maintenance GREAT WALL FLORID 2008 Owner's Guide

[x] Cancel search | Manufacturer: GREAT WALL, Model Year: 2008, Model line: FLORID, Model: GREAT WALL FLORID 2008Pages: 281, PDF Size: 43.97 MB

Page 53 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual46

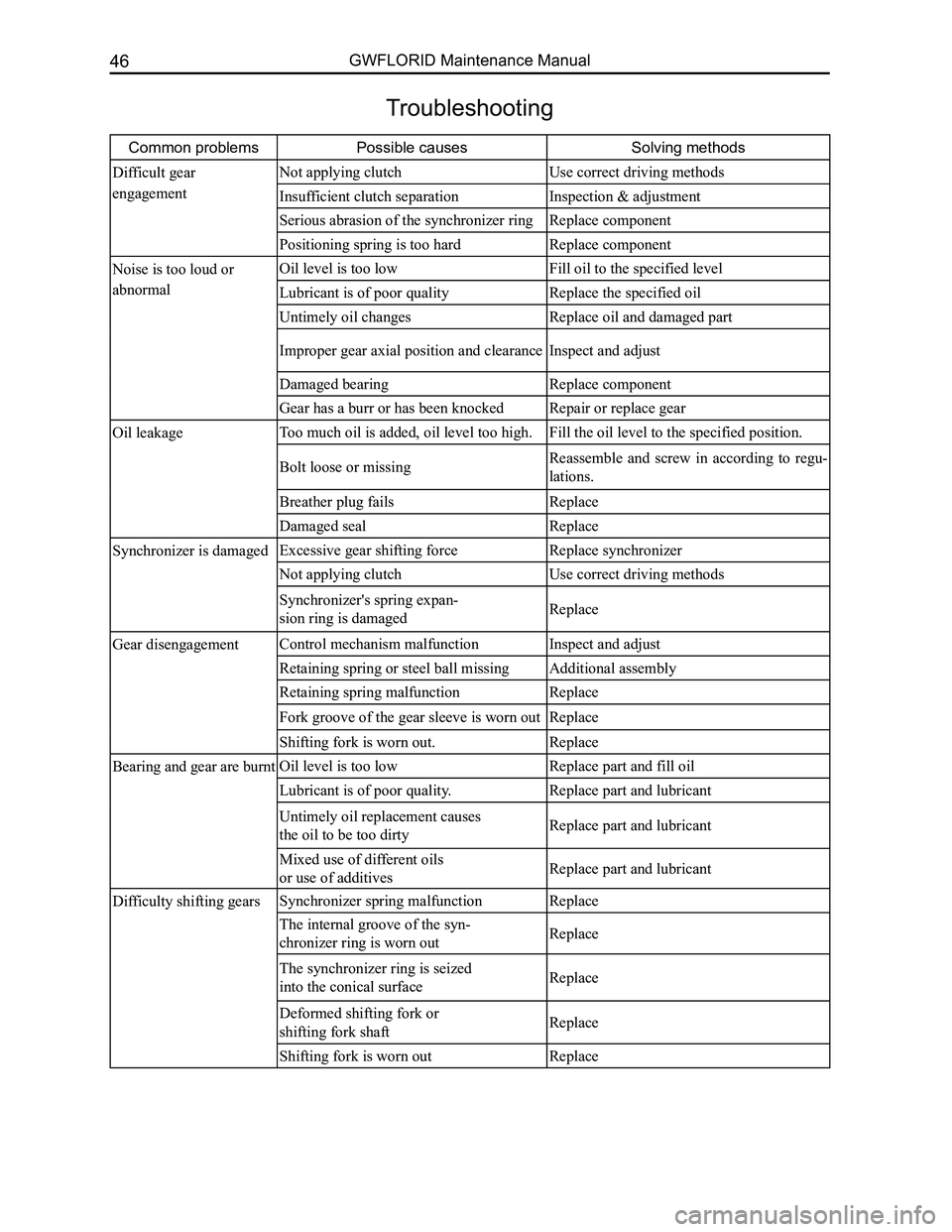

Troubleshooting

Common problemsPossible causesSolving methods

Difficult gear

engagement

Not applying clutchUse correct driving methods

Insufficient clutch separation Inspection & adjustment

Serious abrasion of the synchronizer ringReplace component

Positioning spring is too hardReplace component

Noise is too loud or

abnormal

Oil level is too lowFill oil to the specified level

Lubricant is of poor qualityReplace the specified oil

Untimely oil changesReplace oil and damaged part

Improper gear axial position and clearanceInspect and adjust

Damaged bearingReplace component

Gear has a burr or has been knockedRepair or replace gear

Oil leakageToo much oil is added, oil level too high.Fill the oil level to the specified position.

Bolt loose or missingReassemble and screw in according to regu-

lations.

Breather plug failsReplace

Damaged sealReplace

Synchronizer is damagedExcessive gear shifting force Replace synchronizer

Not applying clutchUse correct driving methods

Synchronizer's spring expan-

sion ring is damagedReplace

Gear disengagementControl mechanism malfunctionInspect and adjust

Retaining spring or steel ball missingAdditional assembly

Retaining spring malfunctionReplace

Fork groove of the gear sleeve is worn outReplace

Shifting fork is worn out.Replace

Bearing and gear are burntOil level is too lowReplace part and fill oil

Lubricant is of poor quality.Replace part and lubricant

Untimely oil replacement causes

the oil to be too dirtyReplace part and lubricant

Mixed use of different oils

or use of additivesReplace part and lubricant

Difficulty shifting gearsSynchronizer spring malfunctionReplace

The internal groove of the syn-

chronizer ring is worn outReplace

The synchronizer ring is seized

into the conical surfaceReplace

Deformed shifting fork or

shifting fork shaftReplace

Shifting fork is worn outReplace

Page 55 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual48

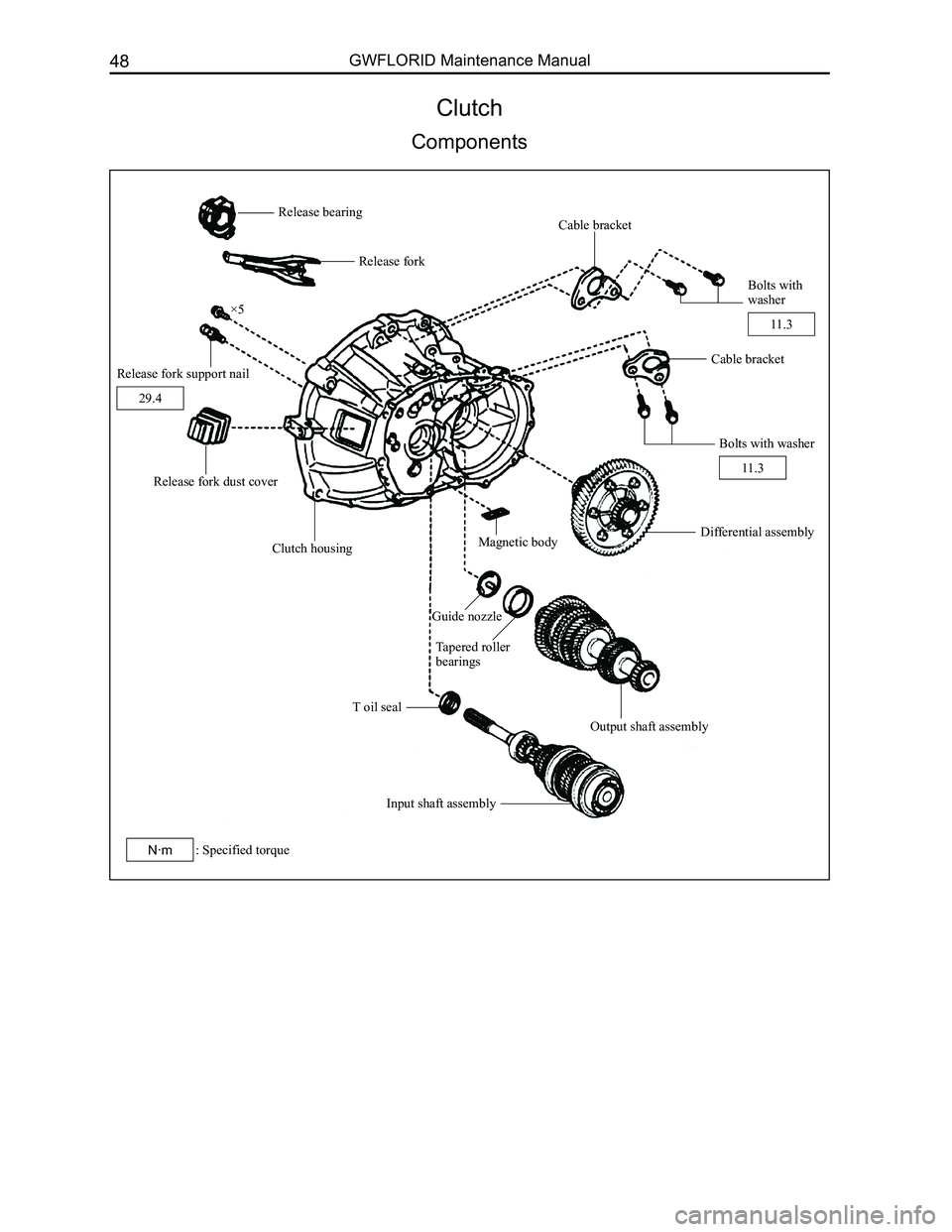

Clutch

Components

Release bearing

Release fork

Cable bracket

Bolts with washer

Bolts with washer

Magnetic bodyDifferential assembly

Output shaft assembly

Input shaft assembly

T oil seal

Tapered roller bearings

Guide nozzle

Clutch housing

Release fork dust cover

Cable bracket

×5

Release fork support nail

29.4

11.3

11.3

: Specified torqueN·m

Page 57 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual50

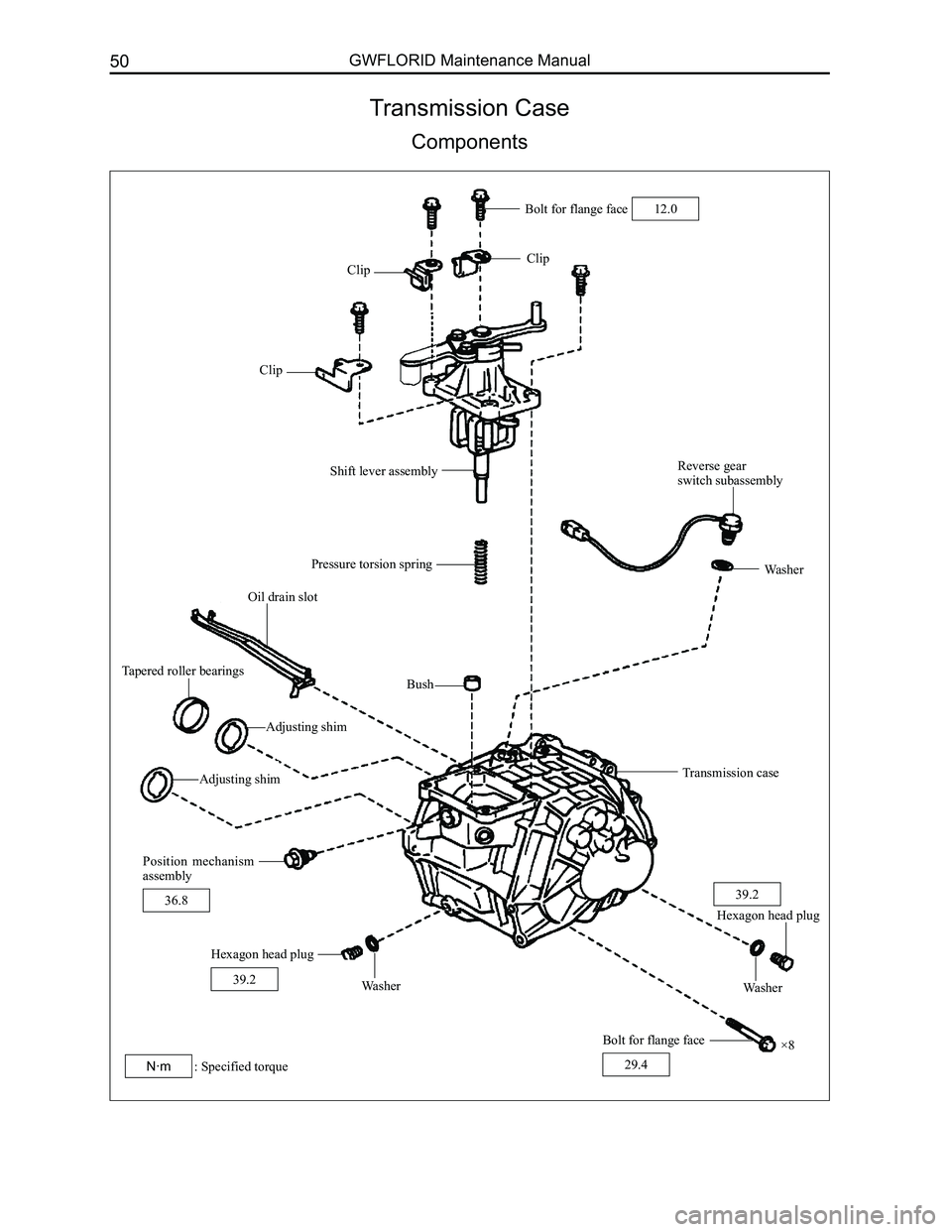

Transmission Case

Components

Clip

Shift lever assembly

Pressure torsion spring

Reverse gear switch subassembly

Washer

Bush

Oil drain slot

Tapered roller bearings

Adjusting shim

Transmission case

Clip

Clip

Adjusting shim

×8

WasherWasher

Hexagon head plug

39.2

Bolt for flange face12.0

: Specified torqueN·m

Hexagon head plug

39.2

Bolt for flange face

29.4

Position mechanism assembly

36.8

Page 59 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual52

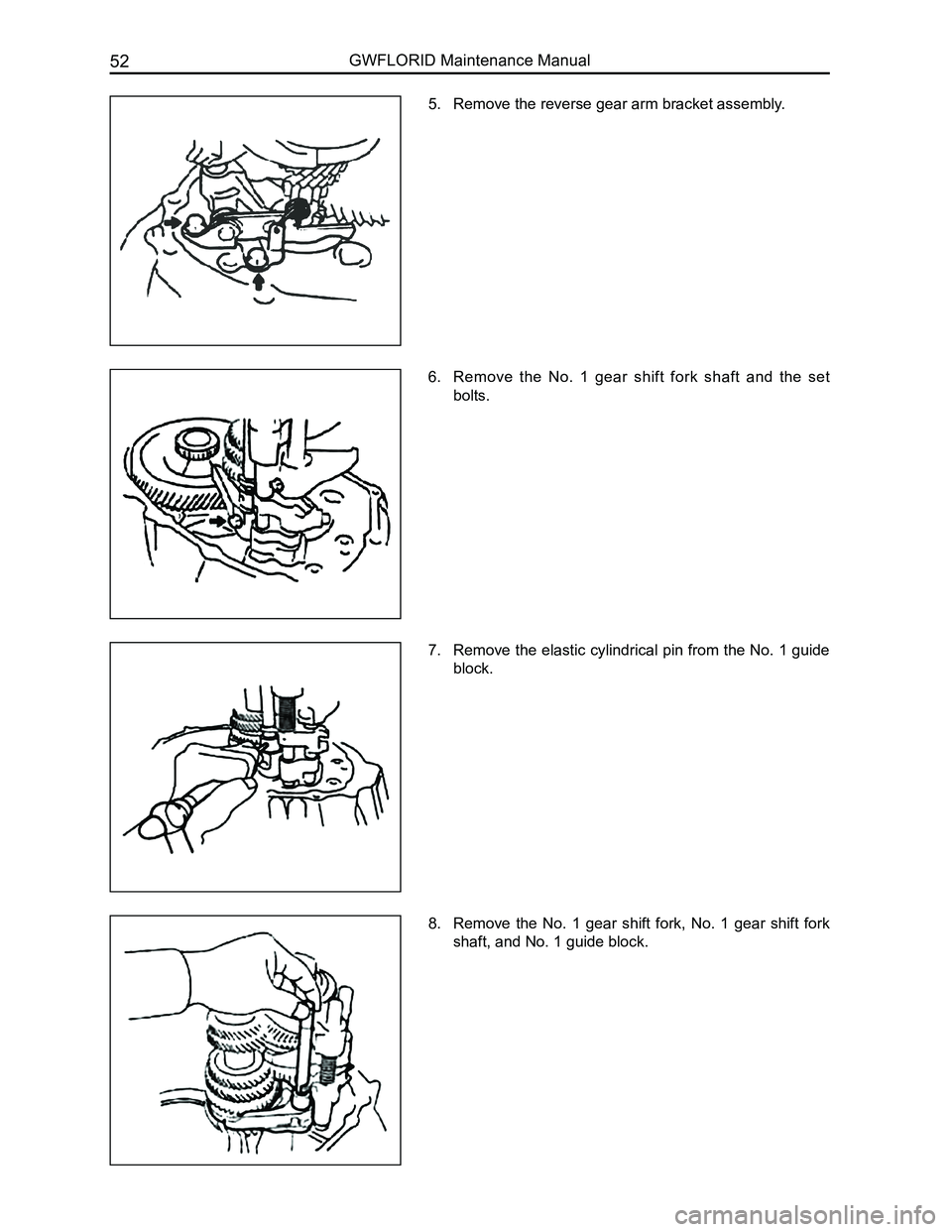

5. Remove the reverse gear arm bracket assembly.

6. Remove the No. 1 gear shift fork shaft and the set

bolts.

7. Remove the elastic cylindrical pin from the No. 1 guide

block.

8. Remove the No. 1 gear shift fork, No. 1 gear shift fork

shaft, and No. 1 guide block.

Page 61 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual54

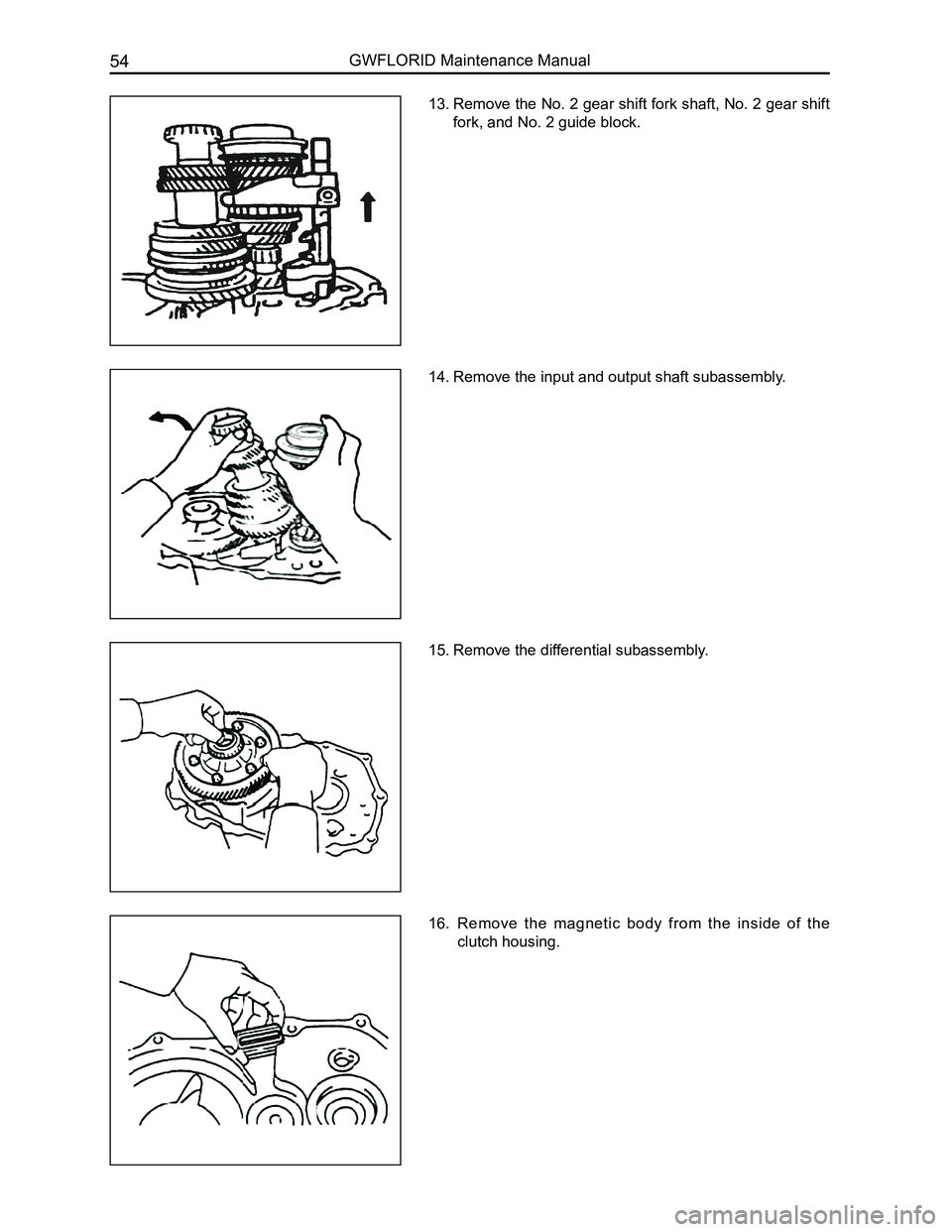

13. Remove the No. 2 gear shift fork shaft, No. 2 gear shift

fork, and No. 2 guide block.

14. Remove the input and output shaft subassembly.

15. Remove the differential subassembly.

16. Remove the magnetic body from the inside of the

clutch housing.

Page 63 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual56

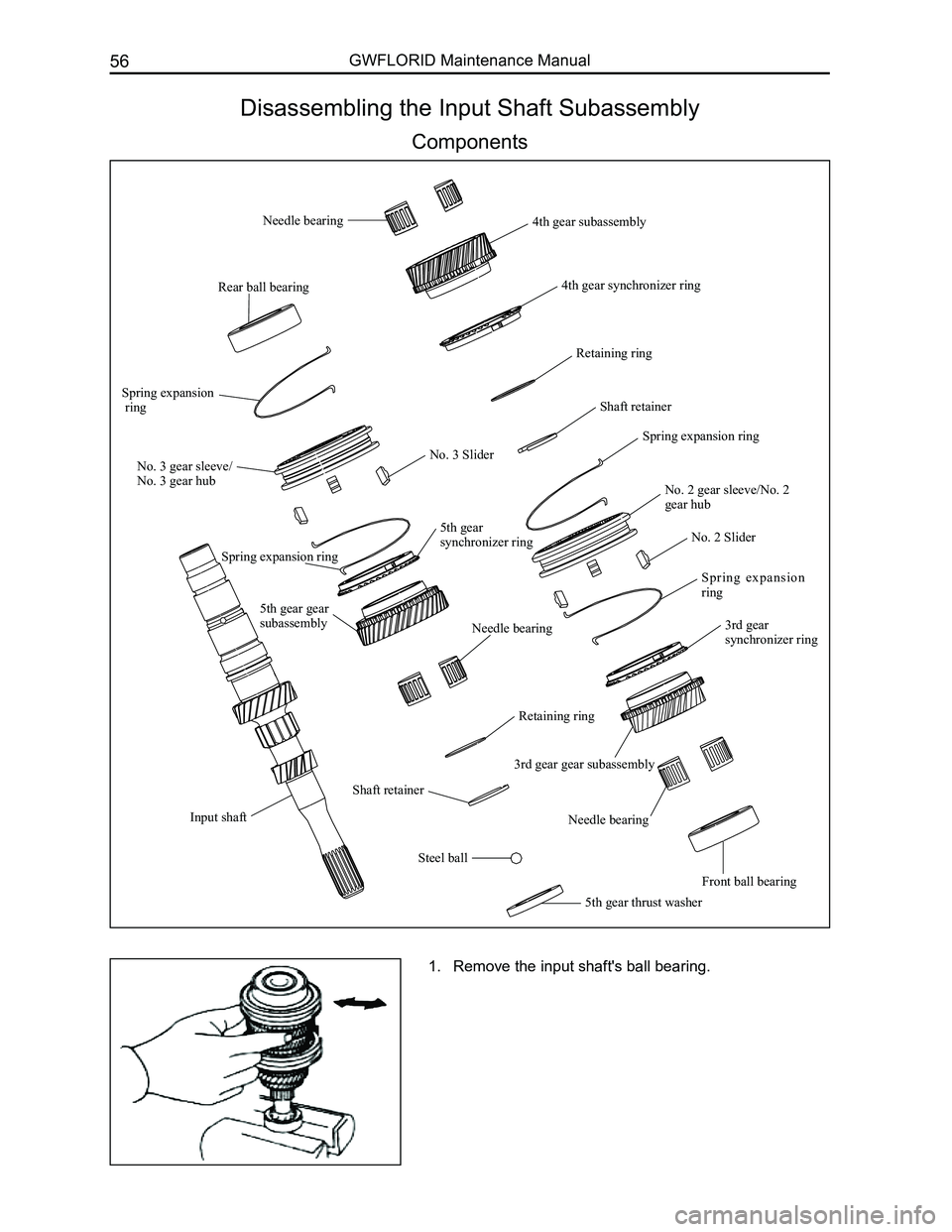

Disassembling the Input Shaft Subassembly

Components

Input shaft

Rear ball bearing

No. 3 gear sleeve/

No. 3 gear hub

No. 3 Slider

Spring expansion ring

5th gear synchronizer ring

5th gear gear subassemblyNeedle bearing

Retaining ring

Shaft retainer

Steel ball

5th gear thrust washer

Needle bearing4th gear subassembly

4th gear synchronizer ring

Retaining ring

Shaft retainer

No. 2 gear sleeve/No. 2 gear hub

No. 2 Slider

Spring expansion ring

3rd gear synchronizer ring

Needle bearing

Front ball bearing

3rd gear gear subassembly

Spring expansion ring

Spring expansion ring

1. Remove the input shaft's ball bearing.

Page 65 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual58

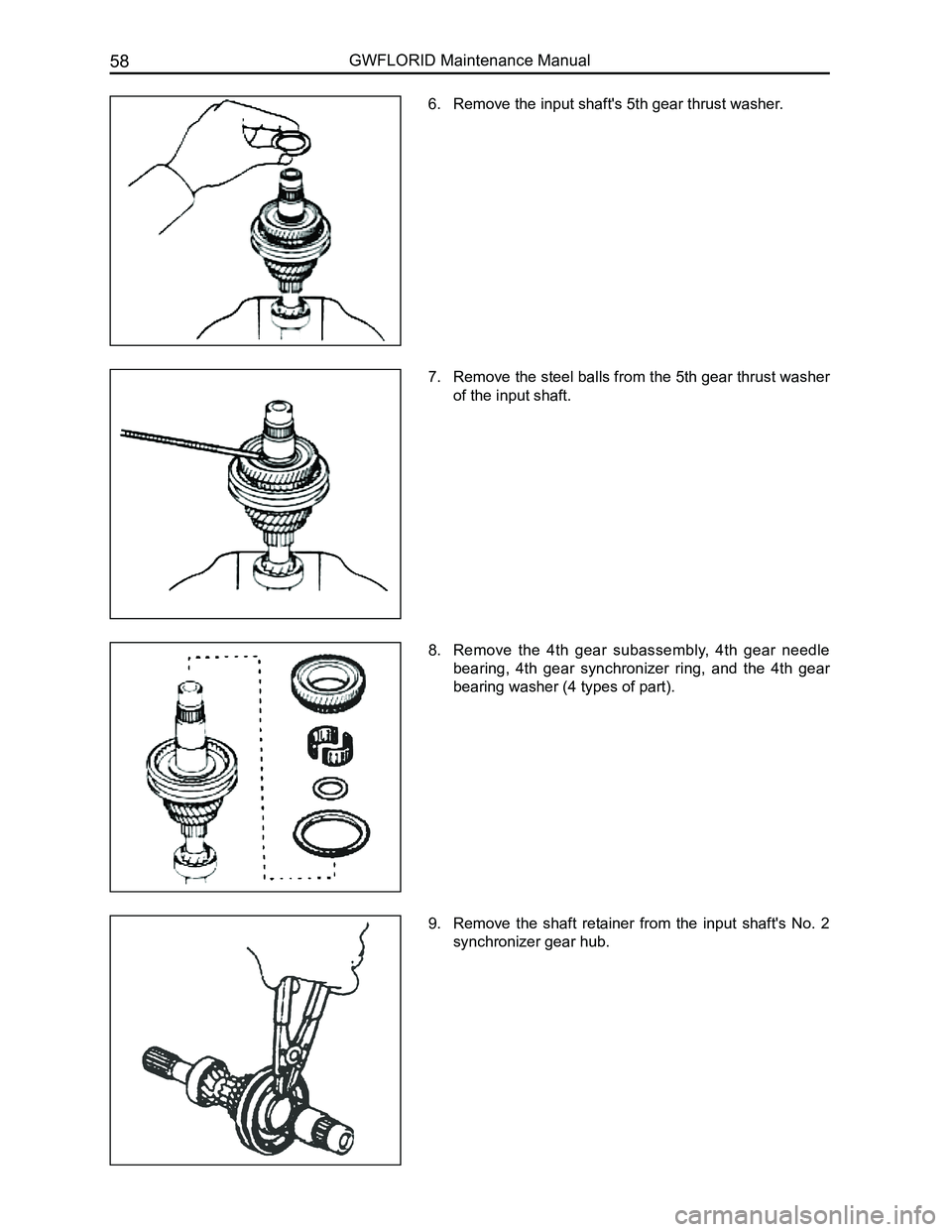

6. Remove the input shaft's 5th gear thrust washer.

7. Remove the steel balls from the 5th gear thrust washer

of the input shaft.

8. Remove the 4th gear subassembly, 4th gear needle

bearing, 4th gear synchronizer ring, and the 4th gear

bearing washer (4 types of part).

9. Remove the shaft retainer from the input shaft's No. 2

synchronizer gear hub.

Page 67 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual60

Disassembling the Output Shaft Subassembly

Components

Front tapered roller bearing

Output shaft

Needle bearing

1st gear gear subassembly

1st gear synchronizer ring

No. 1 gear sleeve/No. 1 gear hub

No. 1 Slider

Spring expansion ring

Shaft retainer

Retaining ring

Needle bearing

2nd gear synchronizer ring

2nd gear gear subassembly

3rd driven gear

Spacer

4th driven gear

5th driven gear

Shaft retainer

Rear tapered roller bearing

1. Remove the output shaft's rear tapered roller bearing.

Page 69 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual62

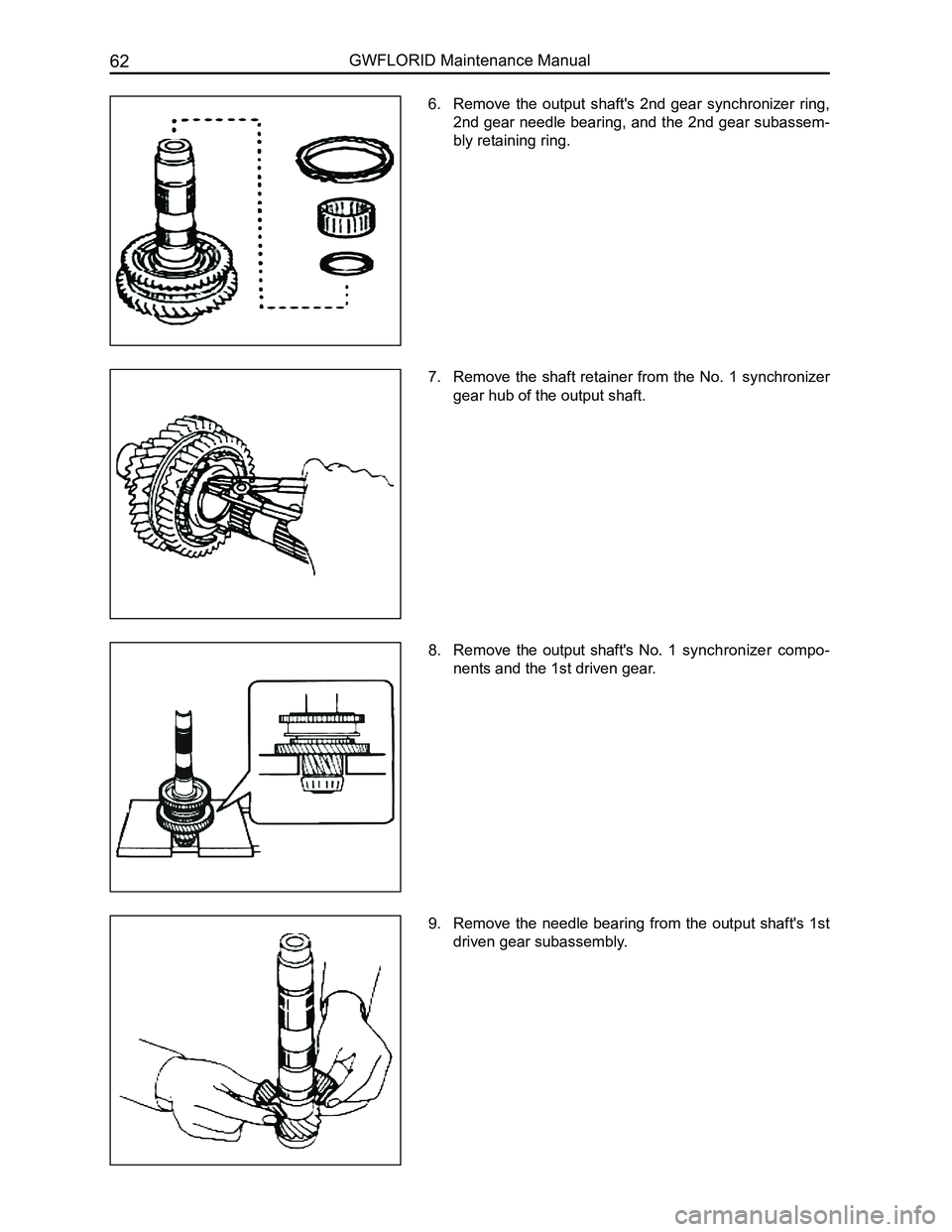

6. Remove the output shaft's 2nd gear synchronizer ring,

2nd gear needle bearing, and the 2nd gear subassem-

bly retaining ring.

7. Remove the shaft retainer from the No. 1 synchronizer

gear hub of the output shaft.

8. Remove the output shaft's No. 1 synchronizer compo-

nents and the 1st driven gear.

9. Remove the needle bearing from the output shaft's 1st

driven gear subassembly.

Page 71 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual64

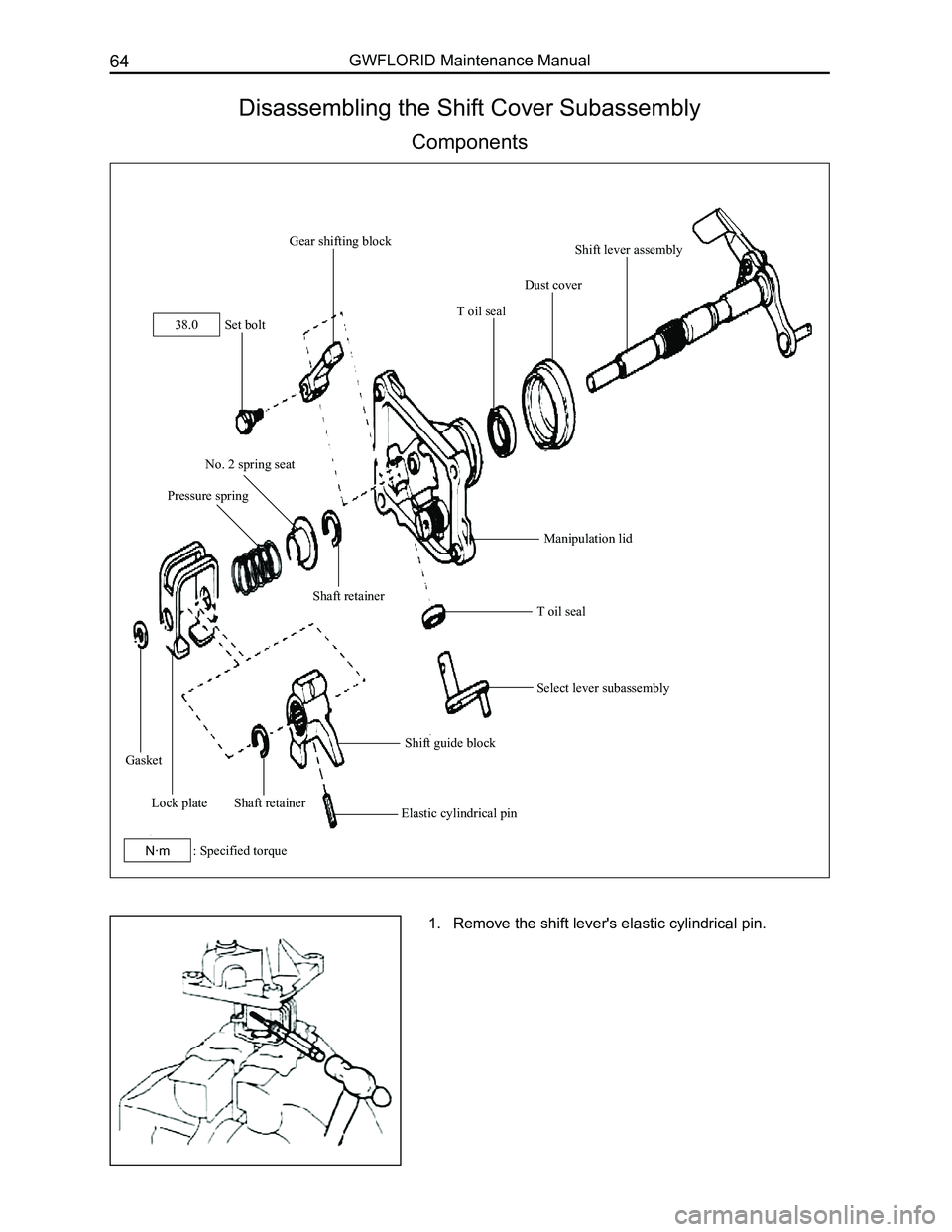

Disassembling the Shift Cover Subassembly

Components

Shift lever assembly

Dust cover

T oil seal

Gear shifting block

No. 2 spring seat

Pressure spring

Shaft retainer

Gasket

Lock plateShaft retainerElastic cylindrical pin

Shift guide block

Select lever subassembly

Manipulation lid

T oil seal

1. Remove the shift lever's elastic cylindrical pin.

Set bolt38.0

: Specified torqueN·m