service schedule GMC SIERRA DENALI 2003 Owners Manual

[x] Cancel search | Manufacturer: GMC, Model Year: 2003, Model line: SIERRA DENALI, Model: GMC SIERRA DENALI 2003Pages: 428, PDF Size: 20.35 MB

Page 2 of 428

The 2003 GMC Sierra Denali Owner Manual a

Seats and Restraint Systems ........................... 1-1

Front Seats ............................................... 1-2

Rear Seats

............................................... 1-7

Safety Belts

.............................................. 1-8

Child Restraints

....................................... 1-30

Air Bag Systems

...................................... 1-57

Restraint System Check

............................ 1-73

Features and Controls

..................................... 2-1

Keys

........................................................ 2-2

Doors and Locks

....................................... 2-6

Windows

................................................. 2-1 0

Theft-Deterrent Systems ............................ 2-1 3

Starting and Operating Your Vehicle ........... 2-15

Mirrors

.................................................... 2-28

Onstar@ System

...................................... 2-33

HomeLink@ Transmitter

............................. 2-35

Storage Areas

......................................... 2-39

Instrument Panel

............................................. 3-1

Vehicle

Personalization

............................. 2-42

Instrument Panel Overview

.......................... 3-2

Climate Controls

...................................... 3-1 8

Warning Lights, Gages and Indicators

......... 3-24

Driver Information Center (DIC)

.................. 3-43

Audio System(s)

....................................... 3-61 Driving Your Vehicle

....................................... 4-1

Your

Driving, the Road, and Your Vehicle ..... 4-2

Towing

................................................... 4-45

Service and Appearance Care

.......................... 5-1

Service

..................................................... 5-3

Fuel

......................................................... 5-5

Checking Things Under the Hood

............................................. 5-10

All-Wheel Drive

........................................ 5-49

Rear Axle

............................................... 5-50

Front Axle

............................................... 5-51

Bulb Replacement

.................................... 5-52

Windshield Wiper Blade Replacement

......... 5-60

Tires

...................................................... 5-61

Appearance Care

..................................... 5-86

Vehicle Identification

................................. 5-94

Electrical System

...................................... 5-95

Capacities and Specifications

................... 5-1 04

Normal Maintenance Replacement Parts

.... 5-1 05

Maintenance Schedule

..................................... 6-1

Maintenance Schedule

................................ 6-2

Customer Assistance Information

.................... 7-1

Customer Assistance Information

.................. 7-2

Reporting Safety Defects

............................ 7-9

Index

................................................................. 1

Page 237 of 428

If the water isn’t too deep, drive slowly through it. At

faster speeds, water splashes on your ignition system

and your vehicle can stall. Stalling can also occur

if you

get your tailpipe under water. And, as long as your

tailpipe is under water, you’ll never be able to start your

engine. When you go through water, remember that

when your brakes get wet, it may take you longer

+- stop.

,,jving thr,,gh rushing water can be

dangerous. Deep water can sweep your vehicle

downstream and you and your passengers

could drown. If it’s only shallow water, it can

still wash away the ground from under your

tires, and you could lose traction and roll the

water.

~ vehicle over. Don’t drive through rushing

I

After Off-Road Driving

Remove any brush or debris that has collected on the

underbody, chassis or under the hood. These

accumulations can be a fire hazard.

After operation

in mud or sand, have the brake linings

cleaned and checked. These substances can cause

glazing and uneven braking. Check the body structure,

steering, suspension, wheels, tires and exhaust

system for damage. Also, check the fuel lines and

cooling system for any leakage.

Your vehicle will require more frequent service due

to

off-road use. Refer to the Maintenance Schedule

for additional information.

See

Driving in Rain and on Wet Roads on page 4-30 for

more information on driving through water.

4-28

Page 260 of 428

Towing a Trailer

If you don’t ,se the correct eq-., ...__. t and

drive properly, you can lose control when you

pull a trailer. For example,

if the trailer is too

heavy, the brakes may not work well

-- or even

at all. You and your passengers could be

seriously injured.

Pull a trailer only if you have

followed all the steps in this section.

Ask your

dealer for advice and information about towing

a trailer with your vehicle.

Notice: Pulling a trailer improperly can damage

your vehicle and result in costly repairs not covered

by your warranty.

To pull a trailer correctly, follow

the advice in this part, and see your dealer for

important information about towing a trailer with

your vehicle. Additional rear axle maintenance is required for a vehicle used to tow a trailer. See

“Scheduled Maintenance Services” in the Index.

To identify the vehicle trailering capacity of your vehicle,

you should read the information in “Weight of the

Trailer” that appears later in this section.

If yours was built with trailering options, as many are,

it’s ready for heavier trailers. But trailering is different

than just driving your vehicle by itself. Trailering means

changes in handling, durability and fuel economy.

Successful, safe trailering takes correct equipment, and it has to be used properly.

That’s the reason for this part. In it are many time-tested,

important trailering tips and safety rules. Many of

these are important for your safety and that of your

passengers.

So please read this section carefully before

you pull a trailer.

If You Do Decide To Pull A Trailer

If you do, here are some important points:

e

There are many different laws, including speed limit

restrictions, having to do with trailering. Make sure

your rig will be legal, not only where you live

but also where you’ll be driving.

A good source for

this information can be state or provincial police.

Consider using a sway control

if your trailer will

weigh

5,000 Ibs. (2 270 kg) or less. You should

always use a sway control

if your trailer will weigh

more than

5,000 Ibs. (2 270 kg). You can ask a

hitch dealer about sway controls.

Don’t tow a trailer at all during the first

500 miles

(800 km) your new vehicle is driven. Your engine,

axle or other parts could be damaged.

4-5 1

Page 268 of 428

When You Are Ready to Leave After

Parking on a

Hill

1. Apply your regular brakes and hold the pedal down

while you:

0 start your engine,

shift into a gear, and

0 release the parking brake.

2. Let up on the brake pedal.

3. Drive slowly until the trailer is clear of the chocks.

4. Stop and have someone pick up and store the

chocks.

Maintenance When Trailer Towing

Your vehicle will need service more often when you’re

pulling a trailer. See the Maintenance Schedule for more

on this. Things that are especially important in trailer

operation are automatic transmission fluid (don’t overfill),

engine

oil, axle lubricant, belt, cooling system and

brake system. Each of these is covered in this manual,

and the Index will help you find them quickly. If

you’re trailering, it’s a good idea to review these sections

before you start your trip.

Check periodically to see that all hitch nuts and bolts

are tight.

4-59

Page 289 of 428

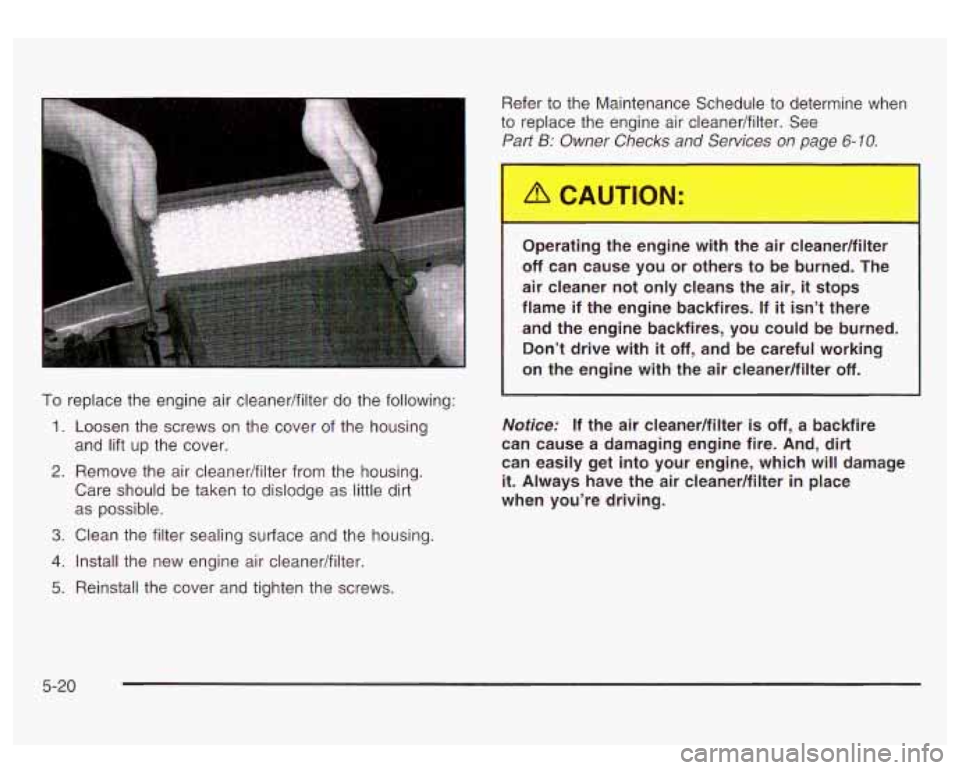

To replace the engine air cleaner/filter do the following:

1. Loosen the screws on the cover of the housing

and lift up the cover.

2. Remove the air cleaner/filter from the housing.

Care should be taken

to dislodge as little dirt

as possible.

3. Clean the filter sealing surface and the housing.

4. Install the new engine air cleanedfilter.

5. Reinstall the cover and tighten the screws. Refer

to the Maintenance Schedule to determine when

to replace the engine air cleaner/filter. See

Part B: Owner Checks and Services on page 6-10.

Operating the engine with the air cleanedfilter

off can cause you or others to be burned. The

air cleaner not only cleans the air,

it stops

flame

if the engine backfires. If it isn’t there

and the engine backfires, you could be burned. Don’t drive with

it off, and be careful working

on the engine with the air cleaner/filter

off.

Notice: If the air cleaner/filter is off, a backfire

can cause a damaging engine fire. And, dirt

can easily get into your engine, which will damage

it. Always have the air cleanedfilter in place

when you’re driving.

5-20

Page 290 of 428

Automatic Transmission Fluid

When to Check and Change

A good time to check your automatic transmission fluid

level

is when the engine oil is changed.

Change both the fluid and filter every

50,000 miles

(83

000 km) if the vehicle is mainly driven under one or

more

of these conditions:

In heavy city traffic where the outside temperature

regularly reaches 90°F (32°C) or higher.

In hilly or mountainous terrain.

When doing frequent trailer towing.

Uses such as found in taxi, police or delivery

If you do not use your vehicle under any of these

conditions, change the fluid and filter every

100,000 miles (1 66 000 km).

See

Part A: Scheduled Maintenance Services on

page

6-4.

service.

How to Check

Because this operation can be a little difficult, you may

choose to have this done at the dealership service

department.

If you do it yourself, be sure to follow all the instructions

here, or you could get a false reading on the dipstick.

Notice: Too much or too little fluid can damage

your transmission. Too much can mean that some

of the fluid could come out and fall on hot engine

part

or exhaust system parts, starting a fire.

Too little fluid could cause the transmission to overheat. Be sure to get an accurate reading if you

check your transmission fluid.

Wait at least

30 minutes before checking the

transmission fluid level

if you have been driving:

0 When outside temperatures are above 90°F (32°C).

At high speed for quite a while.

In heavy traffic - especially in hot weather.

While pulling a trailer.

To get the right reading, the fluid should be at normal

operating temperature, which is 180°F

to 200°F

(82°C to 93°C).

5-2

1

Page 319 of 428

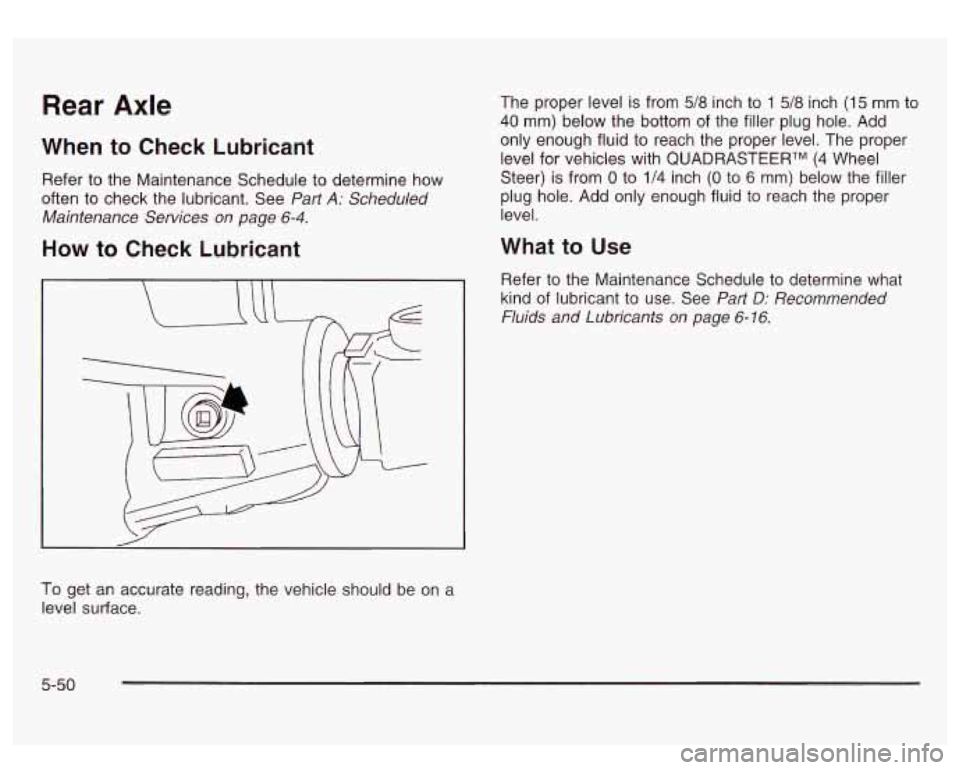

Rear Axle

When to Check Lubricant

Refer to the Maintenance Schedule to determine how

often to check the lubricant. See

PaHA: Scheduled

Maintenance Services on page

6-4.

How to Check Lubricant

To get an accurate reading, the vehicle should be on a

level surface. The

proper level is from

5/8 inch to 1 5/8 inch (1 5 mm to

40 mm) below the bottom of the filler plug hole. Add

only enough fluid to reach the proper level. The proper

level for vehicles with QUADRASTEERTM

(4 Wheel

Steer) is from

0 to 1/4 inch (0 to 6 mm) below the filler

plug hole. Add only enough fluid to reach the proper

level.

What to Use

Refer to the Maintenance Schedule to determine what

kind

of lubricant to use. See Part D: Recommended

Fluids and Lubricants on page

6- 16.

5-50

Page 320 of 428

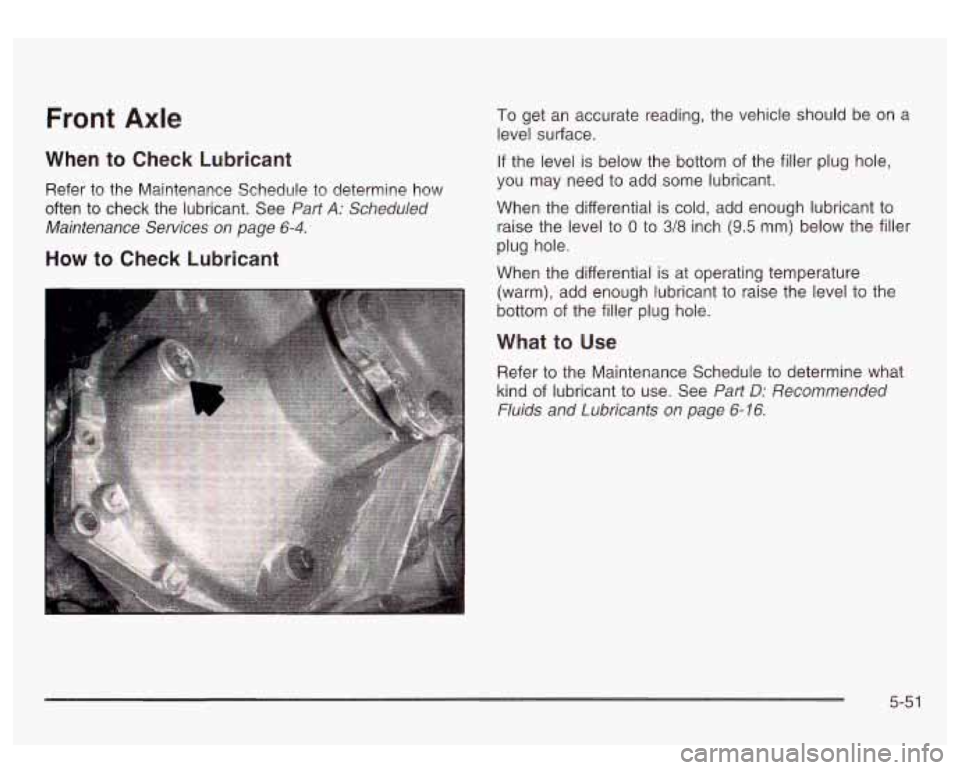

Front Axle

When to Check Lubricant

Refer to the Maintenance Schedule to determine how

often to check the lubricant. See

Pat? A: Scheduled

Maintenance Services on page

6-4.

How to Check Lubricant

To get an accurate reading, the vehicle should be on a

level surface.

If the level is below the bottom

of the filler plug hole,

you may need to add some lubricant.

When the differential is cold, add enough lubricant to

raise the level to

0 to 3/8 inch (9.5 mm) below the filler

plug hole.

When the differential is at operating temperature

(warm), add enough lubricant to raise the level to the

bottom

of the filler plug hole.

What to Use

Refer to the Maintenance Schedule to determine what

kind of lubricant to use. See

Pat? D: Recommended

Fluids and Lubricants on page

6-16.

5-51

Page 332 of 428

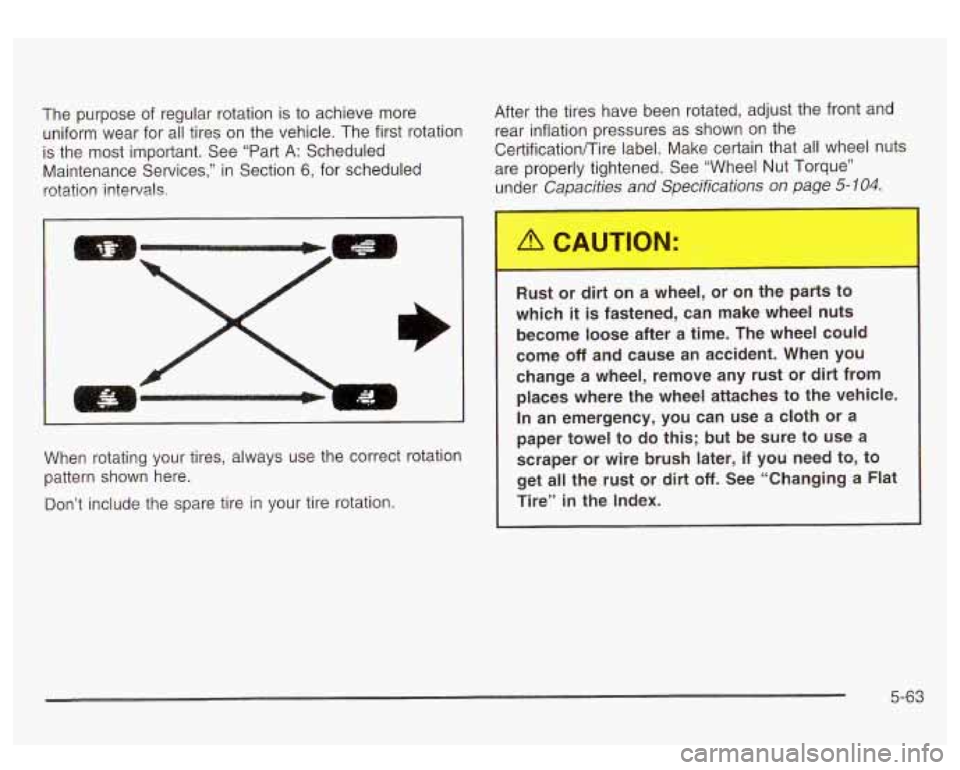

The purpose of regular rotation is to achieve more

uniform wear for all tires on the vehicle. The first rotation

is the most important. See “Part A: Scheduled

Maintenance Services,” in Section

6, for scheduled

rotation

intervals;

After the tires have been rotated, adjust the front and

rear inflation pressures as shown on the

CertificationEire label. Make certain that all wheel nuts

are properly tightened. See “Wheel Nut Torque”

under

Capacities and Specificatiol on ge 5-104.

When rotating your tires, always use the correct rotation

pattern shown here.

Don’t include the spare tire in your tire rotation. Rust or dirt on a

wheel, or on the parts to

which

it is fastened, can make wheel nuts

become loose after a time. The wheel could

come

off and cause an accident. When you

change a wheel, remove any rust or dirt from

places where the wheel attaches to the vehicle,

In an emergency, you can use a cloth or a

paper towel to do

this; but be sure to use a

scraper or wire brush later,

if you need to, to

get all the rust or dirt

off. See “Changing a Flal

Tire”

in the Index.

5-63

Page 376 of 428

Section 6 Maintenance Schedule

Maintenance Schedule ...................................... 6.2

introduction

................................................... 6.2

Your Vehicle and the Environment

.................... 6-2

Maintenance Requirements

.............................. 6-2

How This Section is Organized

......................... 6-3

Part A: Scheduled Maintenance Services

........... 6-4

Using Your Maintenance Schedule

.................... 6-4

Scheduled Maintenance

................................... 6-5

Part

B: Owner Checks and Services ................ 6-10

At Each Fuel Fill

.......................................... 6-10

At Least Once a Month

................ ......... 6-10

At Least Twice a Year

............................... 6-11 At Least

Once a Year

................................... 6-11

Part

C: Periodic Maintenance Inspections ......... 6.14

Steering and Suspension Inspection

................ 6.14

Exhaust System inspection

............................ 6-14

Fuel System Inspection

.................................. 6.14

Engine Cooling System inspection

................... 6.14

(All-Wheel Drive) Inspection

........................ 6.15

Brake System Inspection

................................ 6.15

Part

D: Recommended Fluids and Lubricants .... 6-16

Part E: Maintenance Record

........................... 6.18

Transfer Case and

Front Axle

6- 1