ect GREAT WALL FLORID 2008 Owner's Manual

[x] Cancel search | Manufacturer: GREAT WALL, Model Year: 2008, Model line: FLORID, Model: GREAT WALL FLORID 2008Pages: 281, PDF Size: 43.97 MB

Page 27 of 281

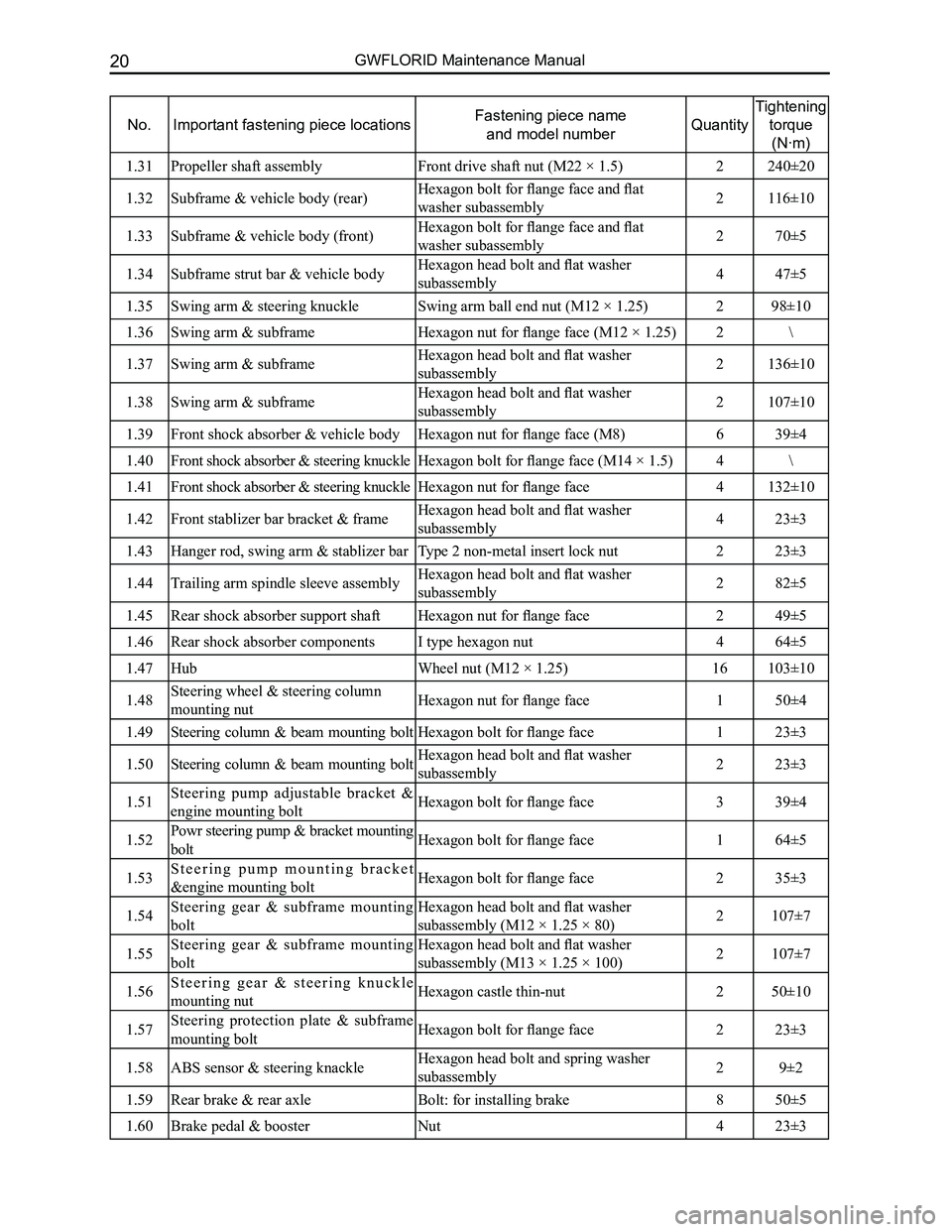

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual20

No.Important fastening piece locationsFastening piece name

and model numberQuantity

Tightening

torque

(N·m)

1.31Propeller shaft assemblyFront drive shaft nut (M22 × 1.5)2240±20

1.32Subframe & vehicle body (rear)Hexagon bolt for flange face and flat

washer subassembly2116±10

1.33Subframe & vehicle body (front)Hexagon bolt for flange face and flat

washer subassembly270±5

1.34Subframe strut bar & vehicle bodyHexagon head bolt and flat washer

subassembly447±5

1.35Swing arm & steering knuckleSwing arm ball end nut (M12 × 1.25)298±10

1.36Swing arm & subframeHexagon nut for flange face (M12 × 1.25)2\

1.37Swing arm & subframeHexagon head bolt and flat washer

subassembly2136±10

1.38Swing arm & subframeHexagon head bolt and flat washer

subassembly2107±10

1.39Front shock absorber & vehicle bodyHexagon nut for flange face (M8)639±4

1.40Front shock absorber & steering knuckleHexagon bolt for flange face (M14 × 1.5)4\

1.41Front shock absorber & steering knuckleHexagon nut for flange face4132±10

1.42Front stablizer bar bracket & frameHexagon head bolt and flat washer

subassembly423±3

1.43Hanger rod, swing arm & stablizer barType 2 non-metal insert lock nut223±3

1.44Trailing arm spindle sleeve assemblyHexagon head bolt and flat washer

subassembly282±5

1.45Rear shock absorber support shaftHexagon nut for flange face249±5

1.46Rear shock absorber componentsI type hexagon nut464±5

1.47Hub Wheel nut (M12 × 1.25)16103±10

1.48Steering wheel & steering column

mounting nutHexagon nut for flange face150±4

1.49Steering column & beam mounting boltHexagon bolt for flange face123±3

1.50Steering column & beam mounting boltHexagon head bolt and flat washer

subassembly223±3

1.51Steering pump adjustable bracket &

engine mounting boltHexagon bolt for flange face339±4

1.52Powr steering pump & bracket mounting

boltHexagon bolt for flange face164±5

1.53S t e e r i n g p u m p m o u n t i n g b r a c k e t

&engine mounting boltHexagon bolt for flange face235±3

1.54Steering gear & subframe mounting

bolt

Hexagon head bolt and flat washer

subassembly (M12 × 1.25 × 80)2107±7

1.55Steering gear & subframe mounting

bolt

Hexagon head bolt and flat washer

subassembly (M13 × 1.25 × 100)2107±7

1.56S t e e r i n g g e a r & s t e e r i n g k n u c k l e

mounting nutHexagon castle thin-nut250±10

1.57Steering protection plate & subframe

mounting boltHexagon bolt for flange face223±3

1.58ABS sensor & steering knackleHexagon head bolt and spring washer

subassembly29±2

1.59Rear brake & rear axleBolt: for installing brake850±5

1.60Brake pedal & boosterNut423±3

Page 28 of 281

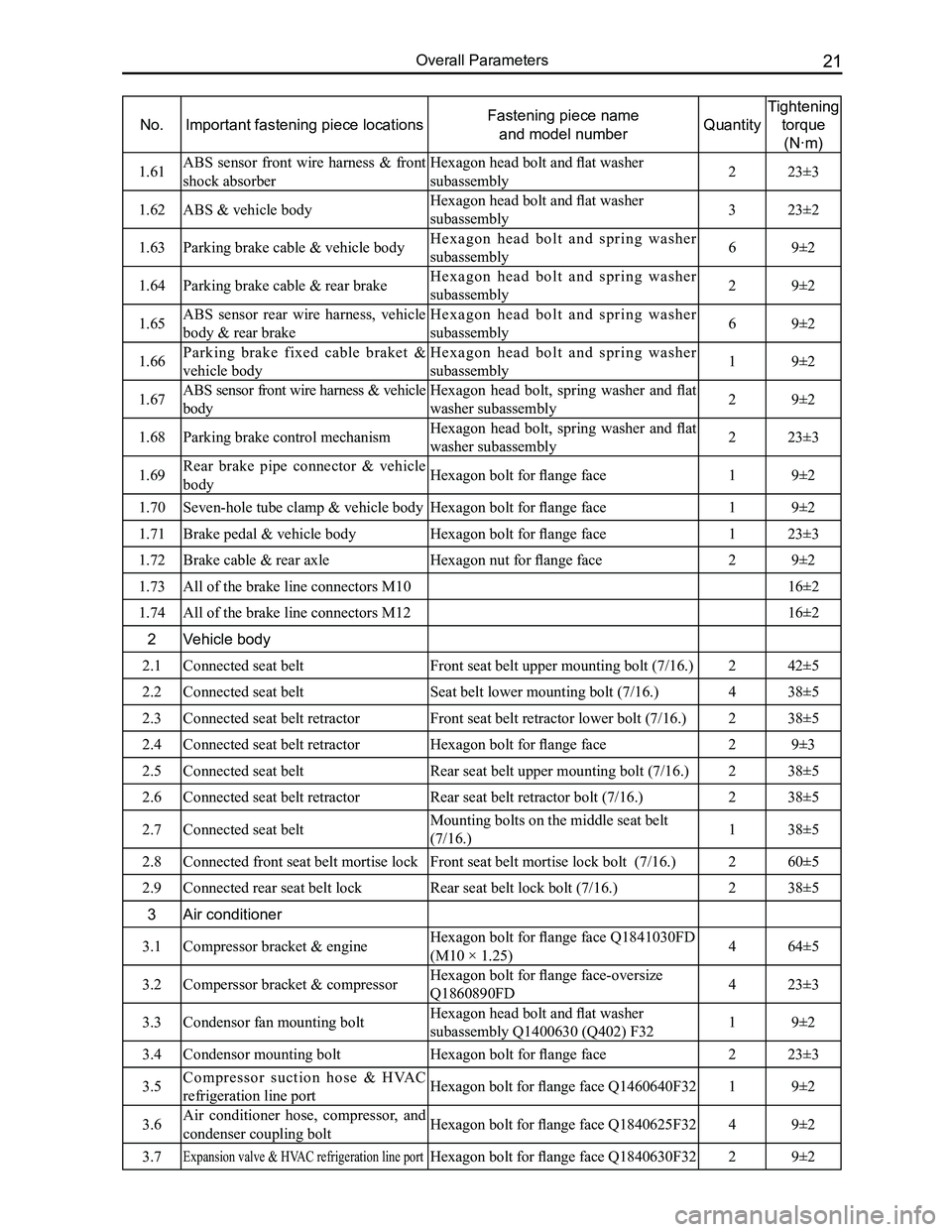

Downloaded from www.Manualslib.com manuals search engine 21Overall Parameters

No.Important fastening piece locationsFastening piece name

and model numberQuantity

Tightening

torque

(N·m)

1.61ABS sensor front wire harness & front

shock absorber

Hexagon head bolt and flat washer

subassembly223±3

1.62ABS & vehicle body Hexagon head bolt and flat washer

subassembly323±2

1.63Parking brake cable & vehicle bodyH e x a g o n h e a d b o l t a n d s p r i n g w a s h e r

subassembly69±2

1.64Parking brake cable & rear brakeH e x a g o n h e a d b o l t a n d s p r i n g w a s h e r

subassembly29±2

1.65ABS sensor rear wire harness, vehicle

body & rear brake

H e x a g o n h e a d b o l t a n d s p r i n g w a s h e r

subassembly69±2

1.66Parking brake fixed cable braket &

vehicle body

H e x a g o n h e a d b o l t a n d s p r i n g w a s h e r

subassembly19±2

1.67ABS sensor front wire harness & vehicle

body

Hexagon head bolt, spring washer and flat

washer subassembly29±2

1.68Parking brake control mechanismHexagon head bolt, spring washer and flat

washer subassembly223±3

1.69Rear brake pipe connector & vehicle

bodyHexagon bolt for flange face19±2

1.70Seven-hole tube clamp & vehicle bodyHexagon bolt for flange face19±2

1.71Brake pedal & vehicle bodyHexagon bolt for flange face123±3

1.72Brake cable & rear axleHexagon nut for flange face29±2

1.73All of the brake line connectors M1016±2

1.74All of the brake line connectors M1216±2

2Vehicle body

2.1Connected seat belt Front seat belt upper mounting bolt (7/16.)242±5

2.2Connected seat belt Seat belt lower mounting bolt (7/16.)438±5

2.3Connected seat belt retractorFront seat belt retractor lower bolt (7/16.)238±5

2.4Connected seat belt retractorHexagon bolt for flange face29±3

2.5Connected seat belt Rear seat belt upper mounting bolt (7/16.)238±5

2.6Connected seat belt retractorRear seat belt retractor bolt (7/16.)238±5

2.7Connected seat belt Mounting bolts on the middle seat belt

(7/16.)138±5

2.8Connected front seat belt mortise lockFront seat belt mortise lock bolt (7/16.)260±5

2.9Connected rear seat belt lockRear seat belt lock bolt (7/16.)238±5

3Air conditioner

3.1Compressor bracket & engineHexagon bolt for flange face Q1841030FD

(M10 × 1.25)464±5

3.2Comperssor bracket & compressorHexagon bolt for flange face-oversize

Q1860890FD423±3

3.3Condensor fan mounting boltHexagon head bolt and flat washer

subassembly Q1400630 (Q402) F3219±2

3.4Condensor mounting boltHexagon bolt for flange face223±3

3.5Compressor suction hose & HVAC

refrigeration line portHexagon bolt for flange face Q1460640F3219±2

3.6Air conditioner hose, compressor, and

condenser coupling boltHexagon bolt for flange face Q1840625F3249±2

3.7Expansion valve & HVAC refrigeration line portHexagon bolt for flange face Q1840630F3229±2

Page 29 of 281

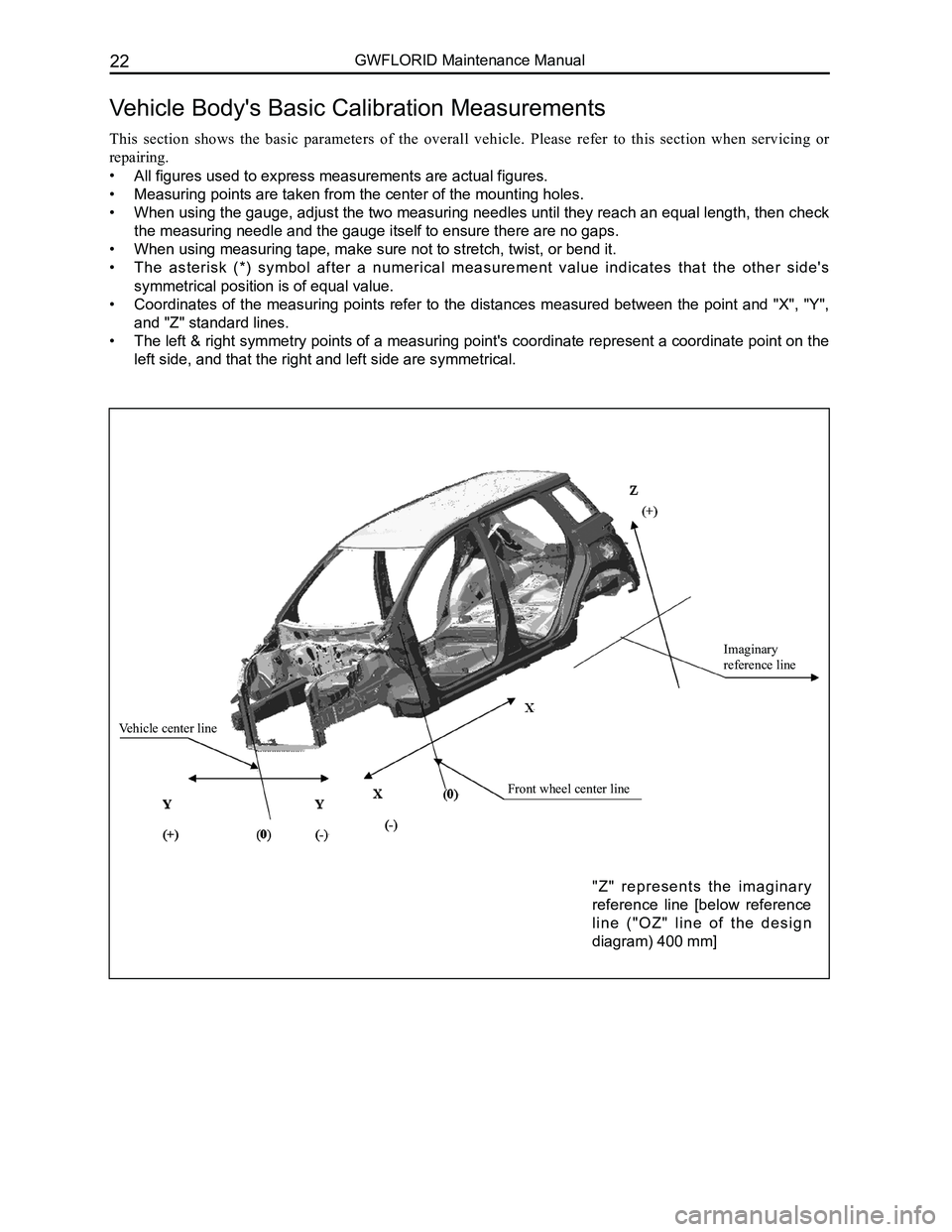

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual22

Imaginary

reference line

Front wheel center line

Vehicle center line

"Z" represents the imaginary

reference line [below reference

l i n e ( " O Z " l i n e o f t h e d e s i g n

diagram) 400 mm]

Vehicle Body's Basic Calibration Measurements

This section shows the basic parameters of the overall vehicle. Please refer to this section when servicing or

repairing.

• All figures used to express measurements are actual figures.

• Measuring points are taken from the center of the mounting holes.

• When using the gauge, adjust the two measuring needles until they reach an equal length, then check

the measuring needle and the gauge itself to ensure there are no gaps.

• When using measuring tape, make sure not to stretch, twist, or bend it. \

• The asterisk (*) symbol after a numerical measurement value indicates that the other side's

symmetrical position is of equal value.

• Coordinates of the measuring points refer to the distances measured between the point and "X", "Y",

and "Z" standard lines.

• The left & right symmetry points of a measuring point's coordinate represent a coordinate point on the

left side, and that the right and left side are symmetrical.

Page 35 of 281

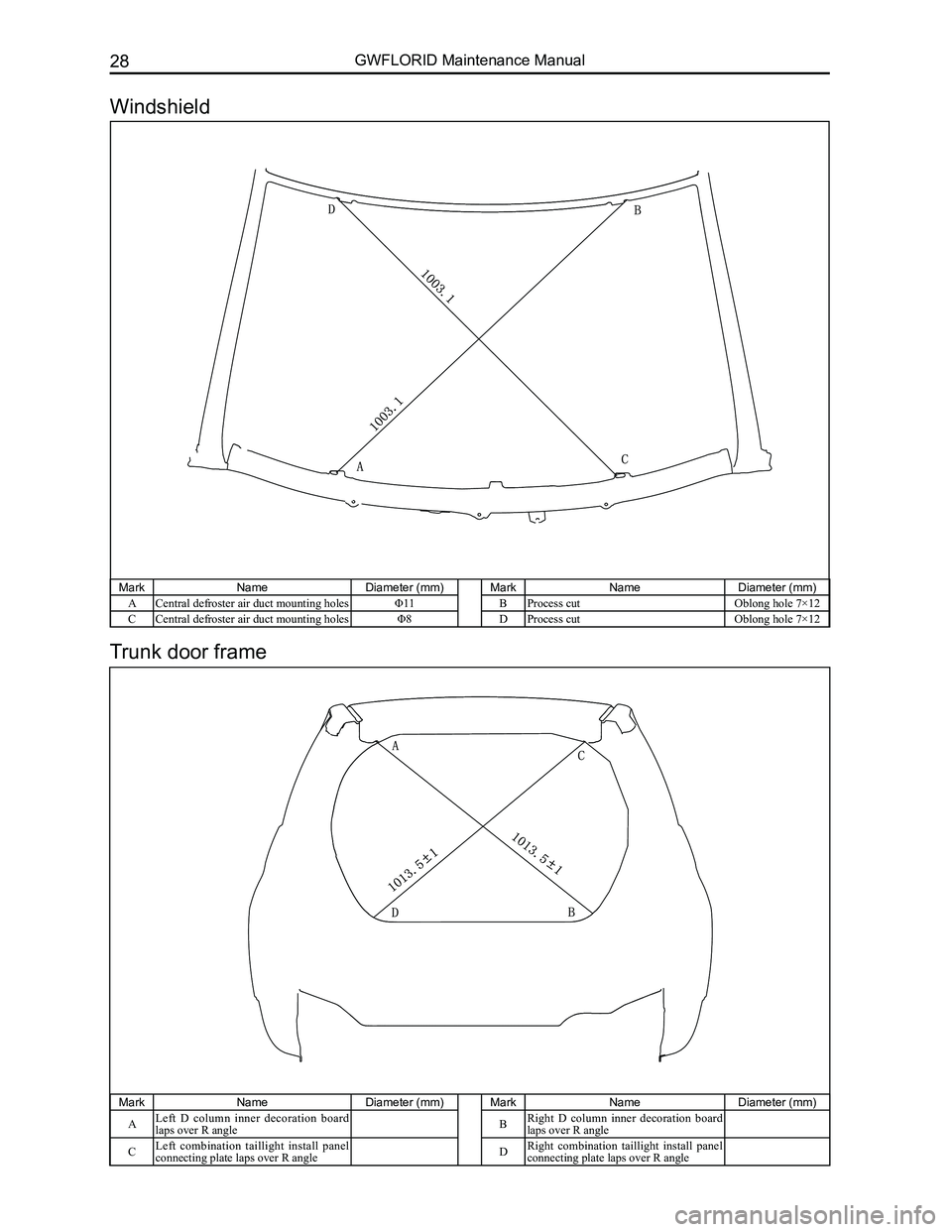

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual28

MarkNameDiameter (mm)MarkNameDiameter (mm)

ACentral defroster air duct mounting holesΦ11BProcess cutOblong hole 7×12

CCentral defroster air duct mounting holesΦ8DProcess cutOblong hole 7×12

MarkNameDiameter (mm)MarkNameDiameter (mm)

ALeft D column inner decoration board laps over R angleBRight D column inner decoration board laps over R angle

CLeft combination taillight install panel connecting plate laps over R angleDRight combination taillight install panel connecting plate laps over R angle

Trunk door frame

Windshield

Page 37 of 281

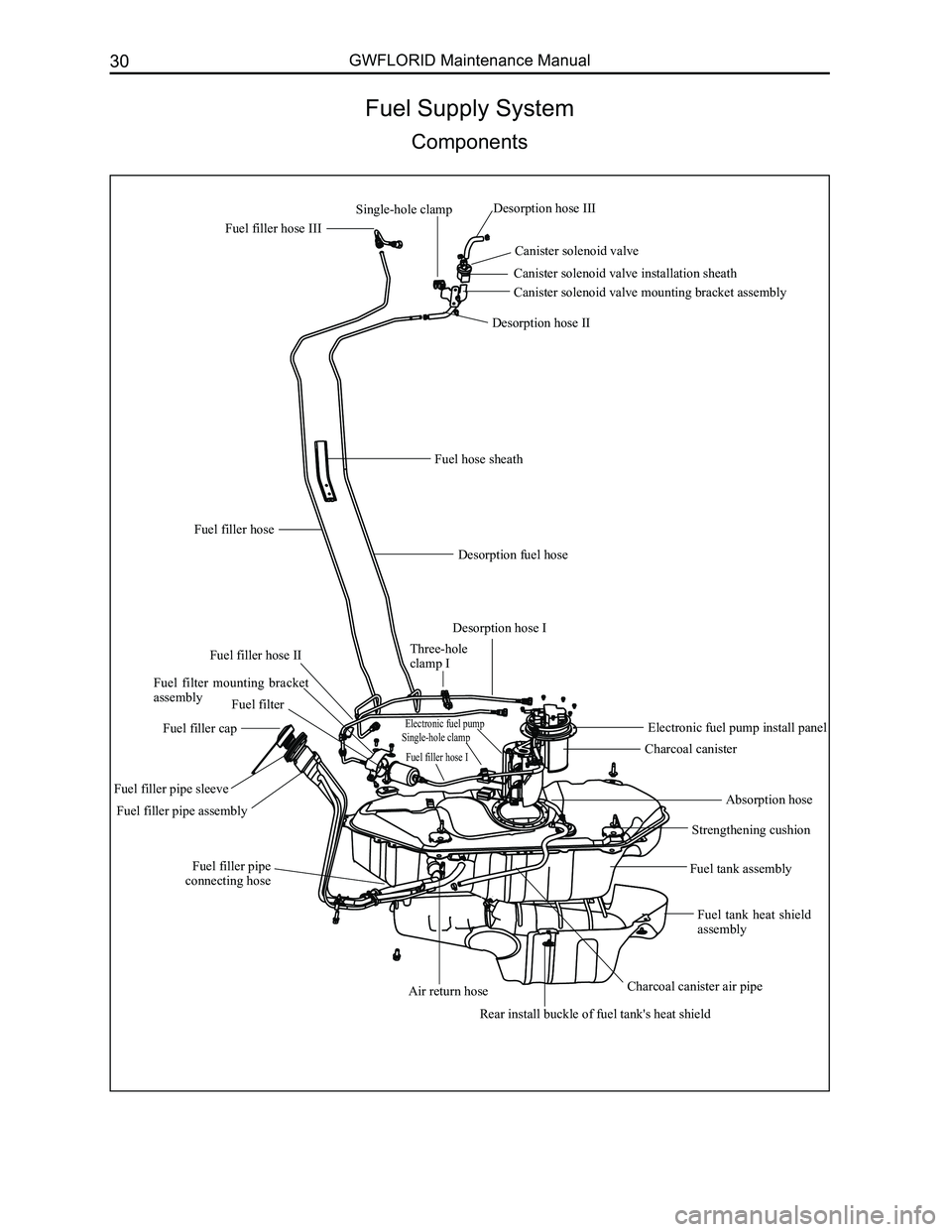

Downloaded from www.Manualslib.com manuals search engine 30GWFLORID Maintenance Manual

Fuel Supply System

Components

Fuel filler hose III

Canister solenoid valve

Canister solenoid valve installation sheath

Canister solenoid valve mounting bracket assembly

Fuel hose sheath

Desorption fuel hose

Fuel filler hose

Desorption hose I

Fuel filler hose IIThree-hole clamp I

Charcoal canister

Fuel tank assembly

Fuel tank heat shield assembly

Charcoal canister air pipeAir return hose

Fuel filler pipe assembly

Electronic fuel pumpSingle-hole clampElectronic fuel pump install panel

Strengthening cushion

Fuel filler pipe connecting hose

Absorption hoseFuel filler pipe sleeve

Single-hole clamp

Fuel filter

Rear install buckle of fuel tank's heat shield

Fuel filler cap

Fuel filler hose I

Desorption hose III

Desorption hose II

Fuel filter mounting bracket assembly

Page 38 of 281

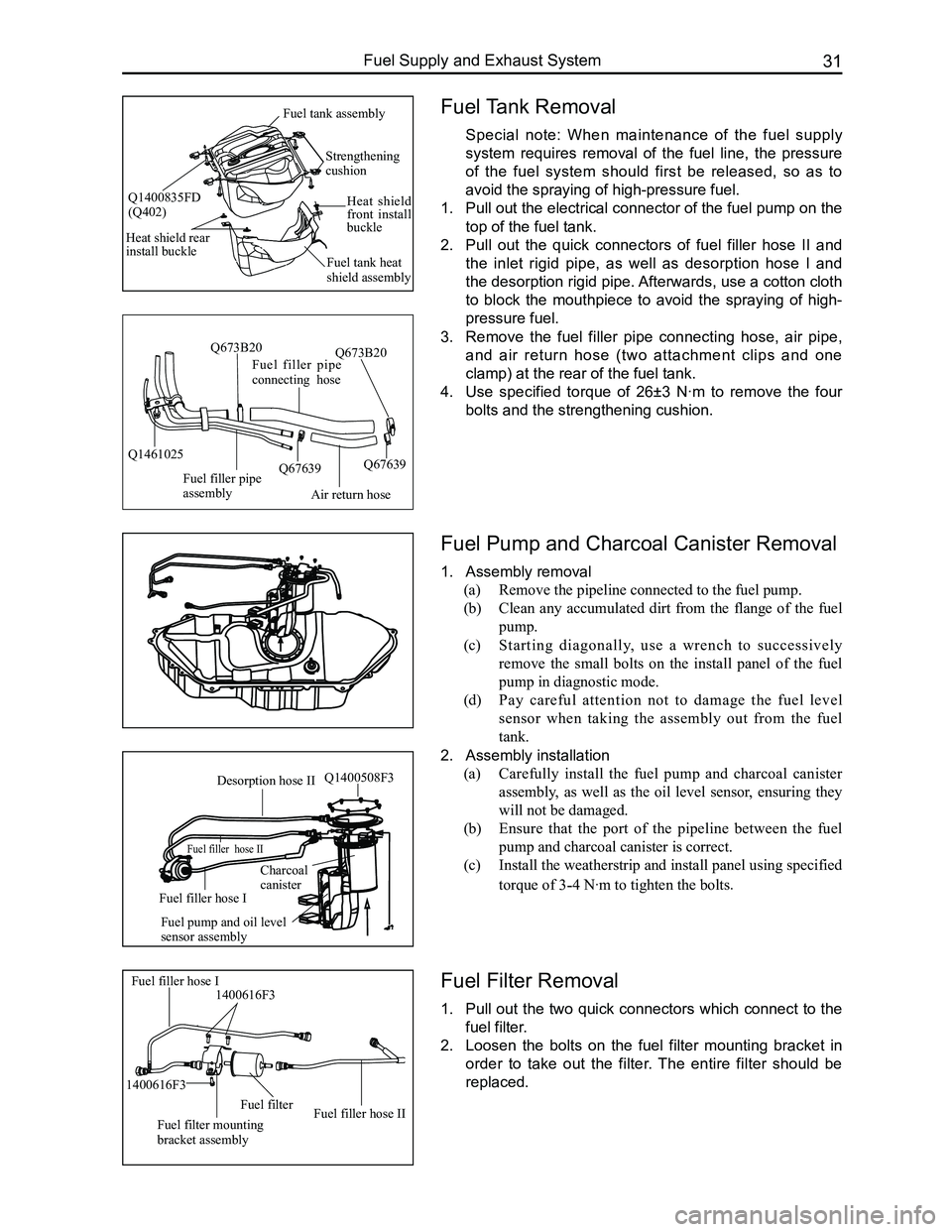

Downloaded from www.Manualslib.com manuals search engine 31Fuel Supply and Exhaust System

Fuel Tank Removal

Special note: When maintenance of the fuel supply

system requires removal of the fuel line, the pressure

of the fuel system should first be released, so as to

avoid the spraying of high-pressure fuel.

1. Pull out the electrical connector of the fuel pump on the

top of the fuel tank.

2. Pull out the quick connectors of fuel filler hose II and

the inlet rigid pipe, as well as desorption hose I and

the desorption rigid pipe. Afterwards, use a cotton cloth

to block the mouthpiece to avoid the spraying of high-

pressure fuel.

3. Remove the fuel filler pipe connecting hose, air pipe,

and air return hose (two attachment clips and one

clamp) at the rear of the fuel tank.

4. Use specified torque of 26±3 N·m to remove the four

bolts and the strengthening cushion.

Fuel Pump and Charcoal Canister Removal

1. Assembly removal

(a) Remove the pipeline connected to the fuel pump.

(b) Clean any accumulated dirt from the flange of the fuel

pump.

(c) Starting diagonally, use a wrench to successively

remove the small bolts on the install panel of the fuel

pump in diagnostic mode.

(d) Pay careful attention not to damage the fuel level

sensor when taking the assembly out from the fuel

tank.

2. Assembly installation

(a) Carefully install the fuel pump and charcoal canister

assembly, as well as the oil level sensor, ensuring they

will not be damaged.

(b) Ensure that the port of the pipeline between the fuel

pump and charcoal canister is correct.

(c) Install the weatherstrip and install panel using specified

torque of 3-4 N·m to tighten the bolts.

Fuel Filter Removal

1. Pull out the two quick connectors which connect to the

fuel filter.

2. Loosen the bolts on the fuel filter mounting bracket in

order to take out the filter. The entire filter should be

replaced.

Air return hose

Fuel filler pipe connecting hose

Fuel filler pipe assembly

Q1461025Q67639

Q673B20

Q67639

Q673B20

Fuel filler hose I1400616F3

Fuel filter mounting bracket assembly

Fuel filterFuel filler hose II

1400616F3

Desorption hose II

Fuel filler hose II

Fuel filler hose I

Charcoalcanister

Fuel pump and oil level sensor assembly

Q1400508F3

Strengthening cushion

Heat shield front install buckle

Fuel tank heat shield assembly

Heat shield rear install buckle

Fuel tank assembly

Q1400835FD(Q402)

Page 39 of 281

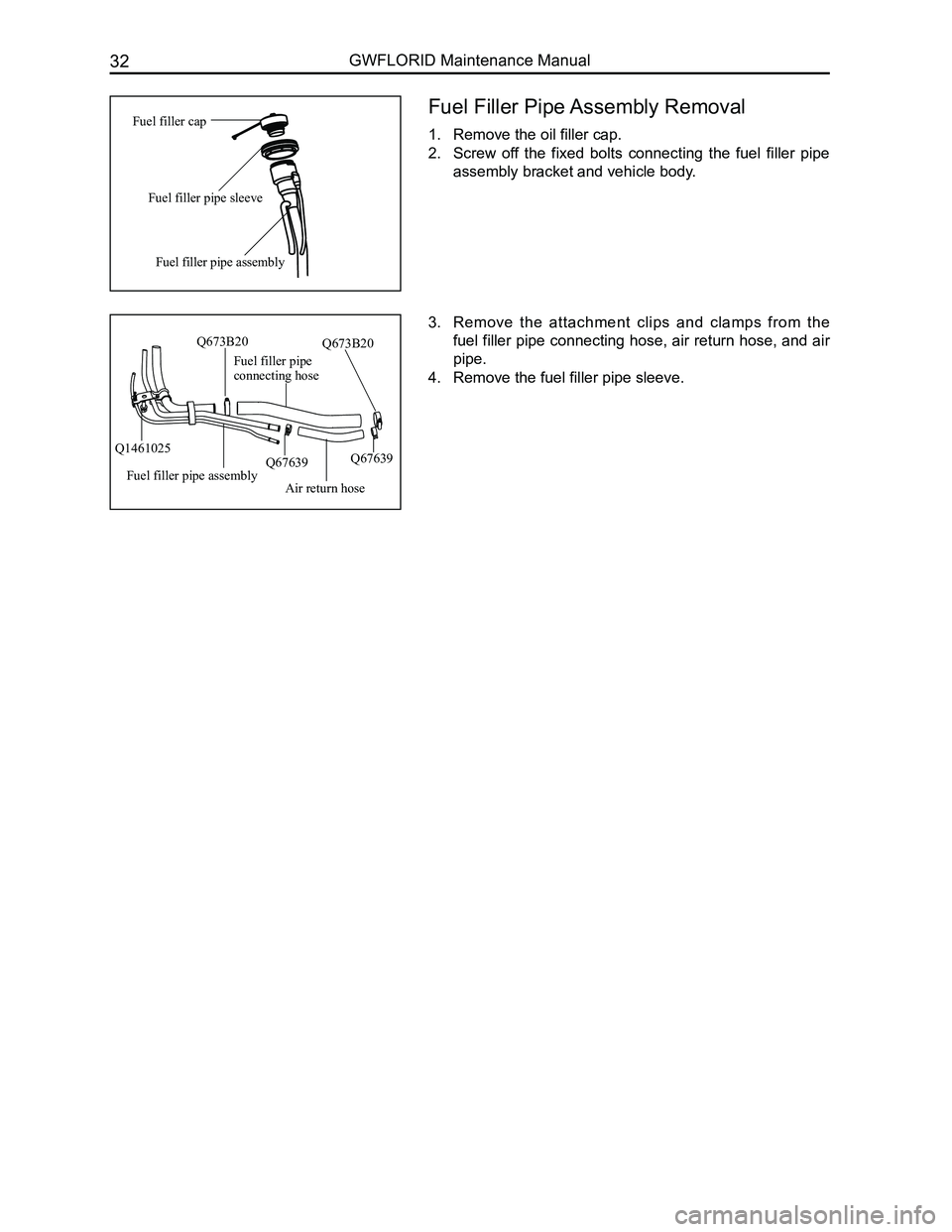

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual32

Fuel Filler Pipe Assembly Removal

1. Remove the oil filler cap.

2. Screw off the fixed bolts connecting the fuel filler pipe

assembly bracket and vehicle body.

Air return hose

Fuel filler pipe connecting hose

Fuel filler pipe assembly

Q1461025Q67639

Q673B20

Q67639

Q673B20

Fuel filler pipe assembly

Fuel filler pipe sleeve

Fuel filler cap

3. Remove the attachment clips and clamps from the

fuel filler pipe connecting hose, air return hose, and air

pipe.

4. Remove the fuel filler pipe sleeve.

Page 40 of 281

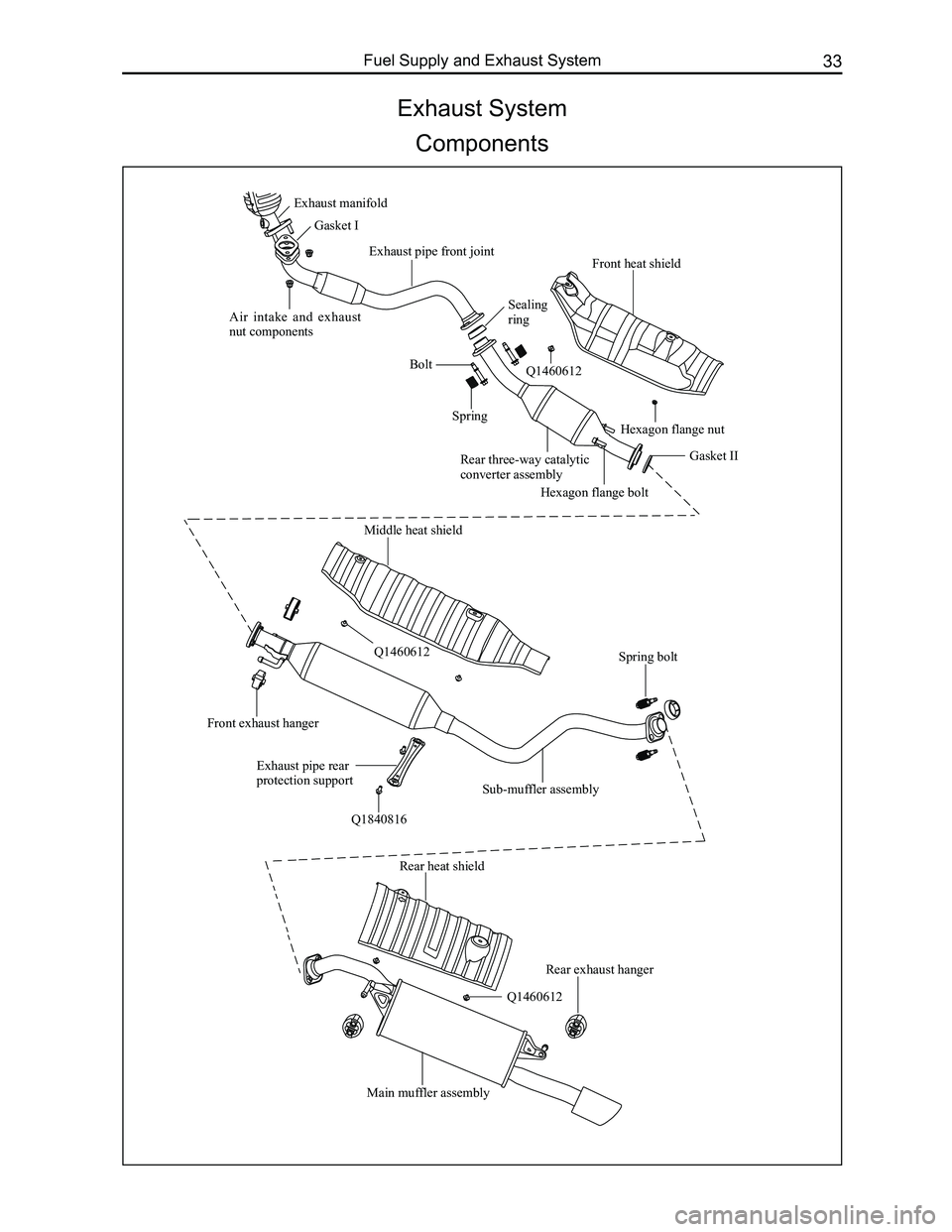

Downloaded from www.Manualslib.com manuals search engine 33Fuel Supply and Exhaust System

Exhaust System

Components

Exhaust manifold

Gasket I

Air intake and exhaust nut components

Exhaust pipe front joint

Sealing ring

Bolt

Spring

Rear three-way catalyticconverter assembly

Gasket II

Front heat shield

Hexagon flange bolt

Hexagon flange nut

Middle heat shield

Front exhaust hanger

Exhaust pipe rear protection supportSub-muffler assembly

Spring bolt

Rear heat shield

Rear exhaust hanger

Main muffler assembly

Q1460612

Q1840816

Q1460612

Q1460612

Page 41 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual34

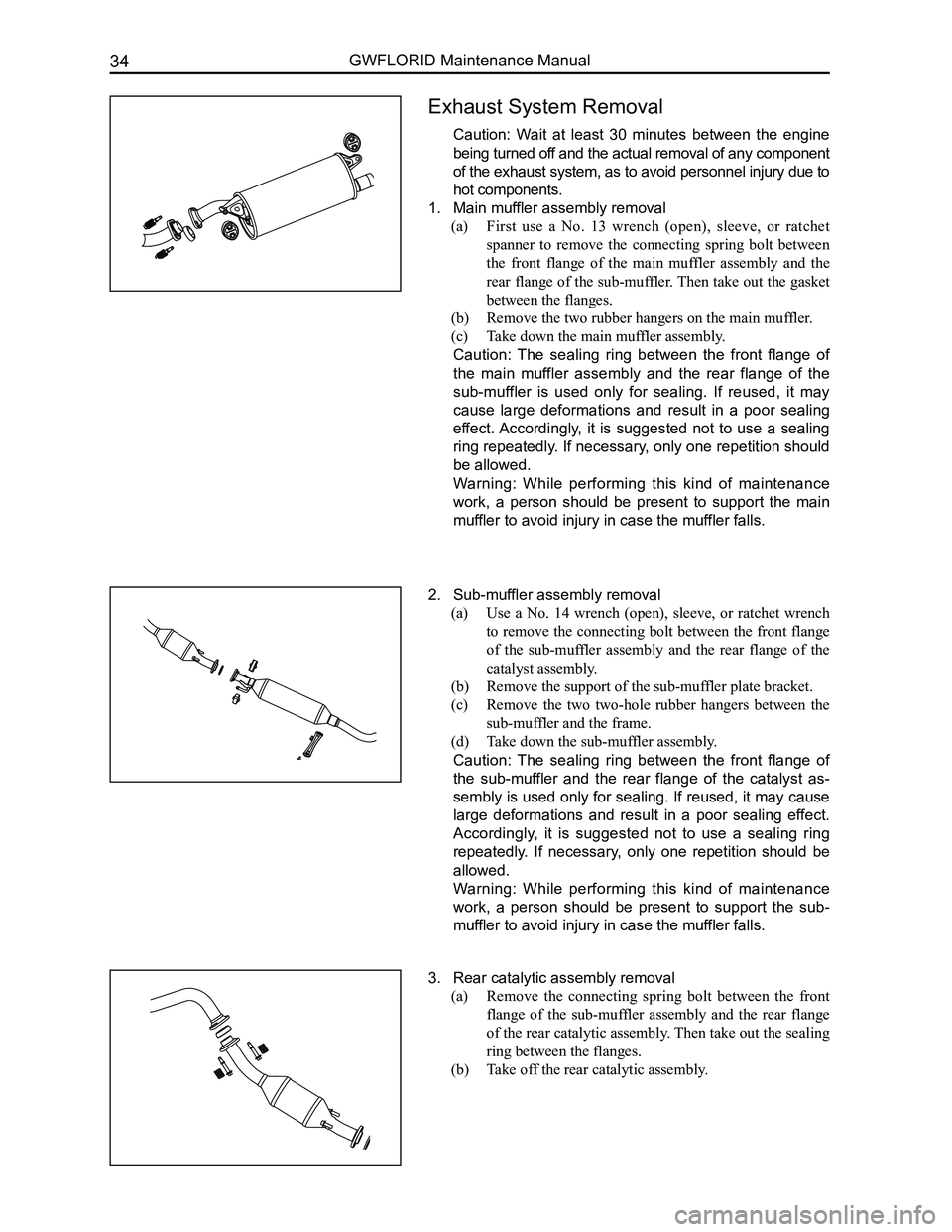

Exhaust System Removal

Caution: Wait at least 30 minutes between the engine

being turned off and the actual removal of any component

of the exhaust system, as to avoid personnel injury due to

hot components.

1. Main muffler assembly removal

(a) First use a No. 13 wrench (open), sleeve, or ratchet

spanner to remove the connecting spring bolt between

the front flange of the main muffler assembly and the

rear flange of the sub-muffler. Then take out the gasket

between the flanges.

(b) Remove the two rubber hangers on the main muffler.

(c) Take down the main muffler assembly.

Caution: The sealing ring between the front flange of

the main muffler assembly and the rear flange of the

sub-muffler is used only for sealing. If reused, it may

cause large deformations and result in a poor sealing

effect. Accordingly, it is suggested not to use a sealing

ring repeatedly. If necessary, only one repetition should

be allowed.

Warning: While performing this kind of maintenance

work, a person should be present to support the main

muffler to avoid injury in case the muffler falls.

2. Sub-muffler assembly removal

(a) Use a No. 14 wrench (open), sleeve, or ratchet wrench

to remove the connecting bolt between the front flange

of the sub-muffler assembly and the rear flange of the

catalyst assembly.

(b) Remove the support of the sub-muffler plate bracket.

(c) Remove the two two-hole rubber hangers between the

sub-muffler and the frame.

(d) Take down the sub-muffler assembly.

Caution: The sealing ring between the front flange of

the sub-muffler and the rear flange of the catalyst as-

sembly is used only for sealing. If reused, it may cause

large deformations and result in a poor sealing effect.

Accordingly, it is suggested not to use a sealing ring

repeatedly. If necessary, only one repetition should be

allowed.

Warning: While performing this kind of maintenance

work, a person should be present to support the sub-

muffler to avoid injury in case the muffler falls.

3. Rear catalytic assembly removal

(a) Remove the connecting spring bolt between the front

flange of the sub-muffler assembly and the rear flange

of the rear catalytic assembly. Then take out the sealing

ring between the flanges.

(b) Take off the rear catalytic assembly.

Page 42 of 281

Downloaded from www.Manualslib.com manuals search engine 35Fuel Supply and Exhaust System

4. Front exhaust pipe removal

(a) Use a No. 14 wrench (open), sleeve, or ratchet wrench

to remove the connecting nut between the front flange

of the front exhaust pipe assembly and the flange of the

exhaust manifold. Then take out the gasket between the

flanges.

(b) Carefully remove the front exhaust pipe from the

subframe.

Caution: The gasket between the front flange of the

f r o n t e x h a u s t p i p e a n d t h e f l a n g e o f t h e e x h a u s t

manifold are used only for sealing. If reused, they may

cause large deformations and result in a poor sealing

effect. Accordingly, it is suggested not to use the

sealing ring repeatedly.

Exhaust System Installation

1. The clearance between the exhaust pipe assembly and

both sides of the individual components should be no

less than 15 mm.

2. Before installing rubber hangers, coat a proper amount

of silicon oil in holes. After installation, even force

should be applied.

3. After installing the center exhaust pipe with the three-

way catalytic converter assembly, ensure the plug of

the oxygen sensor is well connected.