GMC TERRAIN 2010 Owner's Manual

Manufacturer: GMC, Model Year: 2010, Model line: TERRAIN, Model: GMC TERRAIN 2010Pages: 410, PDF Size: 2.55 MB

Page 301 of 410

Vehicle Care 9-27

3. Try to start the engine in eachgear. The vehicle should start

only in P (Park) or N (Neutral).

If the vehicle starts in any other

position, contact your dealer/

retailer for service.

Automatic Transmission

Shift Lock Control

System Check

{WARNING

When you are doing this

inspection, the vehicle could

move suddenly. If the vehicle

moves, you or others could be

injured.

1. Before starting this check, be sure there is enough room

around the vehicle. It should be

parked on a level surface. 2. Firmly apply the parking brake.

See Parking Brake

on

page 8‑40.

Be ready to apply the regular

brake immediately if the vehicle

begins to move.

3. With the engine off, turn the ignition to ON/RUN, but do not

start the engine. Without

applying the regular brake, try to

move the shift lever out of

P (Park) with normal effort. If the

shift lever moves out of P (Park),

contact your dealer/retailer for

service.

Ignition Transmission

Lock Check

While parked, and with the parking

brake set, try to turn the ignition to

LOCK/OFF in each shift lever

position.

.The ignition should turn to

LOCK/OFF only when the shift

lever is in P (Park).

.The ignition key should come

out only in LOCK/OFF.

Contact your dealer/retailer if

service is required.

Page 302 of 410

9-28 Vehicle Care

Park Brake and P (Park)

Mechanism Check

{WARNING

When you are doing this check,

the vehicle could begin to move.

You or others could be injured

and property could be damaged.

Make sure there is room in front

of the vehicle in case it begins to

roll. Be ready to apply the regular

brake at once should the vehicle

begin to move.Park on a fairly steep hill, with the

vehicle facing downhill. Keeping

your foot on the regular brake, set

the parking brake.

.To check the parking brake's

holding ability: With the engine

running and the transmission in

N (Neutral), slowly remove foot

pressure from the regular brake

pedal. Do this until the vehicle is

held by the parking brake only.

.To check the P (Park)

mechanism's holding ability:

With the engine running, shift to

P (Park). Then release the

parking brake followed by the

regular brake.

Contact your dealer/retailer if

service is required.

Wiper Blade Replacement

Windshield wiper blades should be

inspected for wear and cracking.

See Scheduled Maintenance

on

page 10‑2for more information.

Replacement blades come in

different types and are removed in

different ways. For proper type

and length, see Maintenance

Replacement Parts on page 10‑9.

Notice: Allowing the wiper blade

arm to touch the windshield when

no wiper blade is installed could

damage the windshield. Any

damage that occurs would not be

covered by your warranty. Do not

allow the wiper blade arm to

touch the windshield.

Page 303 of 410

Vehicle Care 9-29

Front Wiper Blade

Replacement

To replace the front wiper blades:

1. Lift the wiper arm from thewindshield until no further

movement is possible.

2. Press the square button on thetop side, at the end of the wiper

arm, and pull the wiper blade out

of the end of the wiper arm. 3. Install the wiper blade connector

by sliding into the end of the

wiper arm until the square button

on the wiper blade clicks into

place with the wiper arm.

4. Place the wiper arm with the wiper blade in place back on the

windshield.

Rear Wiper Blade Replacement

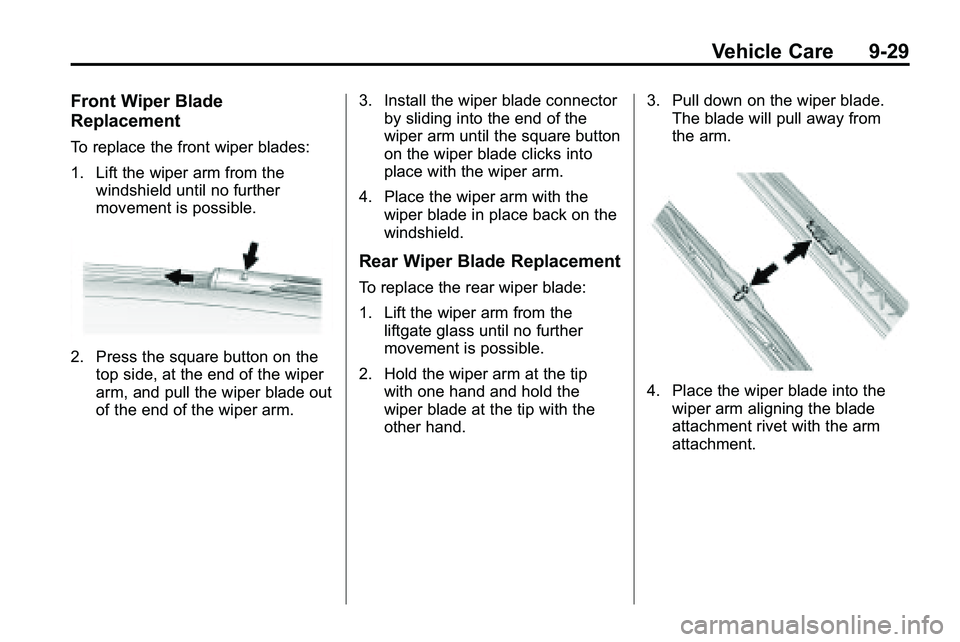

To replace the rear wiper blade:

1. Lift the wiper arm from theliftgate glass until no further

movement is possible.

2. Hold the wiper arm at the tip with one hand and hold the

wiper blade at the tip with the

other hand. 3. Pull down on the wiper blade.

The blade will pull away from

the arm.

4. Place the wiper blade into the

wiper arm aligning the blade

attachment rivet with the arm

attachment.

Page 304 of 410

9-30 Vehicle Care

5. Align the wiper blade with thearm and hold both ends of the

arm while gently squeezing until

the blade snaps into place.

Do not apply excessive force

during this operation.

Reposition the blade in the arm

and repeat, if blade is not

correctly positioned.

6. Place the wiper arm with the wiper blade attached back on

the liftgate glass.Headlamp Aiming

The headlamp aiming system has

been preset at the factory.

If the vehicle is damaged in an

accident, the aim of the headlamps

may be affected and adjustment

may be necessary.

It is recommended that a dealer/

retailer adjust the headlamps. To

re-aim the headlamps yourself, use

the following procedure.

The vehicle should be properly

prepared as follows. The vehicle:

.Should be placed so the

headlamps are 7.6 m (25 ft) from

a light colored wall.

.Must have all four tires on a

level surface which is level all

the way to the wall.

.Should be placed so it is

perpendicular to the wall or other

flat surface.

.Should not have any snow, ice,

or mud on it.

.Should be fully assembled and

all other work stopped while

headlamp aiming is being

performed.

.Should be normally loaded with

a full tank of fuel and one person

or 75 kg (160 lbs) sitting in the

driver's seat.

.Tires should be properly inflated.

Headlamp aiming is done with the

vehicle's low-beam headlamps. The

high-beam headlamps will be

correctly aimed if the low-beam

headlamps are aimed properly.

Page 305 of 410

Vehicle Care 9-31

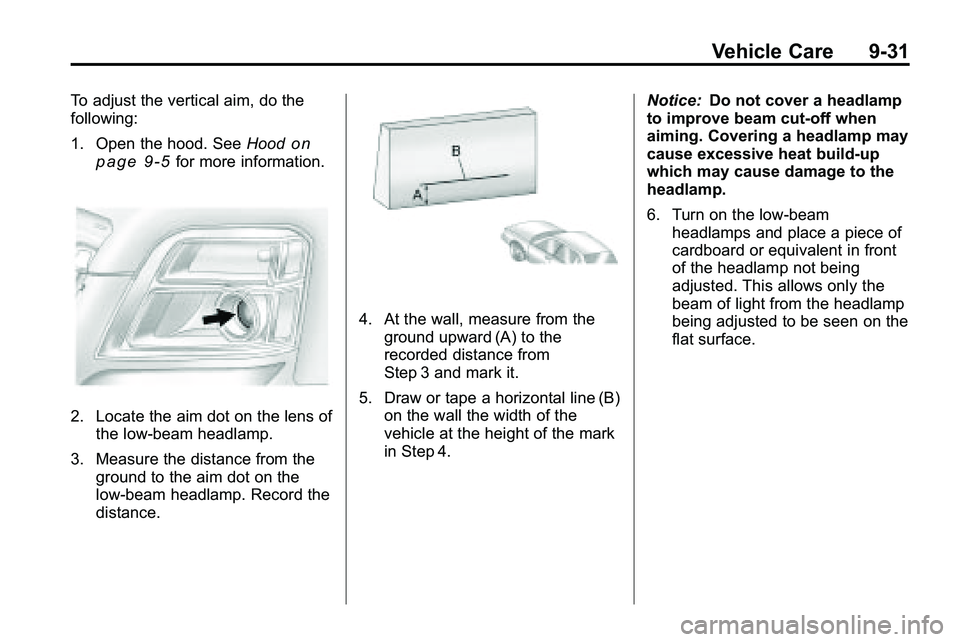

To adjust the vertical aim, do the

following:

1. Open the hood. SeeHood

on

page 9‑5for more information.

2. Locate the aim dot on the lens of the low‐beam headlamp.

3. Measure the distance from the ground to the aim dot on the

low‐beam headlamp. Record the

distance.

4. At the wall, measure from the

ground upward (A) to the

recorded distance from

Step 3 and mark it.

5. Draw or tape a horizontal line (B) on the wall the width of the

vehicle at the height of the mark

in Step 4. Notice:

Do not cover a headlamp

to improve beam cut-off when

aiming. Covering a headlamp may

cause excessive heat build-up

which may cause damage to the

headlamp.

6. Turn on the low-beam

headlamps and place a piece of

cardboard or equivalent in front

of the headlamp not being

adjusted. This allows only the

beam of light from the headlamp

being adjusted to be seen on the

flat surface.

Page 306 of 410

9-32 Vehicle Care

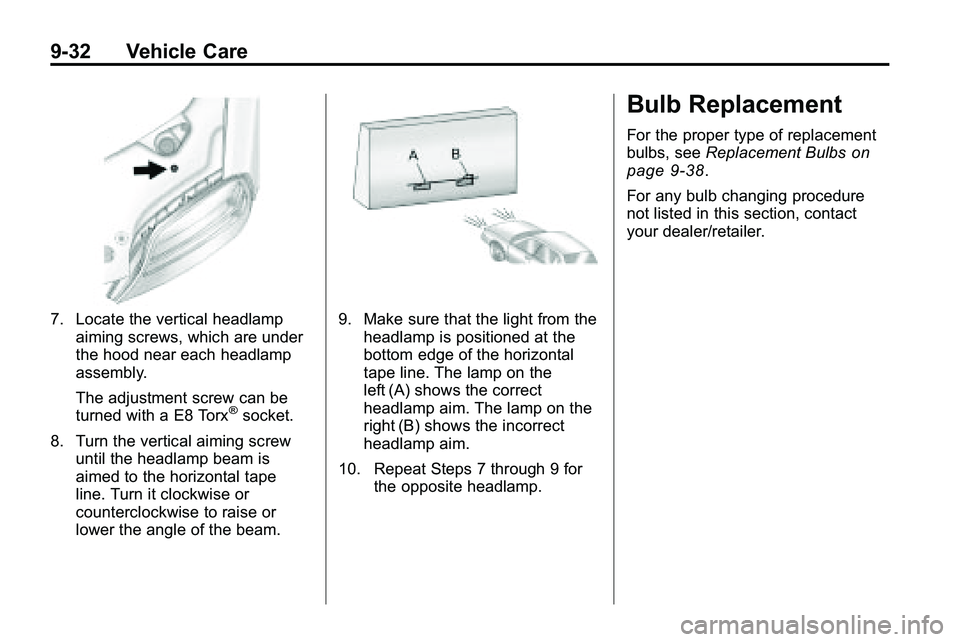

7. Locate the vertical headlampaiming screws, which are under

the hood near each headlamp

assembly.

The adjustment screw can be

turned with a E8 Torx

®socket.

8. Turn the vertical aiming screw until the headlamp beam is

aimed to the horizontal tape

line. Turn it clockwise or

counterclockwise to raise or

lower the angle of the beam.

9. Make sure that the light from theheadlamp is positioned at the

bottom edge of the horizontal

tape line. The lamp on the

left (A) shows the correct

headlamp aim. The lamp on the

right (B) shows the incorrect

headlamp aim.

10. Repeat Steps 7 through 9 for the opposite headlamp.

Bulb Replacement

For the proper type of replacement

bulbs, see Replacement Bulbson

page 9‑38.

For any bulb changing procedure

not listed in this section, contact

your dealer/retailer.

Page 307 of 410

Vehicle Care 9-33

Headlamps, Front Turn

Signal, Sidemarker, and

Parking Lamps

A. Low-Beam Headlamp

B. High-Beam headlamp

C. Side Marker Lamp

D. Park/Turn Signal LampTo replace:

1. Turn the tire to reach the access

port cap located in the front of

wheel well cover.A. Screw

B. Access Port Cap

2. Remove screw (A) and turn the access port cap (B)

counterclockwise to remove.

3. If replacing a low/high headlamp bulb, remove the dust cover cap

from the back of the headlamp

housing by turning the cap

counterclockwise. 4. Turn the low/high beam or

park/turn signal bulb socket

counterclockwise to remove from

the lamp assembly.

5. Turn the sidemarker bulb socket clockwise to remove from the

lamp assembly.

6. Remove the bulb from the socket or disconnect bulb

assembly from harness

connector.

7. Install new bulb.

8. Reinstall the low/high beam or park/turn signal bulb socket to

the lamp assembly, turning

clockwise.

9. Reinstall the sidemarker bulb socket to the lamp assembly,

turning clockwise.

10. Replace the dust cover cap on headlamps.

11. Reinstall the wheel well cover access port cap and secure by

installing screw.

Page 308 of 410

9-34 Vehicle Care

Fog Lamps

To replace one of these bulbs:

1. Locate the fog lamp assemblyunder the front facia.

2. Disconnect the bulb socket from the electrical connector, turn and

pull out the bulb assembly. 3. Remove the old bulb from the

bulb socket and push the new

bulb straight into the bulb socket

until it connects.

4. Push the bulb socket into the fog lamp assembly and turn

counterclockwise to lock it into

place.

5. Reconnect the bulb socket to the electrical connector.

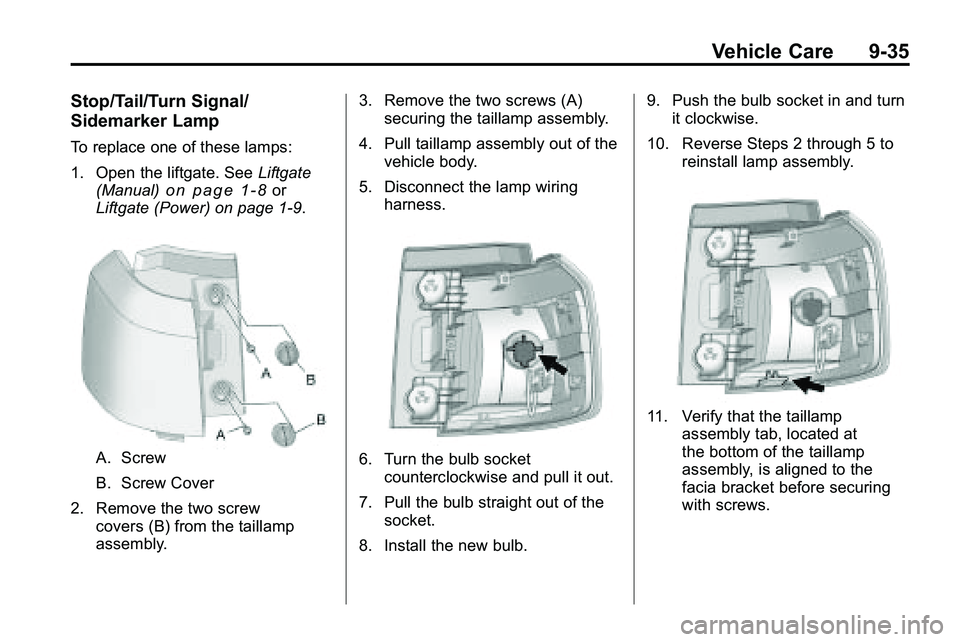

Taillamps, Turn Signal,

Sidemarker, Stoplamps,

and Back-Up Lamps

A. Stop/Tail/Turn Signal/Sidemarker Lamp

B. Auxiliary Taillamp

C. Back-up Lamp

Page 309 of 410

Vehicle Care 9-35

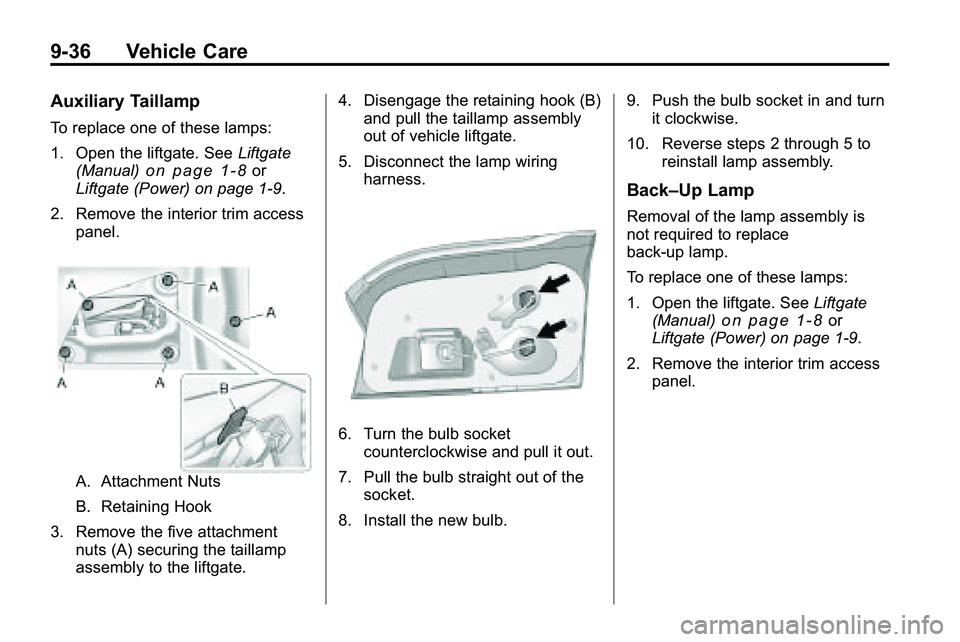

Stop/Tail/Turn Signal/

Sidemarker Lamp

To replace one of these lamps:

1. Open the liftgate. SeeLiftgate

(Manual)

on page 1‑8or

Liftgate (Power) on page 1‑9.

A. Screw

B. Screw Cover

2. Remove the two screw covers (B) from the taillamp

assembly. 3. Remove the two screws (A)

securing the taillamp assembly.

4. Pull taillamp assembly out of the vehicle body.

5. Disconnect the lamp wiring harness.6. Turn the bulb socketcounterclockwise and pull it out.

7. Pull the bulb straight out of the socket.

8. Install the new bulb. 9. Push the bulb socket in and turn

it clockwise.

10. Reverse Steps 2 through 5 to reinstall lamp assembly.

11. Verify that the taillampassembly tab, located at

the bottom of the taillamp

assembly, is aligned to the

facia bracket before securing

with screws.

Page 310 of 410

9-36 Vehicle Care

Auxiliary Taillamp

To replace one of these lamps:

1. Open the liftgate. SeeLiftgate

(Manual)

on page 1‑8or

Liftgate (Power) on page 1‑9.

2. Remove the interior trim access panel.

A. Attachment Nuts

B. Retaining Hook

3. Remove the five attachment nuts (A) securing the taillamp

assembly to the liftgate. 4. Disengage the retaining hook (B)

and pull the taillamp assembly

out of vehicle liftgate.

5. Disconnect the lamp wiring harness.

6. Turn the bulb socketcounterclockwise and pull it out.

7. Pull the bulb straight out of the socket.

8. Install the new bulb. 9. Push the bulb socket in and turn

it clockwise.

10. Reverse steps 2 through 5 to reinstall lamp assembly.

Back–Up Lamp

Removal of the lamp assembly is

not required to replace

back-up lamp.

To replace one of these lamps:

1. Open the liftgate. See Liftgate

(Manual)

on page 1‑8or

Liftgate (Power) on page 1‑9.

2. Remove the interior trim access panel.