lock GMC SIERRA DENALI 2010 Owners Manual

[x] Cancel search | Manufacturer: GMC, Model Year: 2010, Model line: SIERRA DENALI, Model: GMC SIERRA DENALI 2010Pages: 550, PDF Size: 4.17 MB

Page 361 of 550

Trailer Brakes

A loaded trailer that weighs more than 2,000 lbs

(900 kg) needs to have its own brake system that is

adequate for the weight of the trailer. Be sure to read

and follow the instructions for the trailer brakes so they

are installed, adjusted and maintained properly.

Since the vehicle is equipped with StabiliTrak

®, the

trailer brakes cannot tap into the vehicle's hydraulic

system.

Integrated Trailer Brake Control System

The vehicle may have an

Integrated Trailer Brake

Control (ITBC) system for

electric trailer brakes. This symbol is located on the Trailer Brake Control

Panel on vehicles with an Integrated Trailer Brake

Control System. The power output to the trailer brakes

is based on the amount of brake pressure being applied

by the vehicle’

s brake system. This available power

output to the trailer brakes can be adjusted to a wide

range of trailering situations.

The ITBC system is integrated with the vehicle’s brake,

anti‐lock brake and StabiliTrak systems. In trailering

conditions that cause the vehicle’s anti‐lock brake or

StabiliTrak systems to activate, power sent to the

trailer's brakes will be automatically adjusted to

minimize trailer wheel lock-up. This does not imply that

the trailer has the StabiliTrak system.

If the vehicle’s brake, anti‐lock brake or StabiliTrak

systems are not functioning properly, the ITBC system

may not be fully functional or may not function at all.

Make sure all of these systems are fully operational to

ensure full functionality of the ITBC system.

5-49

Page 365 of 550

The trailer and the vehicle's brake lamps will come on

when either vehicle braking or manual trailer brakes are

applied.

Trailer Gain Adjustment Procedure

Trailer Gain should be set for a specific trailering

condition and must be adjusted any time vehicle

loading, trailer loading or road surface conditions

change.

Setting the Trailer Gain properly is needed for the best

trailer stopping performance. A trailer that is

over-gained may result in locked trailer brakes. A trailer

that is under-gained may result in not enough trailer

braking. Both of these conditions may result in poorer

stopping and stability of the vehicle and trailer.

Use the following procedure to correctly adjust Trailer

Gain for each towing condition:1. Make sure the trailer brakes are in proper working condition.

2. Connect a properly loaded trailer to the vehicle and make all necessary mechanical and electrical

connections. See Loading the Vehicle

on

page 5‑31for more information. 3. After the electrical connection is made to a trailer

equipped with electric brakes:

.A TRAILER CONNECTED message will be

briefly displayed on the DIC display.

.The Trailer Brake Display Page will appear on

the DIC showing TRAILER GAIN and TRAILER

OUTPUT.

.In the Trailer Output display on the

DIC, “- - - - - -“ will disappear if there is no error

present. Connecting a trailer without electric

brakes will not clear the six dashed lines.

4. Adjust the Trailer Gain by using the gain adjustment (+ / -) buttons on the Trailer Brake

Control Panel.

5. Drive the vehicle with the trailer attached on a level road surface representative of the towing

condition and free of traffic at about 20 to 25 mph

(32 to 40 km/h) and fully apply the Manual Trailer

Brake Apply lever.

Adjusting trailer gain at speeds lower than

20 to 25 mph (32 to 40 km/h) may result in an

incorrect gain setting.

5-53

Page 366 of 550

6. Adjust the Trailer Gain to just below the point oftrailer wheel lock-up, indicated by trailer wheel

squeal or tire smoke when a trailer wheel locks.

Trailer wheel lock-up may not occur if towing a

heavily loaded trailer. In this case, adjust the

Trailer Gain to the highest allowable setting for the

towing condition.

7. Re-adjust Trailer Gain any time vehicle loading, trailer loading or road surface conditions change or

if trailer wheel lock-up is noticed at any time while

towing.

Other ITBC Related DIC Messages

In addition to displaying TRAILER GAIN and TRAILER

OUTPUT through the DIC, trailer connection and ITBC

system status is displayed in the DIC.

TRAILER CONNECTED –This message will be briefly

displayed when a trailer with electric brakes is first

connected to the vehicle. This message will

automatically turn off in about ten seconds. The driver

can also acknowledge this message before it

automatically turns off. CHECK TRAILER WIRING

–This message will be

displayed if:

1. The ITBC system first determines connection to a trailer with electric brakes and then the trailer

harness becomes disconnected from the vehicle.

If the disconnect occurs while the vehicle is

stationary, this message will automatically turn off

in about thirty seconds. This message will also turn

off if the driver acknowledges this message off or if

the trailer harness is re-connected.

If the disconnect occurs while the vehicle is

moving, this message will continue until the ignition

is turned off. This message will also turn off if the

driver acknowledges this message off or if the

trailer harness is re-connected.

2. There is an electrical fault in the wiring to the electric trailer brakes. This message will continue

as long as there is an electrical fault in the trailer

wiring. This message will also turn off if the driver

acknowledges this message off.

5-54

Page 377 of 550

Section 6 Service and Appearance Care

Vehicle Identification. . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-113

Vehicle Identification Number (VIN) . . . . . . . . . . . 6-113

Service Parts Identification Label . . . . . . . . . . . . . 6-113

Electrical System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-114

Add-On Electrical Equipment . . . . . . . . . . . . . . . . . 6-114

Windshield Wiper Fuses . . . . . . . . . . . . . . . . . . . . . . 6-114 Power Windows and Other Power Options . . . 6-114

Fuses and Circuit Breakers . . . . . . . . . . . . . . . . . . . 6-114

Instrument Panel Fuse Block . . . . . . . . . . . . . . . . . 6-115

Center Instrument Panel Fuse Block . . . . . . . . . . 6-117

Underhood Fuse Block . . . . . . . . . . . . . . . . . . . . . . . 6-118

Capacities and Specifications . . . . . . . . . . . . . . . . . .6-122

6-3

Page 378 of 550

Service

For service and parts needs, visit your dealer/retailer.

You will receive genuine GM parts and GM-trained and

supported service people.

Genuine GM parts have one of these marks:

Accessories and Modifications

When non‐dealer/non‐retailer accessories are added to

the vehicle, they can affect vehicle performance and

safety, including such things as airbags, braking,

stability, ride and handling, emissions systems,

aerodynamics, durability, and electronic systems like

antilock brakes, traction control, and stability control.

Some of these accessories could even cause

malfunction or damage not covered by the vehicle

warranty.

Damage to vehicle components resulting from the

installation or use of non‐GM certified parts, including

control module modifications, is not covered under the

terms of the vehicle warranty and may affect remaining

warranty coverage for affected parts.

GM Accessories are designed to complement and

function with other systems on the vehicle. Your GM

dealer/retailer can accessorize the vehicle using

genuine GM Accessories. When you go to your GM

dealer/retailer and ask for GM Accessories, you will

know that GM-trained and supported service

technicians will perform the work using genuine GM

Accessories.

Also, seeAdding Equipment to Your Airbag-Equipped

Vehicle on page 2‑72.

6-4

Page 385 of 550

The tethered fuel cap is located behind a hinged fuel

door on the driver side of the vehicle. If the vehicle has

E85 fuel capability, the fuel cap will be yellow and

state that E85 or gasoline can be used. SeeFuel E85

(85% Ethanol) on page 6‑9.

To remove the fuel cap, turn it slowly counterclockwise.

{WARNING:

Fuel can spray out on you if you open the fuel cap

too quickly. If you spill fuel and then something

ignites it, you could be badly burned. This spray

can happen if the tank is nearly full, and is more

likely in hot weather. Open the fuel cap slowly and

wait for any hiss noise to stop. Then unscrew the

cap all the way.

If the vehicle is a dual fuel tank chassis cab model, and

it runs out of fuel, refuel the front fuel tank first to ensure

a quick restart.

Be careful not to spill fuel. Do not top off or overfill the

tank and wait a few seconds after you have finished

pumping before removing the nozzle. Clean fuel from

painted surfaces as soon as possible. See Washing

Your Vehicle on page 6‑108.

6-11

Page 386 of 550

When replacing the fuel cap, turn it clockwise until it

clicks. It will require more effort to turn the fuel cap on

the last turn as you tighten it. Make sure the cap is fully

installed. The diagnostic system can determine if the

fuel cap has been left off or improperly installed. This

would allow fuel to evaporate into the atmosphere. See

Malfunction Indicator Lamp on page 4‑38.

The TIGHTEN GAS CAP message displays on the

Driver Information Center (DIC) if the fuel cap is not

properly installed. SeeDIC Warnings and Messages

on

page 4‑57for more information.

{WARNING:

If a fire starts while you are refueling, do not

remove the nozzle. Shut off the flow of fuel by

shutting off the pump or by notifying the station

attendant. Leave the area immediately.

Notice: If you need a new fuel cap, be sure to get

the right type. Your dealer/retailer can get one for

you. If you get the wrong type, it may not fit

properly. This may cause the malfunction indicator

lamp to light and may damage the fuel tank and

emissions system. See Malfunction Indicator Lamp

on page 4‑38.

6-12

Page 391 of 550

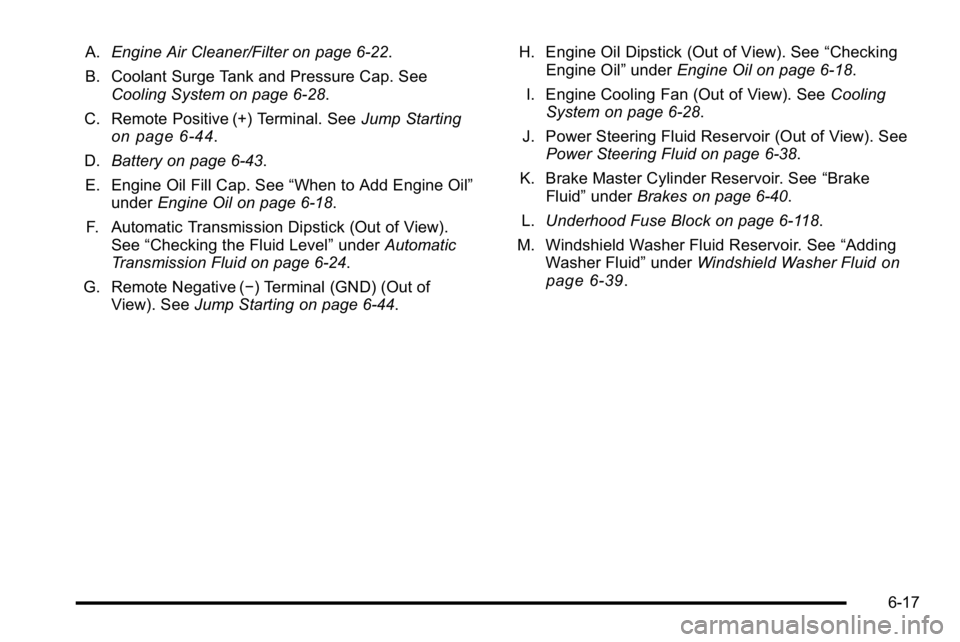

A.Engine Air Cleaner/Filter on page 6‑22.

B. Coolant Surge Tank and Pressure Cap. See Cooling System on page 6‑28.

C. Remote Positive (+) Terminal. See Jump Starting

on page 6‑44.

D. Battery on page 6‑43.

E. Engine Oil Fill Cap. See “When to Add Engine Oil”

under Engine Oil on page 6‑18.

F. Automatic Transmission Dipstick (Out of View). See “Checking the Fluid Level” underAutomatic

Transmission Fluid on page 6‑24.

G. Remote Negative (−) Terminal (GND) (Out of View). See Jump Starting on page 6‑44. H. Engine Oil Dipstick (Out of View). See

“Checking

Engine Oil” underEngine Oil on page 6‑18.

I. Engine Cooling Fan (Out of View). See Cooling

System on page 6‑28.

J. Power Steering Fluid Reservoir (Out of View). See Power Steering Fluid on page 6‑38.

K. Brake Master Cylinder Reservoir. See “Brake

Fluid” under Brakes on page 6‑40.

L. Underhood Fuse Block on page 6‑118.

M. Windshield Washer Fluid Reservoir. See “Adding

Washer Fluid” underWindshield Washer Fluid

on

page 6‑39.

6-17

Page 400 of 550

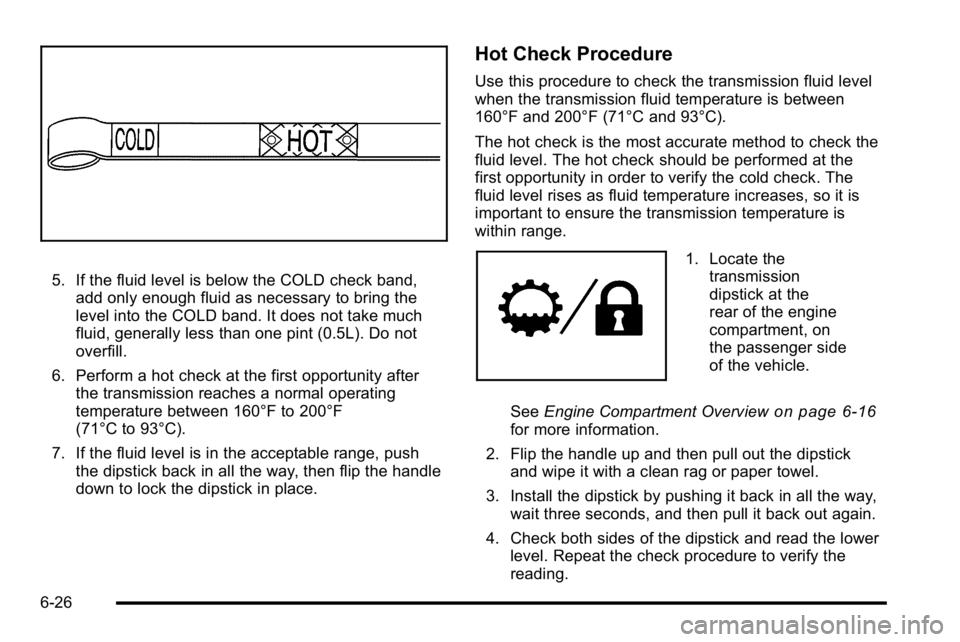

5. If the fluid level is below the COLD check band,add only enough fluid as necessary to bring the

level into the COLD band. It does not take much

fluid, generally less than one pint (0.5L). Do not

overfill.

6. Perform a hot check at the first opportunity after the transmission reaches a normal operating

temperature between 160°F to 200°F

(71°C to 93°C).

7. If the fluid level is in the acceptable range, push the dipstick back in all the way, then flip the handle

down to lock the dipstick in place.

Hot Check Procedure

Use this procedure to check the transmission fluid level

when the transmission fluid temperature is between

160°F and 200°F (71°C and 93°C).

The hot check is the most accurate method to check the

fluid level. The hot check should be performed at the

first opportunity in order to verify the cold check. The

fluid level rises as fluid temperature increases, so it is

important to ensure the transmission temperature is

within range.

1. Locate thetransmission

dipstick at the

rear of the engine

compartment, on

the passenger side

of the vehicle.

See Engine Compartment Overview

on page 6‑16for more information.

2. Flip the handle up and then pull out the dipstick and wipe it with a clean rag or paper towel.

3. Install the dipstick by pushing it back in all the way, wait three seconds, and then pull it back out again.

4. Check both sides of the dipstick and read the lower level. Repeat the check procedure to verify the

reading.

6-26

Page 401 of 550

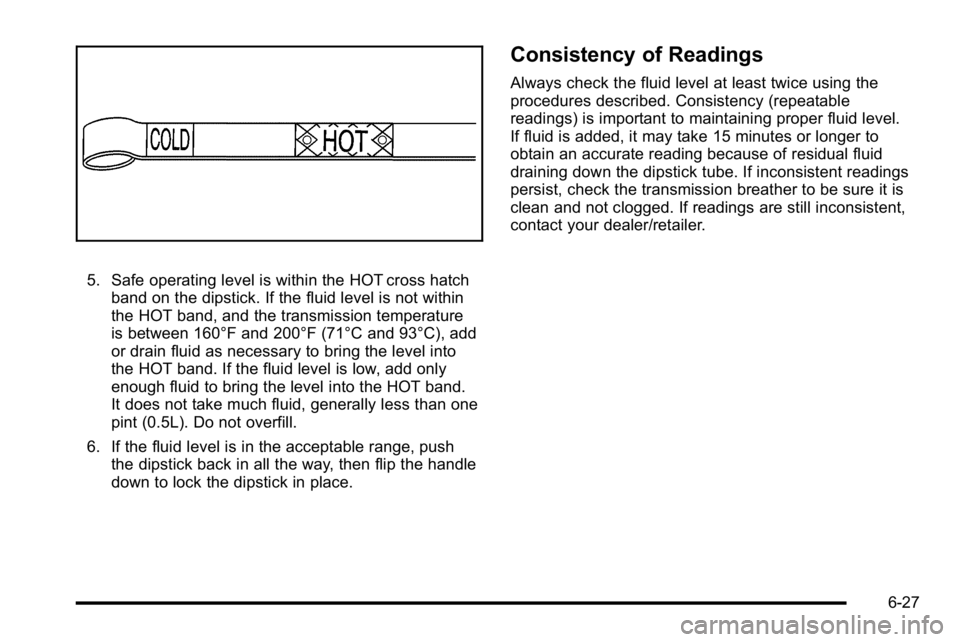

5. Safe operating level is within the HOT cross hatchband on the dipstick. If the fluid level is not within

the HOT band, and the transmission temperature

is between 160°F and 200°F (71°C and 93°C), add

or drain fluid as necessary to bring the level into

the HOT band. If the fluid level is low, add only

enough fluid to bring the level into the HOT band.

It does not take much fluid, generally less than one

pint (0.5L). Do not overfill.

6. If the fluid level is in the acceptable range, push the dipstick back in all the way, then flip the handle

down to lock the dipstick in place.

Consistency of Readings

Always check the fluid level at least twice using the

procedures described. Consistency (repeatable

readings) is important to maintaining proper fluid level.

If fluid is added, it may take 15 minutes or longer to

obtain an accurate reading because of residual fluid

draining down the dipstick tube. If inconsistent readings

persist, check the transmission breather to be sure it is

clean and not clogged. If readings are still inconsistent,

contact your dealer/retailer.

6-27