torque GREAT WALL FLORID 2008 Workshop Manual

[x] Cancel search | Manufacturer: GREAT WALL, Model Year: 2008, Model line: FLORID, Model: GREAT WALL FLORID 2008Pages: 281, PDF Size: 43.97 MB

Page 142 of 281

Downloaded from www.Manualslib.com manuals search engine 135Steering System

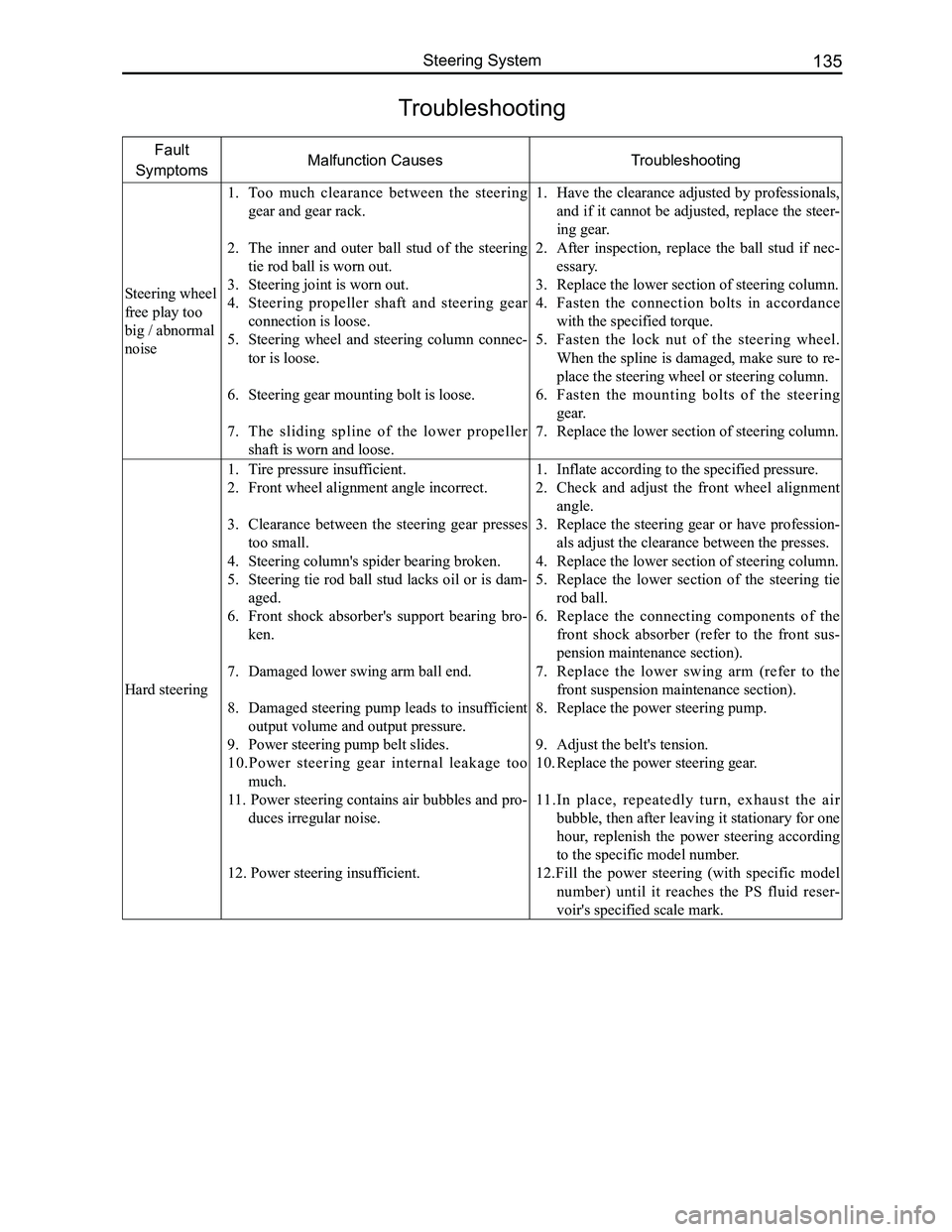

Troubleshooting

Fault

SymptomsMalfunction CausesTroubleshooting

Steering wheel

free play too

big / abnormal

noise

1. Too much clearance between the steering

gear and gear rack.

2. The inner and outer ball stud of the steering

tie rod ball is worn out.

3. Steering joint is worn out.

4. Steering propeller shaft and steering gear

connection is loose.

5. Steering wheel and steering column connec-

tor is loose.

6. Steering gear mounting bolt is loose.

7. The sliding spline of the lower propeller

shaft is worn and loose.

1. Have the clearance adjusted by professionals,

and if it cannot be adjusted, replace the steer-

ing gear.

2. After inspection, replace the ball stud if nec-

essary.

3. Replace the lower section of steering column.

4. Fasten the connection bolts in accordance

with the specified torque.

5. Fasten the lock nut of the steering wheel.

When the spline is damaged, make sure to re-

place the steering wheel or steering column.

6. Fasten the mounting bolts of the steering

gear.

7. Replace the lower section of steering column.

Hard steering

1. Tire pressure insufficient.

2. Front wheel alignment angle incorrect.

3. Clearance between the steering gear presses

too small.

4. Steering column's spider bearing broken.

5. Steering tie rod ball stud lacks oil or is dam-

aged.

6. Front shock absorber's support bearing bro-

ken.

7. Damaged lower swing arm ball end.

8. Damaged steering pump leads to insufficient

output volume and output pressure.

9. Power steering pump belt slides.

10.Power steering gear internal leakage too

much.

11. Power steering contains air bubbles and pro-

duces irregular noise.

12. Power steering insufficient.

1. Inflate according to the specified pressure.

2. Check and adjust the front wheel alignment

angle.

3. Replace the steering gear or have profession-

als adjust the clearance between the presses.

4. Replace the lower section of steering column.

5. Replace the lower section of the steering tie

rod ball.

6. Replace the connecting components of the

front shock absorber (refer to the front sus-

pension maintenance section).

7. Replace the lower swing arm (refer to the

front suspension maintenance section).

8. Replace the power steering pump.

9. Adjust the belt's tension.

10. Replace the power steering gear.

11.In place, repeatedly turn, exhaust the air

bubble, then after leaving it stationary for one

hour, replenish the power steering according

to the specific model number.

12.Fill the power steering (with specific model

number) until it reaches the PS fluid reser-

voir's specified scale mark.

Page 146 of 281

Downloaded from www.Manualslib.com manuals search engine 139Steering System

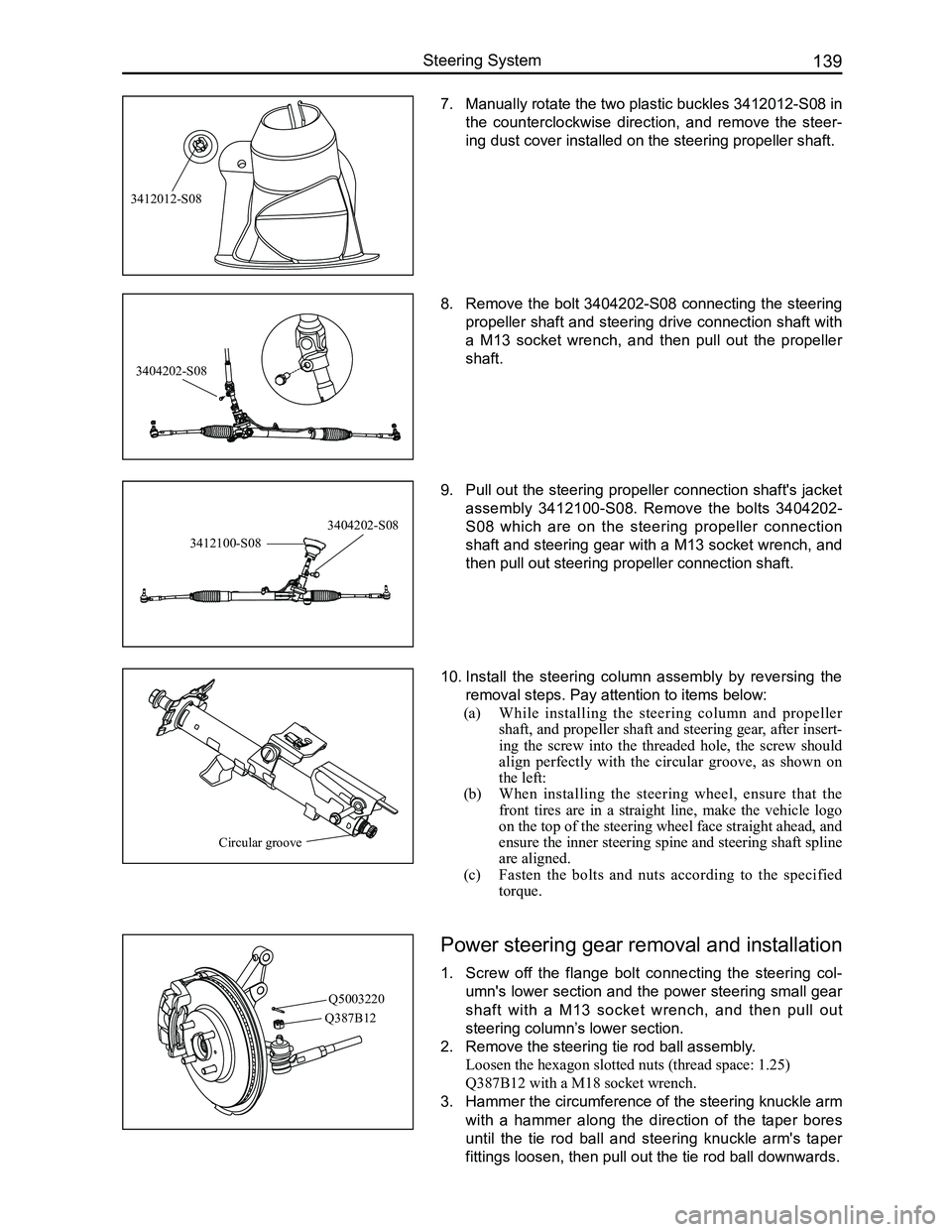

7. Manually rotate the two plastic buckles 3412012-S08 in

the counterclockwise direction, and remove the steer-

ing dust cover installed on the steering propeller shaft.

8. Remove the bolt 3404202-S08 connecting the steering

propeller shaft and steering drive connection shaft with

a M13 socket wrench, and then pull out the propeller

shaft.

9. Pull out the steering propeller connection shaft's jacket

assembly 3412100-S08. Remove the bolts 3404202-

S08 which are on the steering propeller connection

shaft and steering gear with a M13 socket wrench, and

then pull out steering propeller connection shaft.

10. Install the steering column assembly by reversing the

removal steps. Pay attention to items below:

(a) While installing the steering column and propeller

shaft, and propeller shaft and steering gear, after insert-

ing the screw into the threaded hole, the screw should

align perfectly with the circular groove, as shown on

the left:

(b) When installing the steering wheel, ensure that the

front tires are in a straight line, make the vehicle logo

on the top of the steering wheel face straight ahead, and

ensure the inner steering spine and steering shaft spline

are aligned.

(c) Fasten the bolts and nuts according to the specified

torque.

3412012-S08

Circular groove

3412100-S08

3404202-S08

Power steering gear removal and installation

1. Screw off the flange bolt connecting the steering col-

umn's lower section and the power steering small gear

shaft with a M13 socket wrench, and then pull out

steering column’s lower section.

2. Remove the steering tie rod ball assembly.

Loosen the hexagon slotted nuts (thread space: 1.25)

Q387B12 with a M18 socket wrench.

3. Hammer the circumference of the steering knuckle arm

with a hammer along the direction of the taper bores

until the tie rod ball and steering knuckle arm's taper

fittings loosen, then pull out the tie rod ball downwards.

Q5003220

Q387B12

3404202-S08

Page 147 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual140

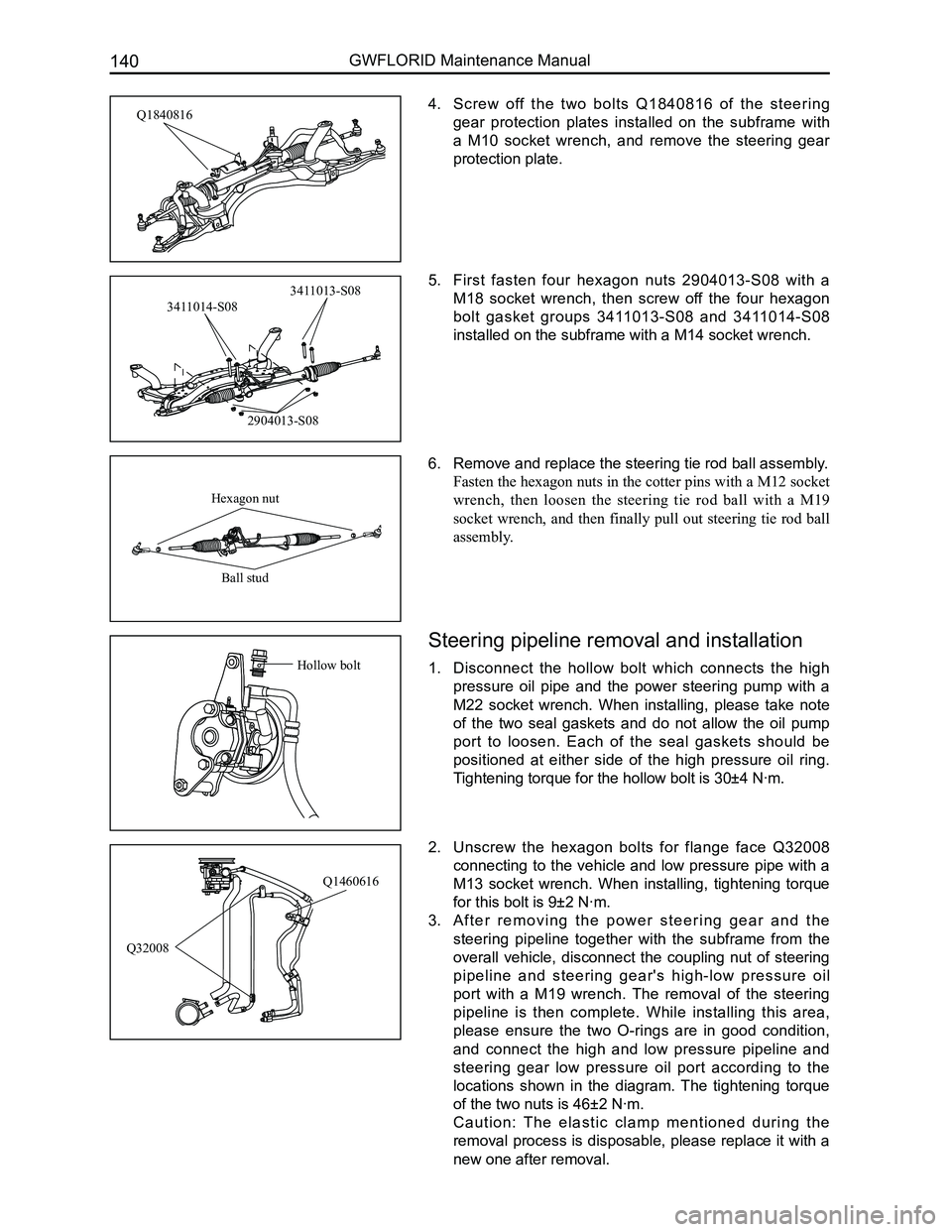

4. Screw off the two bolts Q1840816 of the steering

gear protection plates installed on the subframe with

a M10 socket wrench, and remove the steering gear

protection plate.

5. First fasten four hexagon nuts 2904013-S08 with a

M18 socket wrench, then screw off the four hexagon

bolt gasket groups 3411013-S08 and 3411014-S08

installed on the subframe with a M14 socket wrench.

6. Remove and replace the steering tie rod ball assembly.

Fasten the hexagon nuts in the cotter pins with a M12 socket

wrench, then loosen the steering tie rod ball with a M19

socket wrench, and then finally pull out steering tie rod ball

assembly.

2. Unscrew the hexagon bolts for flange face Q32008

connecting to the vehicle and low pressure pipe with a

M13 socket wrench. When installing, tightening torque

for this bolt is 9±2 N·m.

3. A f t e r r e m o v i n g t h e p o w e r s t e e r i n g g e a r a n d t h e

steering pipeline together with the subframe from the

overall vehicle, disconnect the coupling nut of steering

pipeline and steering gear's high-low pressure oil

port with a M19 wrench. The removal of the steering

pipeline is then complete. While installing this area,

please ensure the two O-rings are in good condition,

and connect the high and low pressure pipeline and

steering gear low pressure oil port according to the

locations shown in the diagram. The tightening torque

of the two nuts is 46±2 N·m.

C a u t i o n : T h e e l a s t i c c l a m p m e n t i o n e d d u r i n g t h e

removal process is disposable, please replace it with a

new one after removal.

Q1460616

Q32008

Q1840816

2904013-S08

3411014-S08

3411013-S08

Hexagon nut

Ball stud

Steering pipeline removal and installation

1. Disconnect the hollow bolt which connects the high

pressure oil pipe and the power steering pump with a

M22 socket wrench. When installing, please take note

of the two seal gaskets and do not allow the oil pump

port to loosen. Each of the seal gaskets should be

positioned at either side of the high pressure oil ring.

Tightening torque for the hollow bolt is 30±4 N·m.

Hollow bolt

Page 148 of 281

Downloaded from www.Manualslib.com manuals search engine 141Steering System

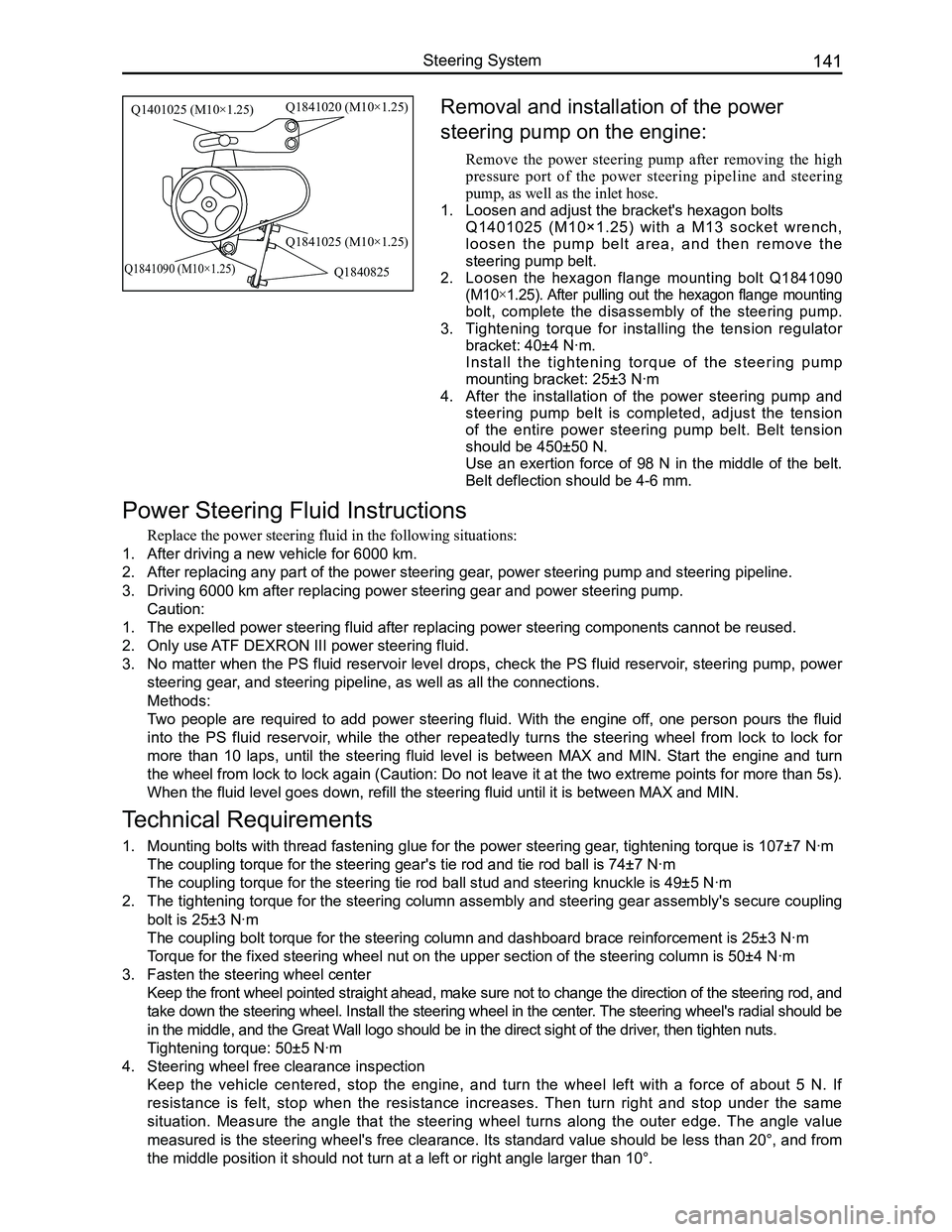

Removal and installation of the power

steering pump on the engine:

Remove the power steering pump after removing the high

pressure port of the power steering pipeline and steering

pump, as well as the inlet hose.

1. Loosen and adjust the bracket's hexagon bolts

Q1401025 (M10×1.25) with a M13 socket wrench,

l o o s e n t h e p u m p b e l t a r e a , a n d t h e n r e m o v e t h e

steering pump belt.

2. Loosen the hexagon flange mounting bolt Q1841090

(M10×1.25). After pulling out the hexagon flange mounting

bolt, complete the disassembly of the steering pump.

3. Tightening torque for installing the tension regulator

bracket: 40±4 N·m.

Install the tightening torque of the steering pump

mounting bracket: 25±3 N·m

4. After the installation of the power steering pump and

steering pump belt is completed, adjust the tension

of the entire power steering pump belt. Belt tension

should be 450±50 N.

Use an exertion force of 98 N in the middle of the belt.

Belt deflection should be 4-6 mm.

Power Steering Fluid Instructions

Replace the power steering fluid in the following situations:

1. After driving a new vehicle for 6000 km.

2. After replacing any part of the power steering gear, power steering pump and steering pipeline.

3. Driving 6000 km after replacing power steering gear and power steering p\

ump.

Caution:

1. The expelled power steering fluid after replacing power steering compone\

nts cannot be reused.

2. Only use ATF DEXRON III power steering fluid.

3. No matter when the PS fluid reservoir level drops, check the PS fluid reservoir, steering pump, power

steering gear, and steering pipeline, as well as all the connections.

Methods:

Two people are required to add power steering fluid. With the engine off, one person pours the fluid

into the PS fluid reservoir, while the other repeatedly turns the steering wheel from lock to lock for

more than 10 laps, until the steering fluid level is between MAX and MIN. Start the engine and turn

the wheel from lock to lock again (Caution: Do not leave it at the two extreme points for more than 5s).

When the fluid level goes down, refill the steering fluid until it is be\

tween MAX and MIN.

Technical Requirements

1. Mounting bolts with thread fastening glue for the power steering gear, tightening torque is 107±7 N·m

The coupling torque for the steering gear's tie rod and tie rod ball is \

74±7 N·m

The coupling torque for the steering tie rod ball stud and steering knuc\

kle is 49±5 N·m

2. The tightening torque for the steering column assembly and steering gear assembly's secure coupling

bolt is 25±3 N·m

The coupling bolt torque for the steering column and dashboard brace rei\

nforcement is 25±3 N·m

Torque for the fixed steering wheel nut on the upper section of the steer\

ing column is 50±4 N·m

3. Fasten the steering wheel center

Keep the front wheel pointed straight ahead, make sure not to change the direction of the steering rod, and

take down the steering wheel. Install the steering wheel in the center. The steering wheel's radial should be

in the middle, and the Great Wall logo should be in the direct sight of the driver, then tighten nuts.

Tightening torque: 50±5 N·m

4. Steering wheel free clearance inspection

Keep the vehicle centered, stop the engine, and turn the wheel left with a force of about 5 N. If

resistance is felt, stop when the resistance increases. Then turn right and stop under the same

situation. Measure the angle that the steering wheel turns along the outer edge. The angle value

measured is the steering wheel's free clearance. Its standard value should be less than 20°, and from

the middle position it should not turn at a left or right angle larger t\

han 10°.

Q1401025 (M10×1.25)Q1841020 (M10×1.25)

Q1841025 (M10×1.25)

Q1840825Q1841090 (M10×1.25)

Page 210 of 281

Downloaded from www.Manualslib.com manuals search engine 203Air Conditioning System

Areas of Importance

1. When putting in a new compressor, adjust the new compressor's inner lubricant to make it the same

level as of the old compressor's.

2. When the air conditioner malfunctions, if the pipeline, condenser or evaporator is the source of the

damage leading to its replacement, just add model number RS20 profession\

al lubricant 5-10 ml.

3. The compressor is a high speed operating component, the smallest impurity in the air conditioning

system can lead to the compressor's damage, therefore the entire air conditioning system must be

cleaned.

4. In order to avoid liquid damage to the compressor, pay careful attention when filling the refrigerant.

When the vehicle stopped, fill the liquid refrigerant from the high pressure side. When in operation, fill

the liquid refrigerant from the low pressure side.

5. When undergoing maintenance, pay attention that the amount of refrigerant being added is 510±10 g.

Observe through the check glass to determine if there is sufficient new refrigerant charge.

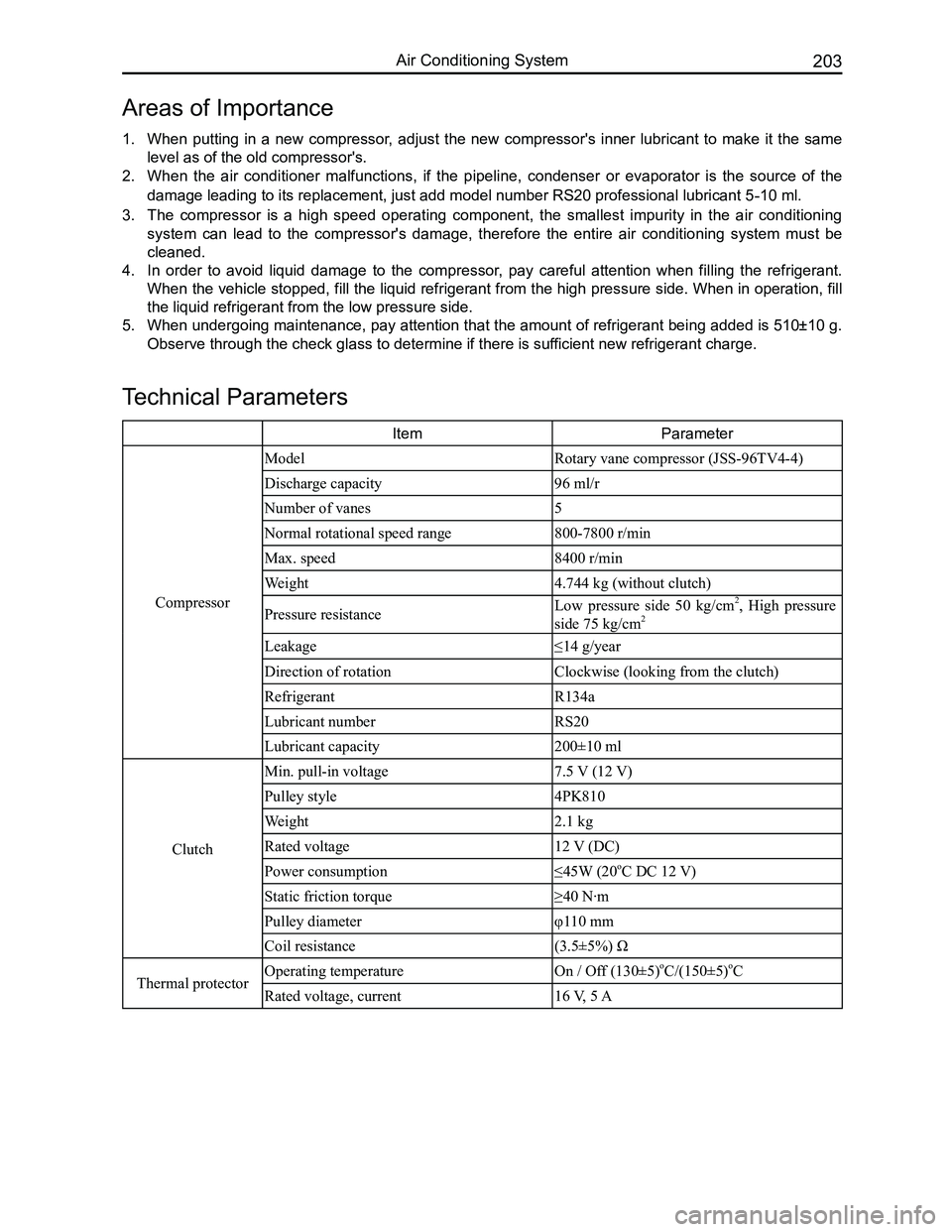

ItemParameter

Compressor

ModelRotary vane compressor (JSS-96TV4-4)

Discharge capacity96 ml/r

Number of vanes5

Normal rotational speed range800-7800 r/min

Max. speed8400 r/min

Weight4.744 kg (without clutch)

Pressure resistanceLow pressure side 50 kg/cm2, High pressure

side 75 kg/cm2

Leakage≤14 g/year

Direction of rotationClockwise (looking from the clutch)

RefrigerantR134a

Lubricant numberRS20

Lubricant capacity 200±10 ml

Clutch

Min. pull-in voltage7.5 V (12 V)

Pulley style 4PK810

Weight2.1 kg

Rated voltage12 V (DC)

Power consumption≤45W (20oC DC 12 V)

Static friction torque≥40 N·m

Pulley diameterφ110 mm

Coil resistance(3.5±5%) Ω

Thermal protectorOperating temperatureOn / Off (130±5)oC/(150±5)oC

Rated voltage, current16 V, 5 A

Technical Parameters

Page 216 of 281

Downloaded from www.Manualslib.com manuals search engine 209Air Conditioning System

Compressor Removal

1. Hoist the vehicle with a jack.

2. Remove the bottom mudguard.

3. Remove the compressor.

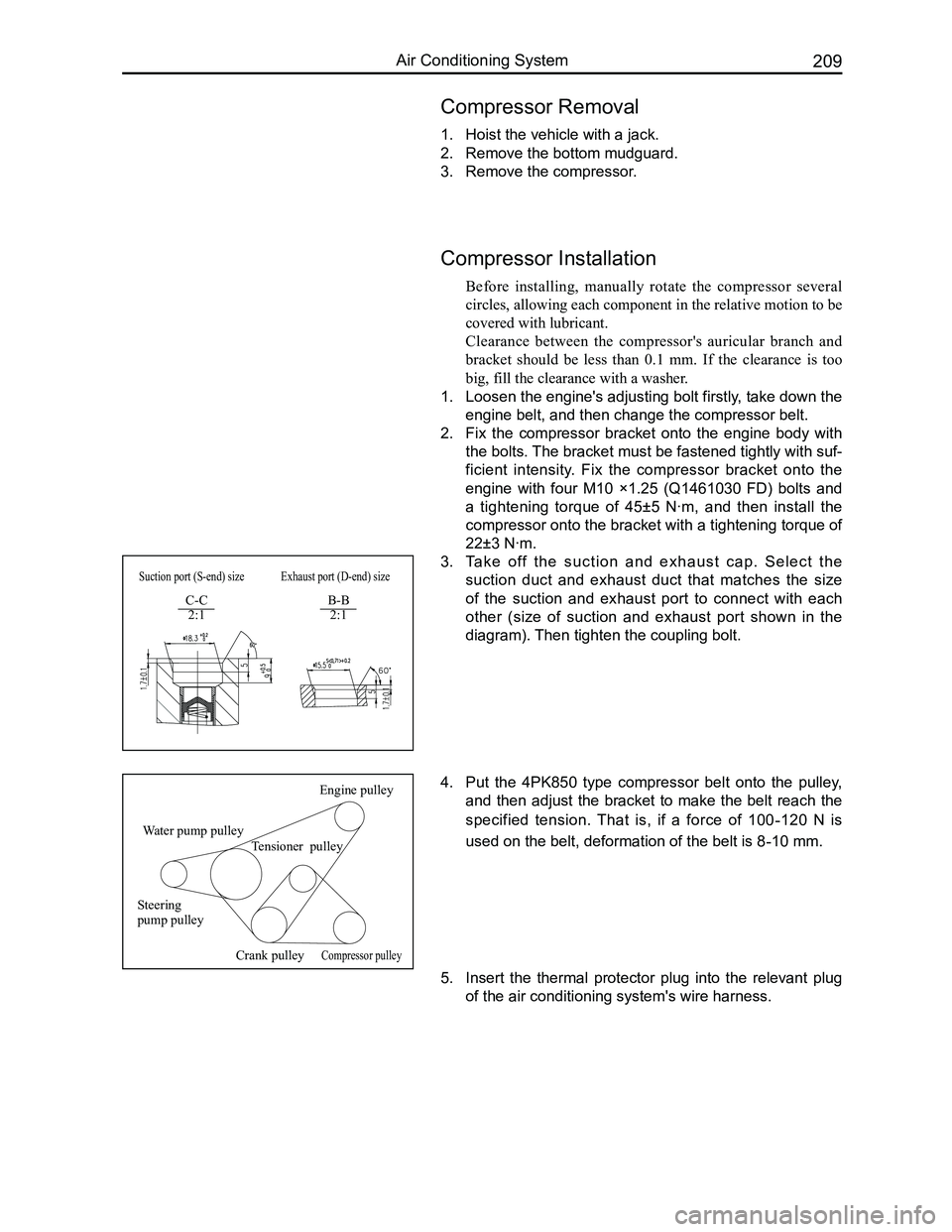

Compressor Installation

Before installing, manually rotate the compressor several

circles, allowing each component in the relative motion to be

covered with lubricant.

Clearance between the compressor's auricular branch and

bracket should be less than 0.1 mm. If the clearance is too

big, fill the clearance with a washer.

1. Loosen the engine's adjusting bolt firstly, take down the

engine belt, and then change the compressor belt.

2. Fix the compressor bracket onto the engine body with

the bolts. The bracket must be fastened tightly with suf-

ficient intensity. Fix the compressor bracket onto the

engine with four M10 ×1.25 (Q1461030 FD) bolts and

a tightening torque of 45±5 N·m, and then install the

compressor onto the bracket with a tightening torque of

22±3 N·m.

3. Ta k e o ff t h e s u c t i o n a n d e x h a u s t c a p . S e l e c t t h e

suction duct and exhaust duct that matches the size

of the suction and exhaust port to connect with each

other (size of suction and exhaust port shown in the

diagram). Then tighten the coupling bolt.

Water pump pulley

Engine pulley

Tensioner pulley

Steering pump pulley

Crank pulleyCompressor pulley

Suction port (S-end) sizeExhaust port (D-end) size

C-C 2:1B-B 2:1

4. Put the 4PK850 type compressor belt onto the pulley,

and then adjust the bracket to make the belt reach the

specified tension. That is, if a force of 100-120 N is

used on the belt, deformation of the belt is 8-10 mm.

5. Insert the thermal protector plug into the relevant plug

of the air conditioning system's wire harness.

Page 218 of 281

Downloaded from www.Manualslib.com manuals search engine 211Air Conditioning System

Clutch Installation

1. Install the solenoid coil at the place pressing up against the head cover's end surface and pay atten-

tion to insert the dowel pin of the solenoid coil into the bottom hole of the head cover. Put the retaining

ring into the groove with circlip pliers, and press the solenoid coil's connecting wire onto the pressing

line plate on the head cover with a SST.

2. Put the compressor on a specially designed fixture or platform, with its head cover facing upwards.

Press the pulley into the head cover shaft, and put the pulley bearing's retaining ring into the groove

with circlip pliers.

3. Install the armature onto the main shaft's spline and seize the clutch's triangular piece with a clamp.

Then tighten the inner hexagon lock screws and washers with a torque wrench. Screw torque should

be between 150-180 N·m. After installation is done, make sure to check if the clutch's pulley and

armature are able to operate freely, and also check the clearance between the pulley and armature,

which should be 0.3-0.6 mm.

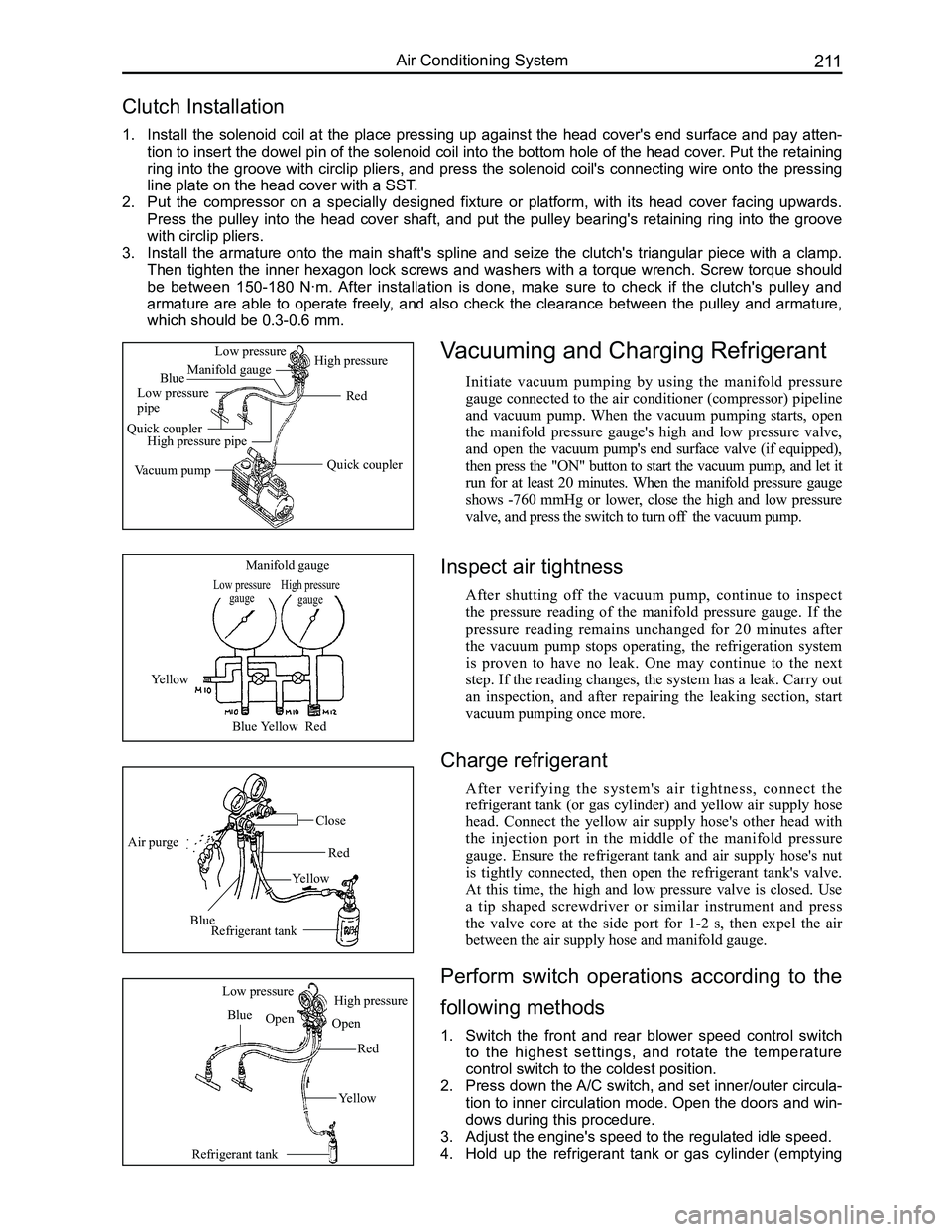

Vacuuming and Charging Refrigerant

Initiate vacuum pumping by using the manifold pressure

gauge connected to the air conditioner (compressor) pipeline

and vacuum pump. When the vacuum pumping starts, open

the manifold pressure gauge's high and low pressure valve,

and open the vacuum pump's end surface valve (if equipped),

then press the "ON" button to start the vacuum pump, and let it

run for at least 20 minutes. When the manifold pressure gauge

shows -760 mmHg or lower, close the high and low pressure

valve, and press the switch to turn off the vacuum pump.

Low pressure gaugeHigh pressure gauge

Manifold gauge

Yellow

BlueYellowRed

Air purge

Blue

Yellow

Red

Close

Refrigerant tank

Refrigerant tank

Blue

Red

Yellow

Low pressureHigh pressure

OpenOpen

Quick coupler

Red

Manifold gauge

Low pressure pipe

Quick couplerHigh pressure pipe

Vacuum pump

Low pressureHigh pressure

Blue

Inspect air tightness

After shutting off the vacuum pump, continue to inspect

the pressure reading of the manifold pressure gauge. If the

pressure reading remains unchanged for 20 minutes after

the vacuum pump stops operating, the refrigeration system

is proven to have no leak. One may continue to the next

step. If the reading changes, the system has a leak. Carry out

an inspection, and after repairing the leaking section, start

vacuum pumping once more.

Charge refrigerant

After verifying the system's air tightness, connect the

refrigerant tank (or gas cylinder) and yellow air supply hose

head. Connect the yellow air supply hose's other head with

the injection port in the middle of the manifold pressure

gauge. Ensure the refrigerant tank and air supply hose's nut

is tightly connected, then open the refrigerant tank's valve.

At this time, the high and low pressure valve is closed. Use

a tip shaped screwdriver or similar instrument and press

the valve core at the side port for 1-2 s, then expel the air

between the air supply hose and manifold gauge.

Perform switch operations according to the

following methods

1. Switch the front and rear blower speed control switch

to the highest settings, and rotate the temperature

control switch to the coldest position.

2. Press down the A/C switch, and set inner/outer circula-

tion to inner circulation mode. Open the doors and win-

dows during this procedure.

3. Adjust the engine's speed to the regulated idle speed.

4. Hold up the refrigerant tank or gas cylinder (emptying

Page 269 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual262

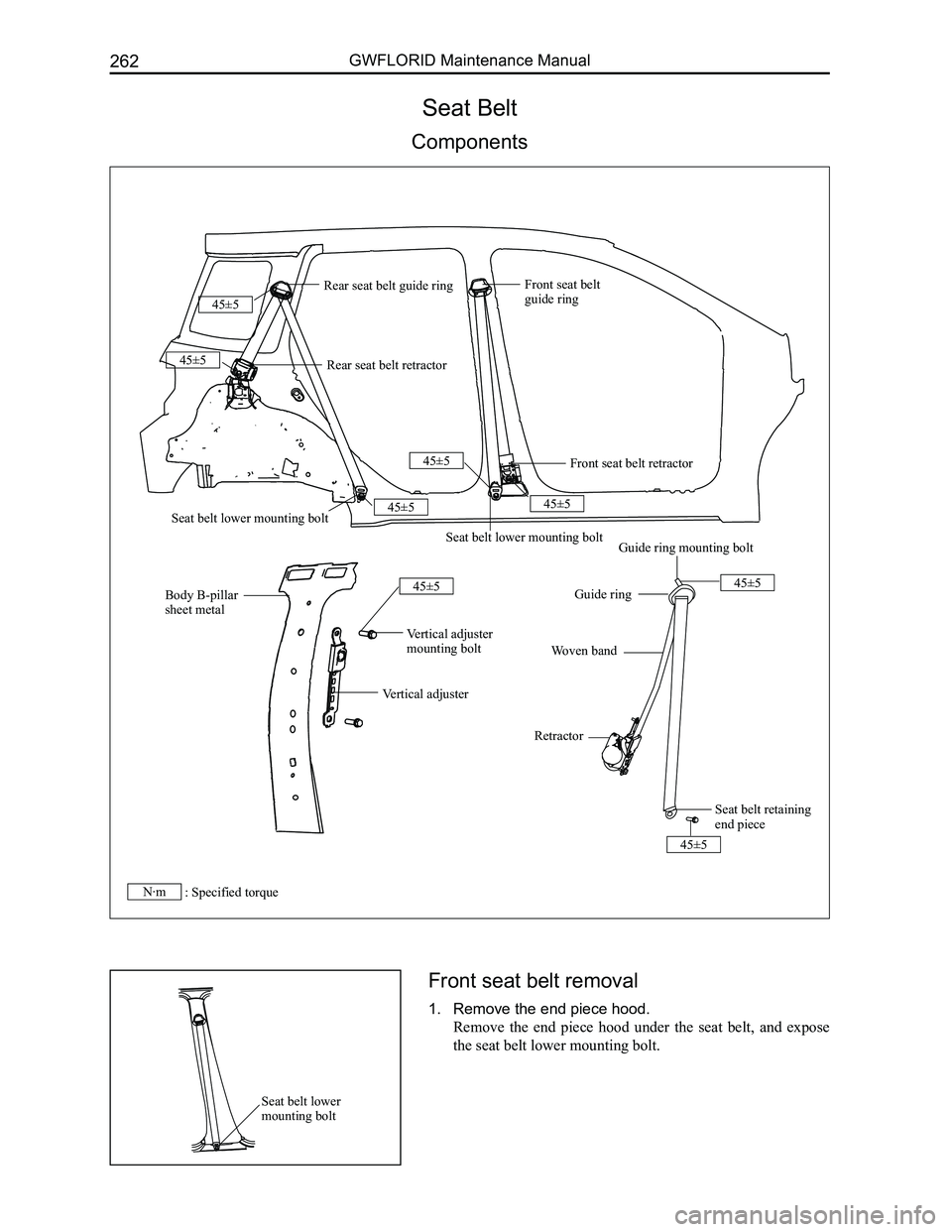

Seat Belt

Components

Front seat belt removal

1. Remove the end piece hood.

Remove the end piece hood under the seat belt, and expose

the seat belt lower mounting bolt.

Rear seat belt guide ring

Rear seat belt retractor

Seat belt lower mounting bolt

Front seat belt retractor

Front seat belt guide ring

Seat belt lower mounting bolt

Vertical adjuster mounting bolt

Body B-pillar sheet metal

Vertical adjuster

Guide ring mounting bolt

Guide ring

Woven band

Retractor

Seat belt retaining end piece

45±5

Seat belt lower mounting bolt

N·m

45±5

45±5

45±5

45±5

45±5

45±5

: Specified torque

45±5

Page 270 of 281

Downloaded from www.Manualslib.com manuals search engine 263Vehicle Body

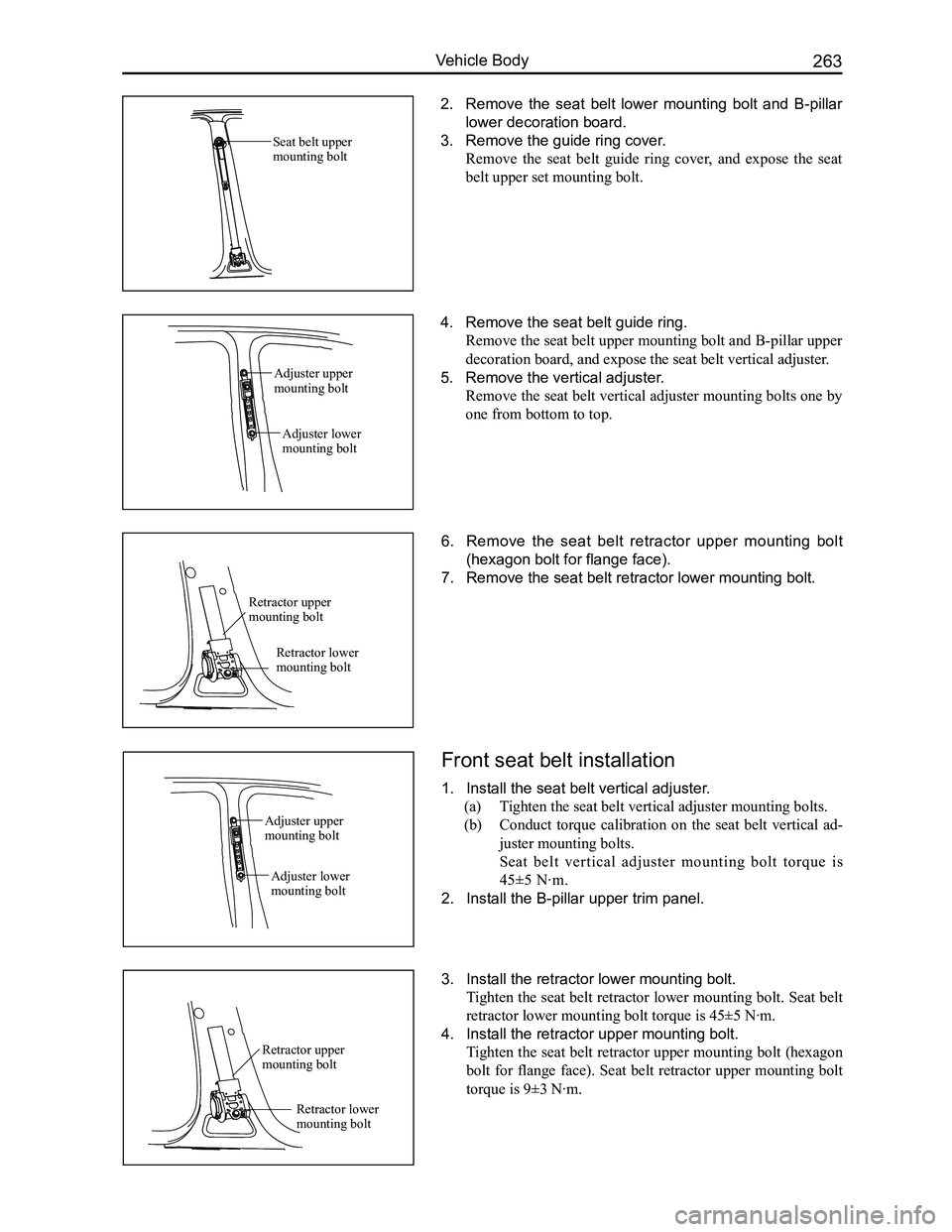

6. Remove the seat belt retractor upper mounting bolt

(hexagon bolt for flange face).

7. Remove the seat belt retractor lower mounting bolt.

Front seat belt installation

1. Install the seat belt vertical adjuster.

(a) Tighten the seat belt vertical adjuster mounting bolts.

(b) Conduct torque calibration on the seat belt vertical ad-

juster mounting bolts.

Seat belt vertical adjuster mounting bolt torque is

45±5 N·m.

2. Install the B-pillar upper trim panel.

3. Install the retractor lower mounting bolt.

Tighten the seat belt retractor lower mounting bolt. Seat belt

retractor lower mounting bolt torque is 45±5 N·m.

4. Install the retractor upper mounting bolt.

Tighten the seat belt retractor upper mounting bolt (hexagon

bolt for flange face). Seat belt retractor upper mounting bolt

torque is 9±3 N·m.

2. Remove the seat belt lower mounting bolt and B-pillar

lower decoration board.

3. Remove the guide ring cover.

Remove the seat belt guide ring cover, and expose the seat

belt upper set mounting bolt.

4. Remove the seat belt guide ring.

Remove the seat belt upper mounting bolt and B-pillar upper

decoration board, and expose the seat belt vertical adjuster.

5. Remove the vertical adjuster.

Remove the seat belt vertical adjuster mounting bolts one by

one from bottom to top.

Retractor upper mounting bolt

Retractor lower mounting bolt

Adjuster upper mounting bolt

Adjuster lower mounting bolt

Retractor upper mounting bolt

Retractor lower mounting bolt

Seat belt upper mounting bolt

Adjuster upper

mounting bolt

Adjuster lower mounting bolt

Page 271 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual264

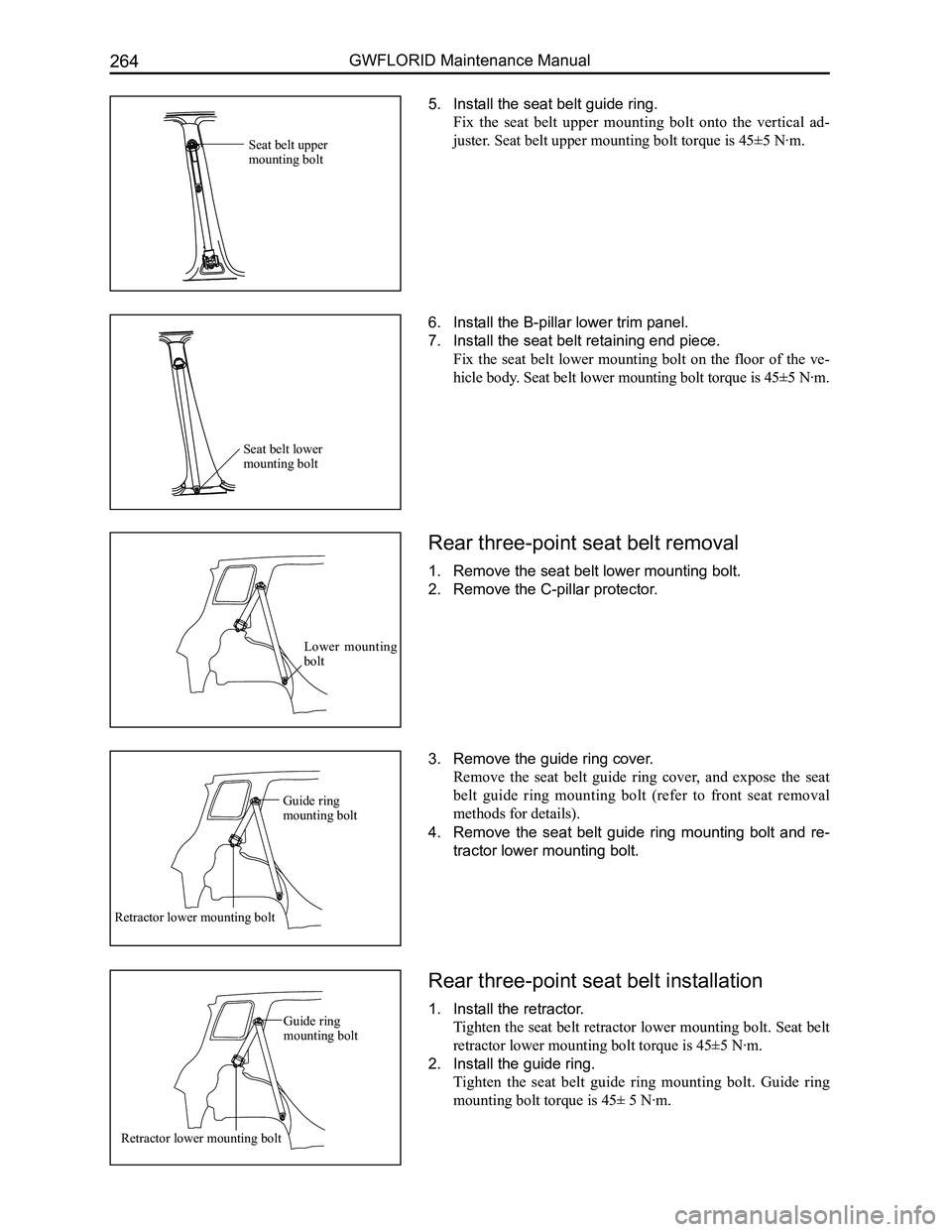

Rear three-point seat belt removal

1. Remove the seat belt lower mounting bolt.

2. Remove the C-pillar protector.

3. Remove the guide ring cover.

Remove the seat belt guide ring cover, and expose the seat

belt guide ring mounting bolt (refer to front seat removal

methods for details).

4. Remove the seat belt guide ring mounting bolt and re-

tractor lower mounting bolt.

Rear three-point seat belt installation

1. Install the retractor.

Tighten the seat belt retractor lower mounting bolt. Seat belt

retractor lower mounting bolt torque is 45±5 N·m.

2. Install the guide ring.

Tighten the seat belt guide ring mounting bolt. Guide ring

mounting bolt torque is 45± 5 N·m.

6. Install the B-pillar lower trim panel.

7. Install the seat belt retaining end piece.

Fix the seat belt lower mounting bolt on the floor of the ve-

hicle body. Seat belt lower mounting bolt torque is 45±5 N·m.

5. Install the seat belt guide ring.

Fix the seat belt upper mounting bolt onto the vertical ad-

juster. Seat belt upper mounting bolt torque is 45±5 N·m.Seat belt upper mounting bolt

Seat belt lower mounting bolt

Lower mounting bolt

Guide ring mounting bolt

Retractor lower mounting bolt

Guide ring mounting bolt

Retractor lower mounting bolt