torque GREAT WALL FLORID 2008 Owner's Manual

[x] Cancel search | Manufacturer: GREAT WALL, Model Year: 2008, Model line: FLORID, Model: GREAT WALL FLORID 2008Pages: 281, PDF Size: 43.97 MB

Page 71 of 281

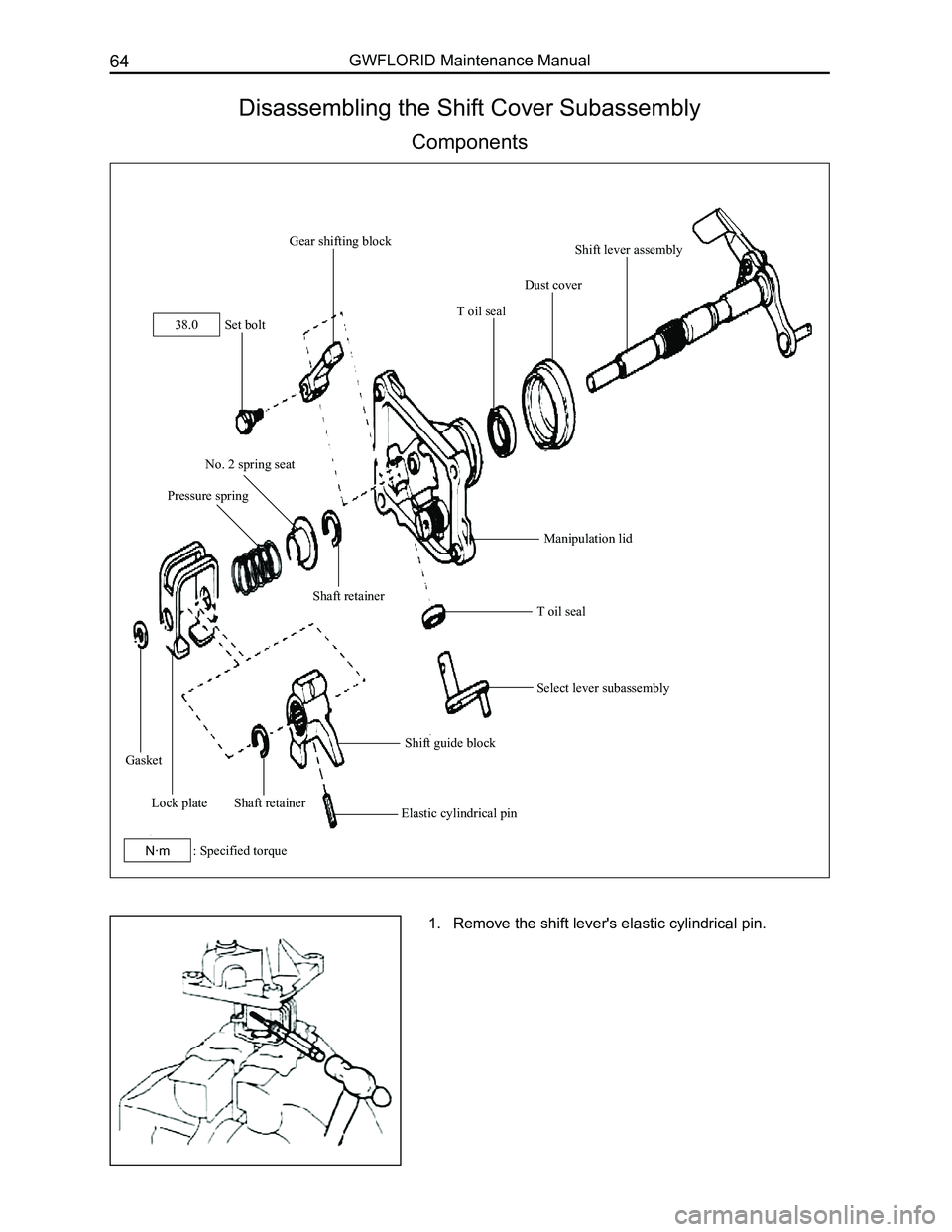

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual64

Disassembling the Shift Cover Subassembly

Components

Shift lever assembly

Dust cover

T oil seal

Gear shifting block

No. 2 spring seat

Pressure spring

Shaft retainer

Gasket

Lock plateShaft retainerElastic cylindrical pin

Shift guide block

Select lever subassembly

Manipulation lid

T oil seal

1. Remove the shift lever's elastic cylindrical pin.

Set bolt38.0

: Specified torqueN·m

Page 75 of 281

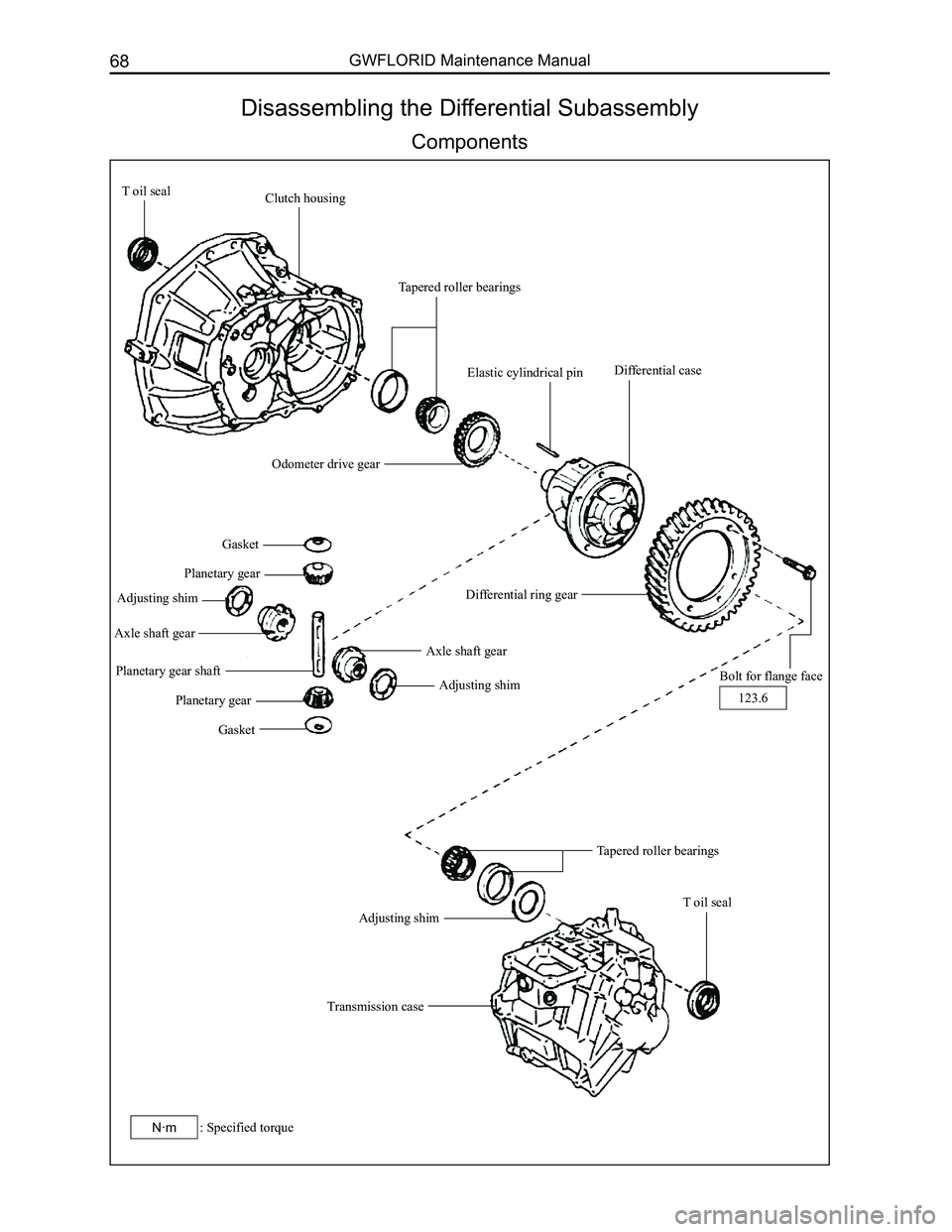

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual68

Disassembling the Differential Subassembly

Components

T oil sealClutch housing

Tapered roller bearings

Elastic cylindrical pin

Odometer drive gear

Differential case

Differential ring gear

Bolt for flange face

Gasket

Planetary gear

Adjusting shim

Axle shaft gear

Planetary gear shaft

Planetary gear

Gasket

Axle shaft gear

Adjusting shim

Tapered roller bearings

Transmission case

Adjusting shim

T oil seal

123.6

: Specified torqueN·m

Page 79 of 281

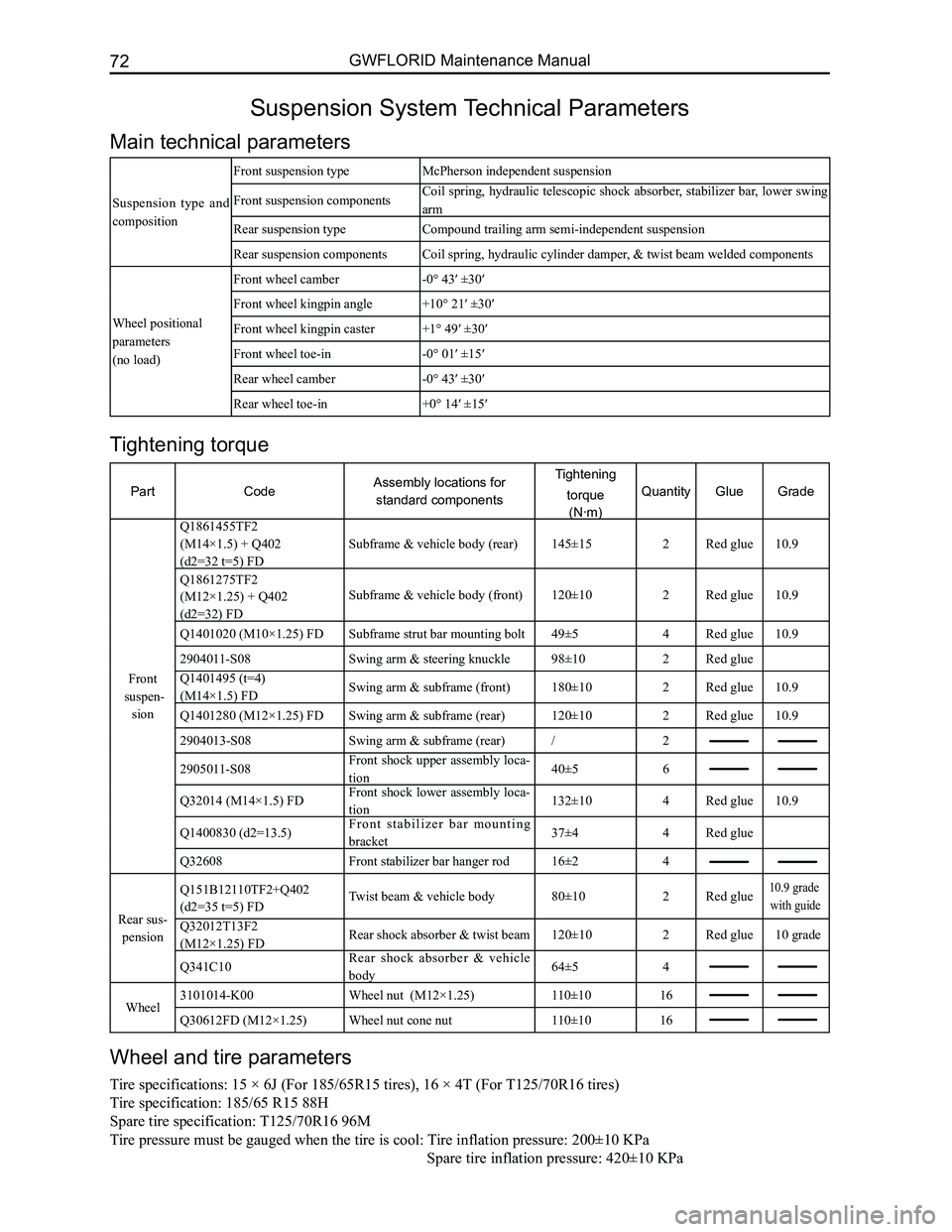

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual72

Suspension System Technical Parameters

Main technical parameters

Suspension type and

composition

Front suspension typeMcPherson independent suspension

Front suspension componentsCoil spring, hydraulic telescopic shock absorber, stabilizer bar, lower swing

arm

Rear suspension typeCompound trailing arm semi-independent suspension

Rear suspension componentsCoil spring, hydraulic cylinder damper, & twist beam welded components

Wheel positional

parameters

(no load)

Front wheel camber-0° 43′ ±30′

Front wheel kingpin angle+10° 21′ ±30′

Front wheel kingpin caster+1° 49′ ±30′

Front wheel toe-in-0° 01′ ±15′

Rear wheel camber-0° 43′ ±30′

Rear wheel toe-in+0° 14′ ±15′

Wheel and tire parameters

Tire specifications: 15 × 6J (For 185/65R15 tires), 16 × 4T (For T125/70R16 tires)

Tire specification: 185/65 R15 88H

Spare tire specification: T125/70R16 96M

Tire pressure must be gauged when the tire is cool: Tire inflation pressure: 200±10 KPa

Spare tir e inflation pressure: 420±10 KPa

Tightening torque

PartCodeAssembly locations for

standard components

Tightening

torque

(N·m)

QuantityGlueGrade

Front

suspen-

sion

Q1861455TF2

(M14×1.5) + Q402

(d2=32 t=5) FD

Subframe & vehicle body (rear)145±15 2Red glue10.9

Q1861275TF2

(M12×1.25) + Q402

(d2=32) FD

Subframe & vehicle body (front)120±102Red glue10.9

Q1401020 (M10×1.25) FDSubframe strut bar mounting bolt49±54Red glue10.9

2904011-S08Swing arm & steering knuckle98±102Red glue

Q1401495 (t=4)

(M14×1.5) FDSwing arm & subframe (front)180±102Red glue10.9

Q1401280 (M12×1.25) FDSwing arm & subframe (rear)120±102Red glue10.9

2904013-S08Swing arm & subframe (rear)/2

2905011-S08Front shock upper assembly loca-

tion40±56

Q32014 (M14×1.5) FDFront shock lower assembly loca-

tion132±104Red glue10.9

Q1400830 (d2=13.5)F r o n t s t a b i l i z e r b a r m o u n t i n g

bracket37±44Red glue

Q32608Front stabilizer bar hanger rod16±24

Rear sus-

pension

Q151B12110TF2+Q402

(d2=35 t=5) FDTwist beam & vehicle body80±102Red glue10.9 grade

with guide

Q32012T13F2

(M12×1.25) FDRear shock absorber & twist beam120±102Red glue10 grade

Q341C10Rear shock absorber & vehicle

body64±54

Wheel3101014-K00Wheel nut (M12×1.25)110±1016

Q30612FD (M12×1.25)Wheel nut cone nut110±1016

Page 80 of 281

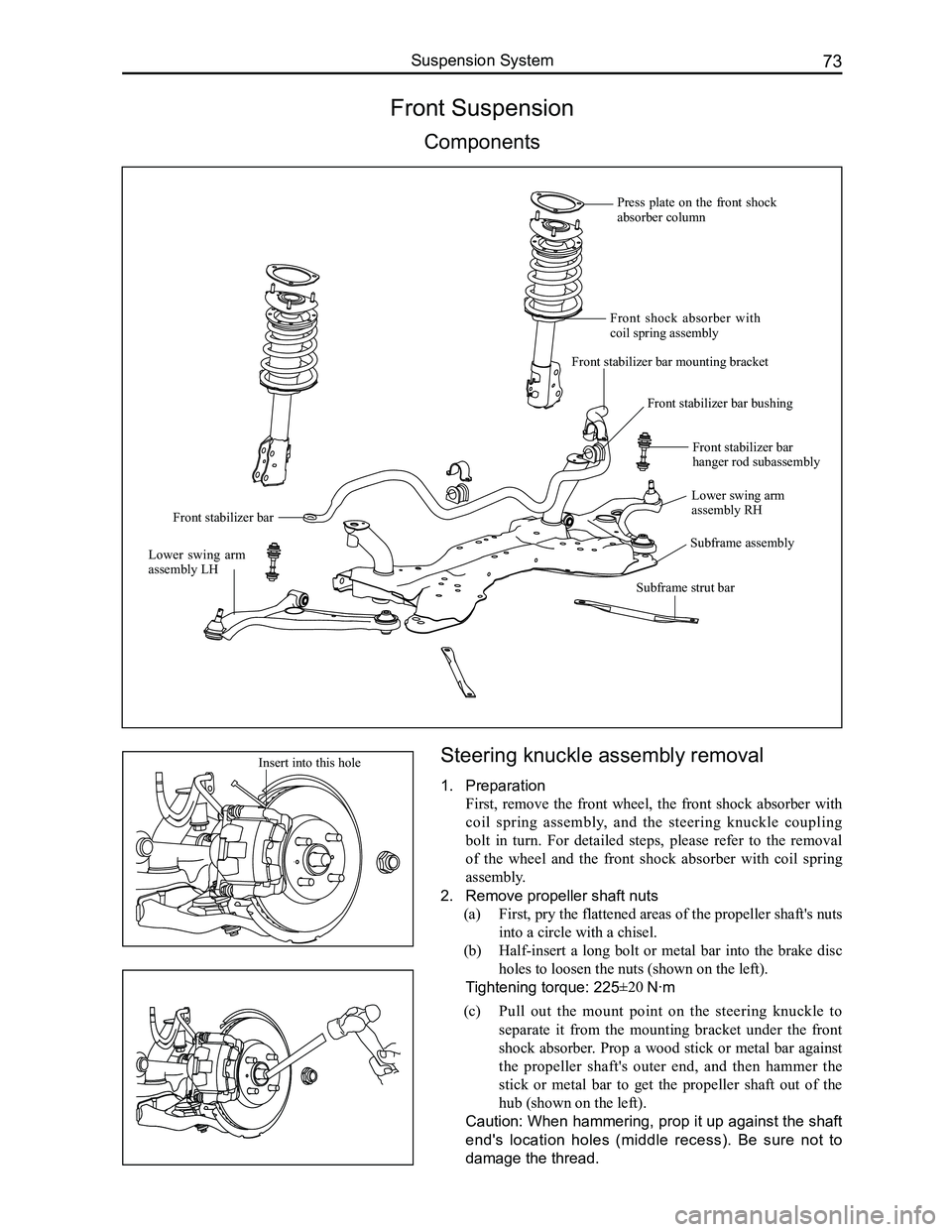

Downloaded from www.Manualslib.com manuals search engine 73Suspension System

Steering knuckle assembly removal

1. Preparation

First, remove the front wheel, the front shock absorber with

coil spring assembly, and the steering knuckle coupling

bolt in turn. For detailed steps, please refer to the removal

of the wheel and the front shock absorber with coil spring

assembly.

2. Remove propeller shaft nuts

(a) First, pry the flattened areas of the propeller shaft's nuts

into a circle with a chisel.

(b) Half-insert a long bolt or metal bar into the brake disc

holes to loosen the nuts (shown on the left).

Tightening torque: 225±20 N·m

Front Suspension

Components

(c) Pull out the mount point on the steering knuckle to

separate it from the mounting bracket under the front

shock absorber. Prop a wood stick or metal bar against

the propeller shaft's outer end, and then hammer the

stick or metal bar to get the propeller shaft out of the

hub (shown on the left).

Caution: When hammering, prop it up against the shaft

end's location holes (middle recess). Be sure not to

damage the thread.

Insert into this hole

Press plate on the front shock absorber column

Front shock absorber with coil spring assembly

Front stabilizer bar mounting bracket

Front stabilizer bar bushing

Front stabilizer bar

Lower swing arm assembly RH

Lower swing arm assembly LH

Subframe assembly

Front stabilizer bar hanger rod subassembly

Subframe strut bar

Page 82 of 281

Downloaded from www.Manualslib.com manuals search engine 75Suspension System

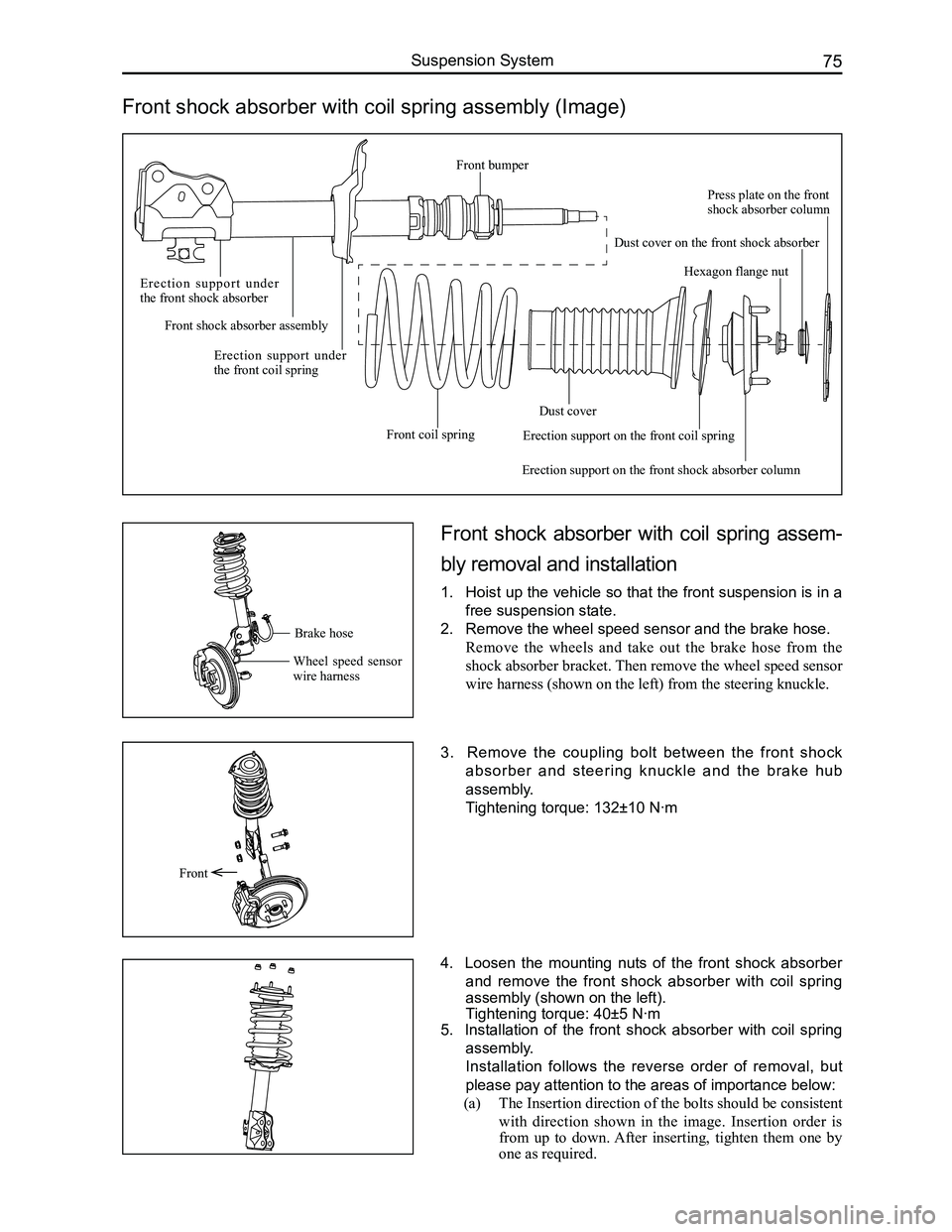

Front shock absorber with coil spring assembly (Image)

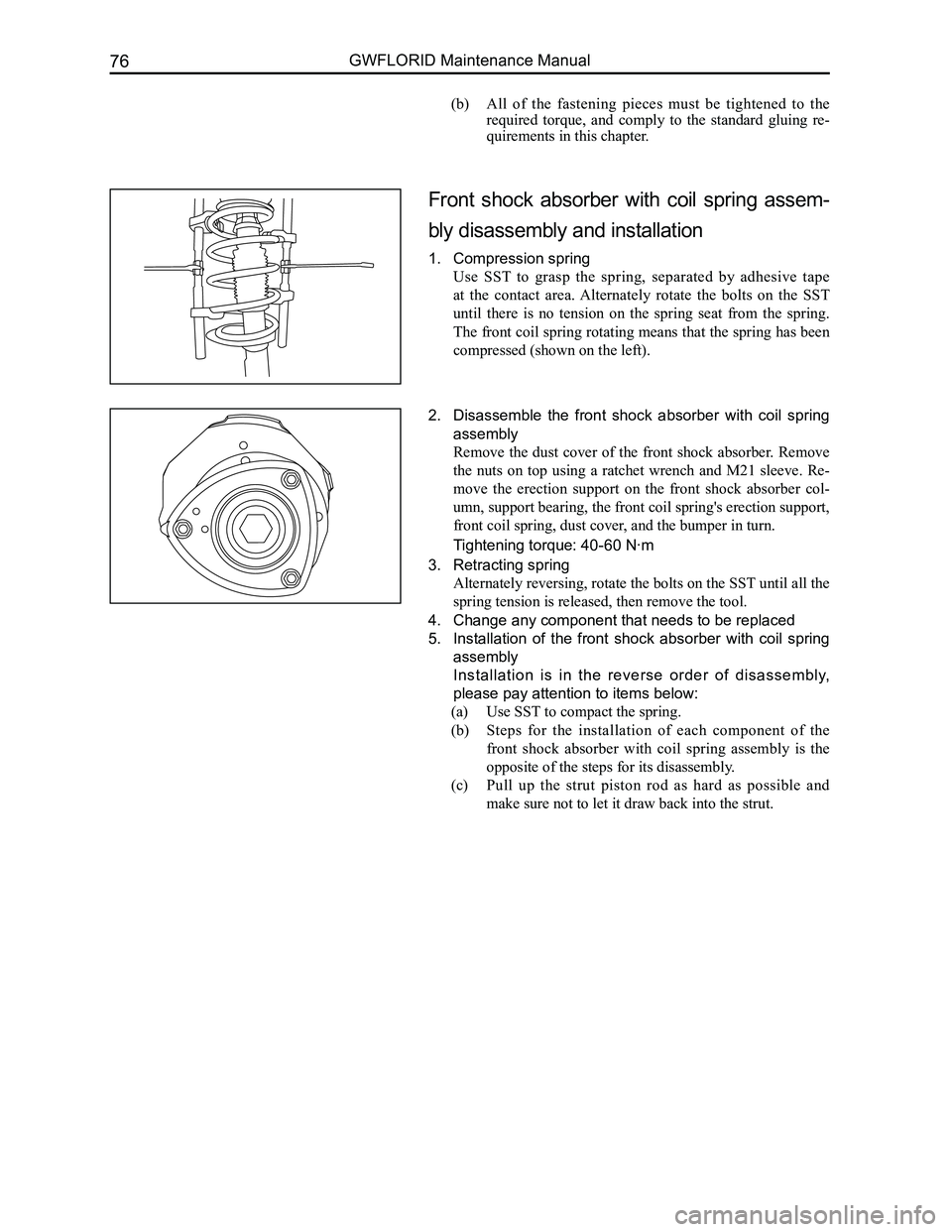

Front shock absorber with coil spring assem-

bly removal and installation

1. Hoist up the vehicle so that the front suspension is in a

free suspension state.

2. Remove the wheel speed sensor and the brake hose.

Remove the wheels and take out the brake hose from the

shock absorber bracket. Then remove the wheel speed sensor

wire harness (shown on the left) from the steering knuckle.

3. Remove the coupling bolt between the front shock

absorber and steering knuckle and the brake hub

assembly.

Tightening torque: 132±10 N·m

4. Loosen the mounting nuts of the front shock absorber

and remove the front shock absorber with coil spring

assembly (shown on the left).

Tightening torque: 40±5 N·m

5. Installation of the front shock absorber with coil spring

assembly.

Installation follows the reverse order of removal, but

please pay attention to the areas of importance below:

(a) The Insertion direction of the bolts should be consistent

with direction shown in the image. Insertion order is

from up to down. After inserting, tighten them one by

one as required.

Front

Brake hose

Wheel speed sensor wire harness

E r e c t i o n s u p p o r t u n d e r the front shock absorber

Front shock absorber assembly

Erection support under the front coil spring

Front coil spring

Dust cover

Erection support on the front shock absorber column

Hexagon flange nut

Press plate on the front shock absorber column

Dust cover on the front shock absorber

Erection support on the front coil spring

Front bumper

Page 83 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual76

Front shock absorber with coil spring assem-

bly disassembly and installation

1. Compression spring

Use SST to grasp the spring, separated by adhesive tape

at the contact area. Alternately rotate the bolts on the SST

until there is no tension on the spring seat from the spring.

The front coil spring rotating means that the spring has been

compressed (shown on the left).

2. Disassemble the front shock absorber with coil spring

assembly

Remove the dust cover of the front shock absorber. Remove

the nuts on top using a ratchet wrench and M21 sleeve. Re-

move the erection support on the front shock absorber col-

umn, support bearing, the front coil spring's erection support,

front coil spring, dust cover, and the bumper in turn.

Tightening torque: 40-60 N·m

3. Retracting spring

Alternately reversing, rotate the bolts on the SST until all the

spring tension is released, then remove the tool.

4. Change any component that needs to be replaced

5. Installation of the front shock absorber with coil spring

assembly

Installation is in the reverse order of disassembly,

please pay attention to items below:

(a) Use SST to compact the spring.

(b) Steps for the installation of each component of the

front shock absorber with coil spring assembly is the

opposite of the steps for its disassembly.

(c) Pull up the strut piston rod as hard as possible and

make sure not to let it draw back into the strut.

(b) All of the fastening pieces must be tightened to the

required torque, and comply to the standard gluing re-

quirements in this chapter.

Page 84 of 281

Downloaded from www.Manualslib.com manuals search engine 77Suspension System

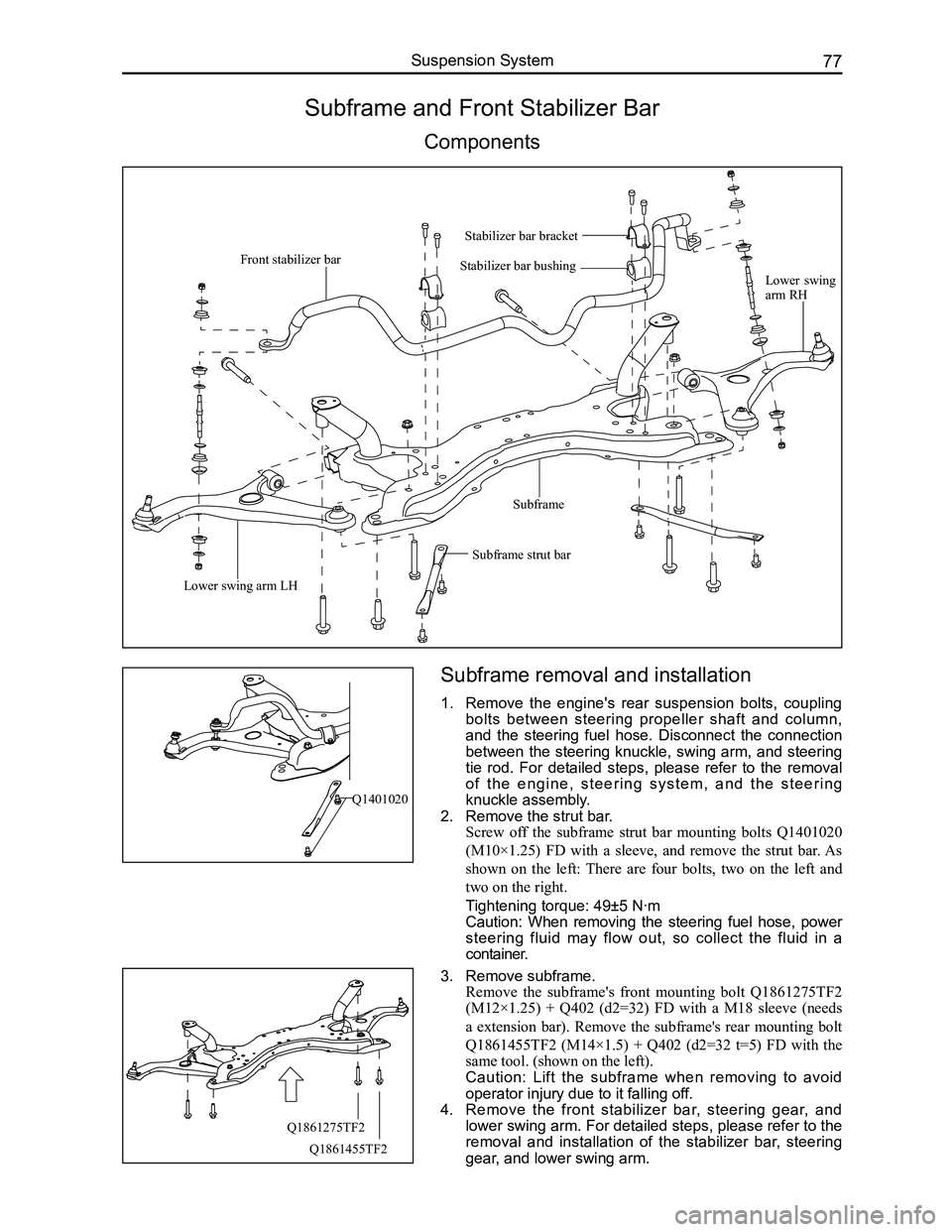

Subframe and Front Stabilizer Bar

Components

Front stabilizer bar

Lower swing arm RH

Subframe

Subframe strut bar

Lower swing arm LH

Stabilizer bar bracket

Stabilizer bar bushing

Subframe removal and installation

1. Remove the engine's rear suspension bolts, coupling

bolts between steering propeller shaft and column,

and the steering fuel hose. Disconnect the connection

between the steering knuckle, swing arm, and steering

tie rod. For detailed steps, please refer to the removal

o f t h e e n g i n e , s t e e r i n g s y s t e m , a n d t h e s t e e r i n g

knuckle assembly.

2. Remove the strut bar.

Screw off the subframe strut bar mounting bolts Q1401020

(M10×1.25) FD with a sleeve, and remove the strut bar. As

shown on the left: There are four bolts, two on the left and

two on the right.

Tightening torque: 49±5 N·m

Caution: When removing the steering fuel hose, power

steering fluid may flow out, so collect the fluid in a

container.

3. Remove subframe.

Remove the subframe's front mounting bolt Q1861275TF2

(M12×1.25) + Q402 (d2=32) FD with a M18 sleeve (needs

a extension bar). Remove the subframe's rear mounting bolt

Q1861455TF2 (M14×1.5) + Q402 (d2=32 t=5) FD with the

same tool. (shown on the left).

Caution: Lift the subframe when removing to avoid

operator injury due to it falling off.

4. Remove the front stabilizer bar, steering gear, and

lower swing arm. For detailed steps, please refer to the

removal and installation of the stabilizer bar, steering

gear, and lower swing arm.

Q1401020

Q1861275TF2

Q1861455TF2

Page 85 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual78

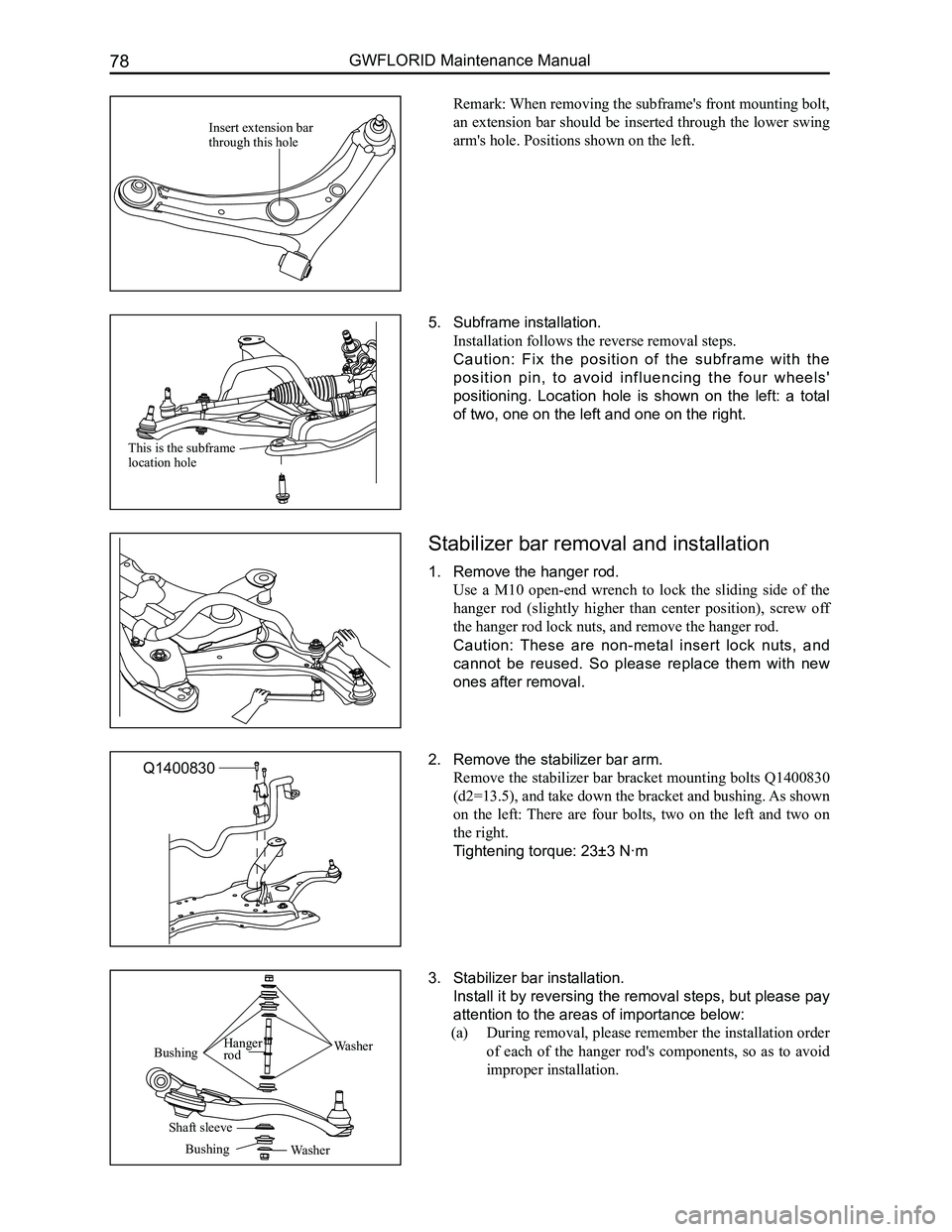

Remark: When removing the subframe's front mounting bolt,

an extension bar should be inserted through the lower swing

arm's hole. Positions shown on the left.

5. Subframe installation.

Installation follows the reverse removal steps.

Caution: Fix the position of the subframe with the

position pin, to avoid influencing the four wheels'

positioning. Location hole is shown on the left: a total

of two, one on the left and one on the right.

Stabilizer bar removal and installation

1. Remove the hanger rod.

Use a M10 open-end wrench to lock the sliding side of the

hanger rod (slightly higher than center position), screw off

the hanger rod lock nuts, and remove the hanger rod.

Caution: These are non-metal insert lock nuts, and

cannot be reused. So please replace them with new

ones after removal.

2. Remove the stabilizer bar arm.

Remove the stabilizer bar bracket mounting bolts Q1400830

(d2=13.5), and take down the bracket and bushing. As shown

on the left: There are four bolts, two on the left and two on

the right.

Tightening torque: 23±3 N·m

3. Stabilizer bar installation.

Install it by reversing the removal steps, but please pay

attention to the areas of importance below:

(a) During removal, please remember the installation order

of each of the hanger rod's components, so as to avoid

improper installation.

Insert extension bar through this hole

This is the subframe location hole

Q1400830

WasherBushingHanger rod

Shaft sleeve

BushingWasher

Page 87 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual80

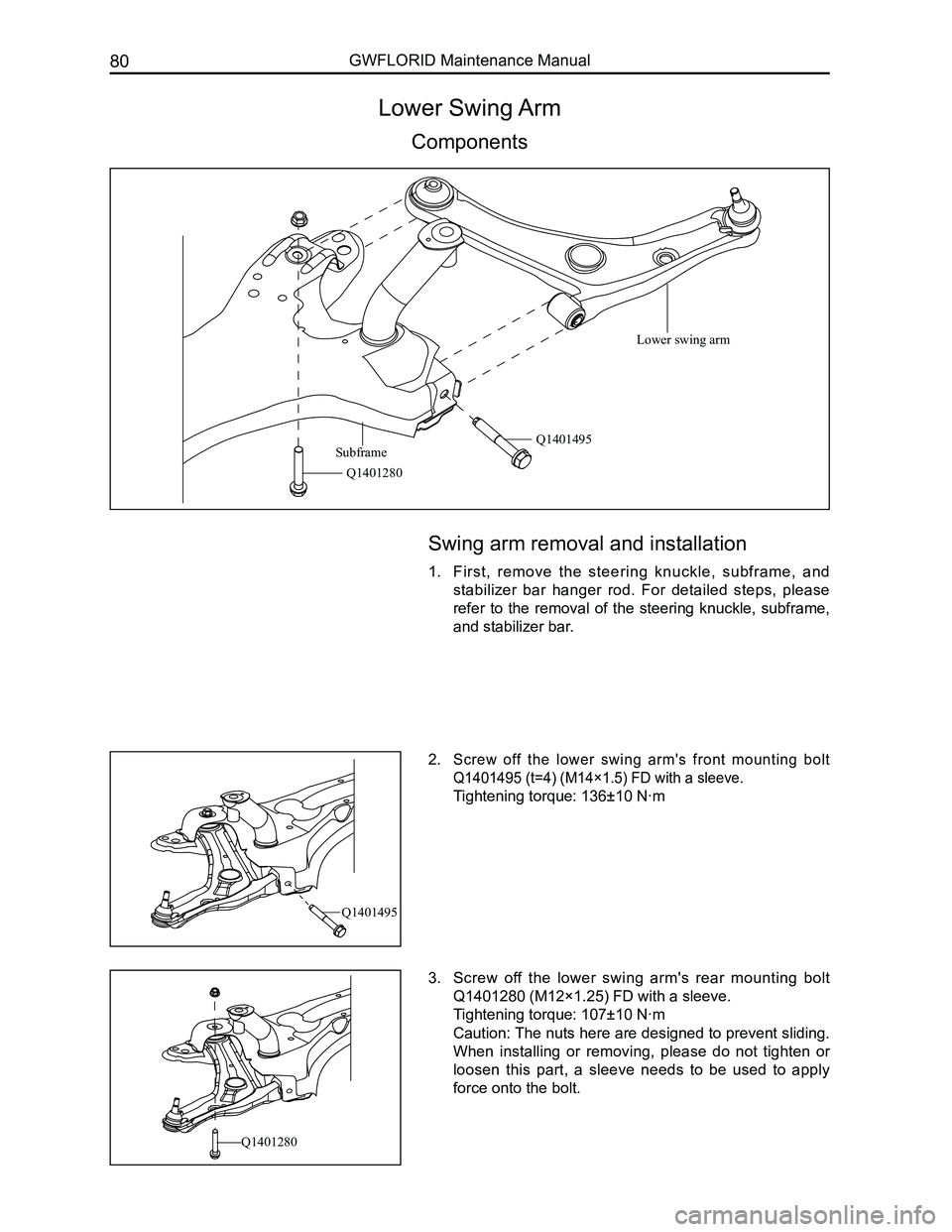

Lower Swing Arm

Components

Swing arm removal and installation

1. First, remove the steering knuckle, subframe, and

stabilizer bar hanger rod. For detailed steps, please

refer to the removal of the steering knuckle, subframe,

and stabilizer bar.

2. Screw off the lower swing arm's front mounting bolt

Q1401495 (t=4) (M14×1.5) FD with a sleeve.

Tightening torque: 136±10 N·m

3. Screw off the lower swing arm's rear mounting bolt

Q1401280 (M12×1.25) FD with a sleeve.

Tightening torque: 107±10 N·m

Caution: The nuts here are designed to prevent sliding.

When installing or removing, please do not tighten or

loosen this part, a sleeve needs to be used to apply

force onto the bolt.

Lower swing arm

SubframeQ1401495

Q1401280

Q1401495

Q1401280

Page 92 of 281

Downloaded from www.Manualslib.com manuals search engine 85Suspension System

Drive shaft installation

1. Insert the drive shaft.

First, align the inner end of the drive shaft and differential

spline. Keep the drive shaft axes and the differential axes

bases uniform, then hammer towards the direction of the

differential drive shaft's outer end until a clear and sharp

clicking sound is heard. Here, the drive shaft and the

transmission should have a clearance of about 1 mm.

2. According to the front suspension and wheel assembly

installation specifications, properly install the front

shock absorber with coil spring assembly LH and

wheel.

3. Use an M32 sleeve, ratchet wrench, and extension bar

to tighten front drive shaft nut LH.

Tightening torque: 225±20 N·m

F

F