lock GMC YUKON 2021 Owners Manual

[x] Cancel search | Manufacturer: GMC, Model Year: 2021, Model line: YUKON, Model: GMC YUKON 2021Pages: 433, PDF Size: 6.54 MB

Page 294 of 433

GMC Yukon/Yukon XL/Denali Owner Manual (GMNA-Localizing-U.S./

Canada/Mexico-13690468) - 2021 - crc - 8/14/20

Driving and Operating 291

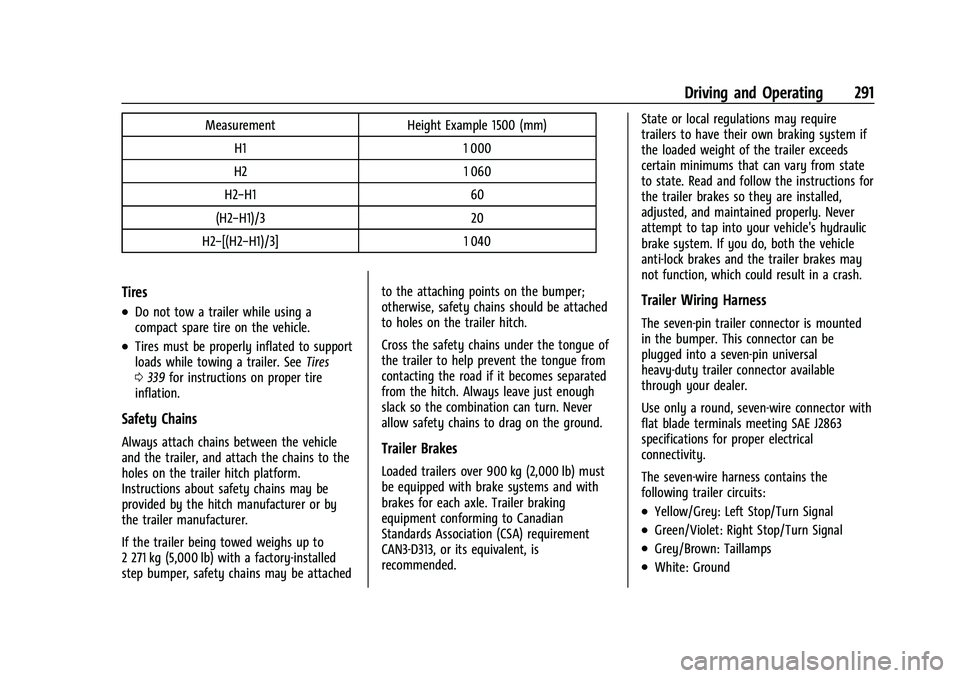

MeasurementHeight Example 1500 (mm)

H1 1 000

H2 1 060

H2−H1 60

(H2−H1)/3 20

H2−[(H2−H1)/3] 1 040

Tires

.Do not tow a trailer while using a

compact spare tire on the vehicle.

.Tires must be properly inflated to support

loads while towing a trailer. SeeTires

0 339 for instructions on proper tire

inflation.

Safety Chains

Always attach chains between the vehicle

and the trailer, and attach the chains to the

holes on the trailer hitch platform.

Instructions about safety chains may be

provided by the hitch manufacturer or by

the trailer manufacturer.

If the trailer being towed weighs up to

2 271 kg (5,000 lb) with a factory-installed

step bumper, safety chains may be attached to the attaching points on the bumper;

otherwise, safety chains should be attached

to holes on the trailer hitch.

Cross the safety chains under the tongue of

the trailer to help prevent the tongue from

contacting the road if it becomes separated

from the hitch. Always leave just enough

slack so the combination can turn. Never

allow safety chains to drag on the ground.Trailer Brakes

Loaded trailers over 900 kg (2,000 lb) must

be equipped with brake systems and with

brakes for each axle. Trailer braking

equipment conforming to Canadian

Standards Association (CSA) requirement

CAN3-D313, or its equivalent, is

recommended.State or local regulations may require

trailers to have their own braking system if

the loaded weight of the trailer exceeds

certain minimums that can vary from state

to state. Read and follow the instructions for

the trailer brakes so they are installed,

adjusted, and maintained properly. Never

attempt to tap into your vehicle's hydraulic

brake system. If you do, both the vehicle

anti-lock brakes and the trailer brakes may

not function, which could result in a crash.

Trailer Wiring Harness

The seven-pin trailer connector is mounted

in the bumper. This connector can be

plugged into a seven-pin universal

heavy-duty trailer connector available

through your dealer.

Use only a round, seven-wire connector with

flat blade terminals meeting SAE J2863

specifications for proper electrical

connectivity.

The seven-wire harness contains the

following trailer circuits:

.Yellow/Grey: Left Stop/Turn Signal

.Green/Violet: Right Stop/Turn Signal

.Grey/Brown: Taillamps

.White: Ground

Page 296 of 433

GMC Yukon/Yukon XL/Denali Owner Manual (GMNA-Localizing-U.S./

Canada/Mexico-13690468) - 2021 - crc - 8/14/20

Driving and Operating 293

The ITBC system is integrated with the

vehicle’s brake, anti-lock brake, and

StabiliTrak systems. In trailering conditions

that cause the vehicle’s anti-lock brake or

StabiliTrak systems to activate, power sent

to the trailer's brakes will be automatically

adjusted to minimize trailer wheel lock-up.

This does not imply that the trailer has

StabiliTrak.

If the vehicle’s brake, anti-lock brake,

or StabiliTrak systems are not functioning

properly, the ITBC system may not function

fully or at all. Make sure all of these

systems are fully operational to allow the

ITBC system to function properly.

The ITBC system is powered through the

vehicle's electrical system. Turning the

ignition off will also turn off the ITBC

system. The ITBC system is fully functional

only when the ignition is in ON/RUN.

{Warning

Connecting a trailer that has an air brake

system may result in reduced or

complete loss of trailer braking, including

increased stopping distance or trailer

instability which could result in serious(Continued)

Warning (Continued)

injury, death, or property damage. Only

use the ITBC system with electric or

electric over hydraulic trailer brake

systems.

Trailer Brake Control Panel

1. Manual Trailer Brake Apply Lever

2. Trailer Symbol

3. Trailer Gain Adjustment Buttons

The ITBC control panel is on the instrument

panel to the left of the steering column. The

control panel allows adjustment to the

amount of output, referred to as Trailer

Gain, available to the trailer brakes and allows manual application of the trailer

brakes. Use the ITBC control panel and the

DIC trailer brake display page to adjust and

display power output to the trailer brakes.

Trailer Brake DIC Display Page

The ITBC display page indicates:

.Trailer Gain setting

.Output to the trailer brakes

.Trailer connection

.System operational status.

To display:

.Scroll through the DIC menu pages

.Press a Trailer Gain (+) or (−) button

.Activate the Manual Trailer Brake Apply

Lever

TRAILER GAIN:

Press a Trailer Gain button to recall the

current Trailer Gain setting. Each press and

release of the gain buttons will then change

the Trailer Gain setting. Press the Trailer

Gain (+) or (−) to adjust. Press and hold to

continuously adjust the Trailer Gain. To turn

the output to the trailer off, adjust the

Trailer Gain setting to 0.0. This setting can

be adjusted from 0.0 to 10.0 with a trailer

connected or disconnected.

Page 297 of 433

GMC Yukon/Yukon XL/Denali Owner Manual (GMNA-Localizing-U.S./

Canada/Mexico-13690468) - 2021 - crc - 8/14/20

294 Driving and Operating

TRAILER OUTPUT: This displays anytime a

trailer with electric brakes is connected.

Output to the trailer brakes is based on the

amount of vehicle braking present and

relative to the Trailer Gain setting. Output is

displayed from 0 to 100% for each gain

setting.

The Trailer Output will indicate“- - - - - -”on

the Trailer Brake Display Page whenever the

following occur:

.No trailer is connected.

.A trailer without electric brakes is

connected, no DIC message will display

.A trailer with electric brakes has become

disconnected, a CHECK TRAILER WIRING

message displays on the DIC

.There is a fault present in the wiring to

the trailer brakes, a CHECK TRAILER

WIRING message displays on the DIC

.The ITBC system is not working due to a

fault, a SERVICE TRAILER BRAKE SYSTEM

message displays in the DIC

Manual Trailer Brake Apply Lever

Slide this lever right to apply the trailer’s

electric brakes independent of the vehicle’s

brakes. Use this lever to adjust Trailer Gain

to achieve the proper power output to the

trailer brakes. This lever may also be used to request additional trailer braking at any

time. The trailer's and the vehicle's brake

lamps will come on when either vehicle

brakes or manual trailer brakes are applied

and properly connected.

Trailer Gain Adjustment Procedure

Trailer Gain should be set for a specific

trailering condition and it must be

readjusted anytime vehicle loading, trailer

loading, or road surface conditions change.

{Warning

Trailer brakes that are over-gained or

under-gained may not stop the vehicle

and the trailer as intended and can result

in a crash. Always follow the instructions

to set the Trailer Gain for the proper

trailer stopping performance.

To adjust Trailer Gain for each towing

condition: 1. Drive the vehicle with the trailer attached on a level road surface

representative of the towing condition

and free of traffic at about 32 to

40 km/h (20 to 25 mph) and fully apply

the Manual Trailer Brake apply lever. Note

Adjusting Trailer Gain at speeds lower than

32 to 40 km/h (20 to 25 mph) may result in

an incorrect gain setting.

2. Adjust the Trailer Gain, using the Trailer Gain adjustment buttons, to just below

the point of trailer wheel lock-up,

indicated by trailer wheel squeal or tire

smoke when a trailer wheel locks.

Note

Trailer wheel lock-up may not occur if

towing a heavily loaded trailer. In this case,

adjust the Trailer Gain to the highest

allowable setting for the towing condition. 3. Readjust Trailer Gain any time vehicle loading, trailer loading, or road surface

conditions change or if trailer wheel

lock-up is noticed at any time while

towing.

Other ITBC-Related DIC Messages

TRAILER CONNECTED: This message will

briefly display when a trailer with electric

brakes is first connected to the vehicle. This

message will automatically turn off in about

10 seconds. This message can be

acknowledged before it automatically

turns off.

Page 311 of 433

GMC Yukon/Yukon XL/Denali Owner Manual (GMNA-Localizing-U.S./

Canada/Mexico-13690468) - 2021 - crc - 8/14/20

308 Vehicle Care

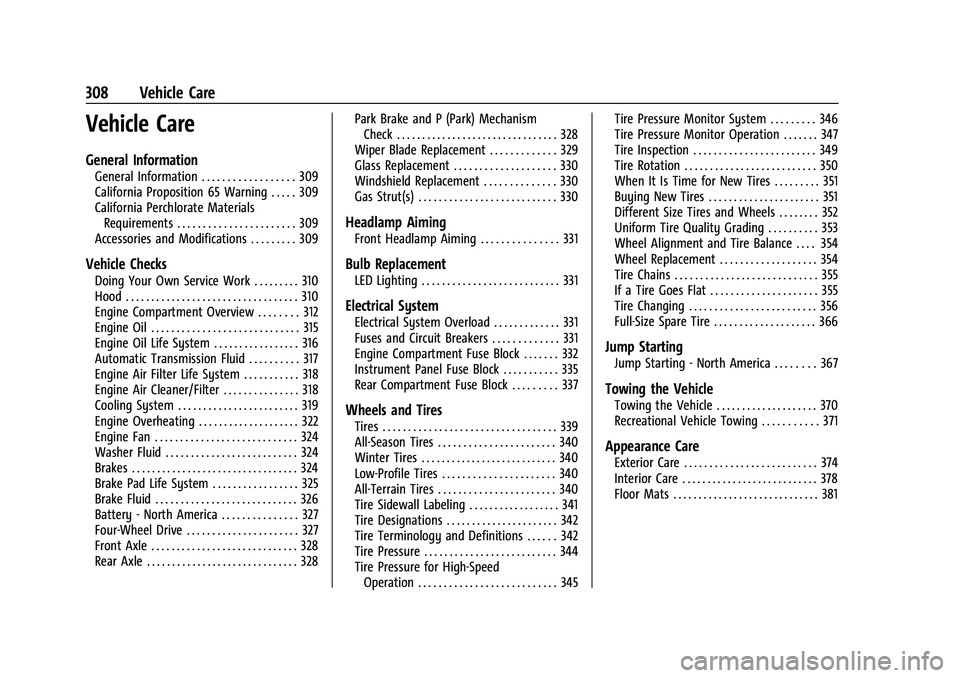

Vehicle Care

General Information

General Information . . . . . . . . . . . . . . . . . . 309

California Proposition 65 Warning . . . . . 309

California Perchlorate MaterialsRequirements . . . . . . . . . . . . . . . . . . . . . . . 309

Accessories and Modifications . . . . . . . . . 309

Vehicle Checks

Doing Your Own Service Work . . . . . . . . . 310

Hood . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 310

Engine Compartment Overview . . . . . . . . 312

Engine Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 315

Engine Oil Life System . . . . . . . . . . . . . . . . . 316

Automatic Transmission Fluid . . . . . . . . . . 317

Engine Air Filter Life System . . . . . . . . . . . 318

Engine Air Cleaner/Filter . . . . . . . . . . . . . . . 318

Cooling System . . . . . . . . . . . . . . . . . . . . . . . . 319

Engine Overheating . . . . . . . . . . . . . . . . . . . . 322

Engine Fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . 324

Washer Fluid . . . . . . . . . . . . . . . . . . . . . . . . . . 324

Brakes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 324

Brake Pad Life System . . . . . . . . . . . . . . . . . 325

Brake Fluid . . . . . . . . . . . . . . . . . . . . . . . . . . . . 326

Battery - North America . . . . . . . . . . . . . . . 327

Four-Wheel Drive . . . . . . . . . . . . . . . . . . . . . . 327

Front Axle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 328

Rear Axle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 328 Park Brake and P (Park) Mechanism

Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 328

Wiper Blade Replacement . . . . . . . . . . . . . 329

Glass Replacement . . . . . . . . . . . . . . . . . . . . 330

Windshield Replacement . . . . . . . . . . . . . . 330

Gas Strut(s) . . . . . . . . . . . . . . . . . . . . . . . . . . . 330

Headlamp Aiming

Front Headlamp Aiming . . . . . . . . . . . . . . . 331

Bulb Replacement

LED Lighting . . . . . . . . . . . . . . . . . . . . . . . . . . . 331

Electrical System

Electrical System Overload . . . . . . . . . . . . . 331

Fuses and Circuit Breakers . . . . . . . . . . . . . 331

Engine Compartment Fuse Block . . . . . . . 332

Instrument Panel Fuse Block . . . . . . . . . . . 335

Rear Compartment Fuse Block . . . . . . . . . 337

Wheels and Tires

Tires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 339

All-Season Tires . . . . . . . . . . . . . . . . . . . . . . . 340

Winter Tires . . . . . . . . . . . . . . . . . . . . . . . . . . . 340

Low-Profile Tires . . . . . . . . . . . . . . . . . . . . . . 340

All-Terrain Tires . . . . . . . . . . . . . . . . . . . . . . . 340

Tire Sidewall Labeling . . . . . . . . . . . . . . . . . . 341

Tire Designations . . . . . . . . . . . . . . . . . . . . . . 342

Tire Terminology and Definitions . . . . . . 342

Tire Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . 344

Tire Pressure for High-Speed Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . 345 Tire Pressure Monitor System . . . . . . . . . 346

Tire Pressure Monitor Operation . . . . . . . 347

Tire Inspection . . . . . . . . . . . . . . . . . . . . . . . . 349

Tire Rotation . . . . . . . . . . . . . . . . . . . . . . . . . . 350

When It Is Time for New Tires . . . . . . . . . 351

Buying New Tires . . . . . . . . . . . . . . . . . . . . . . 351

Different Size Tires and Wheels . . . . . . . . 352

Uniform Tire Quality Grading . . . . . . . . . . 353

Wheel Alignment and Tire Balance . . . . 354

Wheel Replacement . . . . . . . . . . . . . . . . . . . 354

Tire Chains . . . . . . . . . . . . . . . . . . . . . . . . . . . . 355

If a Tire Goes Flat . . . . . . . . . . . . . . . . . . . . . 355

Tire Changing . . . . . . . . . . . . . . . . . . . . . . . . . 356

Full-Size Spare Tire . . . . . . . . . . . . . . . . . . . . 366

Jump Starting

Jump Starting - North America . . . . . . . . 367

Towing the Vehicle

Towing the Vehicle . . . . . . . . . . . . . . . . . . . . 370

Recreational Vehicle Towing . . . . . . . . . . . 371

Appearance Care

Exterior Care . . . . . . . . . . . . . . . . . . . . . . . . . . 374

Interior Care . . . . . . . . . . . . . . . . . . . . . . . . . . . 378

Floor Mats . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 381

Page 312 of 433

GMC Yukon/Yukon XL/Denali Owner Manual (GMNA-Localizing-U.S./

Canada/Mexico-13690468) - 2021 - crc - 8/14/20

Vehicle Care 309

General Information

For service and parts needs, visit your

dealer. You will receive genuine GM parts

and GM-trained and supported service

people.

Genuine GM parts have one of these marks:

California Proposition 65 Warning

{Warning

Most motor vehicles, including this one,

as well as many of its service parts and

fluids, contain and/or emit chemicals

known to the State of California to cause(Continued)

Warning (Continued)

cancer and birth defects or other

reproductive harm. Engine exhaust, many

parts and systems, many fluids, and

some component wear by-products

contain and/or emit these chemicals. For

more information go to

www.P65Warnings.ca.gov/

passenger-vehicle.

See Battery - North America 0327 and

Jump Starting - North America 0367 and

the back cover.

California Perchlorate Materials

Requirements

Certain types of automotive applications,

such as airbag initiators, seat belt

pretensioners, and lithium batteries

contained in electronic keys, may contain

perchlorate materials. Perchlorate Material –

special handling may apply. See

www.dtsc.ca.gov/hazardouswaste/

perchlorate.

Accessories and Modifications

Adding non-dealer accessories or making

modifications to the vehicle can affect

vehicle performance and safety, including

such things as airbags, braking, stability,

ride and handling, emissions systems,

aerodynamics, durability, and electronic

systems like antilock brakes, traction control,

and stability control. These accessories or

modifications could even cause malfunction

or damage not covered by the vehicle

warranty.

Damage to suspension components caused

by modifying vehicle height outside of

factory settings will not be covered by the

vehicle warranty.

Damage to vehicle components resulting

from modifications or the installation or use

of non-GM certified parts, including control

module or software modifications, is not

covered under the terms of the vehicle

warranty and may affect remaining

warranty coverage for affected parts.

GM Accessories are designed to complement

and function with other systems on the

vehicle. See your dealer to accessorize the

vehicle using genuine GM Accessories

installed by a dealer technician.

Page 314 of 433

GMC Yukon/Yukon XL/Denali Owner Manual (GMNA-Localizing-U.S./

Canada/Mexico-13690468) - 2021 - crc - 8/14/20

Vehicle Care 311

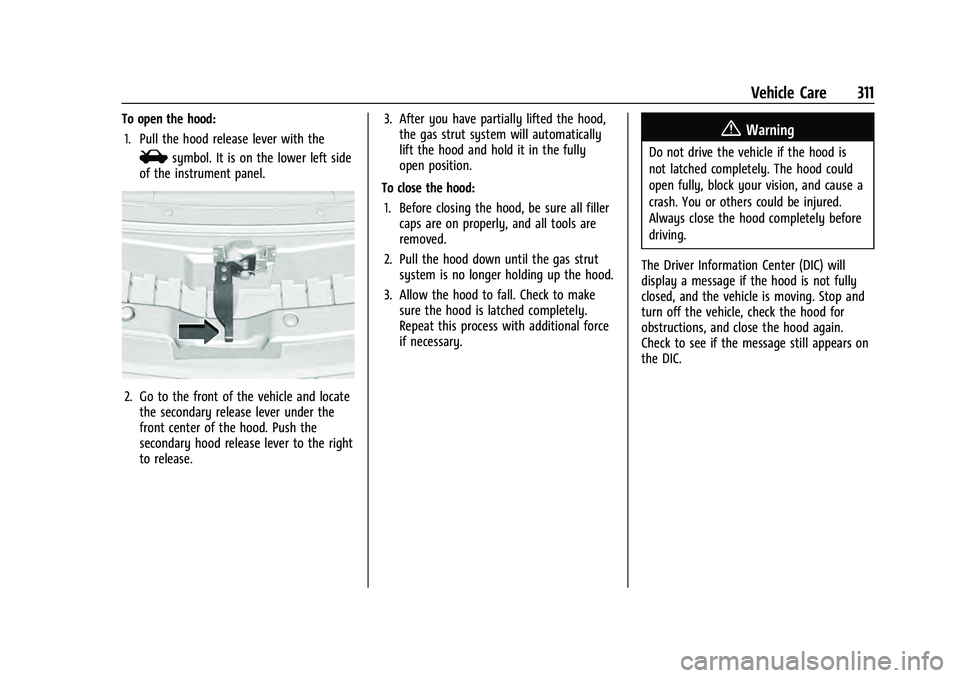

To open the hood:1. Pull the hood release lever with the

isymbol. It is on the lower left side

of the instrument panel.

2. Go to the front of the vehicle and locate the secondary release lever under the

front center of the hood. Push the

secondary hood release lever to the right

to release. 3. After you have partially lifted the hood,

the gas strut system will automatically

lift the hood and hold it in the fully

open position.

To close the hood: 1. Before closing the hood, be sure all filler caps are on properly, and all tools are

removed.

2. Pull the hood down until the gas strut system is no longer holding up the hood.

3. Allow the hood to fall. Check to make sure the hood is latched completely.

Repeat this process with additional force

if necessary.

{Warning

Do not drive the vehicle if the hood is

not latched completely. The hood could

open fully, block your vision, and cause a

crash. You or others could be injured.

Always close the hood completely before

driving.

The Driver Information Center (DIC) will

display a message if the hood is not fully

closed, and the vehicle is moving. Stop and

turn off the vehicle, check the hood for

obstructions, and close the hood again.

Check to see if the message still appears on

the DIC.

Page 316 of 433

GMC Yukon/Yukon XL/Denali Owner Manual (GMNA-Localizing-U.S./

Canada/Mexico-13690468) - 2021 - crc - 8/14/20

Vehicle Care 313

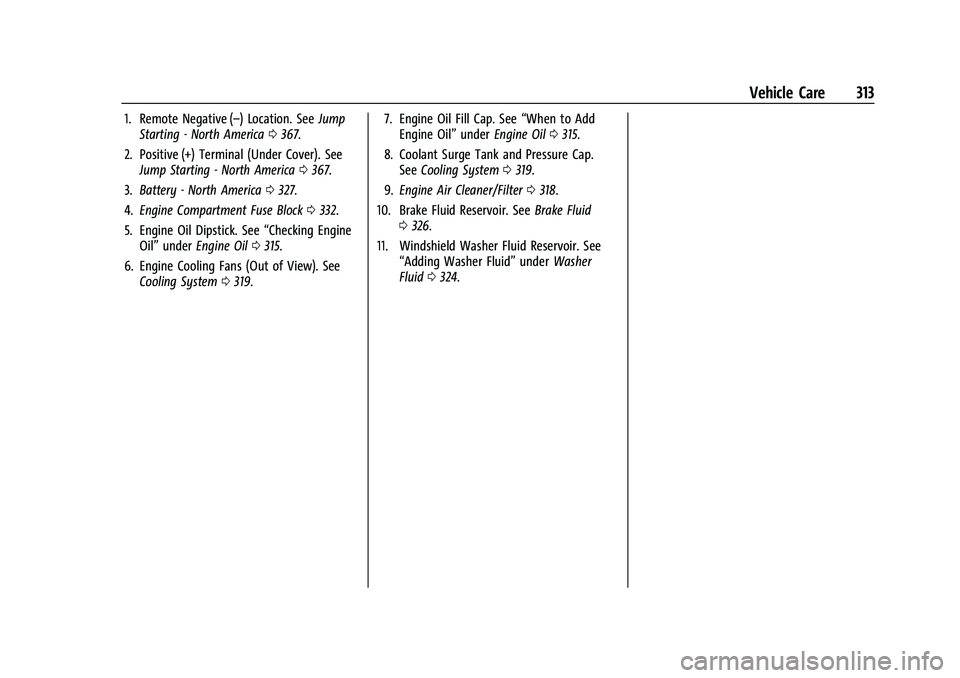

1. Remote Negative (–) Location. SeeJump

Starting - North America 0367.

2. Positive (+) Terminal (Under Cover). See Jump Starting - North America 0367.

3. Battery - North America 0327.

4. Engine Compartment Fuse Block 0332.

5. Engine Oil Dipstick. See “Checking Engine

Oil” under Engine Oil 0315.

6. Engine Cooling Fans (Out of View). See Cooling System 0319. 7. Engine Oil Fill Cap. See

“When to Add

Engine Oil” underEngine Oil 0315.

8. Coolant Surge Tank and Pressure Cap. See Cooling System 0319.

9. Engine Air Cleaner/Filter 0318.

10. Brake Fluid Reservoir. See Brake Fluid

0 326.

11. Windshield Washer Fluid Reservoir. See “Adding Washer Fluid” underWasher

Fluid 0324.

Page 317 of 433

GMC Yukon/Yukon XL/Denali Owner Manual (GMNA-Localizing-U.S./

Canada/Mexico-13690468) - 2021 - crc - 8/14/20

314 Vehicle Care

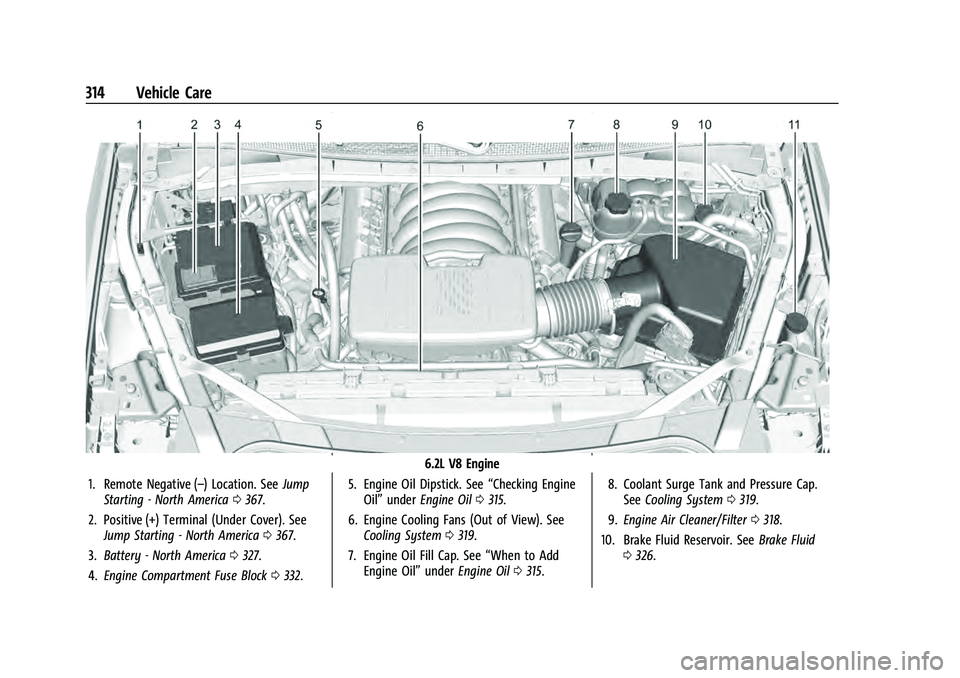

6.2L V8 Engine

1. Remote Negative (–) Location. See Jump

Starting - North America 0367.

2. Positive (+) Terminal (Under Cover). See Jump Starting - North America 0367.

3. Battery - North America 0327.

4. Engine Compartment Fuse Block 0332. 5. Engine Oil Dipstick. See

“Checking Engine

Oil” under Engine Oil 0315.

6. Engine Cooling Fans (Out of View). See Cooling System 0319.

7. Engine Oil Fill Cap. See “When to Add

Engine Oil” underEngine Oil 0315. 8. Coolant Surge Tank and Pressure Cap.

See Cooling System 0319.

9. Engine Air Cleaner/Filter 0318.

10. Brake Fluid Reservoir. See Brake Fluid

0 326.

Page 325 of 433

GMC Yukon/Yukon XL/Denali Owner Manual (GMNA-Localizing-U.S./

Canada/Mexico-13690468) - 2021 - crc - 8/14/20

322 Vehicle Care

Caution

Failure to follow the specific coolant fill

procedure could cause the engine to

overheat and could cause system

damage. If coolant is not visible in the

surge tank, contact your dealer.

If no coolant is visible in the surge tank, add

coolant.

1. Remove the coolant surge tank pressure cap when the cooling system, including

the coolant surge tank pressure cap and

upper radiator hose, is no longer hot.

Turn the pressure cap slowly

counterclockwise about one full turn. If a

hiss is heard, wait for that to stop.

A hiss means there is still some

pressure left.

2. Keep turning the pressure cap slowly, and remove it.

3. Fill the coolant surge tank with the proper mixture to the full cold mark. 4. With the coolant surge tank pressure cap

off, start the engine and let it run until

the engine coolant temperature gauge

indicates approximately 90 °C (195 °F).

By this time, the coolant level inside the

coolant surge tank may be lower. If the

level is lower, add more of the proper

mixture to the coolant surge tank until

the level reaches the indicated mark.

5. Replace the pressure cap tightly.

6. Verify coolant level after the engine is shut off and the coolant is cold.

If necessary, repeat coolant fill procedure

Steps 1–6.

Caution

If the pressure cap is not tightly installed,

coolant loss and engine damage may

occur. Be sure the cap is properly and

tightly secured.

Engine Overheating

Caution

Do not run the engine if there is a leak

in the engine cooling system. This can

cause a loss of all coolant and can

damage the system and vehicle. Have

any leaks fixed right away.

The vehicle has several indicators to warn of

engine overheating.

There is a coolant temperature gauge and a

engine coolant temperature warning light in

the vehicle's instrument cluster. See Engine

Coolant Temperature Gauge 0108 and

Engine Coolant Temperature Warning Light

0 116.

In addition, there are ENGINE OVERHEATED

STOP ENGINE, ENGINE OVERHEATED IDLE

ENGINE, and ENGINE POWER IS REDUCED

messages in the Driver Information

Center (DIC).

If the decision is made not to lift the hood

when this warning appears, get service help

right away. See Roadside Assistance Program

0 402.

Page 332 of 433

GMC Yukon/Yukon XL/Denali Owner Manual (GMNA-Localizing-U.S./

Canada/Mexico-13690468) - 2021 - crc - 8/14/20

Vehicle Care 329

.To check the parking brake's holding

ability: With the engine running and the

transmission in N (Neutral), slowly remove

foot pressure from the regular brake

pedal. Do this until the vehicle is held by

the parking brake only.

.To check the P (Park) mechanism's holding

ability: With the engine running, shift to

P (Park). Then release the parking brake

followed by the regular brake.

Contact your dealer if service is required.

Wiper Blade Replacement

Windshield wiper blades should be inspected

for wear or cracking.

For the proper type and size, see

Maintenance Replacement Parts 0394.

Caution

Allowing the wiper arm to touch the

windshield when no wiper blade is

installed could damage the windshield.

Any damage that occurs would not be

covered by the vehicle warranty. Do not

allow the wiper arm to touch the

windshield.

Front Wiper Blade Replacement

To replace the wiper blade assembly:

1. Pull the windshield wiper assembly away from the windshield.

2. Press the button in the middle of thewiper arm connector, and pull the wiper

blade away from the arm connector.

3. Remove the wiper blade.

4. Reverse Steps 1–3 for wiper blade replacement.

Rear Wiper Blade Replacement

To replace the rear wiper blade: 1. With the rear wiper in the off position,

open the liftglass to access the rear

wiper arm/blade.

The rear wiper blade will not lock in a

vertical position so use care when pulling

it away from the vehicle.

2. Push the release lever (2) to disengagethe hook and push the wiper arm (1) out

of the blade assembly (3).

3. Push the new blade assembly securely in the wiper arm hook until the release

lever clicks into place.

4. Return the wiper arm and blade assembly to the rest position on the

glass.