lock GREAT WALL FLORID 2008 Manual PDF

[x] Cancel search | Manufacturer: GREAT WALL, Model Year: 2008, Model line: FLORID, Model: GREAT WALL FLORID 2008Pages: 281, PDF Size: 43.97 MB

Page 194 of 281

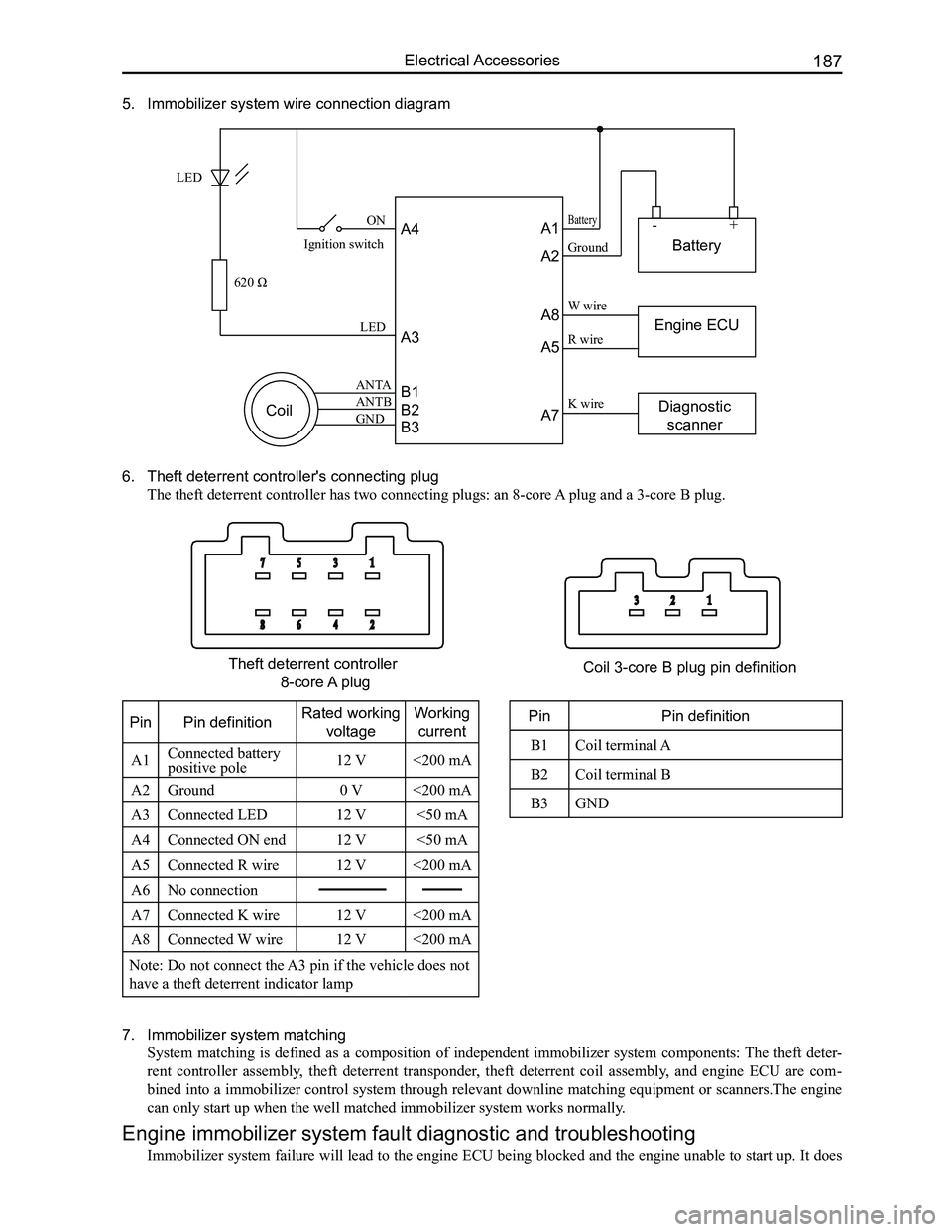

Downloaded from www.Manualslib.com manuals search engine 187Electrical Accessories

Diagnostic

scanner

Engine ECU

Battery

+-

Ignition switch

LED

620 Ω

LED

ON

ANTA

GND

ANTB

Battery

Ground

W wire

R wire

K wire

A4

A3

A1

A2

A8

A5

A7B3

B2

B1

Coil

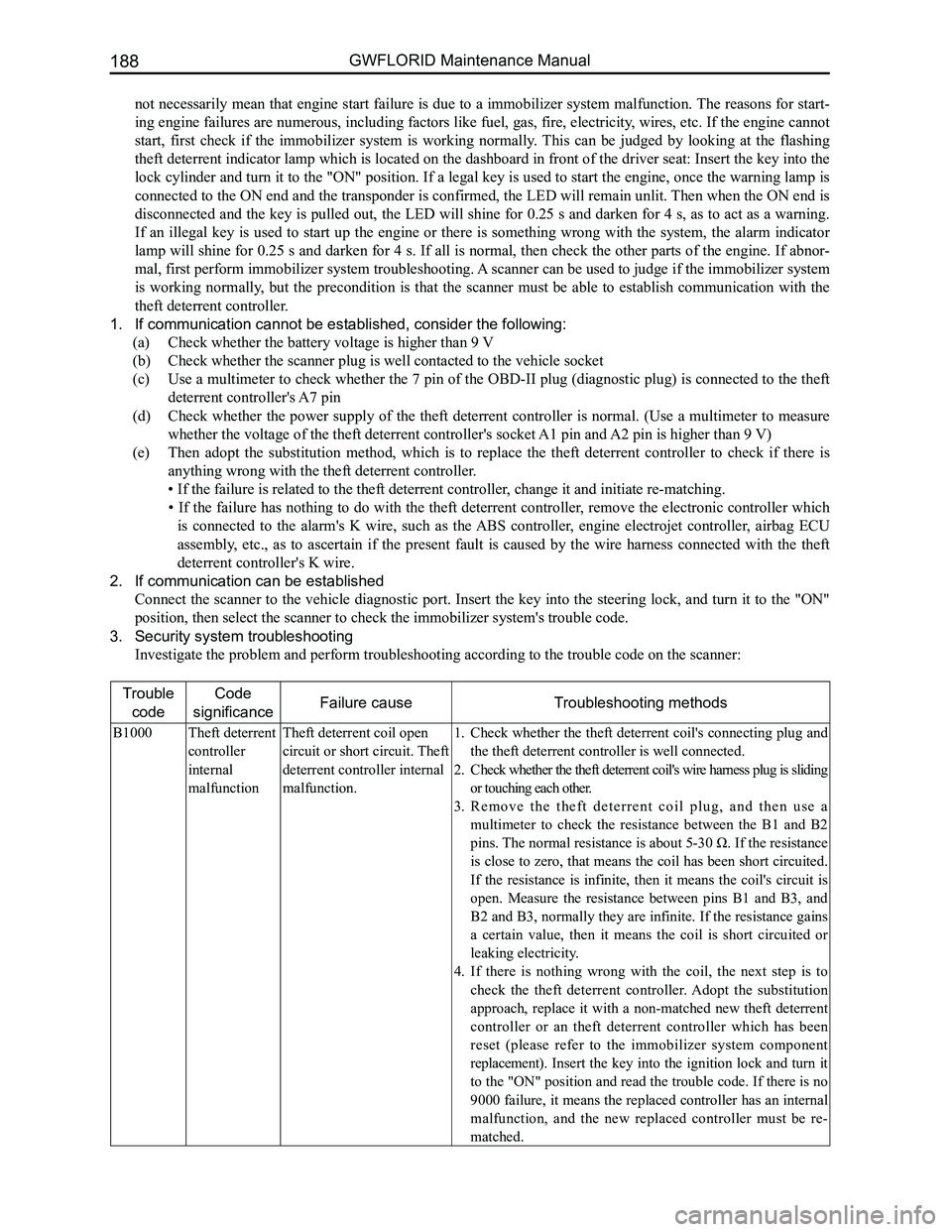

6. Theft deterrent controller's connecting plug

The theft deterrent controller has two connecting plugs: an 8-core A plug and a 3-core B plug.

PinPin definition

B1Coil terminal A

B2Coil terminal B

B3GND

Theft deterrent controller

8-core A plug

Coil 3-core B plug pin definition

7. Immobilizer system matching

System matching is defined as a composition of independent immobilizer system components: The theft deter-

rent controller assembly, theft deterrent transponder, theft deterrent coil assembly, and engine ECU are com-

bined into a immobilizer control system through relevant downline matching equipment or scanners.The engine

can only start up when the well matched immobilizer system works normall\

y.

Engine immobilizer system fault diagnostic and troubleshooting

Immobilizer system failure will lead to the engine ECU being blocked and the engine unable to start up. It does

PinPin definitionRated working

voltage

Working

current

A1Connected battery positive pole12 V<200 mA

A2Ground0 V<200 mA

A3Connected LED12 V<50 mA

A4Connected ON end12 V<50 mA

A5Connected R wire12 V<200 mA

A6No connection

A7Connected K wire12 V<200 mA

A8Connected W wire12 V<200 mA

Note: Do not connect the A3 pin if the vehicle does not

have a theft deterrent indicator lamp

5. Immobilizer system wire connection diagram

Page 195 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual188

not necessarily mean that engine start failure is due to a immobilizer system malfunction. The reasons for start-

ing engine failures are numerous, including factors like fuel, gas, fire, electricity, wires, etc. If the engine cannot

start, first check if the immobilizer system is working normally. This can be judged by looking at the flashing

theft deterrent indicator lamp which is located on the dashboard in front of the driver seat: Insert the key into the

lock cylinder and turn it to the "ON" position. If a legal key is used to start the engine, once the warning lamp is

connected to the ON end and the transponder is confirmed, the LED will remain unlit. Then when the ON end is

disconnected and the key is pulled out, the LED will shine for 0.25 s and darken for 4 s, as to act as a warning.

If an illegal key is used to start up the engine or there is something wrong with the system, the alarm indicator

lamp will shine for 0.25 s and darken for 4 s. If all is normal, then check the other parts of the engine. If abnor-

mal, first perform immobilizer system troubleshooting. A scanner can be used to judge if the immobilizer system

is working normally, but the precondition is that the scanner must be able to establish communication with the

theft deterrent controller.

1. If communication cannot be established, consider the following:

(a) Check whether the battery voltage is higher than 9 V

(b) Check whether the scanner plug is well contacted to the vehicle socket

(c) Use a multimeter to check whether the 7 pin of the OBD-II plug (diagnostic plug) is connected to the theft

deterrent controller's A7 pin

(d) Check whether the power supply of the theft deterrent controller is normal. (Use a multimeter to measure

whether the voltage of the theft deterrent controller's socket A1 pin and A2 pin is higher than 9 V)

(e) Then adopt the substitution method, which is to replace the theft deterrent controller to check if there is

anything wrong with the theft deterrent controller.

• If the failure is related to the theft deterrent controller, change it and initiate re-matching.

• If the failure has nothing to do with the theft deterrent controller, remove the electronic controller which

is connected to the alarm's K wire, such as the ABS controller, engine electrojet controller, airbag ECU

assembly, etc., as to ascertain if the present fault is caused by the wire harness connected with the theft

deterrent controller's K wire.

2. If communication can be established

Connect the scanner to the vehicle diagnostic port. Insert the key into the steering lock, and turn it to the "ON"

position, then select the scanner to check the immobilizer system's trou\

ble code.

3. Security system troubleshooting

Investigate the problem and perform troubleshooting according to the tro\

uble code on the scanner:

Trouble

code

Code

significanceFailure causeTroubleshooting methods

B1000Theft deterrent

controller

internal

malfunction

Theft deterrent coil open

circuit or short circuit. Theft

deterrent controller internal

malfunction.

Check whether the theft deterrent coil's connecting plug and 1.

the theft deterrent controller is well connected.

Check whether the theft deterrent coil's wire harness plug is sliding 2.

or touching each other.

R e m o v e t h e t h e f t d e t e r r e n t c o i l p l u g , a n d t h e n u s e a 3.

multimeter to check the resistance between the B1 and B2

pins. The normal resistance is about 5-30 Ω. If the resistance

is close to zero, that means the coil has been short circuited.

If the resistance is infinite, then it means the coil's circuit is

open. Measure the resistance between pins B1 and B3, and

B2 and B3, normally they are infinite. If the resistance gains

a certain value, then it means the coil is short circuited or

leaking electricity.

If there is nothing wrong with the coil, the next step is to 4.

check the theft deterrent controller. Adopt the substitution

approach, replace it with a non-matched new theft deterrent

controller or an theft deterrent controller which has been

reset (please refer to the immobilizer system component

replacement). Insert the key into the ignition lock and turn it

to the "ON" position and read the trouble code. If there is no

9000 failure, it means the replaced controller has an internal

malfunction, and the new replaced controller must be re-

matched.

Page 198 of 281

Downloaded from www.Manualslib.com manuals search engine 191Electrical Accessories

4. Security system component replacement

When a failure appears in one of the immobilizer system components, this component must be replaced. After

the replacement, perform matching on the immobilizer system again.

Only changing the coil

There is no need to match the immobilizer system again.

Only changing the key (theft deterrent transponder assembly)

(a) Get the vehicle's PIN code from the code located inside the burglar-proof classified envelope

(b) Connect the scanner with the vehicle's diagnostic connection

(c) Insert the key into the ignition lock and turn it to the "ON" position

(d) Check whether the key is legal and matched. If it is illegal or already been matched, then it cannot be

matched again, but will have to be replaced

(e) Input the PIN code with the scanner

(f) Erase the damaged lost key's information

(g) Match the new key according to the scanner's prompt

(h) If it is necessary to match another key, insert the key, and after resetting the scanner, operate according to

steps c, d, e, and g.

Caution: Make sure the key is legal and hasn't been matched before learning the key. Otherwise, the

immobilizer system won’t successfully match or the scanner will display that it has been matched but

the electrojet's validation is not available.

Only replacing the theft deterrent controller assembly

(a) Get the vehicle's PIN code from the code inside the burglar-proof classified envelope

(b) Turn off the ignition switch, and replace with an unmatched new theft deterrent controller or reset the theft

deterrent controller

(c) Insert the key into the ignition lock and turn it to the ON position

(d) Input the PIN code with the scanner

(e) Match the theft deterrent controller assembly according to the scanner prompts

(f) Because the theft deterrent controller is new, there is no VIN and original key information stored in it. It

will need the VIN inputted and must be matched with the original key, otherwise the original key will not

work.

Caution:

(a) Replace the new alarm remote controller or reset the alarm remote controller, or the alarm re-

mote controller system matching can not be completed.

(b) Select "Read EMS to alarm remote controller", not "Read alarm remote controller to EMS", or it

will make the transponder inoperable.

Only replacing the engine ECU

(a) Get the vehicle's PIN code from the code inside the burglar-proof classified envelope

(b) Turn off the ignition switch, and replace with a new non-matched or reset ECU

(c) Insert the key into the ignition lock and turn it to the ON position

(d) Input the PIN code with the scanner

(e) Match the ECU according to the prompts on the scanner, and complete the ECU and theft deterrent

controller matching.

Caution:

(a) Make sure to replace it with a new or reset ECU, otherwise the immobilizer system matching can-

not be completed.

(b) Select the menu of "Read EMS to theft deterrent controller", but not "Read theft deterrent control-

ler to EMS", or it will make the transponder inoperable.

Replacing the theft deterrent controller and EMS controller at the same\

time

If both the theft deterrent controller and EMS controller need to be changed at the same time, then the transpon-

der that has been matched must also be replaced, otherwise the immobilizer system matching cannot be com-

pleted. The immobilizer system needs to be re-matched after being replace.

Matching after sales stage

Problems caused by lost keys or immobilizer system failures requires a duplicate key, replaced parts, etc. These

problems cannot be solved without re-matching the immobilizer system's parts. During the matching, input the

correct PIN code with scanner. Specific possible problems and matching methods the maintenance station may

encounter are as follows:

1. Match an empty key:

(a) Properly connect the engine ECU and the theft deterrent controller, and then insert the key to be matched,

and switch the ignition switch to the ON position

Page 205 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual198

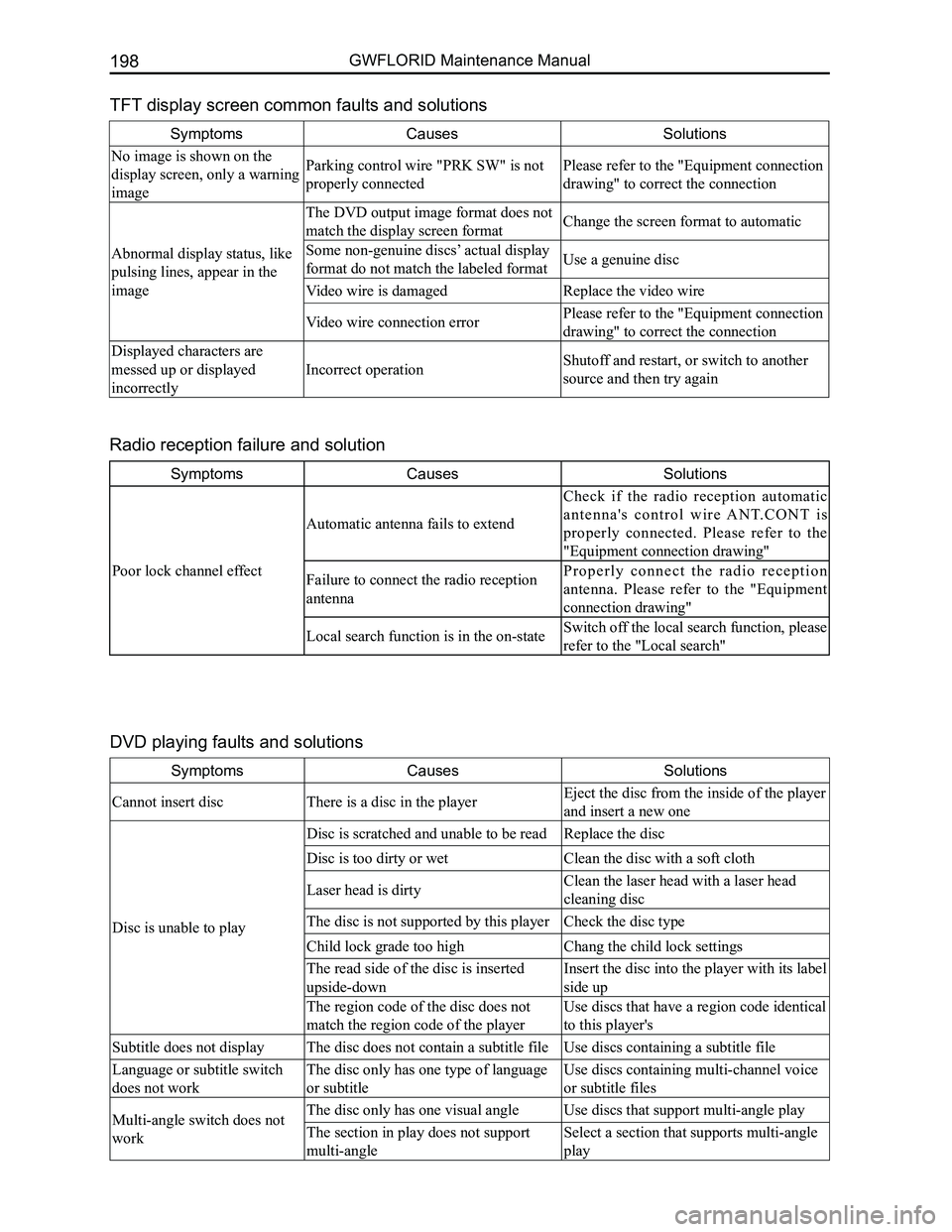

TFT display screen common faults and solutions

SymptomsCausesSolutions

No image is shown on the

display screen, only a warning

image

Parking control wire "PRK SW" is not

properly connected

Please refer to the "Equipment connection

drawing" to correct the connection

Abnormal display status, like

pulsing lines, appear in the

image

The DVD output image format does not

match the display screen formatChange the screen format to automatic

Some non-genuine discs’ actual display

format do not match the labeled formatUse a genuine disc

Video wire is damaged Replace the video wire

Video wire connection error Please refer to the "Equipment connection

drawing" to correct the connection

Displayed characters are

messed up or displayed

incorrectly

Incorrect operation Shutoff and restart, or switch to another

source and then try again

SymptomsCausesSolutions

Poor lock channel effect

Automatic antenna fails to extend

Check if the radio reception automatic

a n t e n n a ' s c o n t r o l w i r e A N T. C O N T i s

properly connected. Please refer to the

"Equipment connection drawing"

Failure to connect the radio reception

antenna

P r o p e r l y c o n n e c t t h e r a d i o r e c e p t i o n

antenna. Please refer to the "Equipment

connection drawing"

Local search function is in the on-state Switch off the local search function, please

refer to the "Local search"

Radio reception failure and solution

DVD playing faults and solutions

SymptomsCausesSolutions

Cannot insert discThere is a disc in the playerEject the disc from the inside of the player

and insert a new one

Disc is unable to play

Disc is scratched and unable to be readReplace the disc

Disc is too dirty or wetClean the disc with a soft cloth

Laser head is dirtyClean the laser head with a laser head

cleaning disc

The disc is not supported by this playerCheck the disc type

Child lock grade too highChang the child lock settings

The read side of the disc is inserted

upside-down

Insert the disc into the player with its label

side up

The region code of the disc does not

match the region code of the player

Use discs that have a region code identical

to this player's

Subtitle does not displayThe disc does not contain a subtitle fileUse discs containing a subtitle file

Language or subtitle switch

does not work

The disc only has one type of language

or subtitle

Use discs containing multi-channel voice

or subtitle files

Multi-angle switch does not

work

The disc only has one visual angleUse discs that support multi-angle play

The section in play does not support

multi-angle

Select a section that supports multi-angle

play

Page 210 of 281

Downloaded from www.Manualslib.com manuals search engine 203Air Conditioning System

Areas of Importance

1. When putting in a new compressor, adjust the new compressor's inner lubricant to make it the same

level as of the old compressor's.

2. When the air conditioner malfunctions, if the pipeline, condenser or evaporator is the source of the

damage leading to its replacement, just add model number RS20 profession\

al lubricant 5-10 ml.

3. The compressor is a high speed operating component, the smallest impurity in the air conditioning

system can lead to the compressor's damage, therefore the entire air conditioning system must be

cleaned.

4. In order to avoid liquid damage to the compressor, pay careful attention when filling the refrigerant.

When the vehicle stopped, fill the liquid refrigerant from the high pressure side. When in operation, fill

the liquid refrigerant from the low pressure side.

5. When undergoing maintenance, pay attention that the amount of refrigerant being added is 510±10 g.

Observe through the check glass to determine if there is sufficient new refrigerant charge.

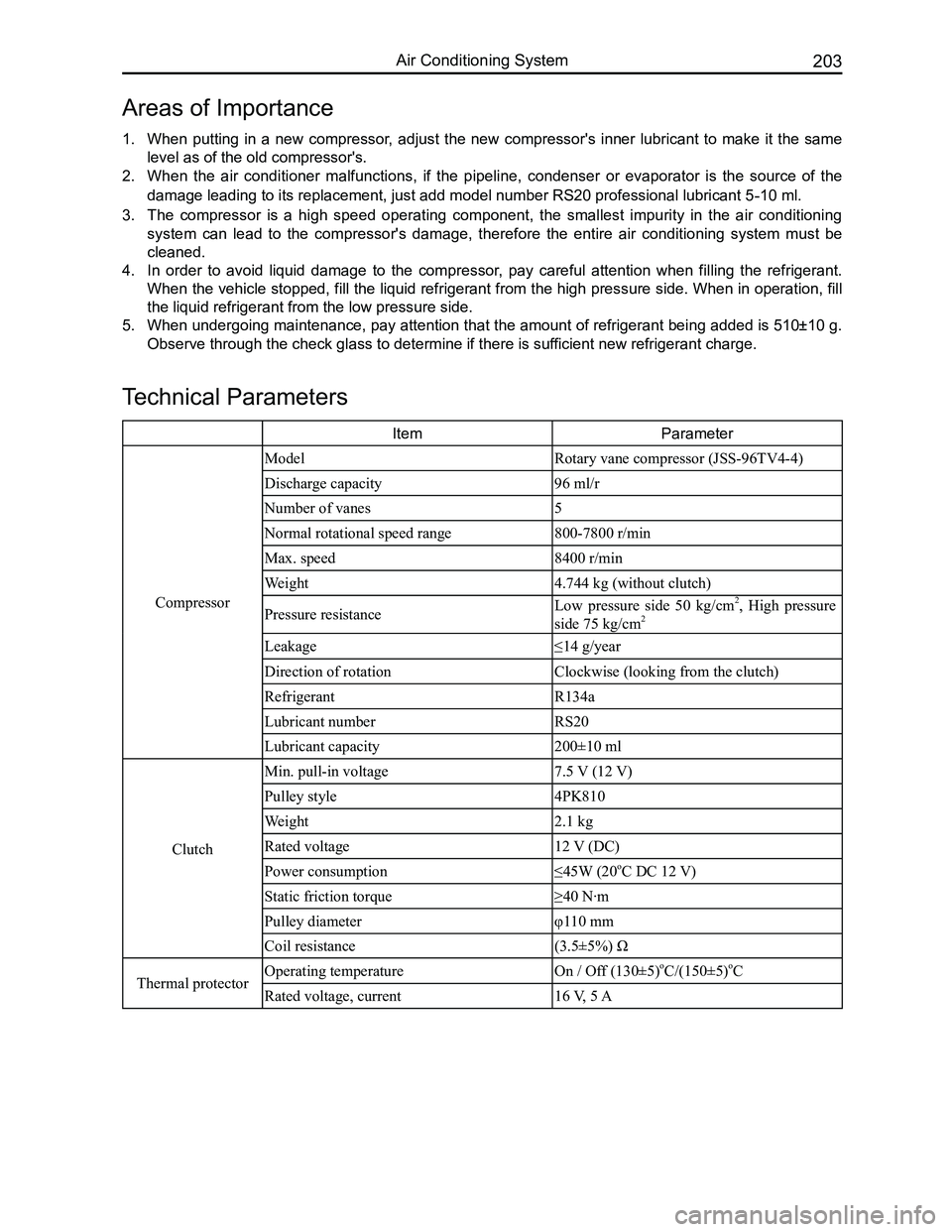

ItemParameter

Compressor

ModelRotary vane compressor (JSS-96TV4-4)

Discharge capacity96 ml/r

Number of vanes5

Normal rotational speed range800-7800 r/min

Max. speed8400 r/min

Weight4.744 kg (without clutch)

Pressure resistanceLow pressure side 50 kg/cm2, High pressure

side 75 kg/cm2

Leakage≤14 g/year

Direction of rotationClockwise (looking from the clutch)

RefrigerantR134a

Lubricant numberRS20

Lubricant capacity 200±10 ml

Clutch

Min. pull-in voltage7.5 V (12 V)

Pulley style 4PK810

Weight2.1 kg

Rated voltage12 V (DC)

Power consumption≤45W (20oC DC 12 V)

Static friction torque≥40 N·m

Pulley diameterφ110 mm

Coil resistance(3.5±5%) Ω

Thermal protectorOperating temperatureOn / Off (130±5)oC/(150±5)oC

Rated voltage, current16 V, 5 A

Technical Parameters

Page 211 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual204

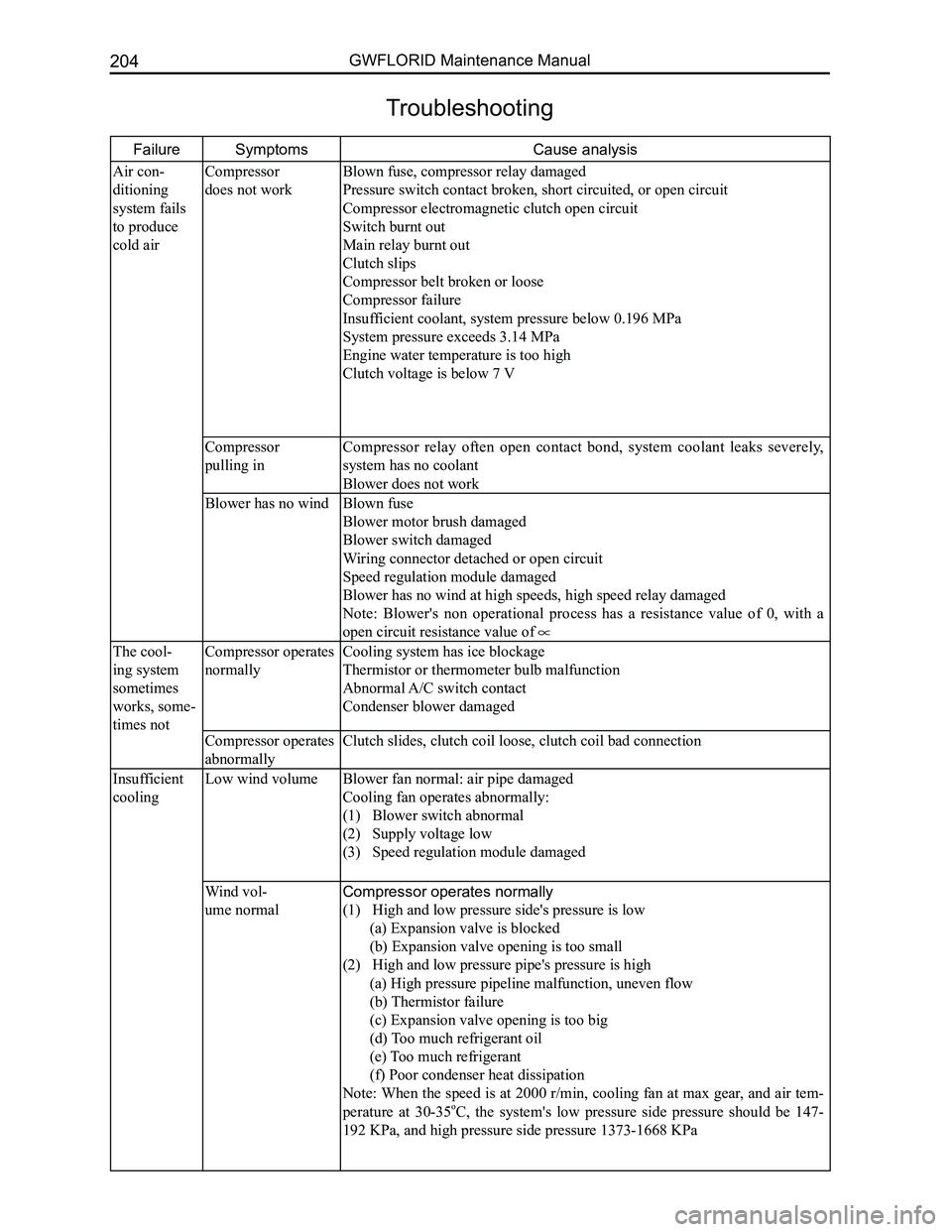

FailureSymptoms Cause analysis

Air con-

ditioning

system fails

to produce

cold air

Compressor

does not work

Blown fuse, compressor relay damaged

Pressure switch contact broken, short circuited, or open circuit

Compressor electromagnetic clutch open circuit

Switch burnt out

Main relay burnt out

Clutch slips

Compressor belt broken or loose

Compressor failure

Insufficient coolant, system pressure below 0.196 MPa

System pressure exceeds 3.14 MPa

Engine water temperature is too high

Clutch voltage is below 7 V

Compressor

pulling in

Compressor relay often open contact bond, system coolant leaks severely,

system has no coolant

Blower does not work

Blower has no windBlown fuse

Blower motor brush damaged

Blower switch damaged

Wiring connector detached or open circuit

Speed regulation module damaged

Blower has no wind at high speeds, high speed relay damaged

Note: Blower's non operational process has a resistance value of 0, with a

open circuit resistance value of

The cool-

ing system

sometimes

works, some-

times not

Compressor operates

normally

Cooling system has ice blockage

Thermistor or thermometer bulb malfunction

Abnormal A/C switch contact

Condenser blower damaged

Compressor operates

abnormally

Clutch slides, clutch coil loose, clutch coil bad connection

Insufficient

cooling

Low wind volume

Blower fan normal: air pipe damaged

Cooling fan operates abnormally:

(1) Blower switch abnormal

(2) Supply voltage low

(3) Speed regulation module damaged

Wind vol-

ume normal

Compressor operates normally

(1) High and low pressure side's pressure is low

(a) Expansion valve is blocked

(b) Expansion valve opening is too small

(2) High and low pressure pipe's pressure is high

(a) High pressure pipeline malfunction, uneven flow

(b) Thermistor failure

(c) Expansion valve opening is too big

(d) Too much refrigerant oil

(e) Too much refrigerant

(f) Poor condenser heat dissipation

Note: When the speed is at 2000 r/min, cooling fan at max gear, and air tem-

perature at 30-35oC, the system's low pressure side pressure should be 147-

192 KPa, and high pressure side pressure 1373-1668 KPa

Troubleshooting

Page 212 of 281

Downloaded from www.Manualslib.com manuals search engine 205Air Conditioning System

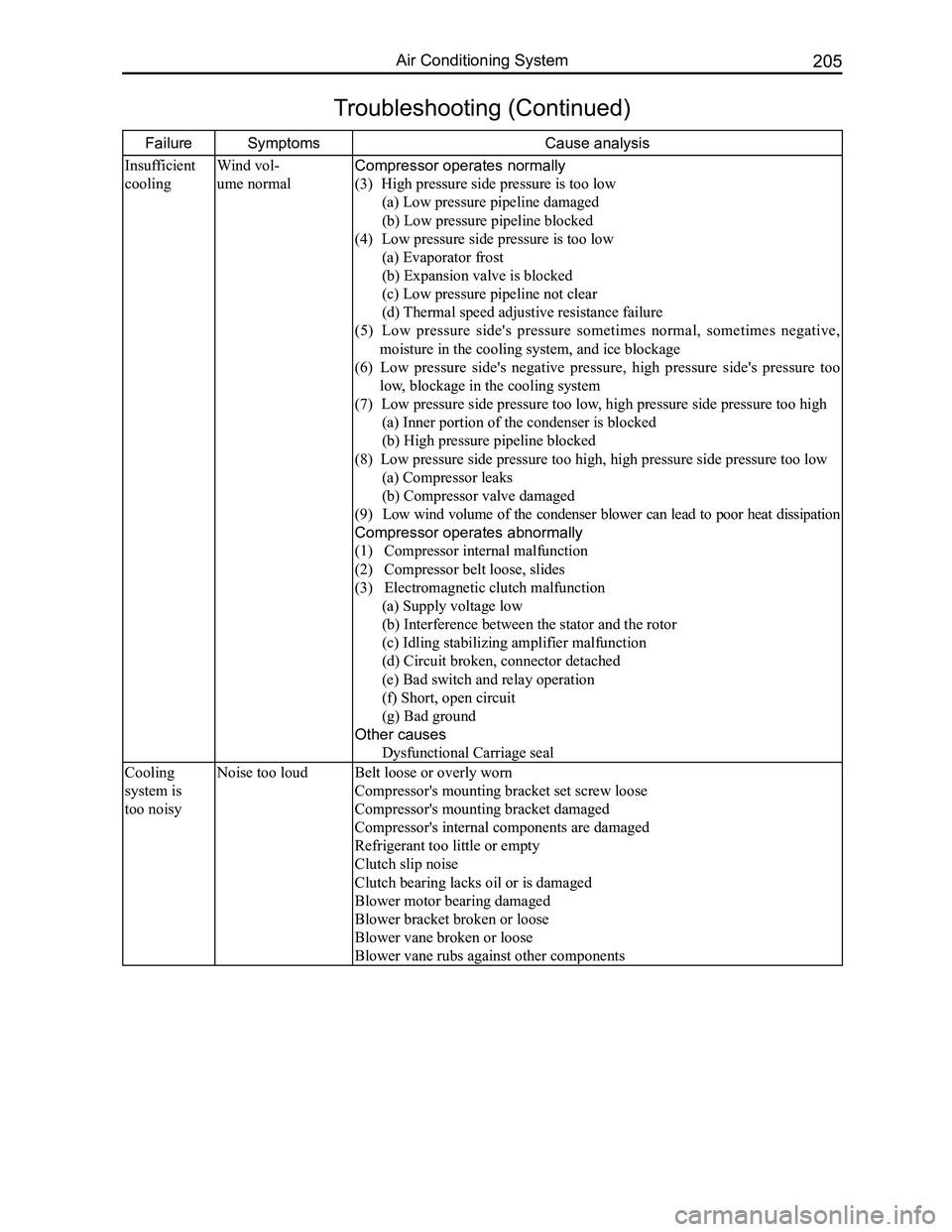

FailureSymptoms Cause analysis

Insufficient

cooling

Wind vol-

ume normal

Compressor operates normally

(3) High pressure side pressure is too low

(a) Low pressure pipeline damaged

(b) Low pressure pipeline blocked

(4) Low pressure side pressure is too low

(a) Evaporator frost

(b) Expansion valve is blocked

(c) Low pressure pipeline not clear

(d) Thermal speed adjustive resistance failure

(5) Low pressure side's pressure sometimes normal, sometimes negative,

moisture in the cooling system, and ice blockage

(6) Low pressure side's negative pressure, high pressure side's pressure too

low, blockage in the cooling system

(7) Low pressure side pressure too low, high pressure side pressure too high

(a) Inner portion of the condenser is blocked

(b) High pressure pipeline blocked

(8) Low pressure side pressure too high, high pressure side pressure \

too low

(a) Compressor leaks

(b) Compressor valve damaged

(9) Low wind volume of the condenser blower can lead to poor heat dissipation

Compressor operates abnormally

(1) Compressor internal malfunction

(2) Compressor belt loose, slides

(3) Electromagnetic clutch malfunction

(a) Supply voltage low

(b) Interference between the stator and the rotor

(c) Idling stabilizing amplifier malfunction

(d) Circuit broken, connector detached

(e) Bad switch and relay operation

(f) Short, open circuit

(g) Bad ground

Other causes

Dysfunctional Carriage seal

Cooling

system is

too noisy

Noise too loudBelt loose or overly worn

Compressor's mounting bracket set screw loose

Compressor's mounting bracket damaged

Compressor's internal components are damaged

Refrigerant too little or empty

Clutch slip noise

Clutch bearing lacks oil or is damaged

Blower motor bearing damaged

Blower bracket broken or loose

Blower vane broken or loose

Blower vane rubs against other components

Troubleshooting (Continued)

Page 213 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual206

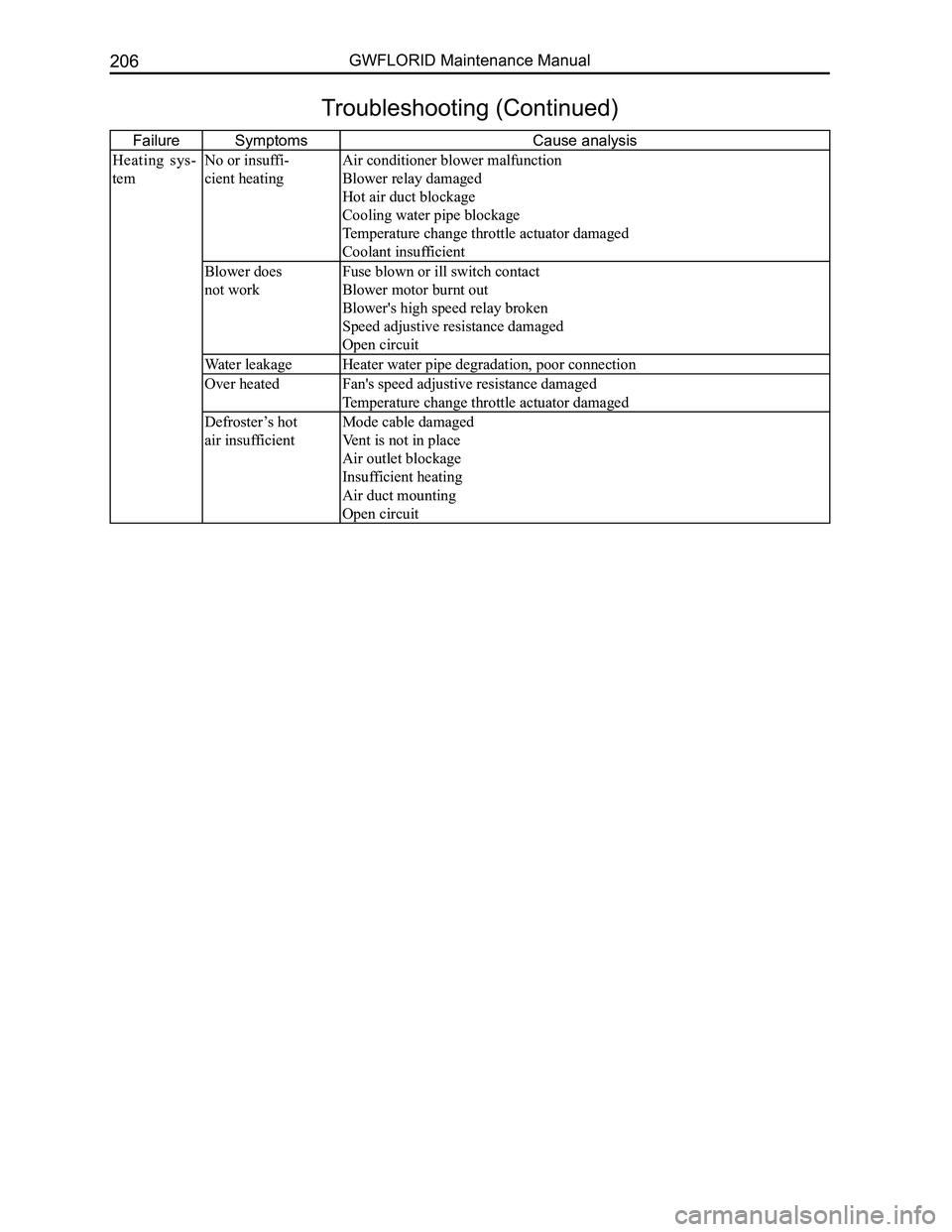

FailureSymptoms Cause analysis

Heating sys-

tem

No or insuffi-

cient heating

Air conditioner blower malfunction

Blower relay damaged

Hot air duct blockage

Cooling water pipe blockage

Temperature change throttle actuator damaged

Coolant insufficient

Blower does

not work

Fuse blown or ill switch contact

Blower motor burnt out

Blower's high speed relay broken

Speed adjustive resistance damaged

Open circuit

Water leakageHeater water pipe degradation, poor connection

Over heatedFan's speed adjustive resistance damaged

Temperature change throttle actuator damaged

Defroster’s hot

air insufficient

Mode cable damaged

Vent is not in place

Air outlet blockage

Insufficient heating

Air duct mounting

Open circuit

Troubleshooting (Continued)

Page 217 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual210

Electromagnetic Clutch

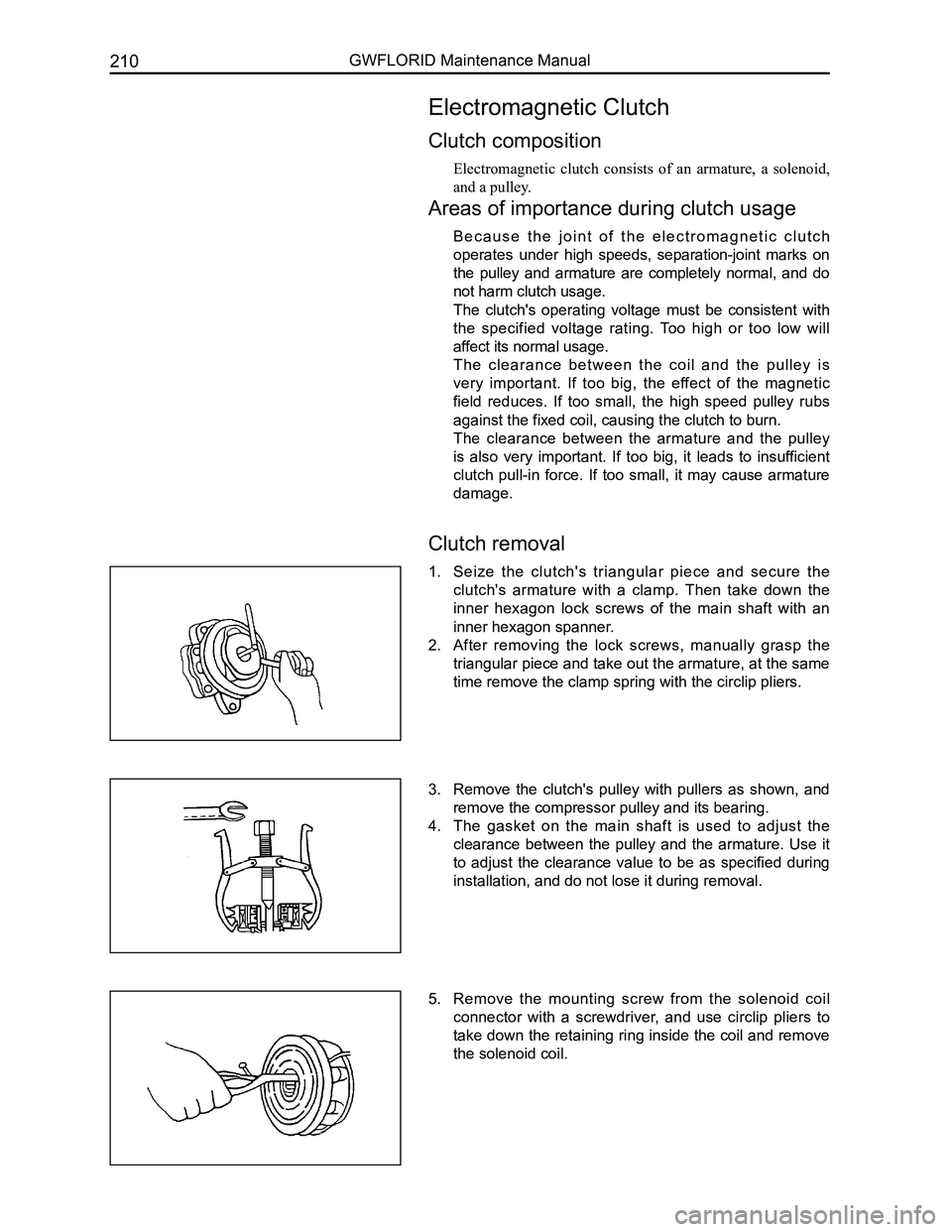

Clutch composition

Electromagnetic clutch consists of an armature, a solenoid,

and a pulley.

Areas of importance during clutch usage

B e c a u s e t h e j o i n t o f t h e e l e c t r o m a g n e t i c c l u t c h

operates under high speeds, separation-joint marks on

the pulley and armature are completely normal, and do

not harm clutch usage.

The clutch's operating voltage must be consistent with

the specified voltage rating. Too high or too low will

affect its normal usage.

The clearance between the coil and the pulley is

very important. If too big, the effect of the magnetic

field reduces. If too small, the high speed pulley rubs

against the fixed coil, causing the clutch to burn.

The clearance between the armature and the pulley

is also very important. If too big, it leads to insufficient

clutch pull-in force. If too small, it may cause armature

damage.

Clutch removal

1. Seize the clutch's triangular piece and secure the

clutch's armature with a clamp. Then take down the

inner hexagon lock screws of the main shaft with an

inner hexagon spanner.

2. After removing the lock screws, manually grasp the

triangular piece and take out the armature, at the same

time remove the clamp spring with the circlip pliers.

3. Remove the clutch's pulley with pullers as shown, and

remove the compressor pulley and its bearing.

4. The gasket on the main shaft is used to adjust the

clearance between the pulley and the armature. Use it

to adjust the clearance value to be as specified during

installation, and do not lose it during removal.

5. Remove the mounting screw from the solenoid coil

connector with a screwdriver, and use circlip pliers to

take down the retaining ring inside the coil and remove

the solenoid coil.

Page 218 of 281

Downloaded from www.Manualslib.com manuals search engine 211Air Conditioning System

Clutch Installation

1. Install the solenoid coil at the place pressing up against the head cover's end surface and pay atten-

tion to insert the dowel pin of the solenoid coil into the bottom hole of the head cover. Put the retaining

ring into the groove with circlip pliers, and press the solenoid coil's connecting wire onto the pressing

line plate on the head cover with a SST.

2. Put the compressor on a specially designed fixture or platform, with its head cover facing upwards.

Press the pulley into the head cover shaft, and put the pulley bearing's retaining ring into the groove

with circlip pliers.

3. Install the armature onto the main shaft's spline and seize the clutch's triangular piece with a clamp.

Then tighten the inner hexagon lock screws and washers with a torque wrench. Screw torque should

be between 150-180 N·m. After installation is done, make sure to check if the clutch's pulley and

armature are able to operate freely, and also check the clearance between the pulley and armature,

which should be 0.3-0.6 mm.

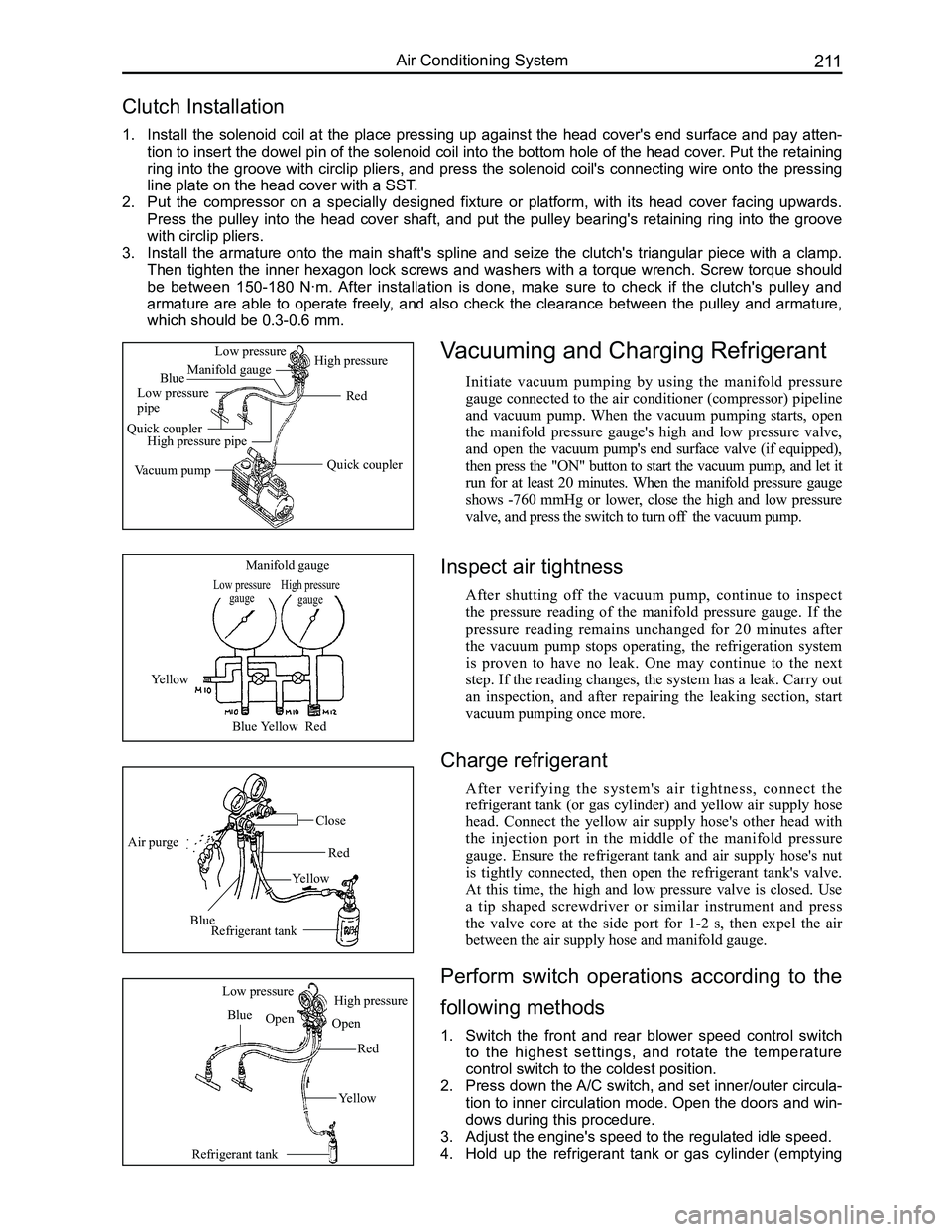

Vacuuming and Charging Refrigerant

Initiate vacuum pumping by using the manifold pressure

gauge connected to the air conditioner (compressor) pipeline

and vacuum pump. When the vacuum pumping starts, open

the manifold pressure gauge's high and low pressure valve,

and open the vacuum pump's end surface valve (if equipped),

then press the "ON" button to start the vacuum pump, and let it

run for at least 20 minutes. When the manifold pressure gauge

shows -760 mmHg or lower, close the high and low pressure

valve, and press the switch to turn off the vacuum pump.

Low pressure gaugeHigh pressure gauge

Manifold gauge

Yellow

BlueYellowRed

Air purge

Blue

Yellow

Red

Close

Refrigerant tank

Refrigerant tank

Blue

Red

Yellow

Low pressureHigh pressure

OpenOpen

Quick coupler

Red

Manifold gauge

Low pressure pipe

Quick couplerHigh pressure pipe

Vacuum pump

Low pressureHigh pressure

Blue

Inspect air tightness

After shutting off the vacuum pump, continue to inspect

the pressure reading of the manifold pressure gauge. If the

pressure reading remains unchanged for 20 minutes after

the vacuum pump stops operating, the refrigeration system

is proven to have no leak. One may continue to the next

step. If the reading changes, the system has a leak. Carry out

an inspection, and after repairing the leaking section, start

vacuum pumping once more.

Charge refrigerant

After verifying the system's air tightness, connect the

refrigerant tank (or gas cylinder) and yellow air supply hose

head. Connect the yellow air supply hose's other head with

the injection port in the middle of the manifold pressure

gauge. Ensure the refrigerant tank and air supply hose's nut

is tightly connected, then open the refrigerant tank's valve.

At this time, the high and low pressure valve is closed. Use

a tip shaped screwdriver or similar instrument and press

the valve core at the side port for 1-2 s, then expel the air

between the air supply hose and manifold gauge.

Perform switch operations according to the

following methods

1. Switch the front and rear blower speed control switch

to the highest settings, and rotate the temperature

control switch to the coldest position.

2. Press down the A/C switch, and set inner/outer circula-

tion to inner circulation mode. Open the doors and win-

dows during this procedure.

3. Adjust the engine's speed to the regulated idle speed.

4. Hold up the refrigerant tank or gas cylinder (emptying