removal

A. Heavy, Unpainted Metal Engine Part or Remote

9. Good Battery or Remote Positive (+) and Remote

C. Dead Battery or Remote Positive (+) Terminal

Negative Terminal

Negative

(-) Terminals To

disconnect the jumper cables from both vehicles do

the following:

1. Disconnect the black negative (-) cable from the

2. Disconnect the black negative (-) cable from

3. Disconnect the red positive (+) cable from the

vehicle that

had the bad battery.

vehicle with the good battery.

vehicle with the good battery.

4. Disconnect the red positive (+) cable from the

other vehicle.

5. Return the positive (+) remote terminal cover to its

original position.

5-48

Page 338 of 428

A rear blowout, particularly on a curve, acts much like a Changing a Flat Tire

skid and may require the same correction you’d use

in a skid. In any rear blowout, remove your foot from the

If a tire goes flat, avoid further tire and wheel damage

accelerator pedal. Get the vehicle under control by by driving slowly

to a level place. Turn on your

steering

the way you want the vehicle to go. it may be hazard warning flashers.

very bumpy and noisy, but you can still steer. Gently

brake

to a stop - well off the road if possible.

If a tire goes flat, the next part shows how

to use your

jacking equipment to change a flat tire safely.

C..-nging a tire can cause

an injury. The

vehicle can slip

off the jack and roll over you

or other people. You and they could be badly

injured. Find a level place to change your tire.

To help prevent the vehicle from moving:

1. Set the parking brake firmly.

2. Put the shift lever in PARK (P).

3. Turn off the engine.

4. Put the wheel blocks at the front and rear

of the tire farthest away from the one

being changed. That

would be the tire on

the other side of the vehicle, at the

opposite end.

5-69

Page 363 of 428

Vehicle Identification

Vehicle Identification Number (VIN)

SAMPLE4UX1 M072675

This is the legal identifier for your vehicle. It appears on

a plate in the front corner of the instrument panel, on

the driver’s side. You can see it

if you look through the

windshield from outside your vehicle. The VIN also

appears on the Vehicle Certification and Service Parts

labels and the certificates of title and registration.

Engine Identification

The 8th character in your VIN is the engine code. This

code will help you identify your engine, specifications

and replacement parts.

Service Parts Identification Label

You’ll find this label located in the glove box. It’s very

helpful

if you ever need to order parts. On this label is:

your VIN,

the model designation,

paint information and

a list of all production options and special

equipment.

Be sure that this label is not removed from the vehicle.

5-94

Page 368 of 428

Underhood Fuse Block The underhood fuse block in the engine compartment

on the driver's side of the vehicle near the battery.

Lift the cover for access to the fusehelay block.

To remove fuses hold the end of the fuse between your

thumb and

index finger and pull straight out.

See

Engine Compartment Overview on page 5-12 for

more information on its location.

5-99

Page 369 of 428

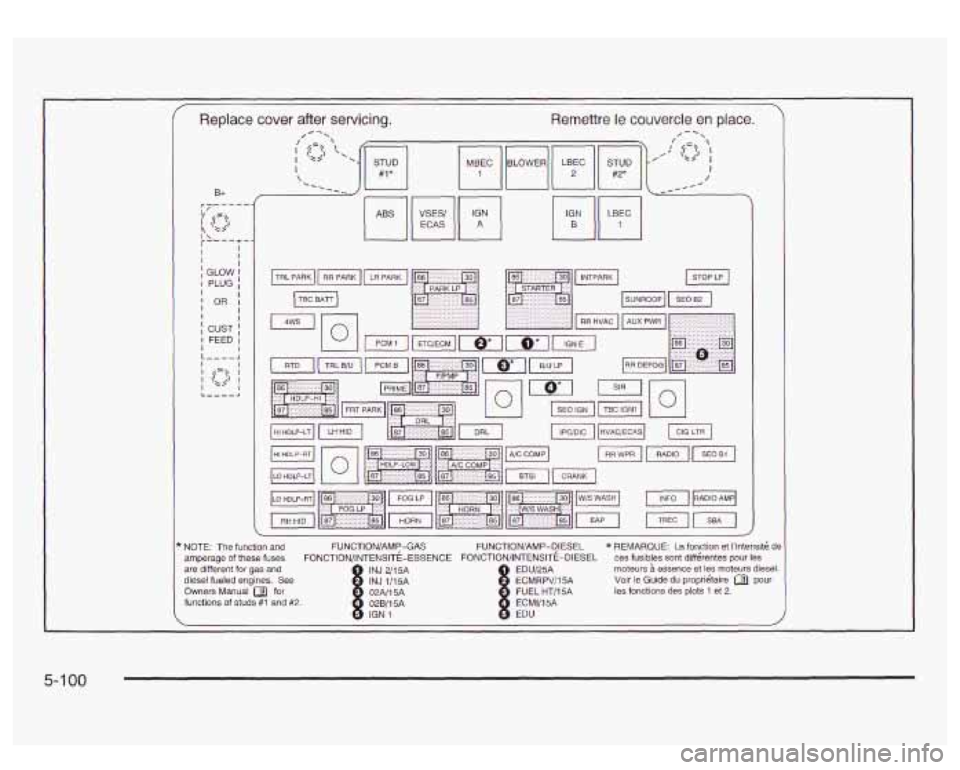

Replace cover after servicing. Remettre le couvercle en place.

I ? i I I I I I

I

I I I

I

I I I L I 1 I I L

B+

GLOW I PLUG

OR I

I CUST I FEED I I -_--l

NOTE: The function and FUNCTION/AMy-GAS

amperage of these fuses FONCTION/INTENSIT!-ESSENCE FONCTIONIINTENSITE-DIESEL ces fusibles sont diffbrentes pour les

FUNCTION/AMP-QlESEL * REMARQUE: La fonction

et I'intensitk de

are different for gas and INJ 2/15A EDU/25A moteurs essence et les rnoteurs diesel.

diesel fueled engines. See

Owners Manual for

functions

of studs #I and #2. ECMV15A f

tCMRPV/I5A

FUEL HT/15A Voir le Guide du propri6taire a pour

les fonctions des plots 1 et 2.

5- 1 00

Page 370 of 428

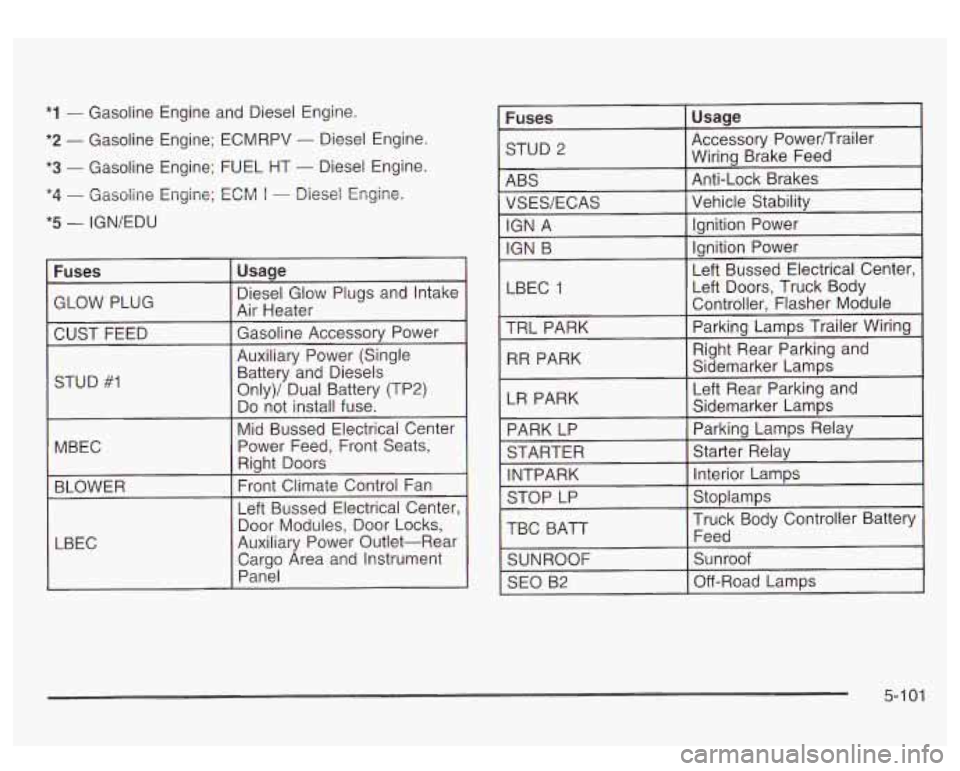

*I - Gasoline Engine and Diesel Engine.

*2 - Gasoline Engine; ECMRPV - Diesel Engine.

*3 - Gasoline Engine; FUEL HT - Diesel Engine.

*4 - Gasoline Engine; ECM f - Diesel Engine.

*5 - IGN/EDU

r Fuses

GLOW PLUG

CUST FEED

STUD

#I

MBEC

BLOWER

LBEC Only)/ Dual Battery

(TP2)

Do not install fuse.

Mid Bussed Electrical Center

Power Feed, Front Seats,

Riaht Doors TRL

PARK Parking Lamps Trailer Wiring

RR PARK Right

Rear Parking and

Sidemarker LamDs

TBC BATT Truck Body

Controller Battery

I Feed

5-1 01

Page 373 of 428

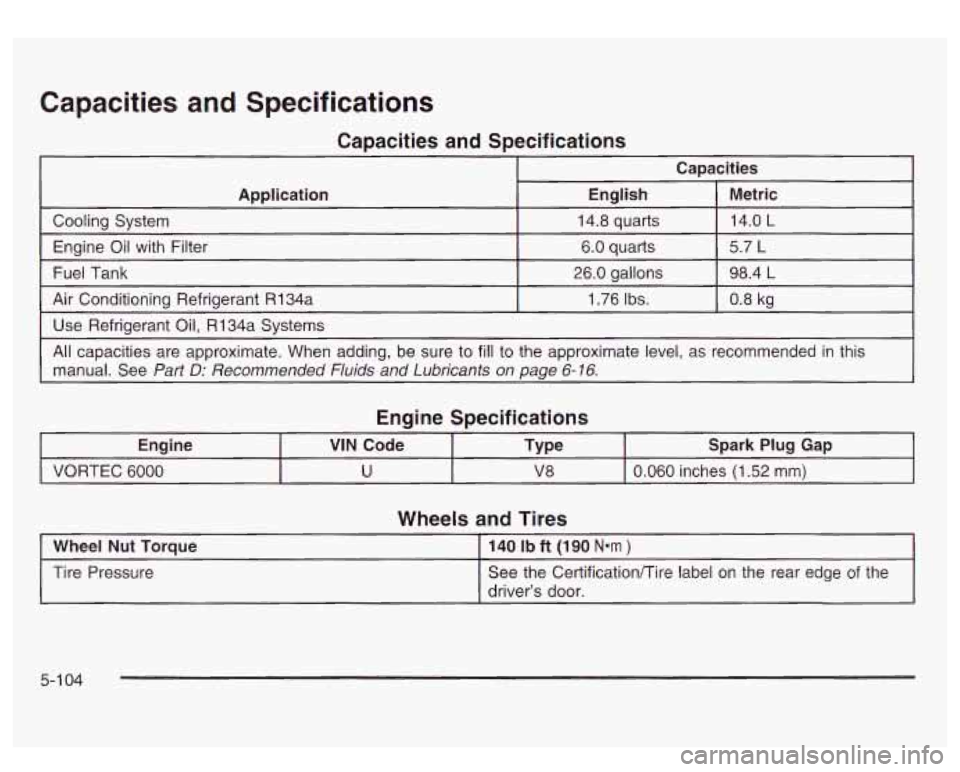

Capacities and Specifications

Capacities and Specifications

Capacities

Application

All capacities are approximate. When adding, be sure to

fill to the approximate level, as recommended in this

Use

Refrigerant Oil, R134a Systems 0.8

kg

1.76 Ibs.

Air Conditioning Refrigerant R134a 98.4

L 26.0 gallons

Fuel

Tank 5.7

L 6.0 quarts

Engine Oil

with Filter 14.0

L 14.8 quarts

Cooling

System Metric

English

manual. See

Part D: Recommended Fluids and Lubricants on page 6-16.

Engine Specifications

Engine Spark Plug Gap

Type

VIN Code

VORTEC 6000

0.060 inches (1.52 mm) V8

U

Wheels and Tires

Wheel Nut Torque

See the CertificationKire label on the rear edge of the

Tire

Pressure 140 Ib ft (190 N*m )

driver’s door.

5-1 04

Page 376 of 428

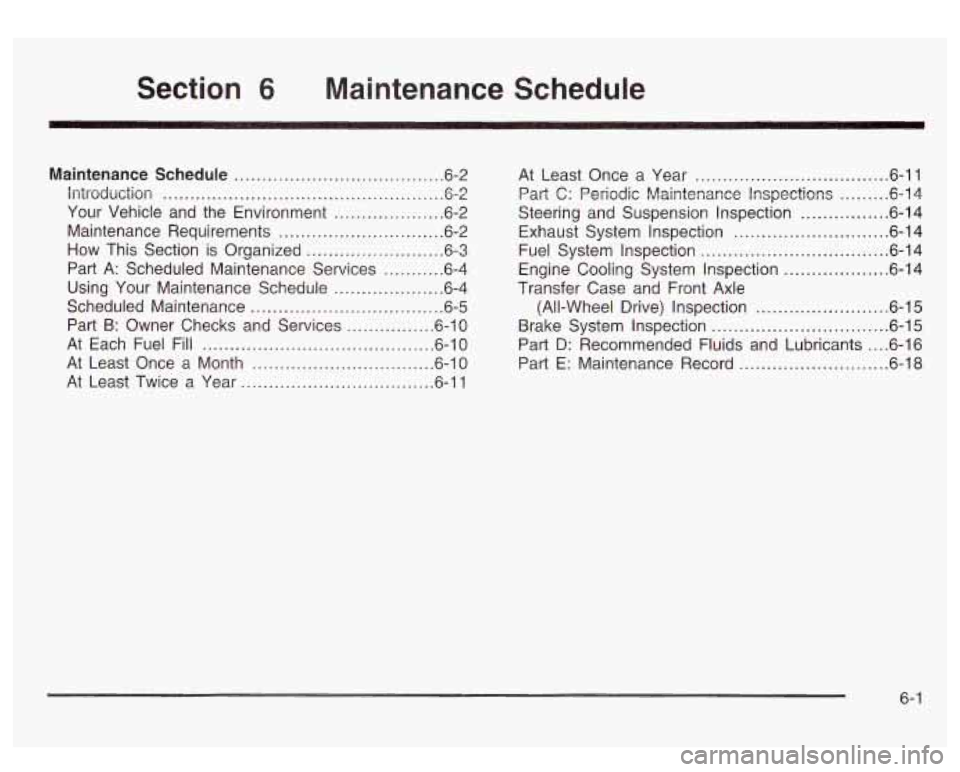

Section 6 Maintenance Schedule

Maintenance Schedule ...................................... 6.2

introduction

................................................... 6.2

Your Vehicle and the Environment

.................... 6-2

Maintenance Requirements

.............................. 6-2

How This Section is Organized

......................... 6-3

Part A: Scheduled Maintenance Services

........... 6-4

Using Your Maintenance Schedule

.................... 6-4

Scheduled Maintenance

................................... 6-5

Part

B: Owner Checks and Services ................ 6-10

At Each Fuel Fill

.......................................... 6-10

At Least Once a Month

................ ......... 6-10

At Least Twice a Year

............................... 6-11 At Least

Once a Year

................................... 6-11

Part

C: Periodic Maintenance Inspections ......... 6.14

Steering and Suspension Inspection

................ 6.14

Exhaust System inspection

............................ 6-14

Fuel System Inspection

.................................. 6.14

Engine Cooling System inspection

................... 6.14

(All-Wheel Drive) Inspection

........................ 6.15

Brake System Inspection

................................ 6.15

Part

D: Recommended Fluids and Lubricants .... 6-16

Part E: Maintenance Record

........................... 6.18

Transfer Case and

Front Axle

6- 1