lock GMC SIERRA DENALI 2010 Owners Manual

[x] Cancel search | Manufacturer: GMC, Model Year: 2010, Model line: SIERRA DENALI, Model: GMC SIERRA DENALI 2010Pages: 550, PDF Size: 4.17 MB

Page 474 of 550

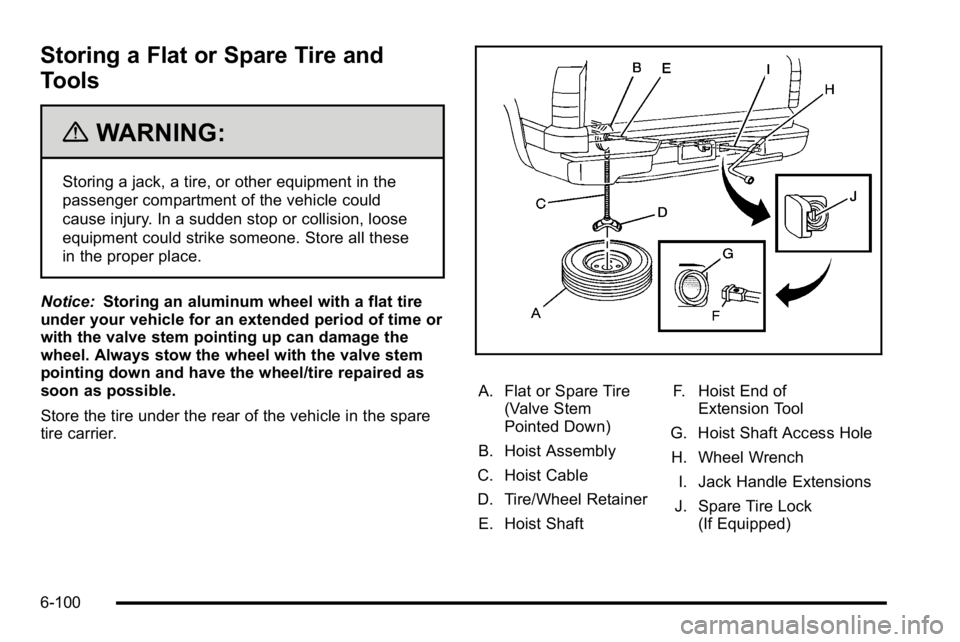

Storing a Flat or Spare Tire and

Tools

{WARNING:

Storing a jack, a tire, or other equipment in the

passenger compartment of the vehicle could

cause injury. In a sudden stop or collision, loose

equipment could strike someone. Store all these

in the proper place.

Notice: Storing an aluminum wheel with a flat tire

under your vehicle for an extended period of time or

with the valve stem pointing up can damage the

wheel. Always stow the wheel with the valve stem

pointing down and have the wheel/tire repaired as

soon as possible.

Store the tire under the rear of the vehicle in the spare

tire carrier.

A. Flat or Spare Tire (Valve Stem

Pointed Down)

B. Hoist Assembly

C. Hoist Cable

D. Tire/Wheel Retainer

E. Hoist Shaft F. Hoist End of

Extension Tool

G. Hoist Shaft Access Hole H. Wheel Wrench I. Jack Handle Extensions

J. Spare Tire Lock (If Equipped)

6-100

Page 476 of 550

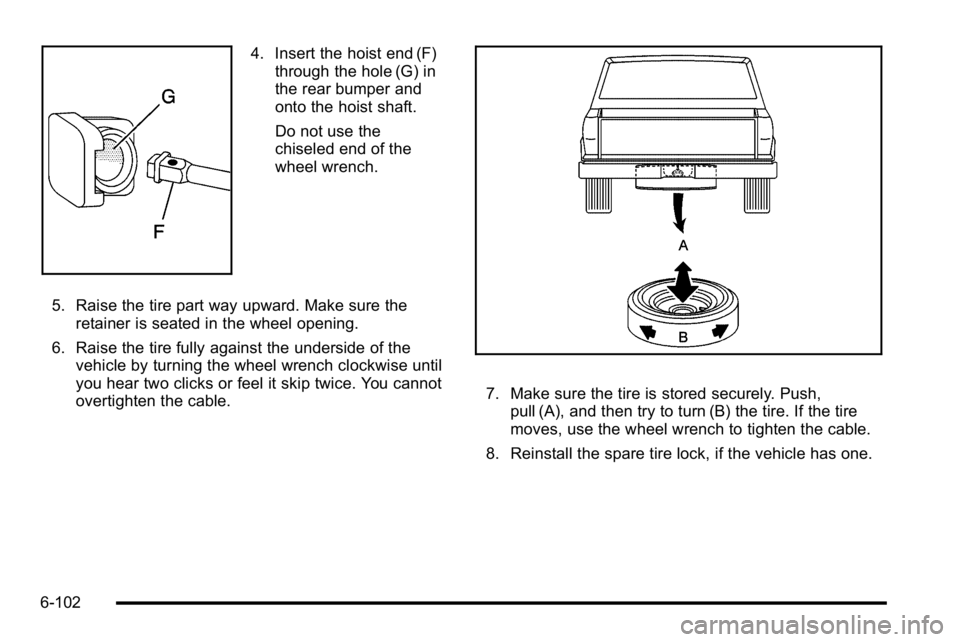

4. Insert the hoist end (F)through the hole (G) in

the rear bumper and

onto the hoist shaft.

Do not use the

chiseled end of the

wheel wrench.

5. Raise the tire part way upward. Make sure the retainer is seated in the wheel opening.

6. Raise the tire fully against the underside of the vehicle by turning the wheel wrench clockwise until

you hear two clicks or feel it skip twice. You cannot

overtighten the cable.

7. Make sure the tire is stored securely. Push,

pull (A), and then try to turn (B) the tire. If the tire

moves, use the wheel wrench to tighten the cable.

8. Reinstall the spare tire lock, if the vehicle has one.

6-102

Page 477 of 550

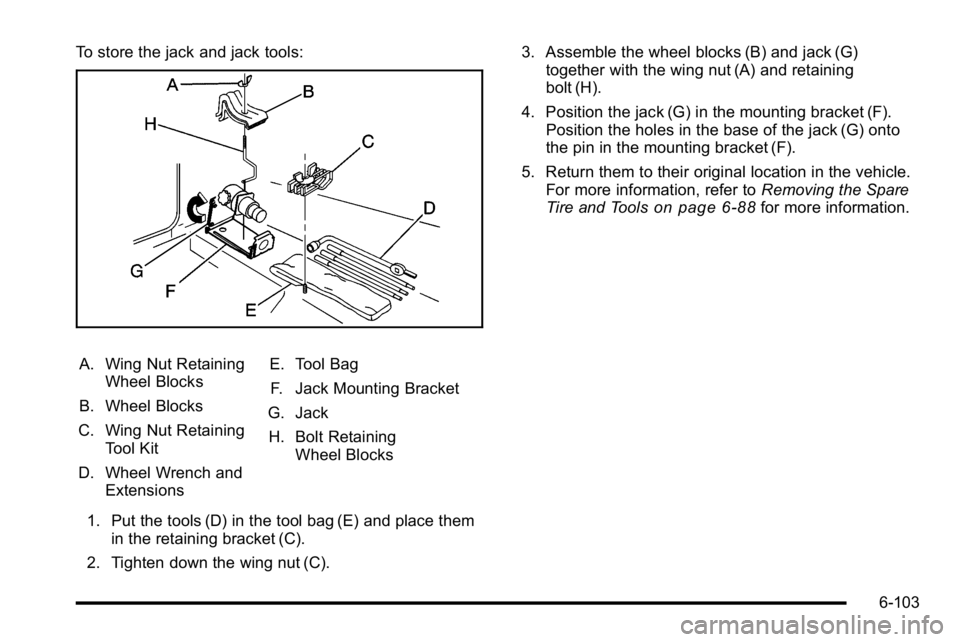

To store the jack and jack tools:

A. Wing Nut RetainingWheel Blocks

B. Wheel Blocks

C. Wing Nut Retaining Tool Kit

D. Wheel Wrench and Extensions E. Tool Bag

F. Jack Mounting Bracket

G. Jack

H. Bolt Retaining Wheel Blocks

1. Put the tools (D) in the tool bag (E) and place them in the retaining bracket (C).

2. Tighten down the wing nut (C). 3. Assemble the wheel blocks (B) and jack (G)

together with the wing nut (A) and retaining

bolt (H).

4. Position the jack (G) in the mounting bracket (F). Position the holes in the base of the jack (G) onto

the pin in the mounting bracket (F).

5. Return them to their original location in the vehicle. For more information, refer to Removing the Spare

Tire and Tools

on page 6‑88for more information.

6-103

Page 489 of 550

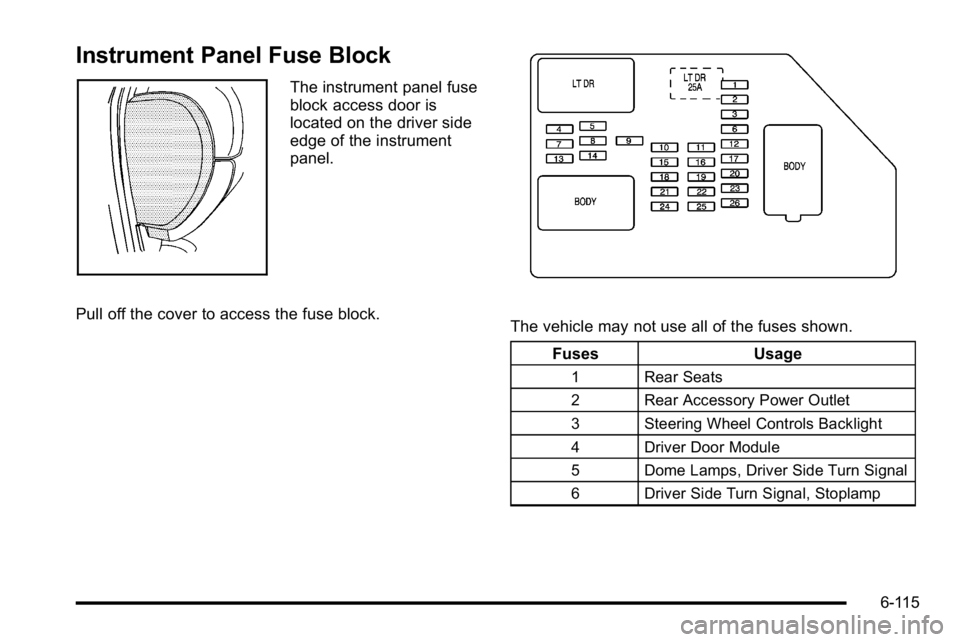

Instrument Panel Fuse Block

The instrument panel fuse

block access door is

located on the driver side

edge of the instrument

panel.

Pull off the cover to access the fuse block.

The vehicle may not use all of the fuses shown. Fuses Usage

1 Rear Seats

2 Rear Accessory Power Outlet

3 Steering Wheel Controls Backlight

4 Driver Door Module

5 Dome Lamps, Driver Side Turn Signal

6 Driver Side Turn Signal, Stoplamp

6-115

Page 490 of 550

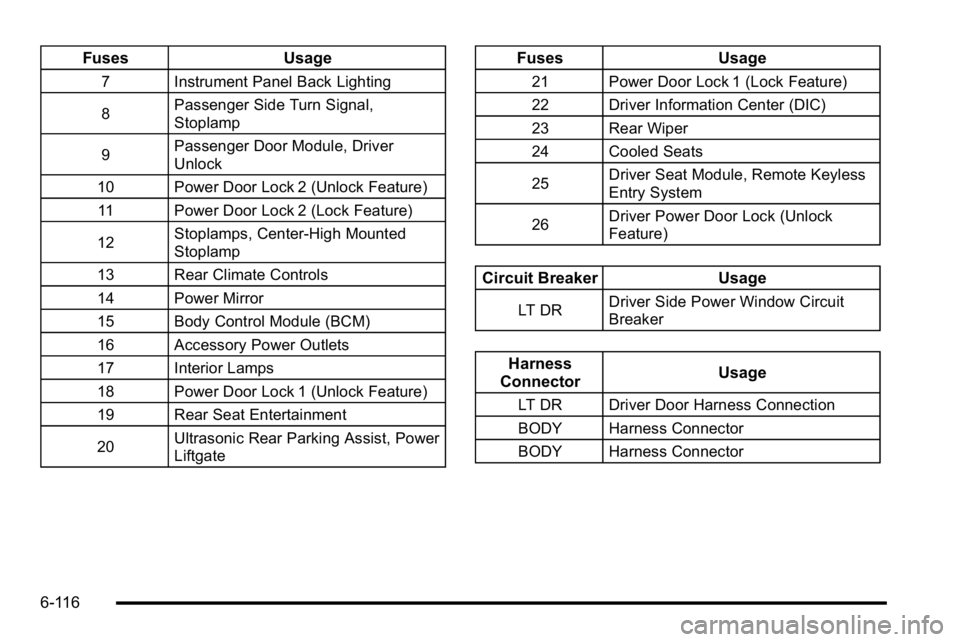

FusesUsage

7 Instrument Panel Back Lighting

8Passenger Side Turn Signal,

Stoplamp

9 Passenger Door Module, Driver

Unlock

10 Power Door Lock 2 (Unlock Feature) 11 Power Door Lock 2 (Lock Feature)

12 Stoplamps, Center-High Mounted

Stoplamp

13 Rear Climate Controls

14 Power Mirror

15 Body Control Module (BCM)

16 Accessory Power Outlets

17 Interior Lamps

18 Power Door Lock 1 (Unlock Feature)

19 Rear Seat Entertainment

20 Ultrasonic Rear Parking Assist, Power

Liftgate

Fuses

Usage

21 Power Door Lock 1 (Lock Feature)

22 Driver Information Center (DIC)

23 Rear Wiper

24 Cooled Seats

25Driver Seat Module, Remote Keyless

Entry System

26 Driver Power Door Lock (Unlock

Feature)

Circuit Breaker

Usage

LT DRDriver Side Power Window Circuit

Breaker

Harness

Connector Usage

LT DR Driver Door Harness Connection

BODY Harness Connector

BODY Harness Connector

6-116

Page 491 of 550

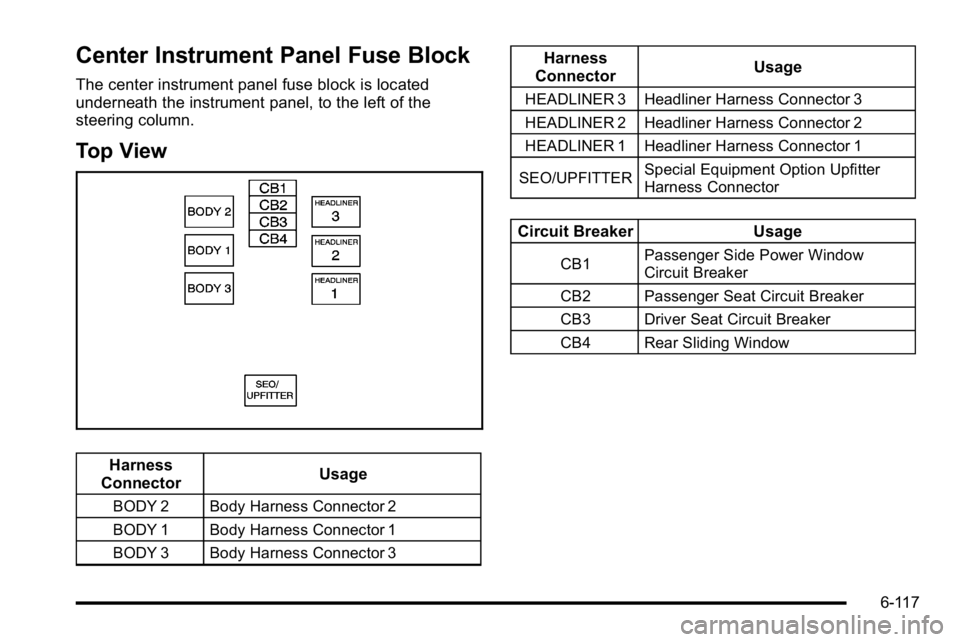

Center Instrument Panel Fuse Block

The center instrument panel fuse block is located

underneath the instrument panel, to the left of the

steering column.

Top View

Harness

Connector Usage

BODY 2 Body Harness Connector 2

BODY 1 Body Harness Connector 1

BODY 3 Body Harness Connector 3

Harness

Connector Usage

HEADLINER 3 Headliner Harness Connector 3

HEADLINER 2 Headliner Harness Connector 2

HEADLINER 1 Headliner Harness Connector 1

SEO/UPFITTER Special Equipment Option Upfitter

Harness Connector

Circuit Breaker

Usage

CB1Passenger Side Power Window

Circuit Breaker

CB2 Passenger Seat Circuit Breaker

CB3 Driver Seat Circuit Breaker

CB4 Rear Sliding Window

6-117

Page 492 of 550

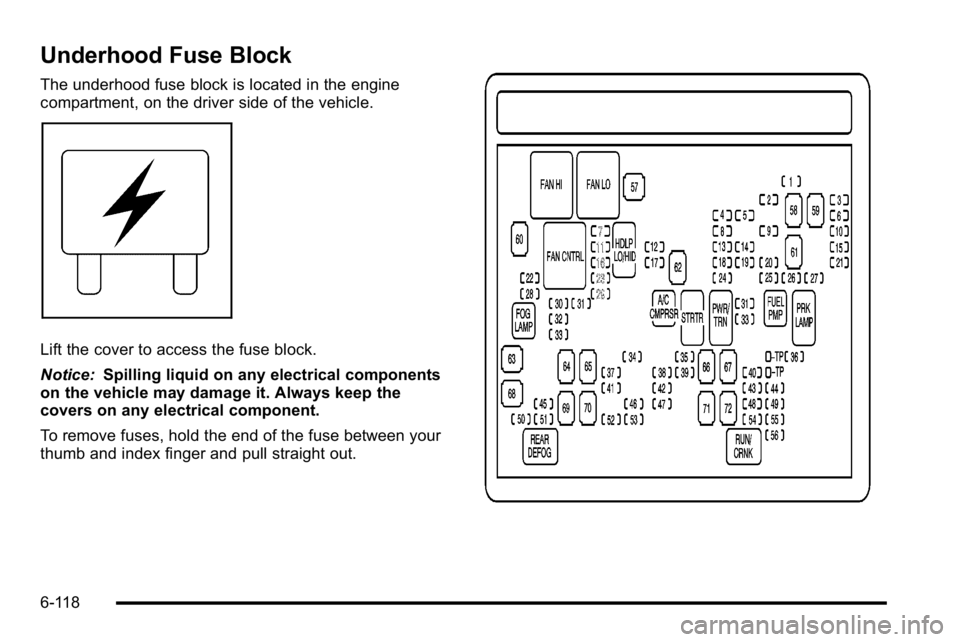

Underhood Fuse Block

The underhood fuse block is located in the engine

compartment, on the driver side of the vehicle.

Lift the cover to access the fuse block.

Notice:Spilling liquid on any electrical components

on the vehicle may damage it. Always keep the

covers on any electrical component.

To remove fuses, hold the end of the fuse between your

thumb and index finger and pull straight out.

6-118

Page 493 of 550

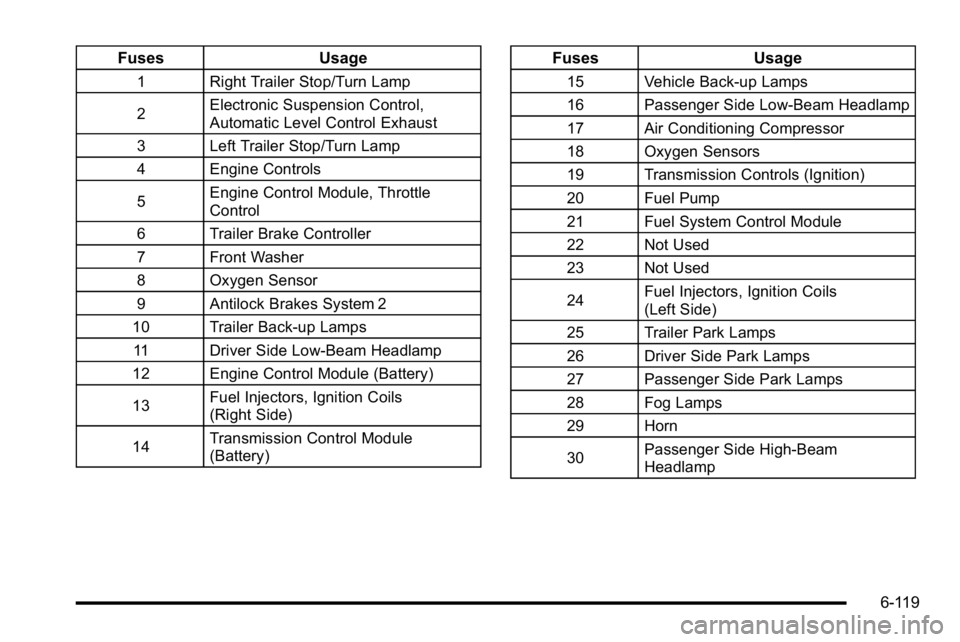

FusesUsage

1 Right Trailer Stop/Turn Lamp

2Electronic Suspension Control,

Automatic Level Control Exhaust

3 Left Trailer Stop/Turn Lamp

4 Engine Controls

5 Engine Control Module, Throttle

Control

6 Trailer Brake Controller

7 Front Washer

8 Oxygen Sensor

9 Antilock Brakes System 2

10 Trailer Back-up Lamps 11 Driver Side Low-Beam Headlamp

12 Engine Control Module (Battery)

13 Fuel Injectors, Ignition Coils

(Right Side)

14 Transmission Control Module

(Battery)

Fuses

Usage

15 Vehicle Back-up Lamps

16 Passenger Side Low-Beam Headlamp

17 Air Conditioning Compressor

18 Oxygen Sensors

19 Transmission Controls (Ignition)

20 Fuel Pump

21 Fuel System Control Module

22 Not Used

23 Not Used

24Fuel Injectors, Ignition Coils

(Left Side)

25 Trailer Park Lamps

26 Driver Side Park Lamps

27 Passenger Side Park Lamps

28 Fog Lamps

29 Horn

30 Passenger Side High-Beam

Headlamp

6-119

Page 495 of 550

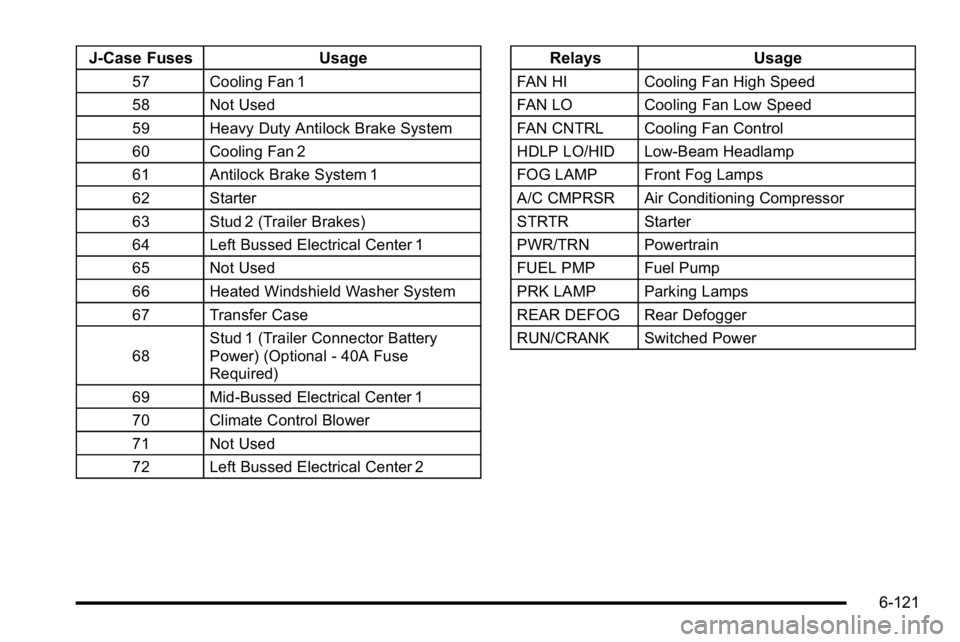

J-Case FusesUsage

57 Cooling Fan 1

58 Not Used

59 Heavy Duty Antilock Brake System

60 Cooling Fan 2

61 Antilock Brake System 1

62 Starter

63 Stud 2 (Trailer Brakes)

64 Left Bussed Electrical Center 1

65 Not Used

66 Heated Windshield Washer System

67 Transfer Case

68Stud 1 (Trailer Connector Battery

Power) (Optional - 40A Fuse

Required)

69 Mid-Bussed Electrical Center 1

70 Climate Control Blower

71 Not Used

72 Left Bussed Electrical Center 2

Relays Usage

FAN HI Cooling Fan High Speed

FAN LO Cooling Fan Low Speed

FAN CNTRL Cooling Fan Control

HDLP LO/HID Low-Beam Headlamp

FOG LAMP Front Fog Lamps

A/C CMPRSR Air Conditioning Compressor

STRTR Starter

PWR/TRN Powertrain

FUEL PMP Fuel Pump

PRK LAMP Parking Lamps

REAR DEFOG Rear Defogger

RUN/CRANK Switched Power

6-121

Page 500 of 550

.Fluids visual leak check (or every 12 months,

whichever occurs first). A leak in any system must

be repaired and the fluid level checked.

.Engine air cleaner filter inspection (vehicles driven

in dusty conditions only). SeeEngine Air

Cleaner/Filter on page 6‑22.

.Brake system inspection (or every 12 months,

whichever occurs first).

Maintenance II

.Perform all services described in Maintenance I.

.Steering and suspension inspection. Visual

inspection for damaged, loose, or missing parts or

signs of wear.

.Lubricate the front suspension, steering linkage,

and parking brake cable guides. Control arm ball

joints are maintenance‐free.

.Engine cooling system inspection. Visual

inspection of hoses, pipes, fittings, and clamps and

replacement, if needed.

.Windshield wiper blade inspection for wear,

cracking, or contamination and windshield and

wiper blade cleaning, if contaminated. See

Windshield and Wiper Blades

on page 6‑110. Worn

or damaged wiper blade replacement. See

Windshield Wiper Blade Replacement

on

page 6‑61.

.Body hinges and latches, key lock cylinders,

folding seat hardware, and liftgate hinges, linkage,

and handle pivot points lubrication. See

Recommended Fluids and Lubricants

on

page 7‑11. More frequent lubrication may be

required when vehicle is exposed to a corrosive

environment. Applying silicone grease on

weatherstrips with a clean cloth makes them last

longer, seal better, and not stick or squeak.

.Restraint system component check. See Checking

the Restraint Systems on page 2‑73.

.Automatic transmission fluid level check and

adding fluid, if needed. See Automatic

Transmission Fluid on page 6‑24.

.Transfer case fluid level check and adding fluid,

if needed.

.Engine air cleaner filter inspection. See Engine Air

Cleaner/Filter on page 6‑22.

7-4