Fan GREAT WALL FLORID 2008 User Guide

[x] Cancel search | Manufacturer: GREAT WALL, Model Year: 2008, Model line: FLORID, Model: GREAT WALL FLORID 2008Pages: 281, PDF Size: 43.97 MB

Page 219 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual212

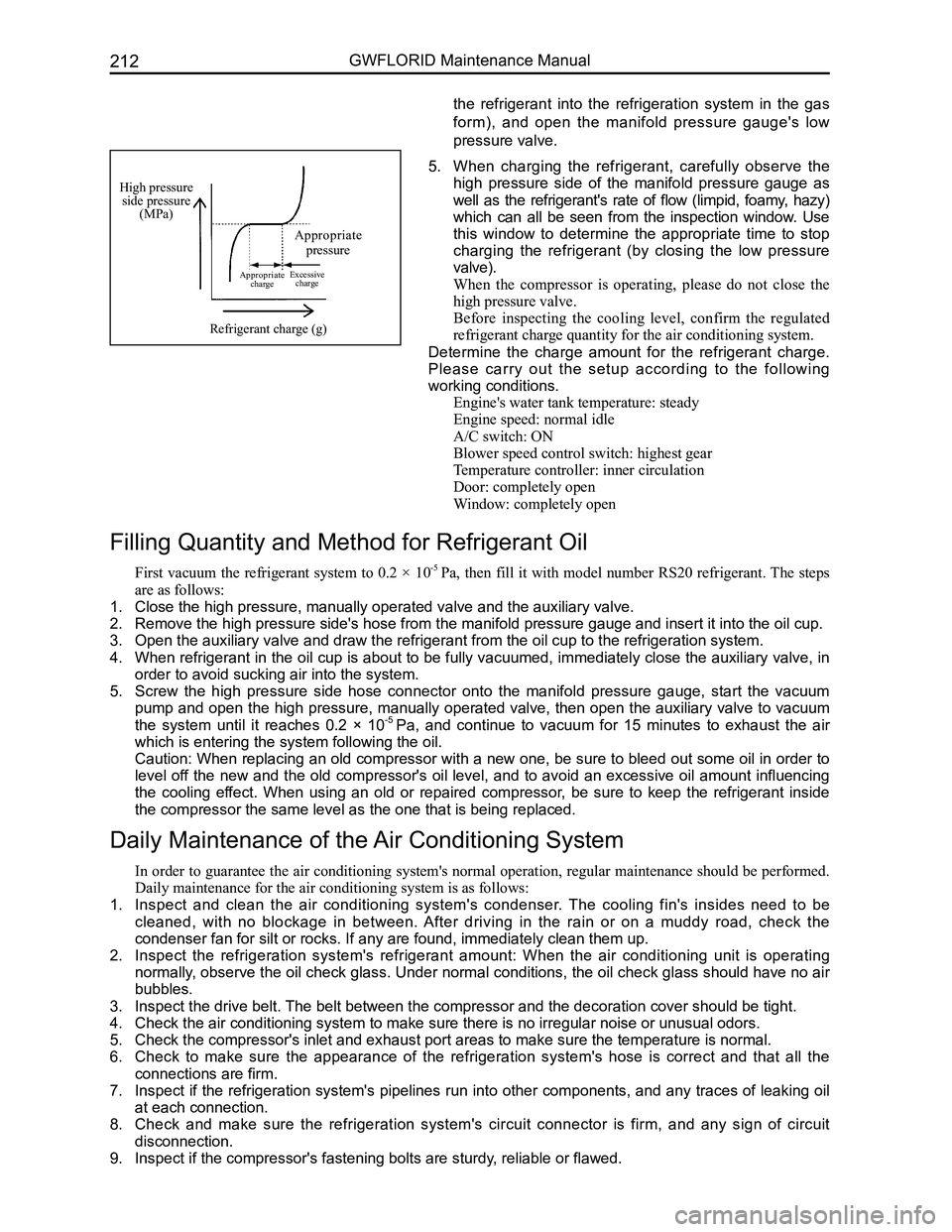

High pressure side pressure(MPa)

Appropriate pressure

Appropriate chargeExcessive charge

Refrigerant charge (g)

5. When charging the refrigerant, carefully observe the

high pressure side of the manifold pressure gauge as

well as the refrigerant's rate of flow (limpid, foamy, hazy)

which can all be seen from the inspection window. Use

this window to determine the appropriate time to stop

charging the refrigerant (by closing the low pressure

valve).

When the compressor is operating, please do not close the

high pressure valve.

Before inspecting the cooling level, confirm the regulated

refrigerant charge quantity for the air conditioning system.

Determine the charge amount for the refrigerant charge.

Please carry out the setup according to the following

working conditions.

Engine's water tank temperature: steady

Engine speed: normal idle

A/C switch: ON

Blower speed control switch: highest gear

Temperature controller: inner circulation

Door: completely open

Window: completely open

Filling Quantity and Method for Refrigerant Oil

First vacuum the refrigerant system to 0.2 × 10-5 Pa, then fill it with model number RS20 refrigerant. The steps

are as follows:

1. Close the high pressure, manually operated valve and the auxiliary valve\

.

2. Remove the high pressure side's hose from the manifold pressure gauge an\

d insert it into the oil cup.

3. Open the auxiliary valve and draw the refrigerant from the oil cup to th\

e refrigeration system.

4. When refrigerant in the oil cup is about to be fully vacuumed, immediately close the auxiliary valve, in

order to avoid sucking air into the system.

5. Screw the high pressure side hose connector onto the manifold pressure gauge, start the vacuum

pump and open the high pressure, manually operated valve, then open the auxiliary valve to vacuum

the system until it reaches 0.2 × 10-5 Pa, and continue to vacuum for 15 minutes to exhaust the air

which is entering the system following the oil.

Caution: When replacing an old compressor with a new one, be sure to bleed out some oil in order to

level off the new and the old compressor's oil level, and to avoid an excessive oil amount influencing

the cooling effect. When using an old or repaired compressor, be sure to keep the refrigerant inside

the compressor the same level as the one that is being replaced.

Daily Maintenance of the Air Conditioning System

In order to guarantee the air conditioning system's normal operation, regular maintenance should be performed.

Daily maintenance for the air conditioning system is as follows:

1. Inspect and clean the air conditioning system's condenser. The cooling fin's insides need to be

cleaned, with no blockage in between. After driving in the rain or on a muddy road, check the

condenser fan for silt or rocks. If any are found, immediately clean the\

m up.

2. Inspect the refrigeration system's refrigerant amount: When the air conditioning unit is operating

normally, observe the oil check glass. Under normal conditions, the oil check glass should have no air

bubbles.

3. Inspect the drive belt. The belt between the compressor and the decoration cover should be tight\

.

4. Check the air conditioning system to make sure there is no irregular noi\

se or unusual odors.

5. Check the compressor's inlet and exhaust port areas to make sure the tem\

perature is normal.

6. Check to make sure the appearance of the refrigeration system's hose is correct and that all the

connections are firm.

7. Inspect if the refrigeration system's pipelines run into other components, and any traces of leaking oil

at each connection.

8. Check and make sure the refrigeration system's circuit connector is firm, and any sign of circuit

disconnection.

9. Inspect if the compressor's fastening bolts are sturdy, reliable or flawed.

the refrigerant into the refrigeration system in the gas

form), and open the manifold pressure gauge's low

pressure valve.

Page 253 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual246

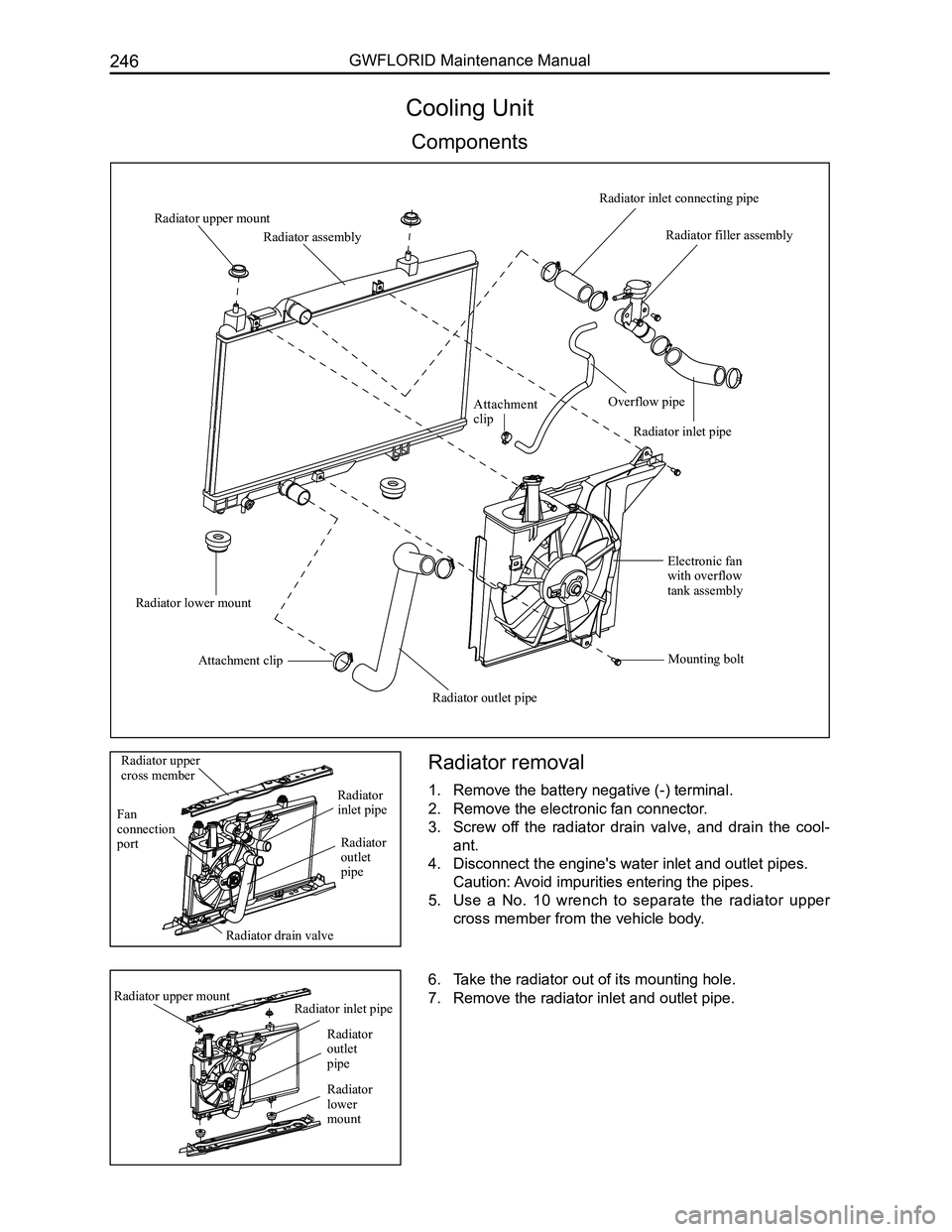

Cooling Unit

Components

Radiator removal

1. Remove the battery negative (-) terminal.

2. Remove the electronic fan connector.

3. Screw off the radiator drain valve, and drain the cool-

ant.

4. Disconnect the engine's water inlet and outlet pipes.

Caution: Avoid impurities entering the pipes.

5. Use a No. 10 wrench to separate the radiator upper

cross member from the vehicle body.

6. Take the radiator out of its mounting hole.

7. Remove the radiator inlet and outlet pipe.

Radiator filler assembly

Radiator upper mount

Radiator inlet connecting pipe

Attachment clip

Radiator assembly

Overflow pipe

Radiator inlet pipe

Electronic fan with overflow tank assembly

Mounting bolt

Radiator outlet pipe

Attachment clip

Radiator lower mount

Radiator drain valve

Fan connection port

Radiator upper cross member

Radiator lower mount

Radiator upper mount

Radiator outlet pipe

Radiator inlet pipe

Radiator

outlet pipe

Radiator inlet pipe

Page 254 of 281

Downloaded from www.Manualslib.com manuals search engine 247Vehicle Body

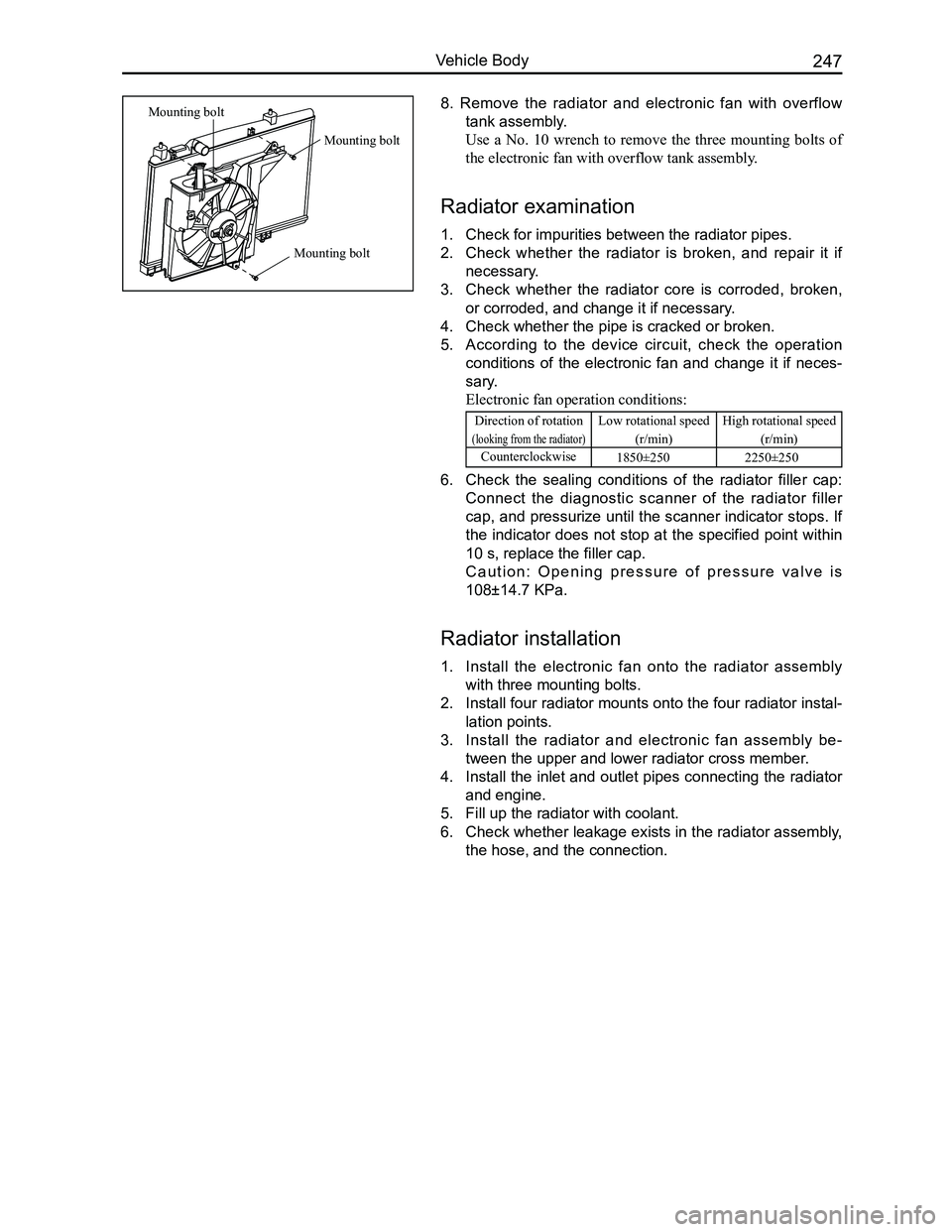

8. Remove the radiator and electronic fan with overflow

tank assembly.

Use a No. 10 wrench to remove the three mounting bolts of

the electronic fan with overflow tank assembly.

Radiator examination

1. Check for impurities between the radiator pipes.

2. Check whether the radiator is broken, and repair it if

necessary.

3. Check whether the radiator core is corroded, broken,

or corroded, and change it if necessary.

4. Check whether the pipe is cracked or broken.

5. According to the device circuit, check the operation

conditions of the electronic fan and change it if neces-

sary.

Electronic fan operation conditions:

Direction of rotation

(looking from the radiator)

Low rotational speed

(r/min)

High rotational speed

(r/min)

Counterclockwise1850±250 2250±250

6. Check the sealing conditions of the radiator filler cap:

Connect the diagnostic scanner of the radiator filler

cap, and pressurize until the scanner indicator stops. If

the indicator does not stop at the specified point within

10 s, replace the filler cap.

C a u t i o n : O p e n i n g p r e s s u r e o f p r e s s u r e v a l v e i s

108±14.7 KPa.

Radiator installation

1. Install the electronic fan onto the radiator assembly

with three mounting bolts.

2. Install four radiator mounts onto the four radiator instal-

lation points.

3. Install the radiator and electronic fan assembly be-

tween the upper and lower radiator cross member.

4. Install the inlet and outlet pipes connecting the radiator

and engine.

5. Fill up the radiator with coolant.

6. Check whether leakage exists in the radiator assembly,

the hose, and the connection.

Mounting bolt

Mounting bolt

Mounting bolt